Design and Construction Method of Improving the Crack Resistance of Mass Concrete Floor

A large-volume concrete and construction method technology, which is applied in the processing of building materials, construction, building construction, etc., can solve problems such as construction cold joints, affecting construction progress, and weak impermeability, so as to reduce temperature stress and improve expansion efficiency , to avoid the effect of stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

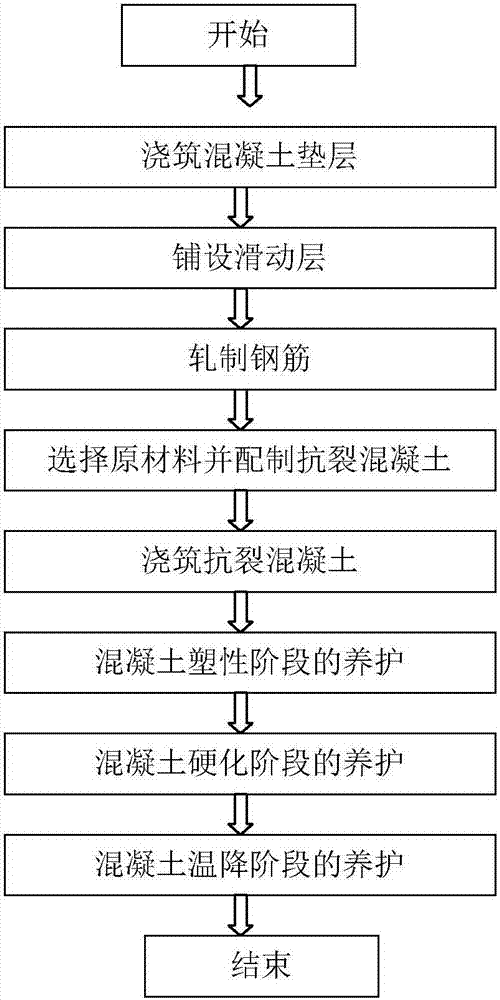

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

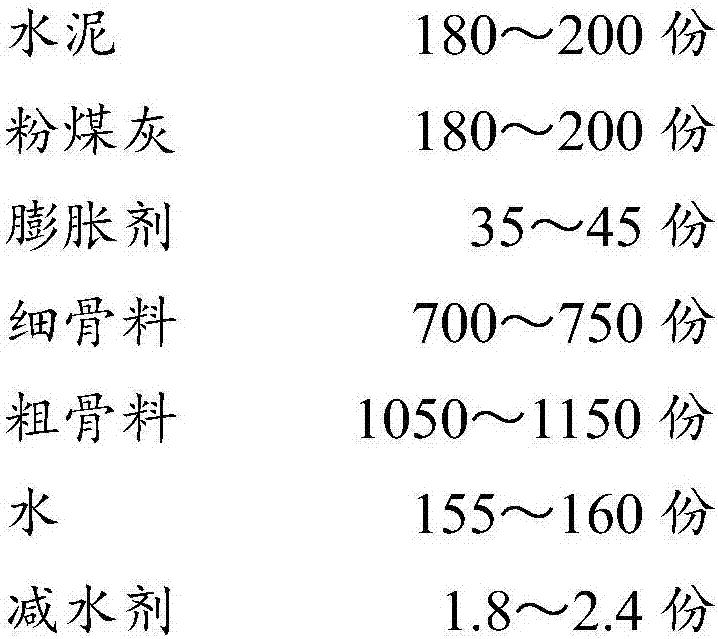

[0037] The material selected for use in the following examples is as follows:

[0038] The cement is P.O42.5 cement produced by Anhui Conch Cement Co., Ltd.;

[0039] The fly ash is Class I fly ash produced by Huaneng Thermal Power Plant;

[0040] The talc powder is talc powder with a fineness of 400 mesh produced by Nanjing Kanglong Stone Powder Co., Ltd.;

[0041] The plastic film is made of polyvinyl chloride plastic film produced by Nanjing Plastic Factory, with a tensile strength of 27MPa;

[0042] The water reducing agent is selected from Jiangsu Subote New Material Co., Ltd. Polycarboxylate high-performance water reducer;

[0043] The calcium oxide expansion agent is a calcium oxide expansion agent with a f-CaO content of 70% produced by Jiangsu Subote New Material Co., Ltd.;

[0044] The magnesium oxide expansion agent is a magnesium oxide expan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| slump | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com