Calcium-magnesium composite expansion agent for super-long and super-thick structural concrete and preparation method thereof

A composite expansion agent and concrete technology, which is applied in the field of expansion agent preparation, can solve the problems of low effective expansion of calcium expansion components and restrictions on production areas, and achieve the effects of optimizing particle gradation, increasing expansion efficiency, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

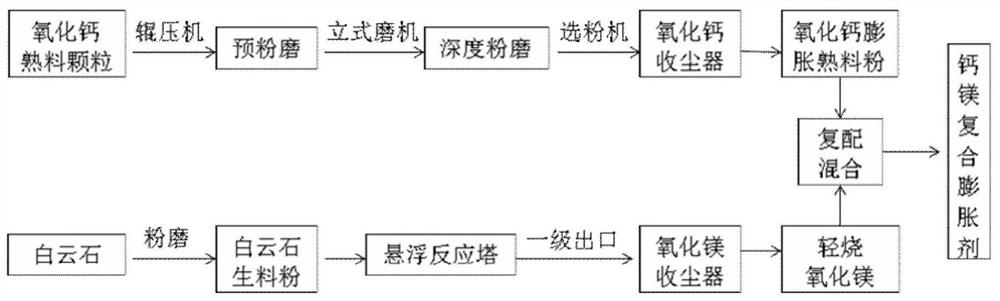

[0030] A preparation method for a calcium-magnesium composite expansion agent for super-long and super-thick structural concrete, comprising the following steps:

[0031](1) put the calcium oxide clinker granule that f-CaO content is 70% into roller press and carry out pre-grinding treatment, the speed of roller press is controlled at 1.4m / s, after calcium oxide clinker is extruded by roller press, Coarse particles with a particle size ≥ 3 mm are screened out by the screening equipment and returned to the roller press for re-extrusion until all the calcium oxide clinker particles are ground into fine particles with a particle size of 0.10mm is returned to the vertical mill for continuous grinding, and the fine powder with a particle size ≤ 0.10mm is sent to the calcium oxide dust collector for processing After collection, the calcium oxide expansion clinker powder required by the present invention can be obtained - the calcium oxide expansion clinker powder whose particle size...

Embodiment 2

[0038] A preparation method for a calcium-magnesium composite expansion agent for super-long and super-thick structural concrete, comprising the following steps:

[0039] (1) put the calcium oxide clinker granule that f-CaO content is 75% into roller press and carry out pre-grinding treatment, the speed of roller press is controlled at 1.5m / s, after calcium oxide clinker is extruded by roller press, Coarse particles with a particle size ≥ 3 mm are screened out by the screening equipment and returned to the roller press for re-extrusion until all the calcium oxide clinker particles are ground into fine particles with a particle size of 0.10mm is returned to the vertical mill for continuous grinding, and the fine powder with a particle size ≤ 0.10mm is sent to the calcium oxide dust collector for processing After collection, the calcium oxide expansion clinker powder required by the present invention can be obtained - the calcium oxide expansion clinker powder whose particle siz...

Embodiment 3

[0046] A preparation method for a calcium-magnesium composite expansion agent for super-long and super-thick structural concrete, comprising the following steps:

[0047] (1) The calcium oxide clinker granules with f-CaO content of 80% are put into a roller press for pre-grinding treatment, the speed of the roller press is controlled at 1.5m / s, after the calcium oxide clinker is extruded by the roller press, Coarse particles with a particle size ≥ 3 mm are screened out by the screening equipment and returned to the roller press for re-extrusion until all the calcium oxide clinker particles are ground into fine particles with a particle size of 0.10mm is returned to the vertical mill for continuous grinding, and the fine powder with a particle size ≤ 0.10mm is sent to the calcium oxide dust collector for processing After collection, the calcium oxide expansion clinker powder required by the present invention can be obtained - the calcium oxide expansion clinker powder whose par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com