Explosion reshaping treatment method for primary slow sideslope

A technology of shaping treatment and slope, applied in blasting, excavation, construction, etc., can solve problems such as loss of universality, and achieve the effect of improving reasonable distribution, simple construction and reducing foundation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] A blasting and plastic treatment method for an original gentle slope of soft rock, the specific steps of which are as follows:

[0018] 1. Determine the location of the production platform according to the layout requirements of the steps, measure the series of actual slope profiles of the original gentle slope section to be processed, and determine the chassis resistance line values at different positions.

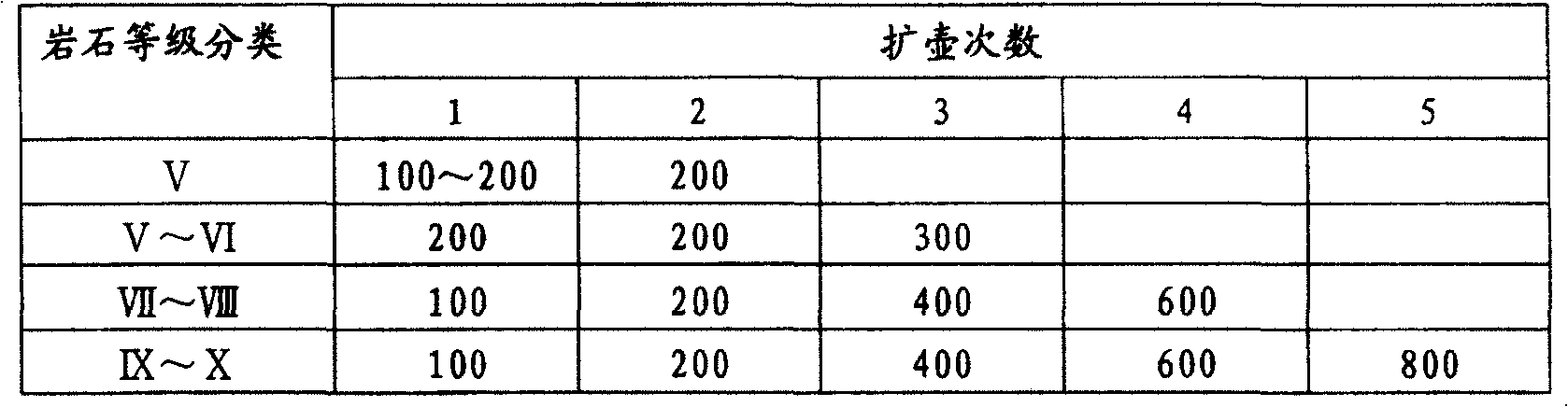

[0019] 2. According to the slope profile, after designing the hole position, the hole diameter is determined to be 180mm, the hole depth is 13m, the inclination angle of the blasthole is 75°, the charge of the blasthole is 400kg, and the volume of the explosive expansion pot required is 0.5m 3 . In this embodiment, a 150mm drill bit is used to drill a hole with a diameter of 180mm.

[0020] 3. Explosion pot blasting for the first time

[0021] According to the charge amount 2πr in the blasting of the initial expansion pot 3 ρ 0 ≤Q≤4.2πr 3 ρ 0 , where: ρ 0 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com