A kind of magnesia high-efficiency anti-cracking agent for cement concrete, its preparation method and application

A technology of cement concrete and anti-cracking agent, which is applied in the field of magnesia and temperature-controlled high-efficiency anti-cracking agent for cement concrete. It can solve the problems of accelerated loss of concrete slump, increased dosage of water-reducing agent, and inability to release slowly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

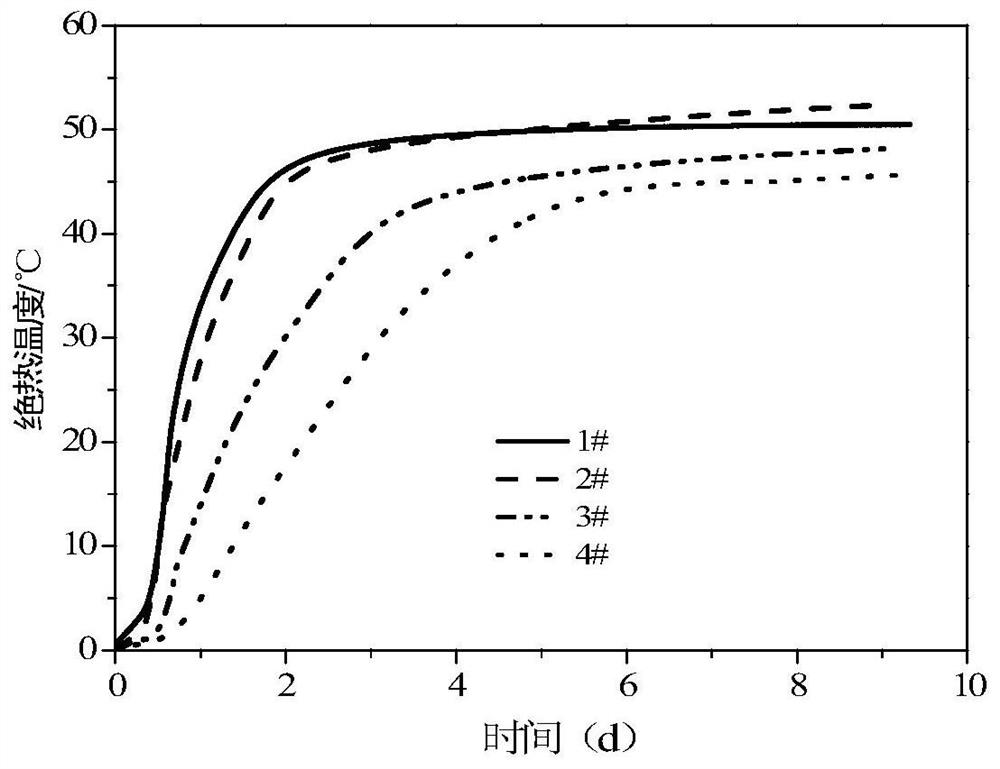

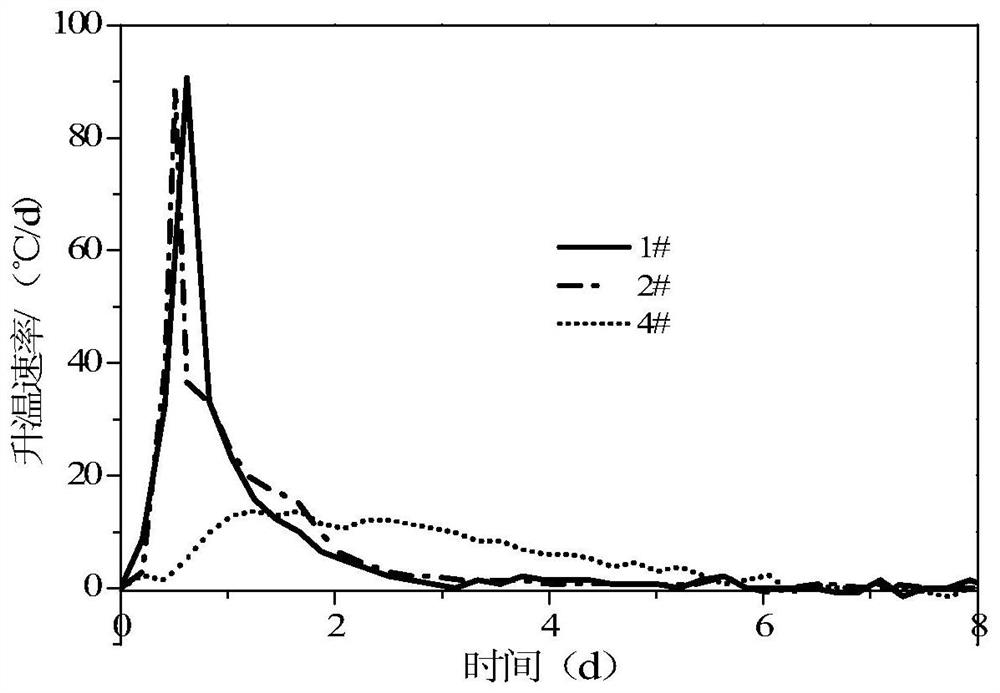

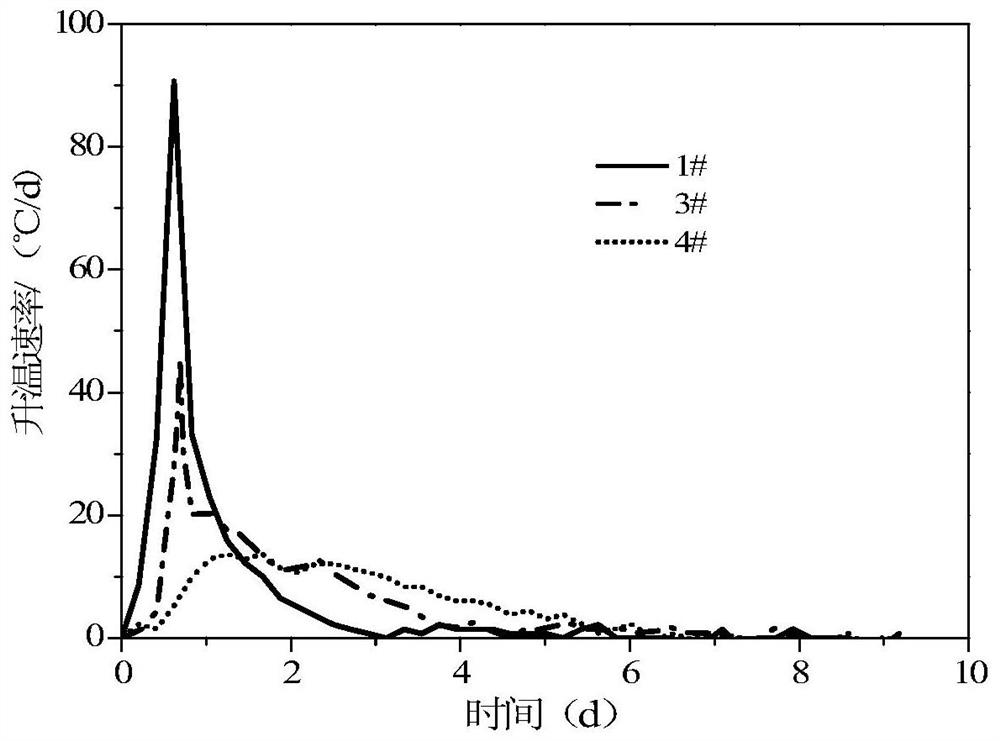

Examples

Embodiment 1

[0041] (1) Preparation of a magnesia high-efficiency anti-cracking agent for cement concrete

[0042] The magnesia expansion component is the hydration activity value of suspension kiln production of 35s (using DL / T 5296-2013 detection method), MgO content of 80.0%, and specific surface area of 400m 2 / kg magnesia expansion material; cement hydration heat control components are selected from Jiangsu Subote New Materials Co., Ltd. The content of dextrin in the cement hydration heat control material liquid is 40wt%, and the number average molecular weight of dextrin is 7000-20000g / mol.

[0043] The magnesium expansion component powder is added to the powder feeder of the spray drying tower, and the magnesium expansion component is transported to the front section of the hot air distributor at the top of the drying tower by compressed air with a pressure of 0.1 MPa. The magnesia expansion component is dispersed in the hot air flow by the hot air in the drying tower. The inter...

Embodiment 2

[0068] (1) Preparation of a magnesia high-efficiency anti-cracking agent for cement concrete

[0069]The magnesia expansion component is the hydration activity value of suspension kiln production of 100s (using DL / T 5296-2013 detection method), MgO content of 90.0%, and specific surface area of 400m 2 / kg magnesia expansion material; cement hydration heat control components are selected from Jiangsu Subote New Materials Co., Ltd. The content of dextrin in the cement hydration heat regulating material liquid is 60wt%, and the number average molecular weight of dextrin is 7000-20000g / mol.

[0070] The magnesium expansion component powder is added to the powder feeder of the spray drying tower, and the magnesium expansion component is transported to the front section of the hot air distributor at the top of the drying tower by compressed air with a pressure of 0.2MPa. The magnesia expansion component is dispersed in the hot air flow by the hot air in the drying tower. The int...

Embodiment 3

[0095] (1) Preparation of a magnesia high-efficiency anti-cracking agent for cement concrete

[0096] The magnesia expansion component is the hydration activity value of suspension kiln production of 150s (using DL / T 5296-2013 detection method), MgO content of 85.0%, and specific surface area of 300m 2 / kg magnesia expansion material; cement hydration heat control components are selected from Jiangsu Subote New Materials Co., Ltd. The content of dextrin in the cement hydration heat regulating material liquid is 80wt%, and the number average molecular weight of dextrin is 7000-20000g / mol.

[0097] The magnesium expansion component powder is added to the powder feeder of the spray drying tower, and the magnesium expansion component is transported to the front section of the hot air distributor at the top of the drying tower by compressed air with a pressure of 0.3MPa. The magnesia expansion component is dispersed in the hot air flow by the hot air in the drying tower. The in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com