Ceramic tile adhesive additive and application thereof in cement-based ceramic tile adhesive

A ceramic tile adhesive and additive technology, which is applied to the ceramic tile adhesive additive and its application in cement-based tile adhesive, can solve the problems of laborious construction of tile adhesive with high adhesive force, can not solve the problem of large tile slippage, etc. water properties, improved slip resistance, improved bond strength reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

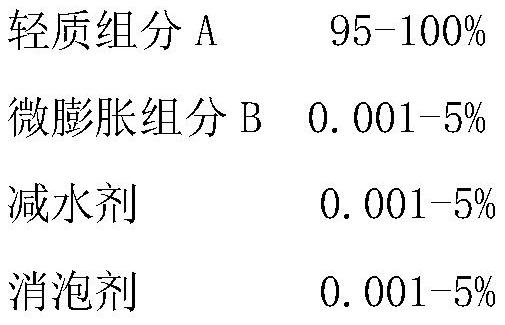

Method used

Image

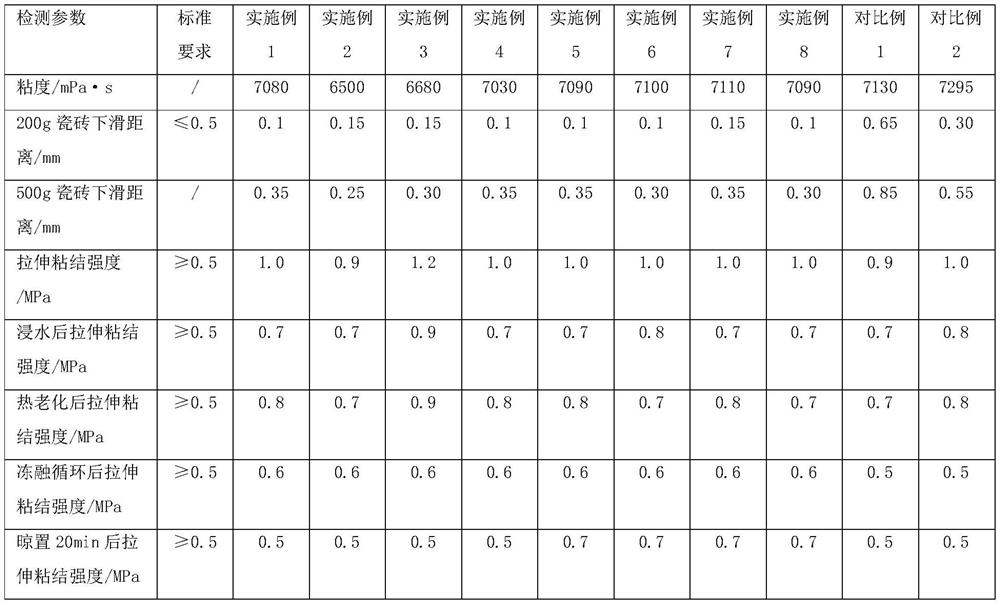

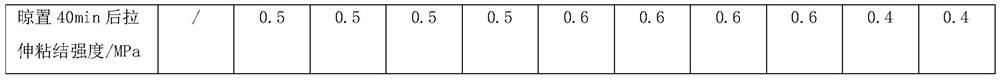

Examples

Embodiment 1

[0023] Provide a tile adhesive additive, the light component A is 100%; no micro-expansion component B, water reducing agent and defoamer are added; wherein, in the light component A, perlite: light sand: light pulverized coal Ash:silica fume=100:0:0:0.

[0024] Tile adhesive additives account for 2% of the tile adhesive; in addition, the tile adhesive is also added with: dispersible latex powder 1.5%, water retention agent 0.4%, calcium formate 1%, heavy calcium 15%, silicate 42.5 cement 35%, Fine sand 45.1%.

Embodiment 2

[0026] Provide a tile adhesive additive, the light component A is 100%, no micro-expansion component B, a water reducer and a defoamer are added; wherein, in the light component A, perlite: light sand: light pulverized coal Ash:silica fume=100:0:0:0.

[0027] The tile adhesive additives account for 15% of the tile adhesive; in addition, the tile adhesive is also added with: dispersible latex powder 2%, water retention agent 0.4%, calcium formate 1%, heavy calcium 15%, silicate 42.5 cement 35%, Fine sand 31.6%.

Embodiment 3

[0029] Provide a tile adhesive additive, the light component A is 100%, no micro-expansion component B, water reducing agent and defoamer are added; wherein, in the light component A, perlite: light sand: light pulverized coal Ash:silica fume=100:0:0:0.

[0030] The tile adhesive additive accounts for 0.5% of the tile adhesive; in addition, the tile adhesive is also added with: dispersible latex powder 2%, water retention agent 0.4%, calcium formate 1%, heavy calcium 15%, silicate 42.5 cement 35%, Fine sand 46.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com