Control method of transverse corner cracks of casting blank of chamfering crystallizer

A technology of chamfering crystallizer and control method, which is applied in the field of continuous casting, can solve problems such as difficult control of corner transverse cracks, and achieve the effect of preventing corner transverse cracks and making up for shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

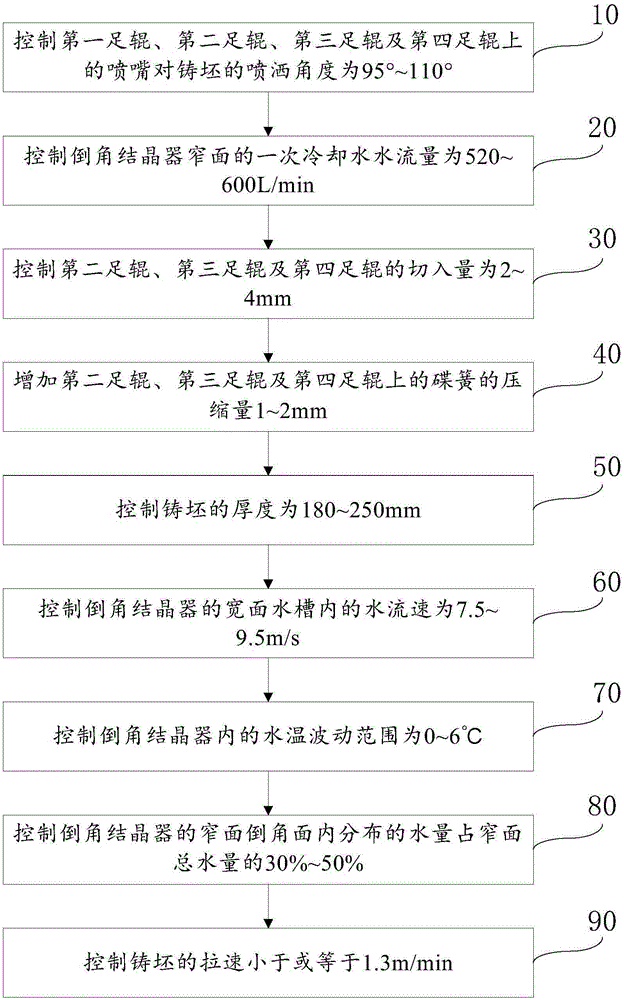

Embodiment 1

[0039] In the continuous casting process of micro-alloyed steel, the method of controlling the transverse cracks at the corners of the cast slab in the chamfering mold includes: controlling the first foot roll, the second foot roll, the third foot roll and the fourth foot roll The spray angle of the nozzle to the slab is 100°. Control the primary cooling water flow of the chamfering crystallizer narrow face to 540L / min. Control the cutting amount of the second foot roller, the third foot roller and the fourth foot roller to 3.5mm, increase the compression amount of the disc spring on the second foot roller, the third foot roller and the fourth foot roller by 1.3mm, and control the The thickness is 210mm. Control the water flow rate in the wide surface tank of the chamfering crystallizer to 8.1m / s, and control the fluctuation range of the water temperature in the chamfering crystallizer to 3°C. The amount of water distributed in the chamfering surface of the chamfering mold i...

Embodiment 2

[0041] In the continuous casting process of micro-alloyed steel, the method of controlling the transverse cracks at the corners of the cast slab in the chamfering mold includes: controlling the first foot roll, the second foot roll, the third foot roll and the fourth foot roll The spray angle of the nozzle to the slab is 107°. Control the primary cooling water flow of the chamfering crystallizer narrow face to 586L / min. Control the cutting amount of the second foot roller, the third foot roller and the fourth foot roller to 2.5mm, increase the compression amount of the disc spring on the second foot roller, the third foot roller and the fourth foot roller by 1.5mm, control The thickness of the slab was 225 mm. Control the water flow rate in the wide surface tank of the chamfering crystallizer to 8.5m / s, and control the fluctuation range of the water temperature in the chamfering crystallizer to 3.5°C. The amount of water distributed in the chamfering surface of the chamferin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com