Environment-friendly epoxy floor

An epoxy floor, environmentally friendly technology, applied in the direction of floors, buildings, building structures, etc., can solve the problems affecting the quality of cleaning and sterilization of epoxy floors, increase the quality of cleaning and sterilization, reduce sanitation dead corners, and prevent excessive compression. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

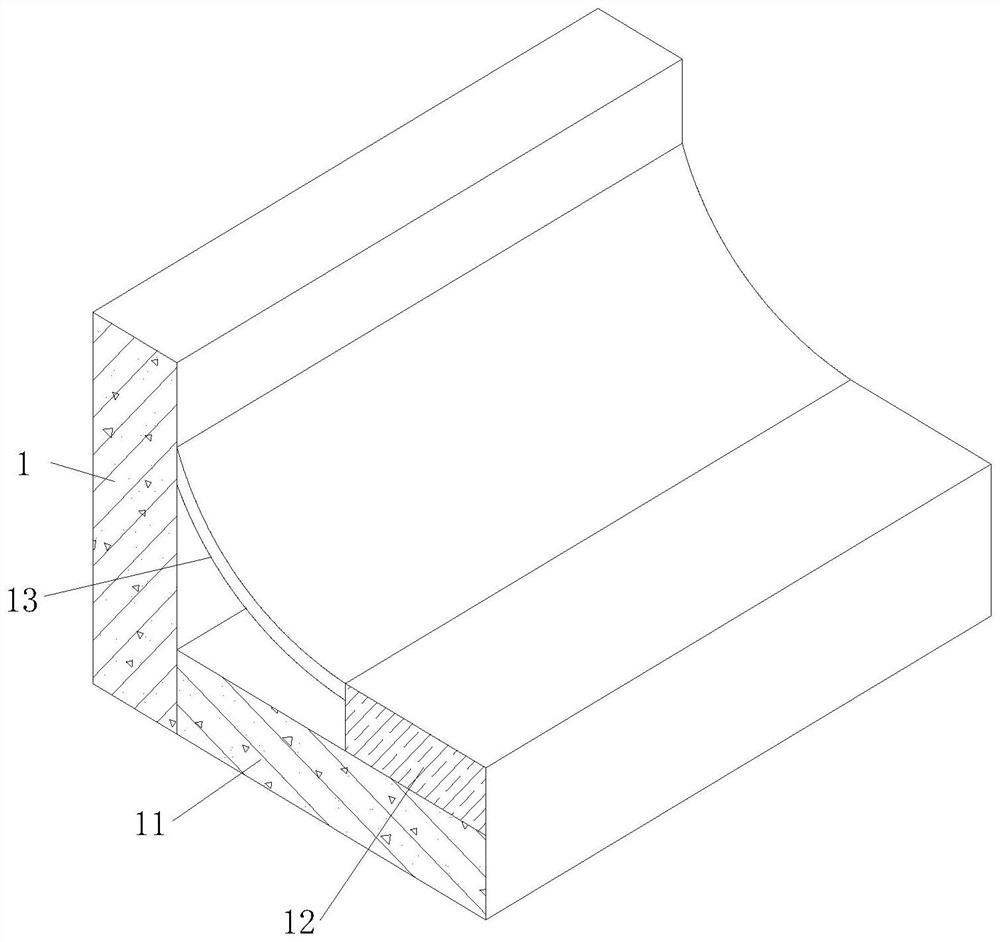

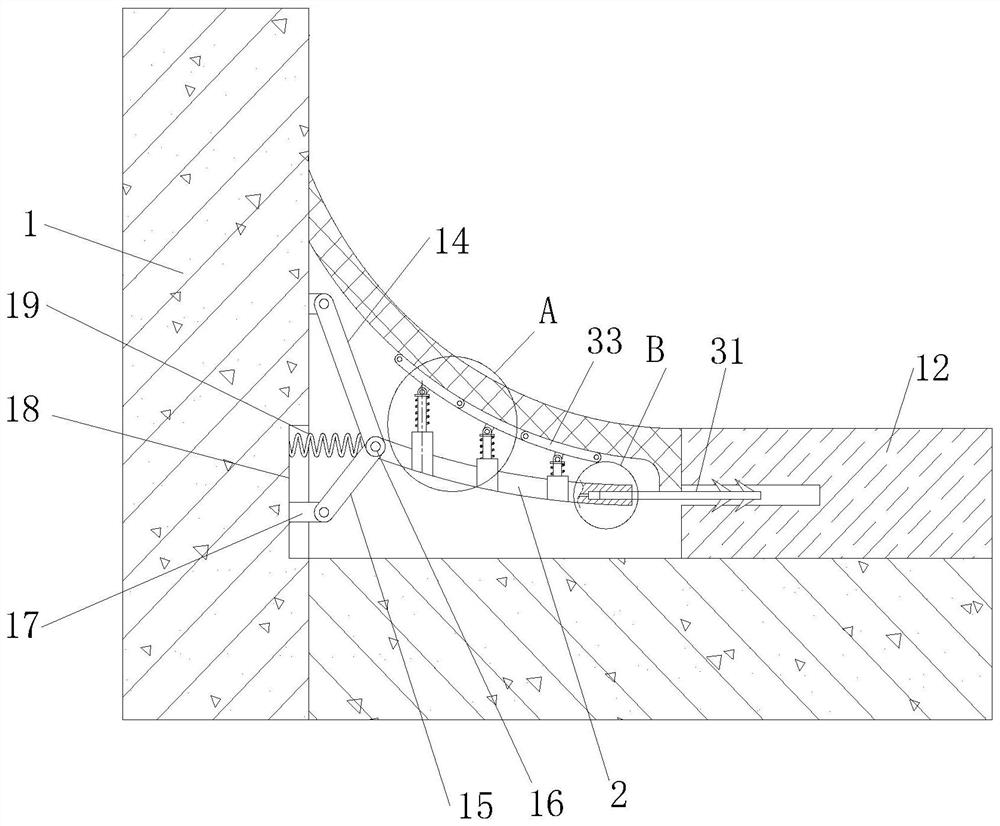

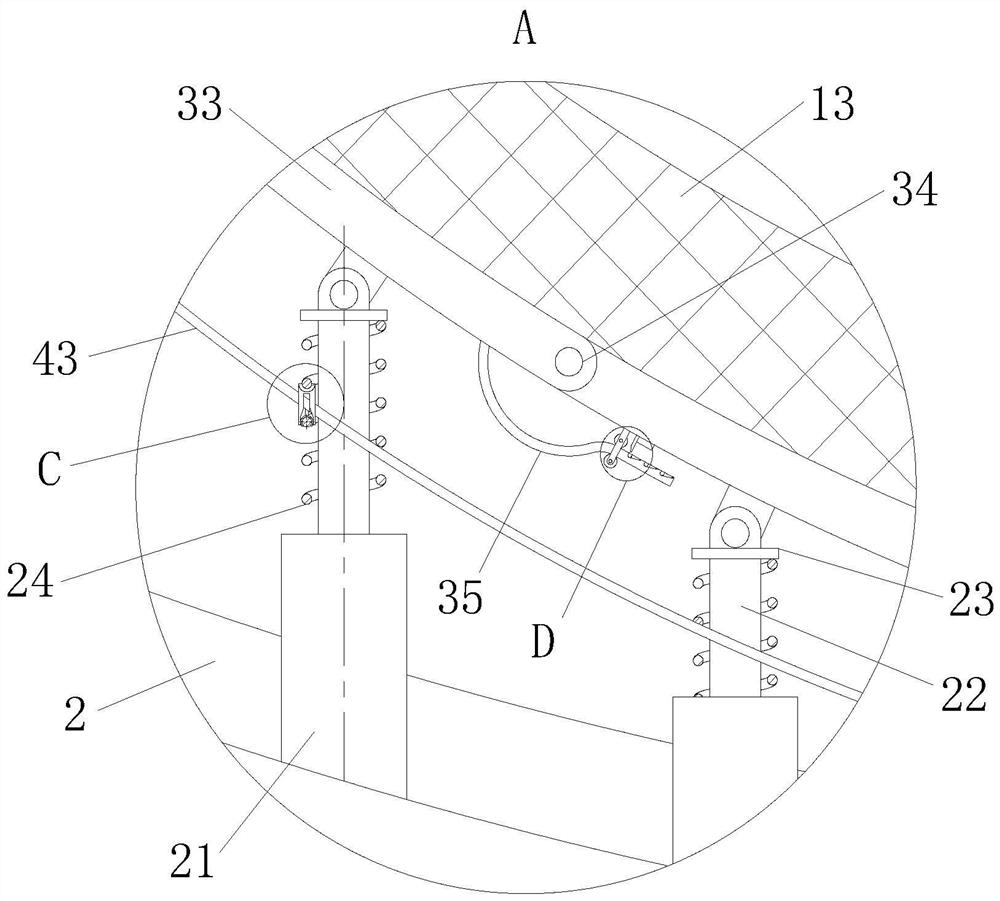

[0028] As an embodiment of the present invention, a group of cylinders 21 are evenly distributed between the top of the strut 2 and the elastic membrane 13, the end of the piston rod 22 of the cylinder 21 is connected to the elastic membrane 13, and the piston rod 22 is fixedly connected near the end. The limit ring 23, the piston rod 22 between the limit ring 23 and the cylinder body of the cylinder 21 is provided with a spring 24; the cylinder 21 cooperates with the spring 24 to increase the support of the elastic membrane 13, reducing the elastic membrane 13 when it is rolled. The tearing caused by local excessive deformation further ensures the smooth transition and tightness of the wall 1 and the epoxy material surface 12, and at the same time controls the deformation of the elastic membrane 13 through the limited stroke of the piston rod 22 in the cylinder body of the cylinder 21, Further ensure that the elastic membrane 13 is within the range of elastic deformation, prol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com