Patents

Literature

33results about How to "Reduce sanitary corners" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

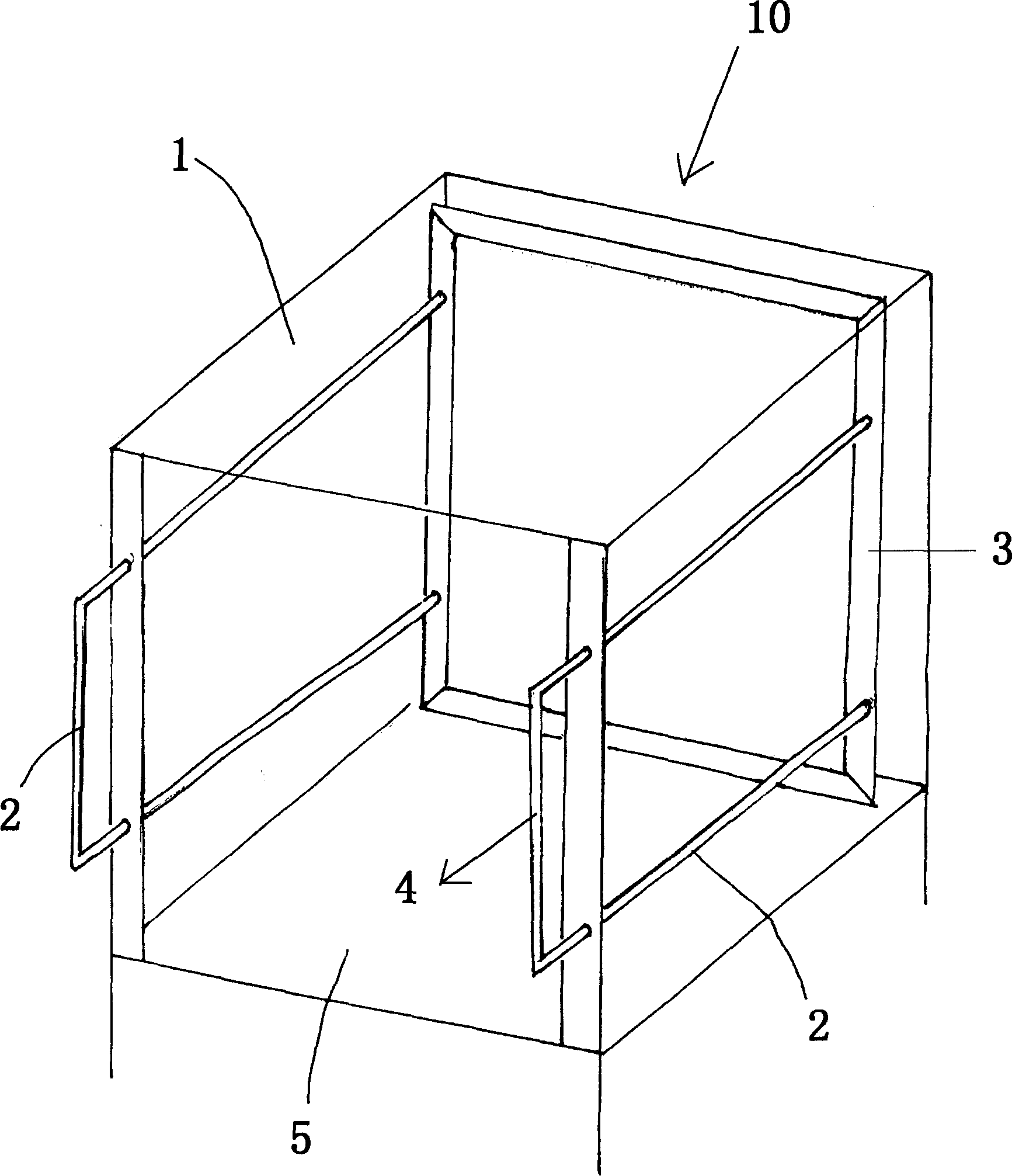

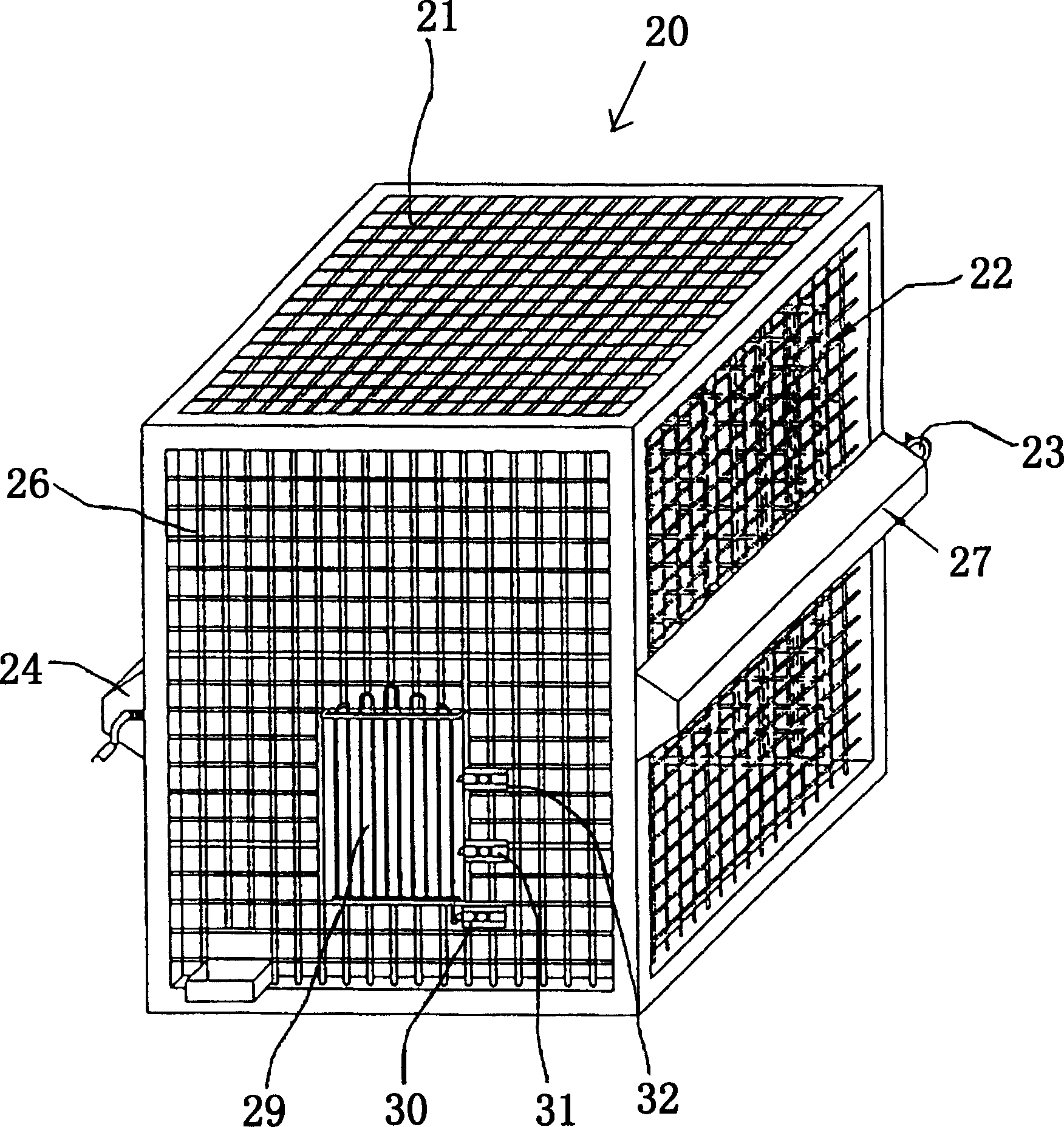

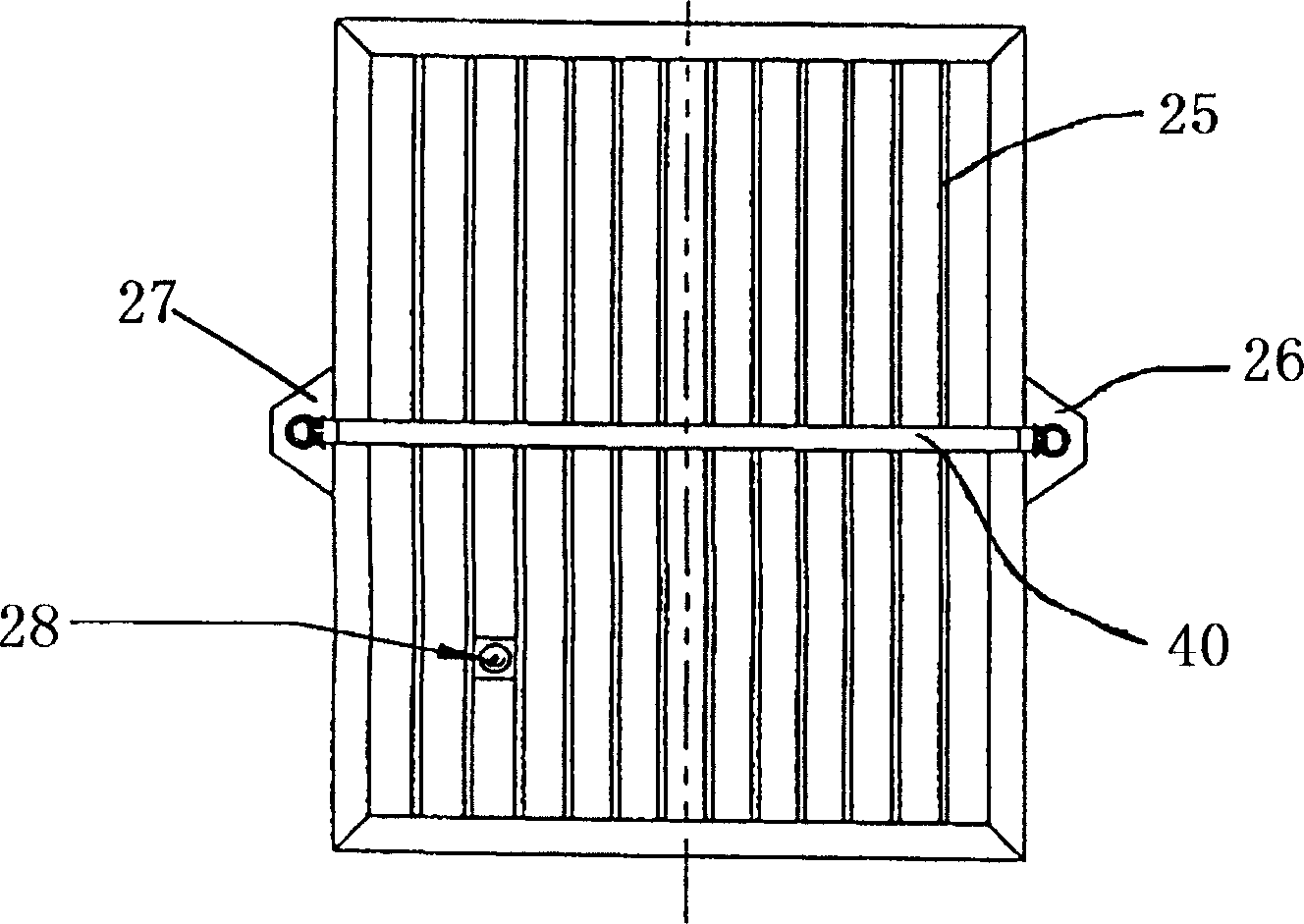

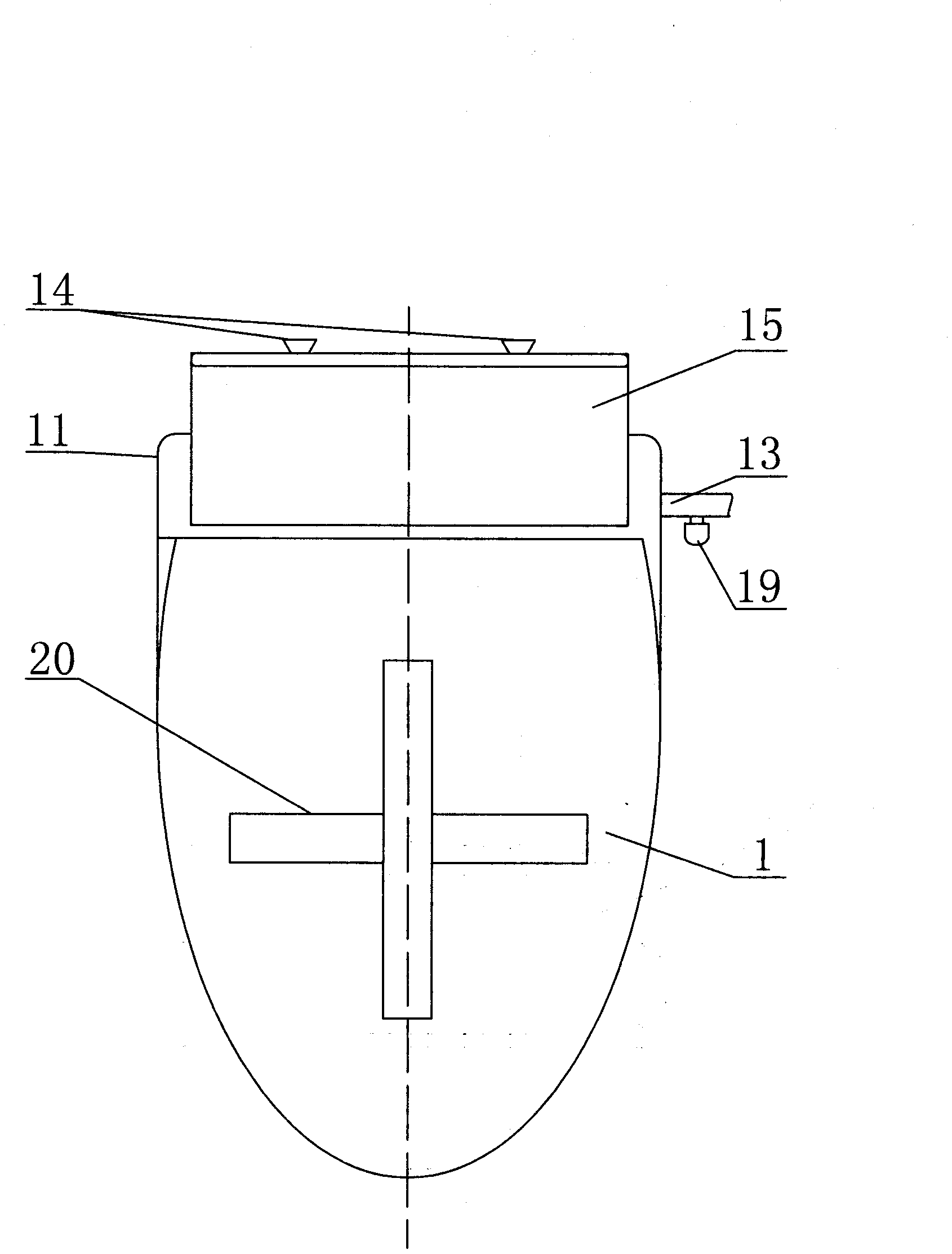

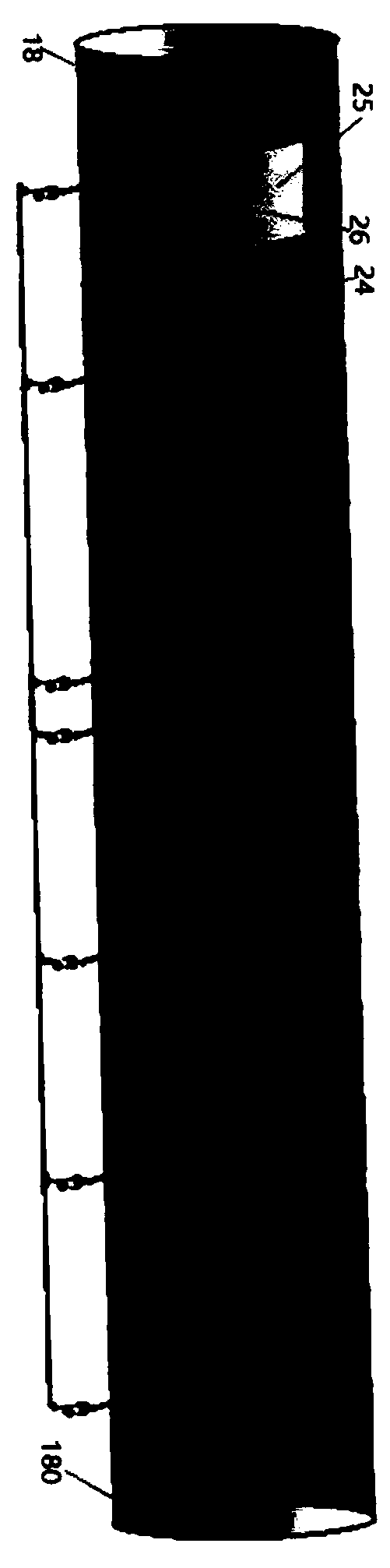

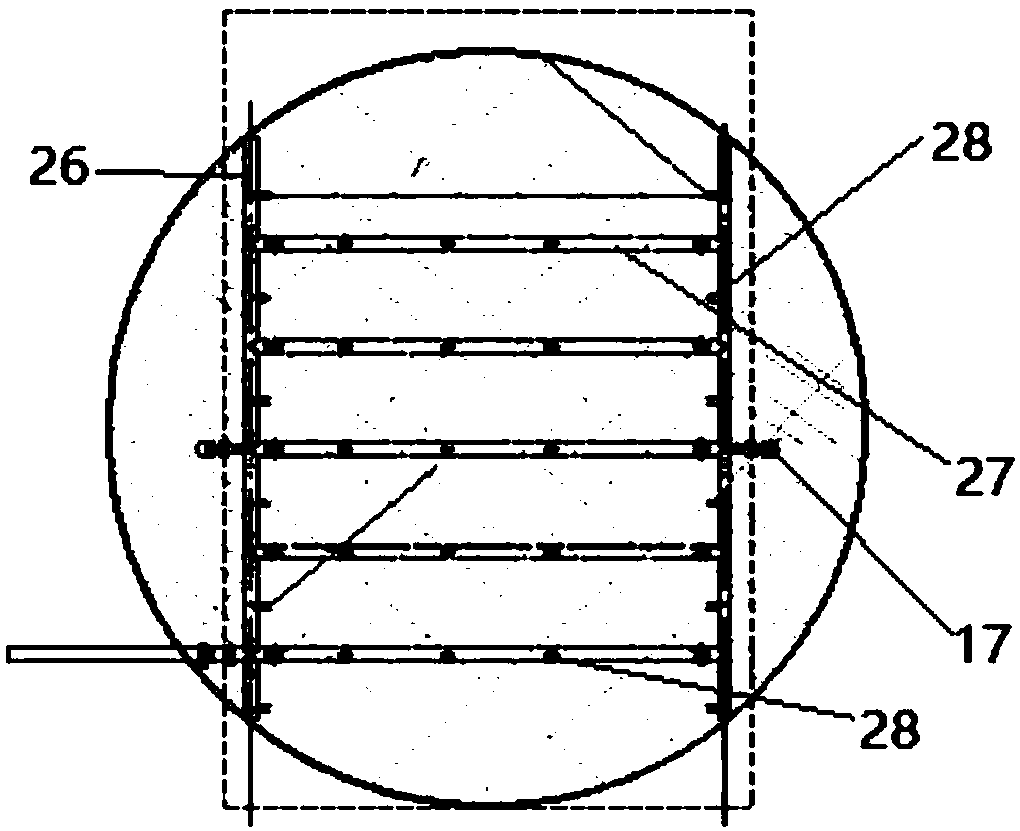

Gear drive for locating cases of monkey

InactiveCN1625943AReduce sanitary cornersEasy to cleanAnimal housingAnimal fetteringGear driveUtilization rate

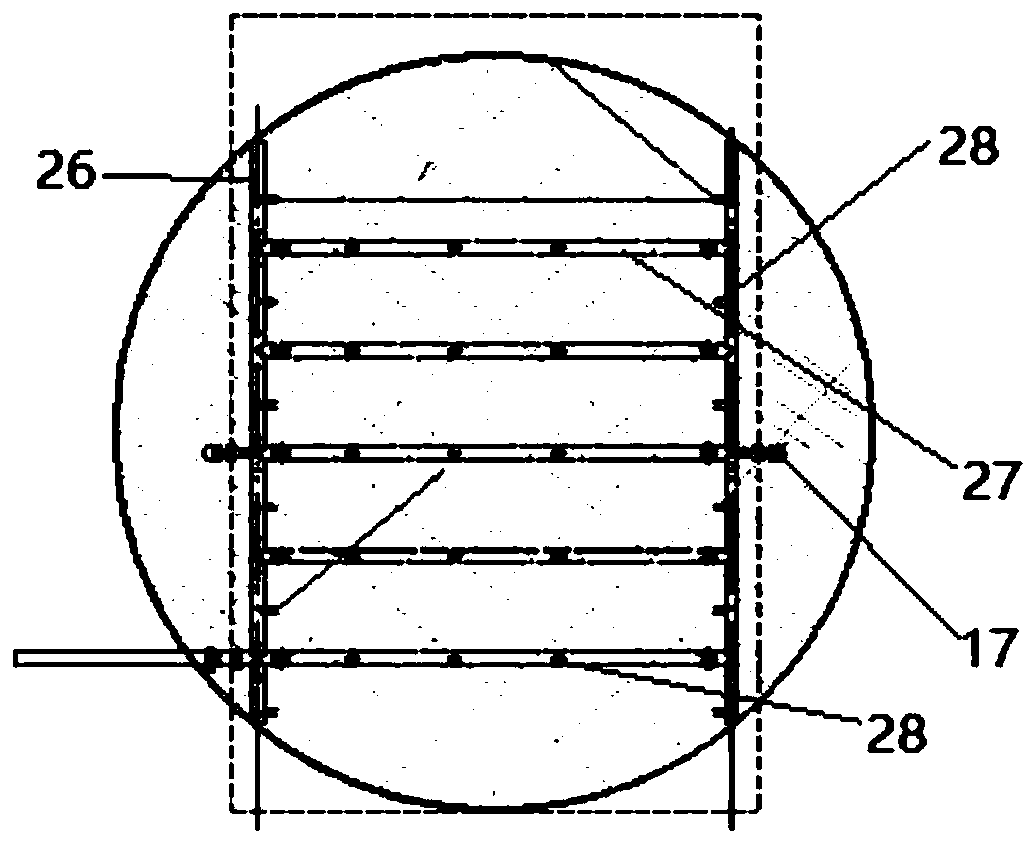

A monkey cage driven and locating by gear set is composed of a square cage body, a movable grate in said cage body, and a gear-scew bar driving module consisting of two screw bars, gear set and rockerarm for moving said movable grate. Its advantages are convenient regulation, correct location and high utilization rate of space.

Owner:GUANGDONG LAB ANIMALS MONITORING INST

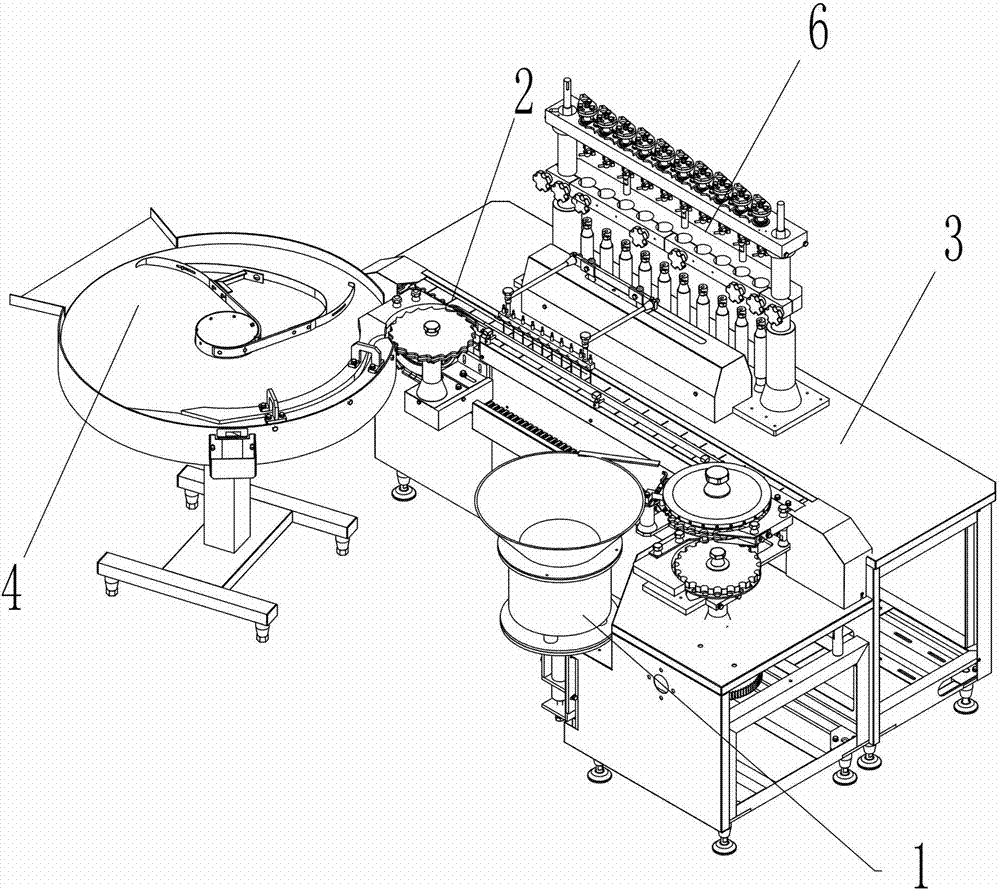

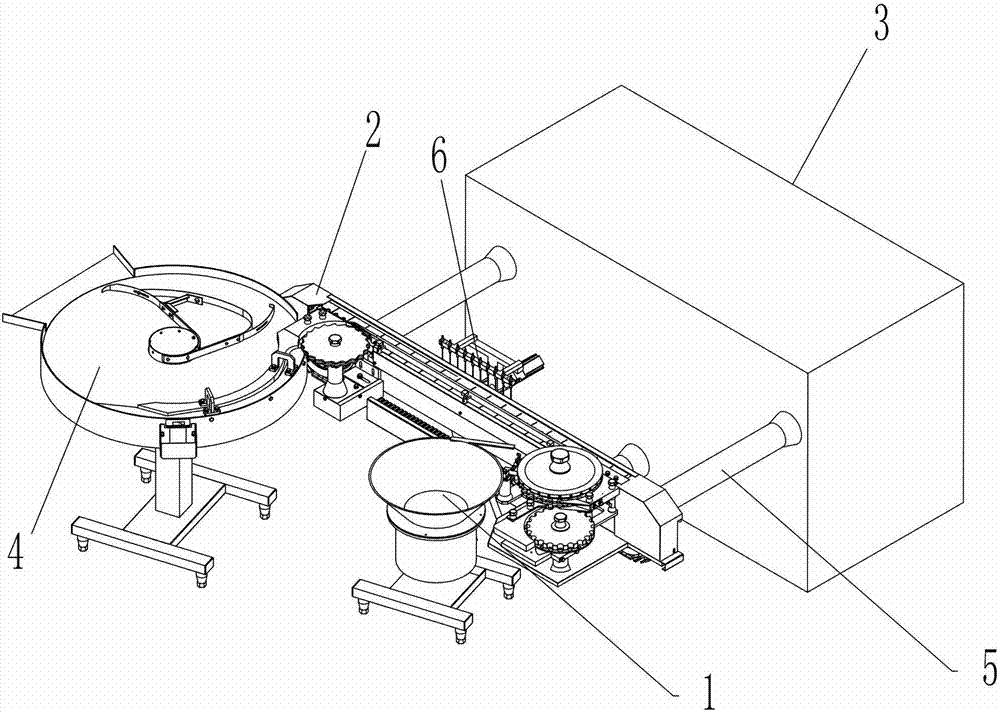

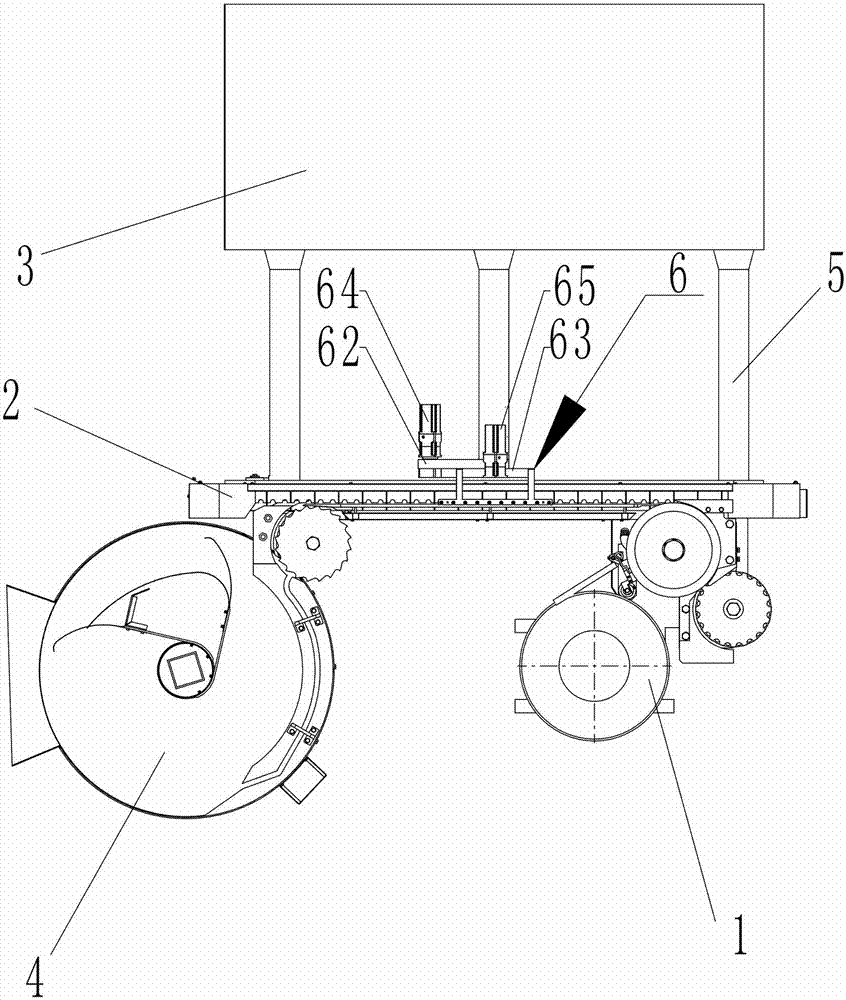

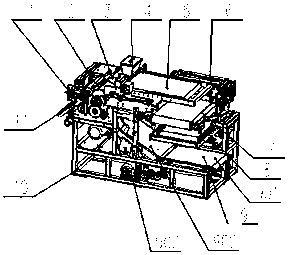

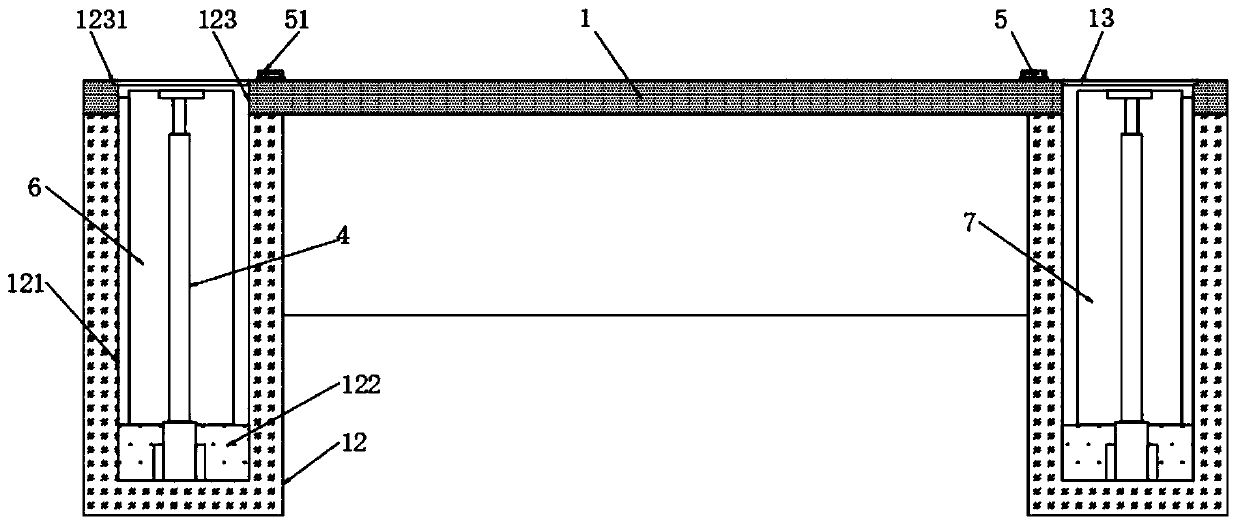

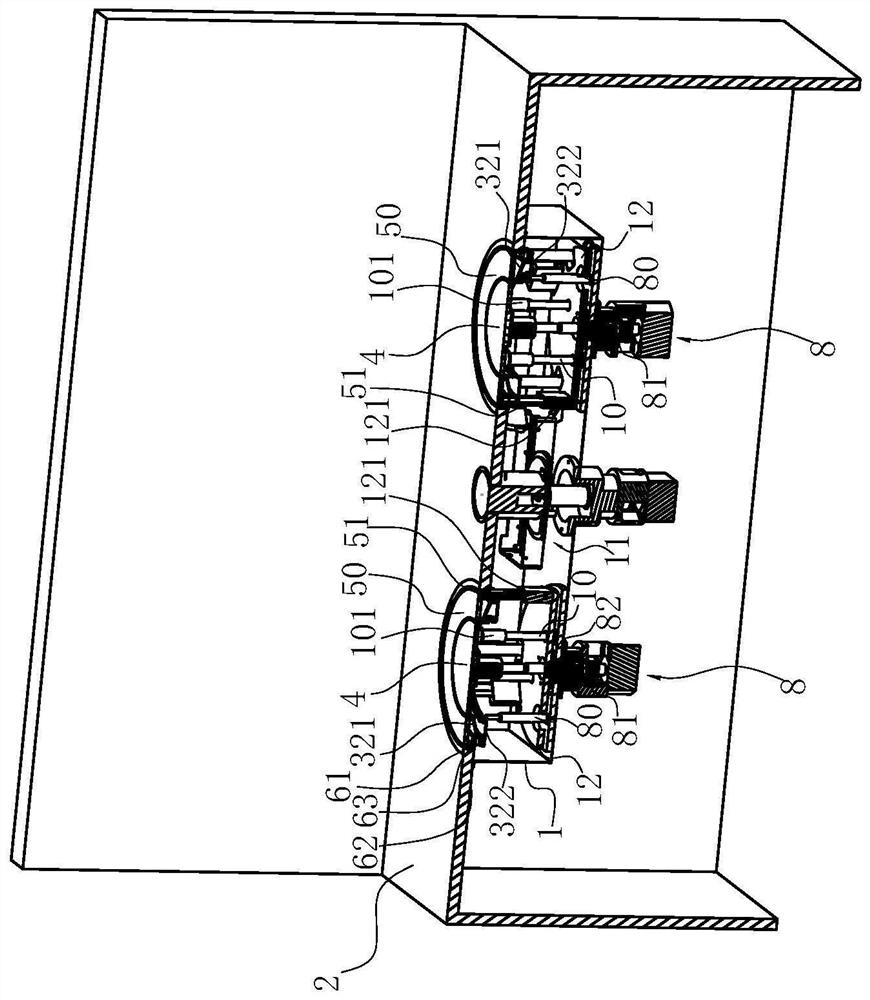

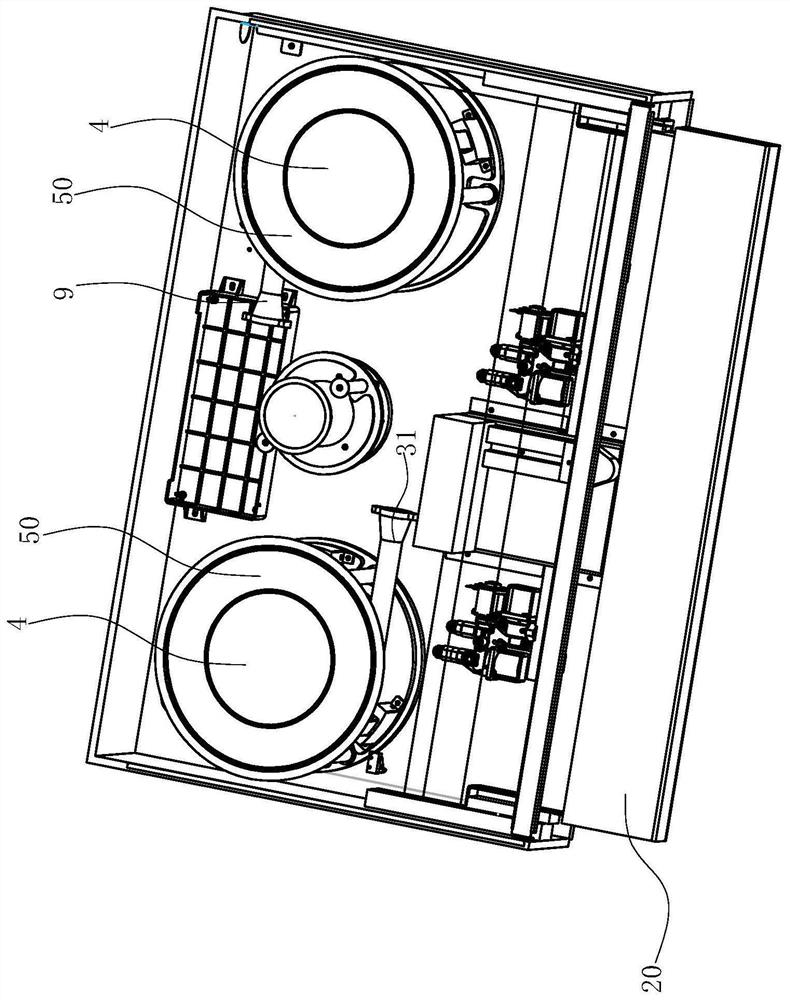

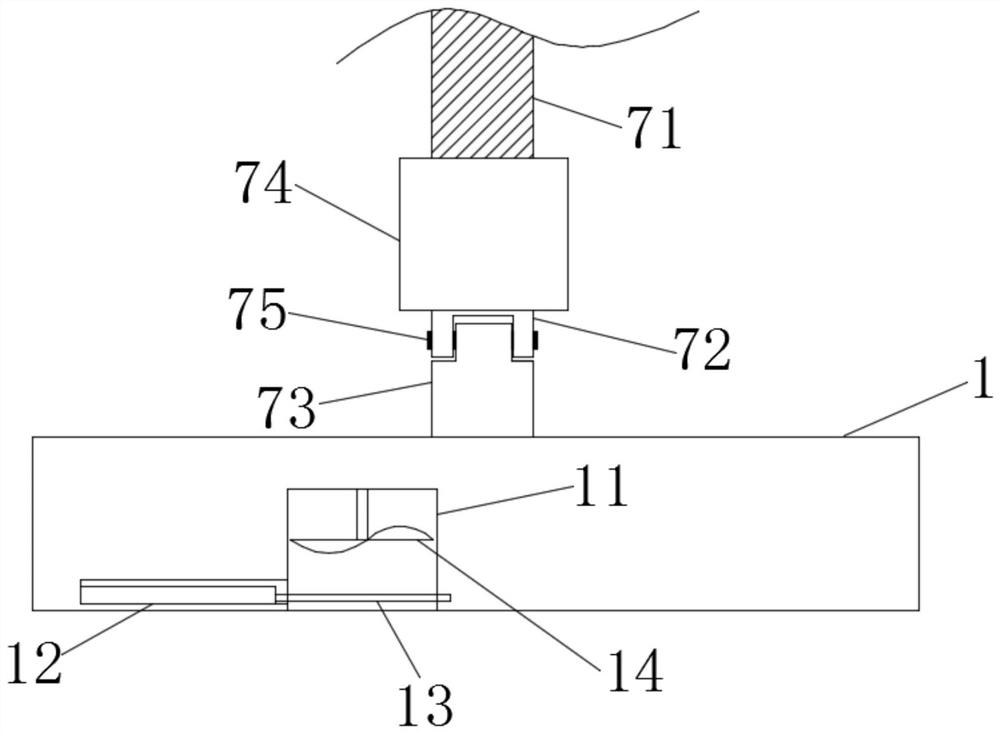

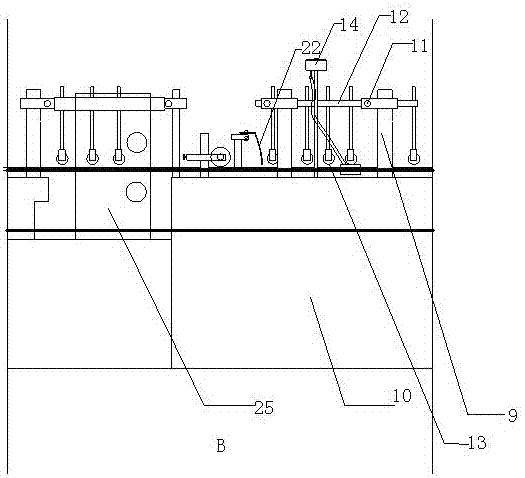

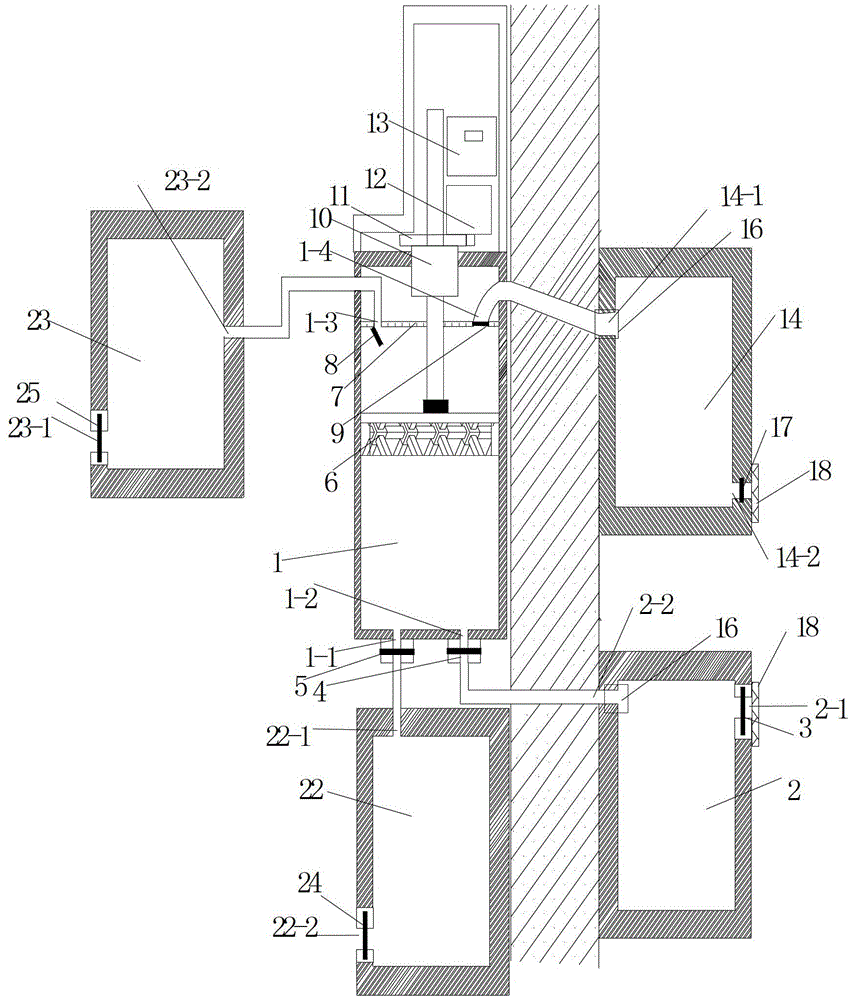

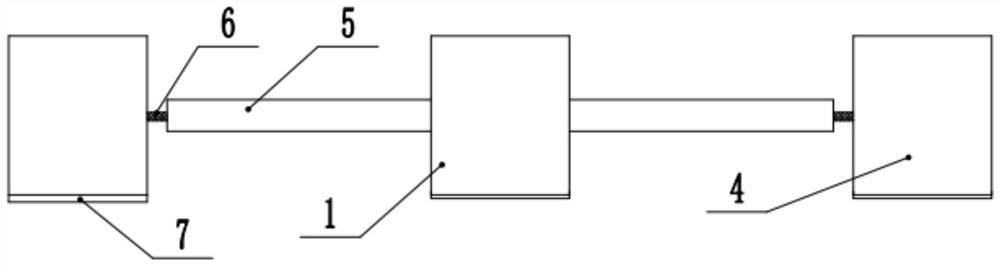

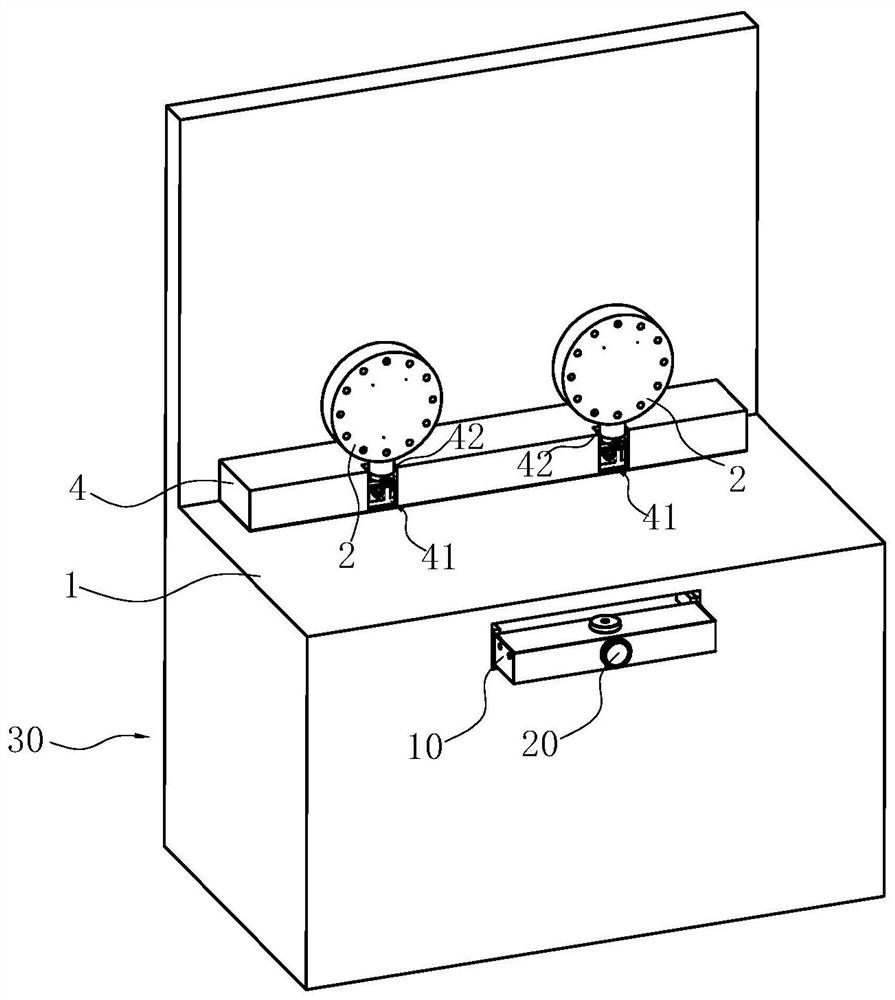

a filling machine

The invention discloses a filling machine, which comprises a bottle inlet component, a bottle conveying component, a frame component, a filling component and a bottle outlet component, wherein the bottle inlet component, the bottle outlet component and the frame component are arranged on the ground through respective support parts; the bottle conveying component and the frame component are arranged side by side, and a distance is formed between the bottle conveying component and the frame component; and the bottle conveying component is supported and connected to the frame component through more than one support beams. The filling machine has the advantages of simple and compact structure, reasonable layout, simple operation, capacity of improving the reliability and cleanness of the whole machine and the like.

Owner:TRUKING TECH LTD

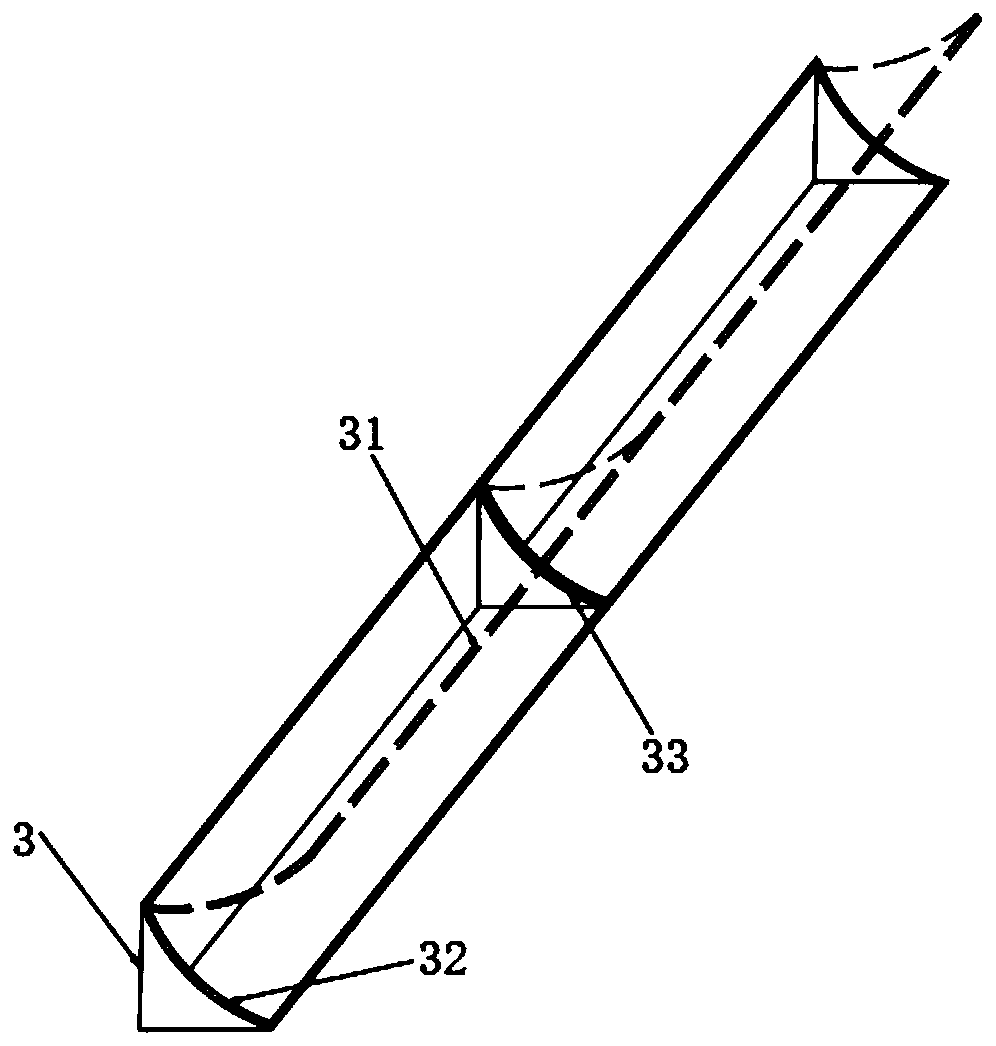

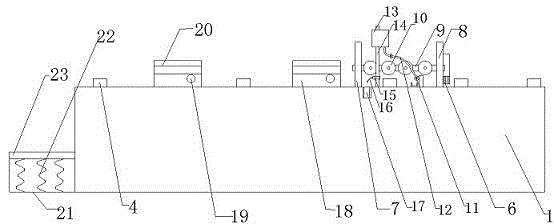

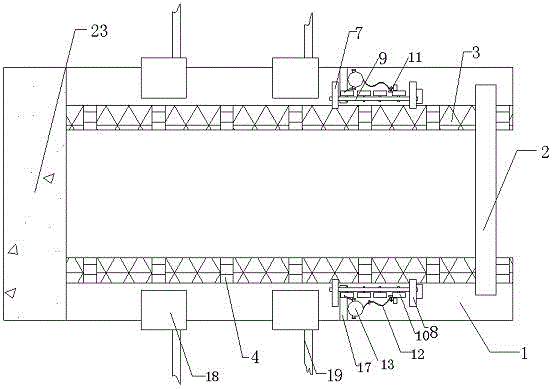

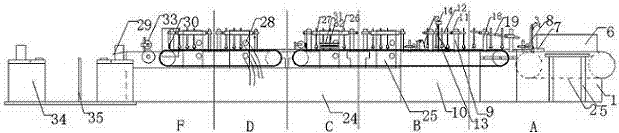

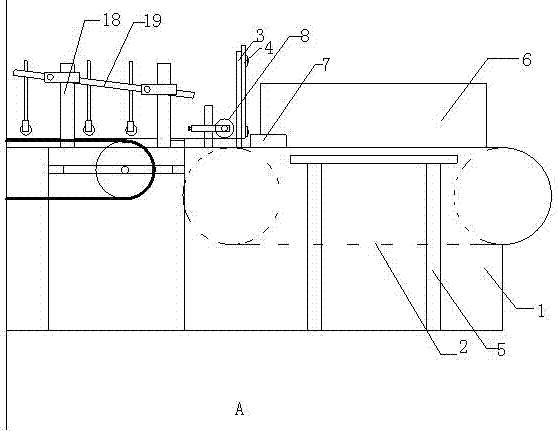

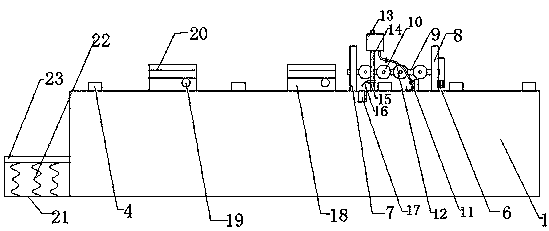

Floor long and short side edge painting production line

ActiveCN105436019AAvoid affecting the effect of paintingReduce impactPretreated surfacesCoatingsProduction lineEngineering

The present invention is a floor long and short side edge painting production line, including long side painting equipment, short side painting equipment and a transition apparatus, the long side painting equipment and the short side painting equipment are vertically arranged, the long side painting equipment includes a feeding apparatus, a long side painting apparatus and a drying apparatus, after a material is applied to a floor, the floor passes through the long side painting apparatus and the drying apparatus, and then is sent to the short side painting equipment by the transition apparatus, one end of the short side painting equipment is also provided with a material receiving apparatus, the material receiving apparatus comprises a material support rack, and a plurality of springs are arranged in the material support rack. The floor long and short side edge painting production line is simple in structure, easy to operate and reasonable in design, can effectively paint floor long and short sides, prevents the presence of V-grooves of spliced floors, and can reduce health dead corners.

Owner:JIANGSU KENTIER WOOD

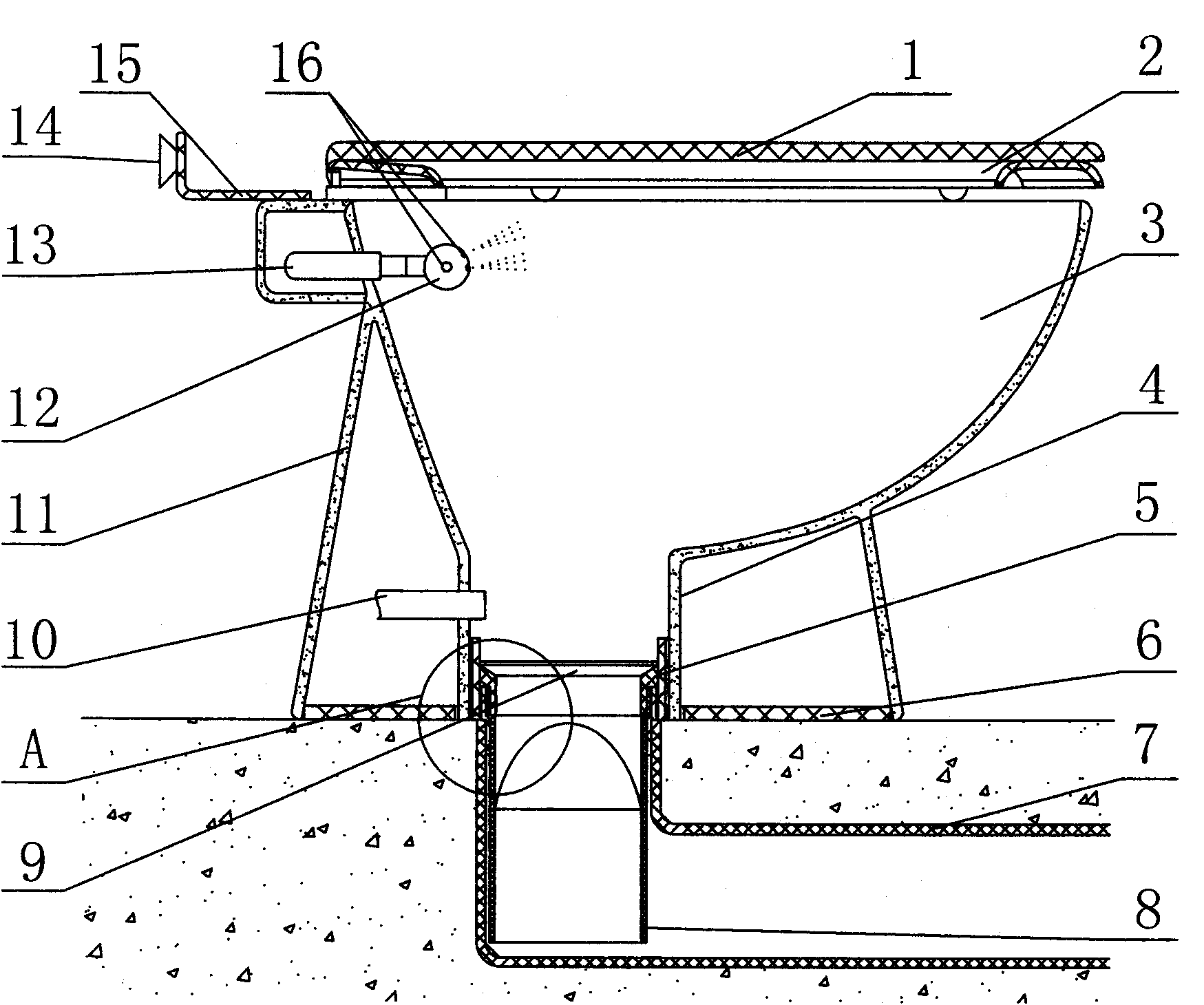

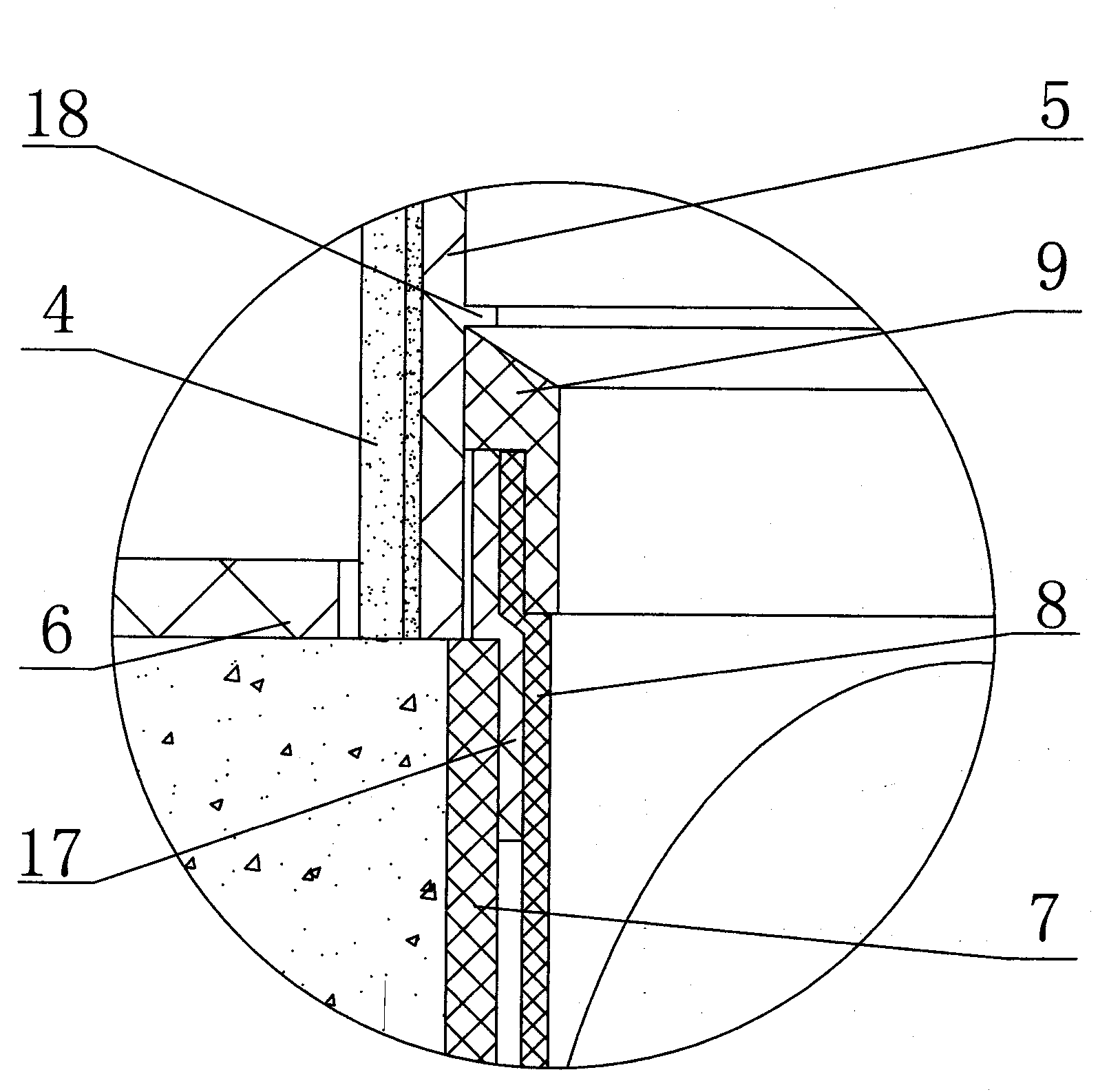

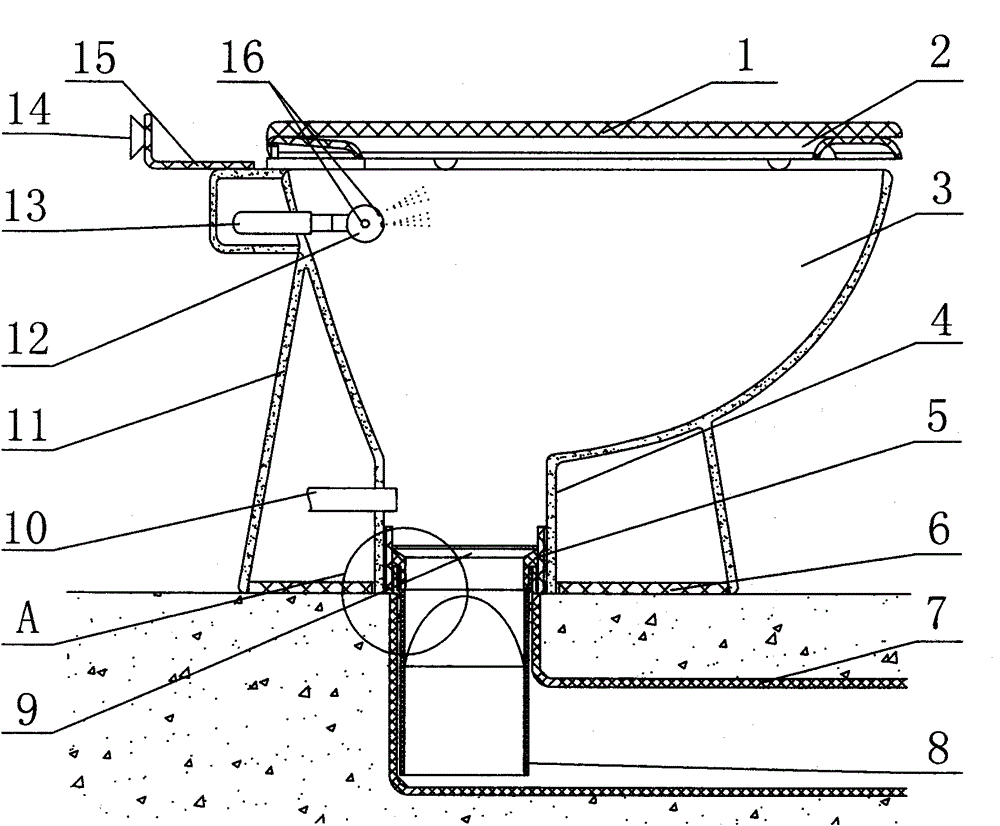

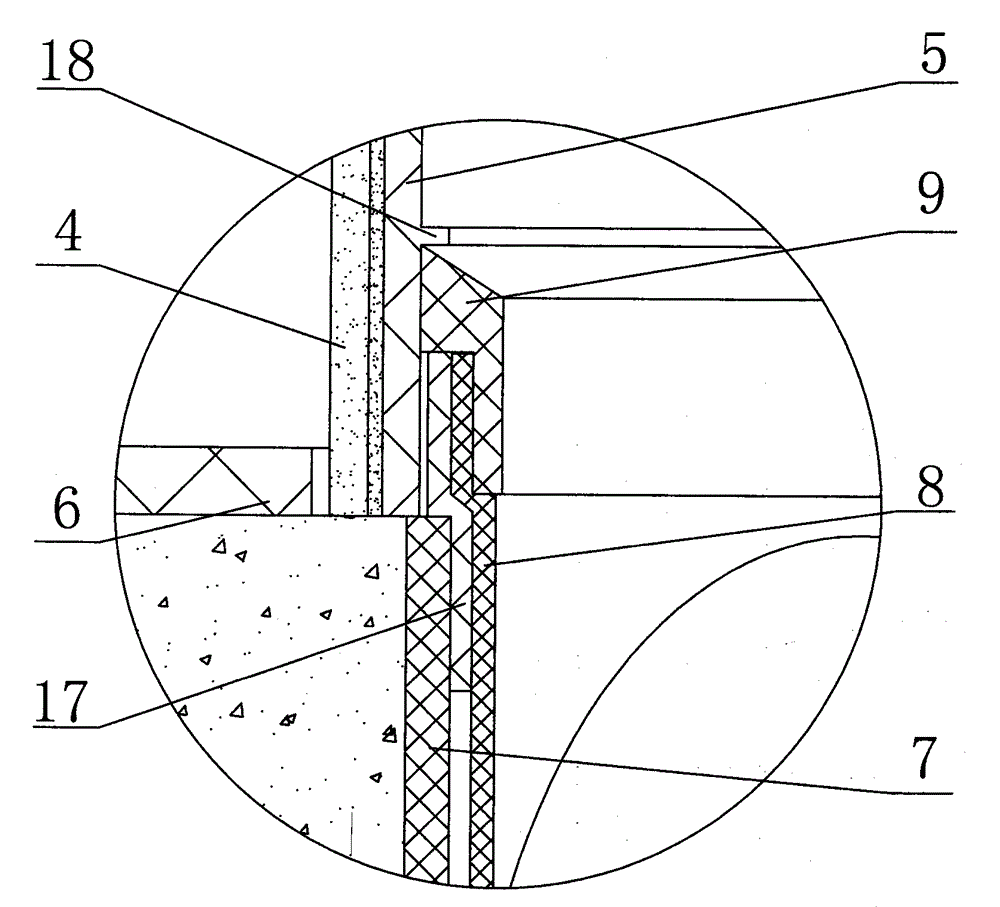

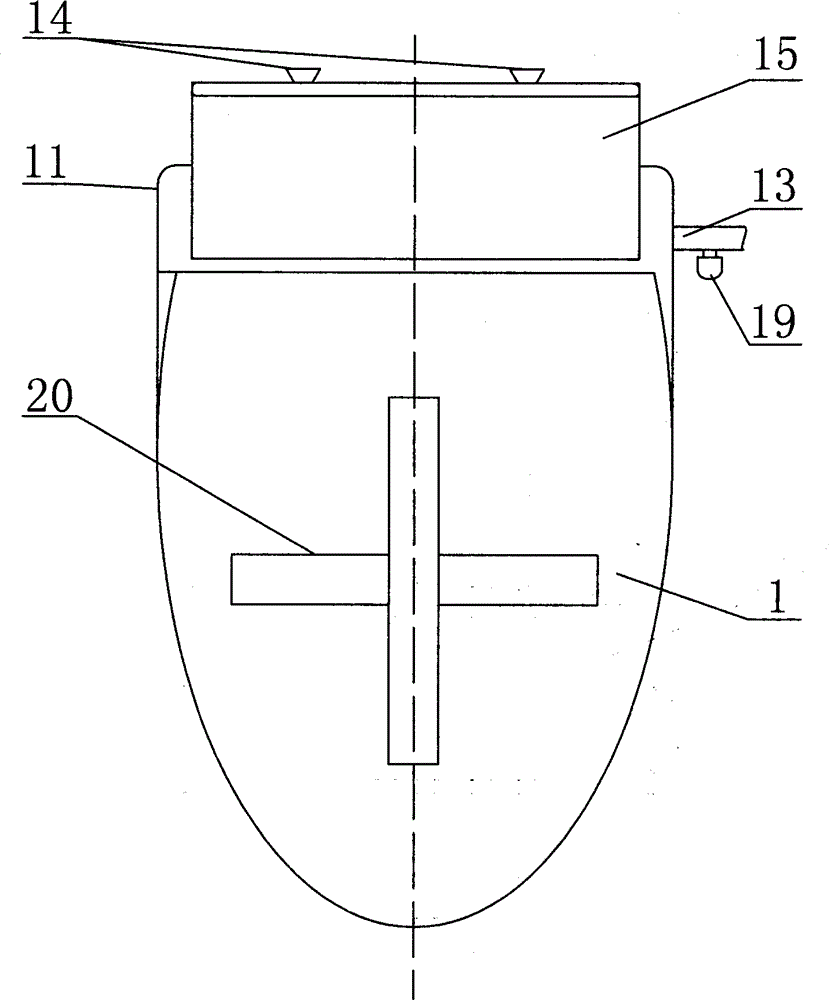

Multifunctional water-saving closestool

ActiveCN103835359AExtended service lifeOvercoming the pitfalls of early retirementWater closetsBathroom coversWater savingInterference fit

The invention belongs to the field of sanitary ware, and particularly relates to a multifunctional water-saving closestool. The multifunctional water-saving closestool comprises a closestool body, a closestool cover, a closestool cushion, a purified water inlet pipe, a urinal and a blow-off pipe, a blow-off pipe connector is connected into a pipe cavity in the lower portion of the blow-off pipe in a sleeved mode, a defecating hose connector is connected into the blow-off pipe connector in a sleeved mode and is a diameter-changing connector, the upper portion of the defecating hose connector is placed in the blow-off pipe connector and in interference fit with the blow-off pipe connector, the lower portion of the defecating hose connector is a shrinking and diameter changing structure and sleeved with a defecating hose and a sewer pipe connector sequentially from interior to exterior in a connected mode, the sewer pipe connector is also a diameter changing connecter, the upper portion of the sewer pipe connector is arranged outside the defecating hose connector in a sleeved mode and matched with the defecating hose connector in a tensioning mode, the lower portion of the sewer pipe connector is the shrinking and diameter changing structure and arranged in a sewer pipe and matched with the sewer pipe in a tensioning mode, and the pipe wall of the lower portion of the defecating hose is a self-suction sheet structure and placed in the sewer pipe. The multifunctional water-saving closestool is simple in structure, low in cost, obvious in water-saving effect, diversified in function and ideal.

Owner:高建国

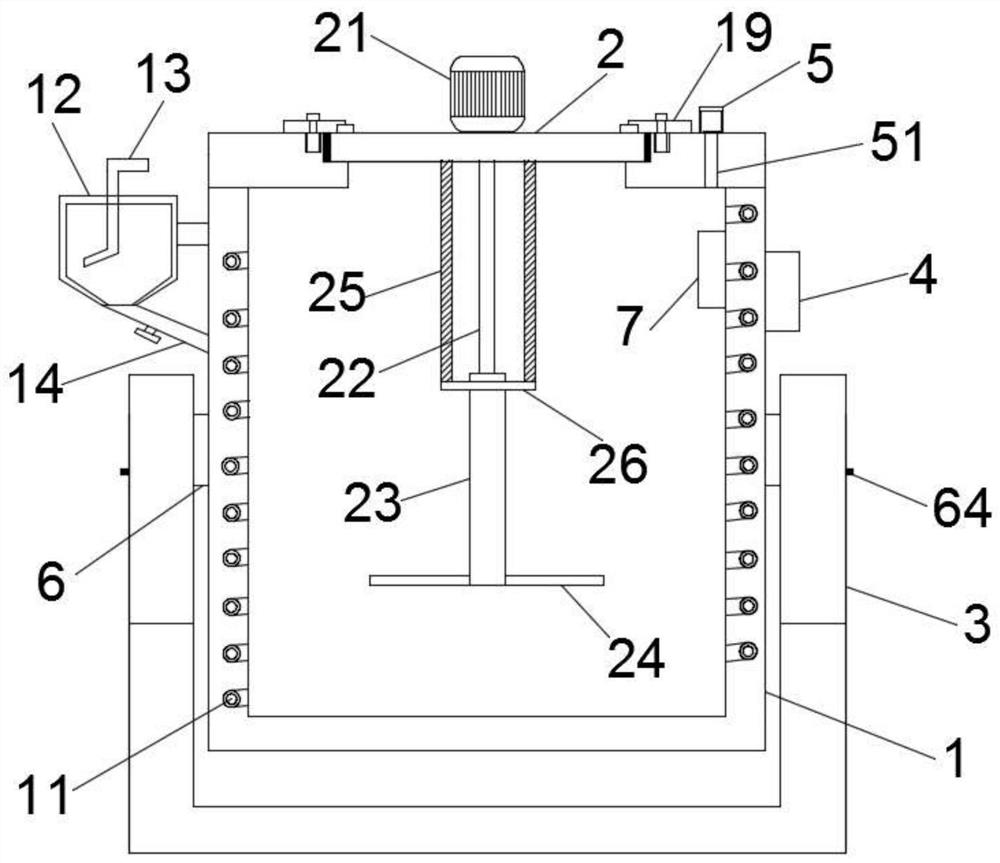

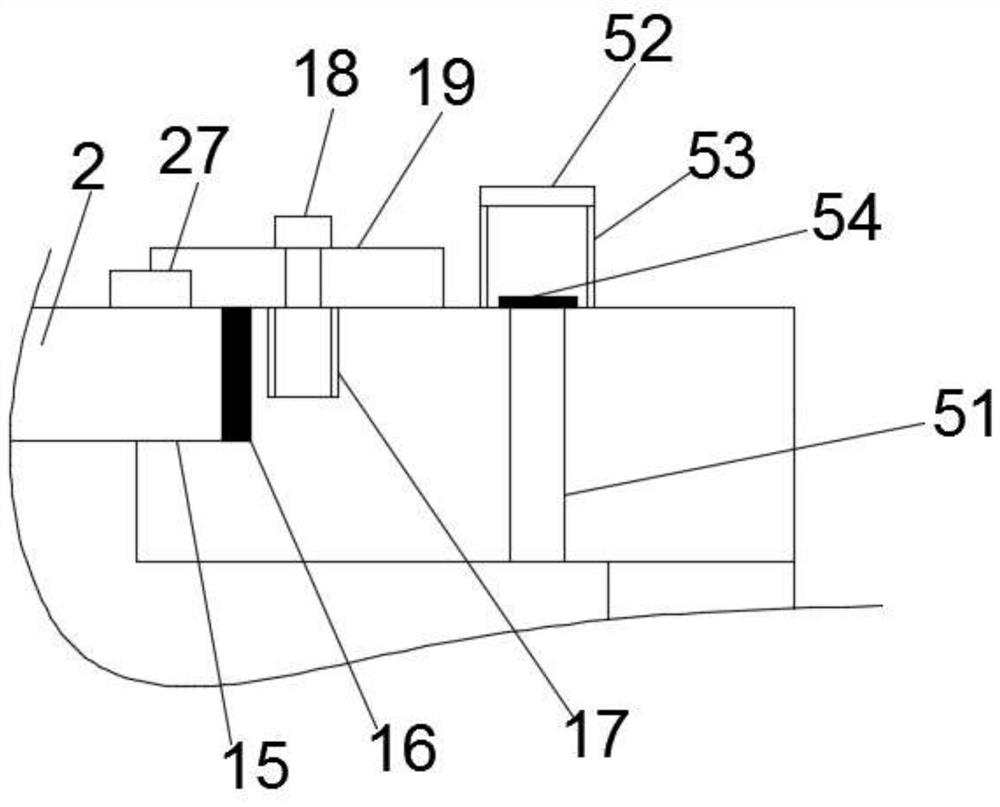

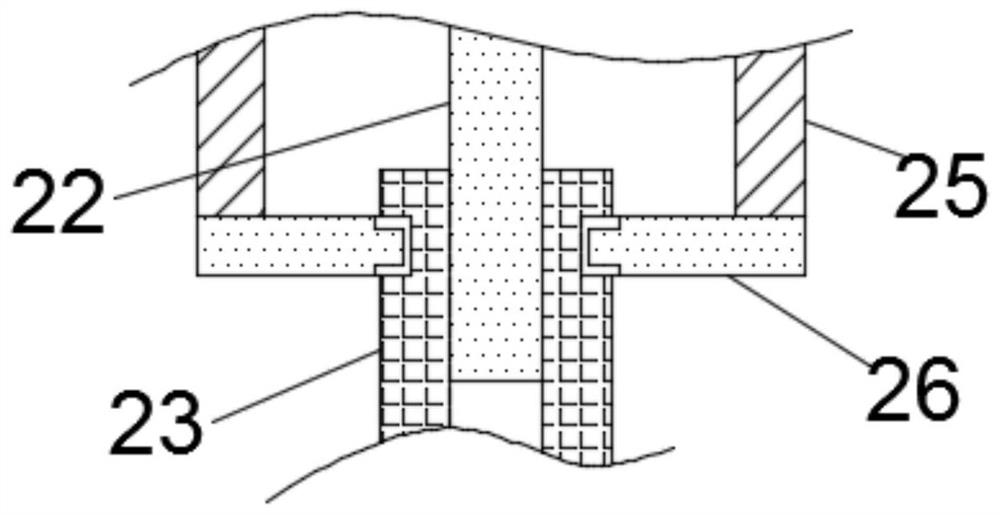

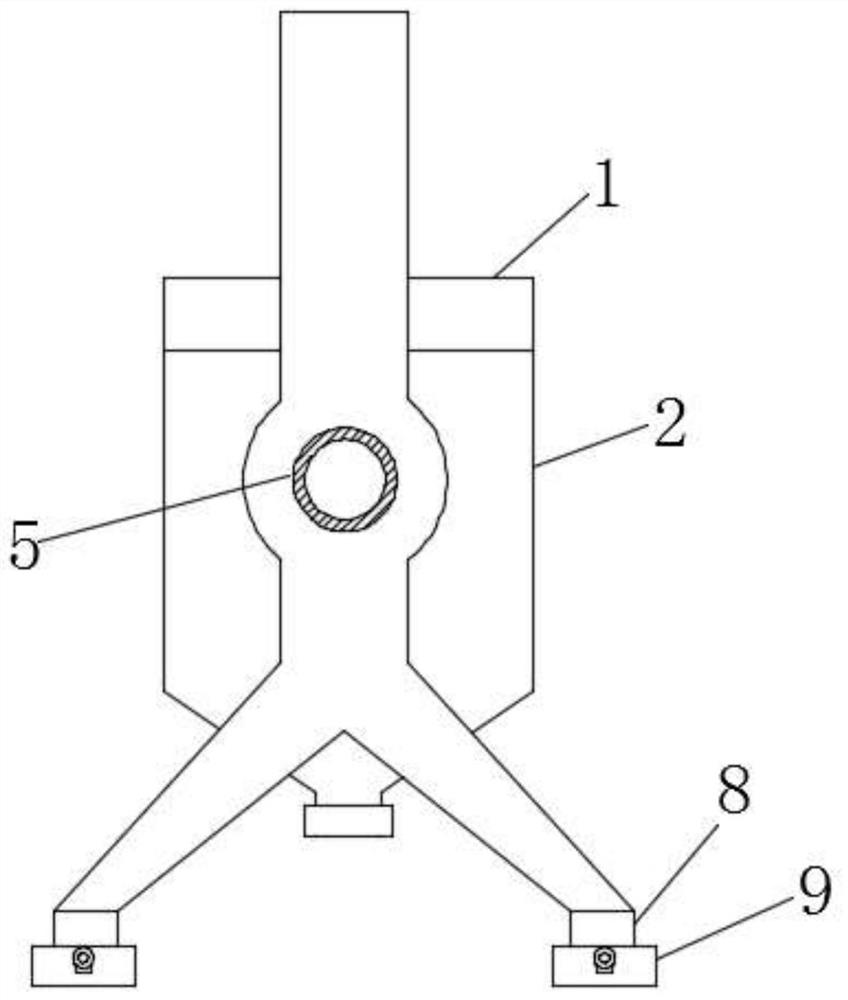

Fermentation equipment for bread processing

The invention relates to the technical field of bread fermentation devices, in particular to fermentation equipment for bread processing; the fermentation equipment for bread processing comprises a fermentation chamber, a top cover and a support frame, wherein the top cover is provided with a stirring motor and a stirring shaft; the output end of the stirring motor is connected with the stirring shaft; the stirring shaft is fixedly connected with a stirring rod; the fermentation chamber comprises a jacket, a buffer chamber, an exhaust valve and a pressure gauge. A spiral heating ring is installed in the jacket and connected with a temperature controller; the buffer chamber comprises a feeding hopper, a crank handle and a discharging pipe; the crank handle and the feeding hopper are rotationally sealed; the exhaust valve comprises exhaust holes and limiting pieces; the bottom faces of the limiting pieces are connected with the periphery of the corresponding exhaust holes through a plurality of stand columns, and exhaust pieces are arranged between the stand columns. The exhaust pieces abut against the periphery of the exhaust holes. The rotating stirring rod enables raw material tobe mixed evenly, the pressure intensity in the fermentation chamber is reduced through the pressure gauge, the exhaust pieces block the exhaust holes, the fermentation temperature in the fermentationchamber is adjusted, the bread fermentation speed is increased, and the fermentation efficiency is improved.

Owner:黄山市胡兴堂文化发展有限公司

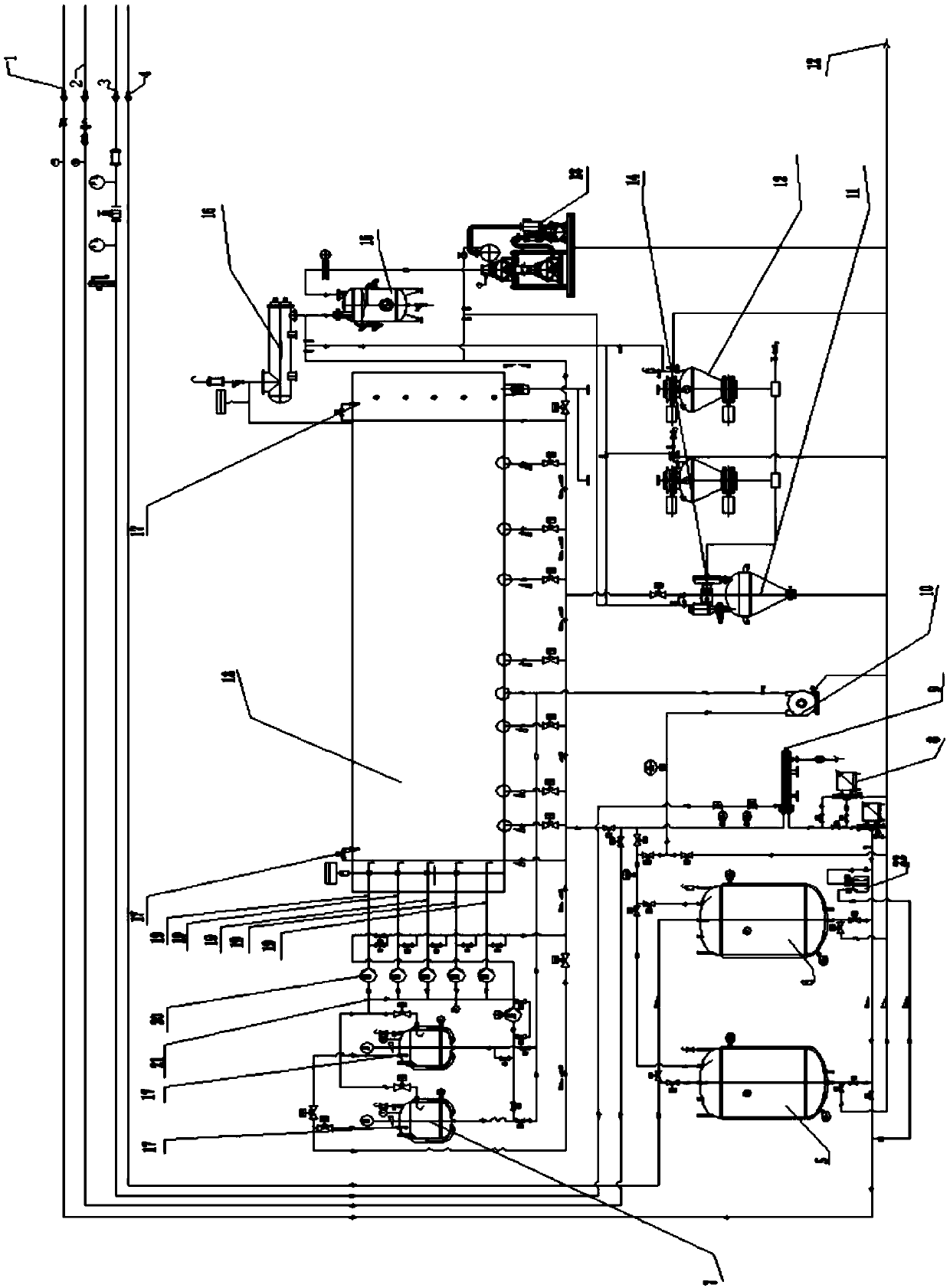

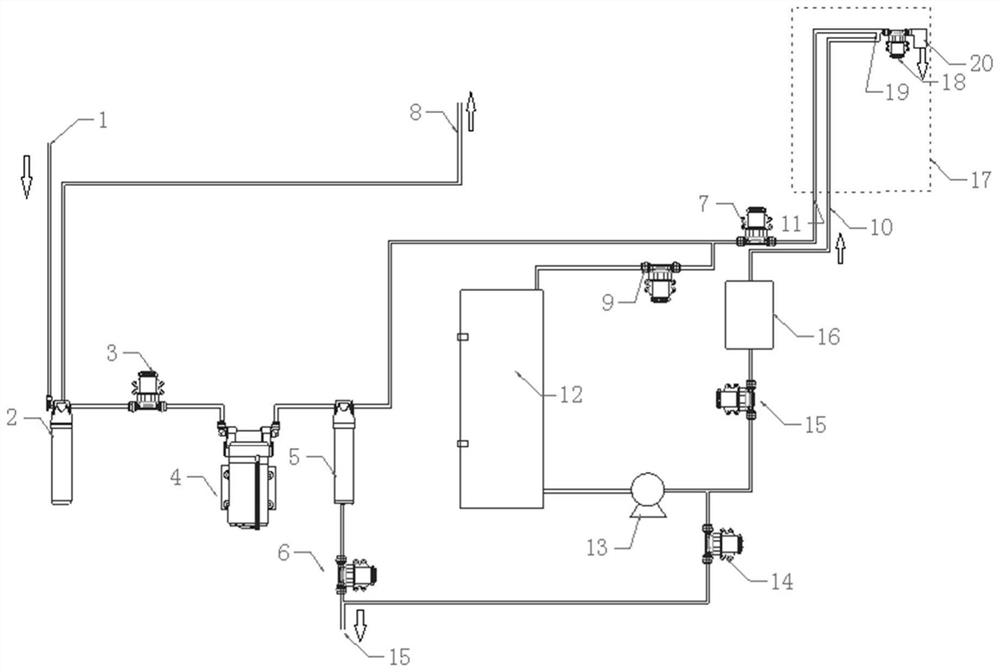

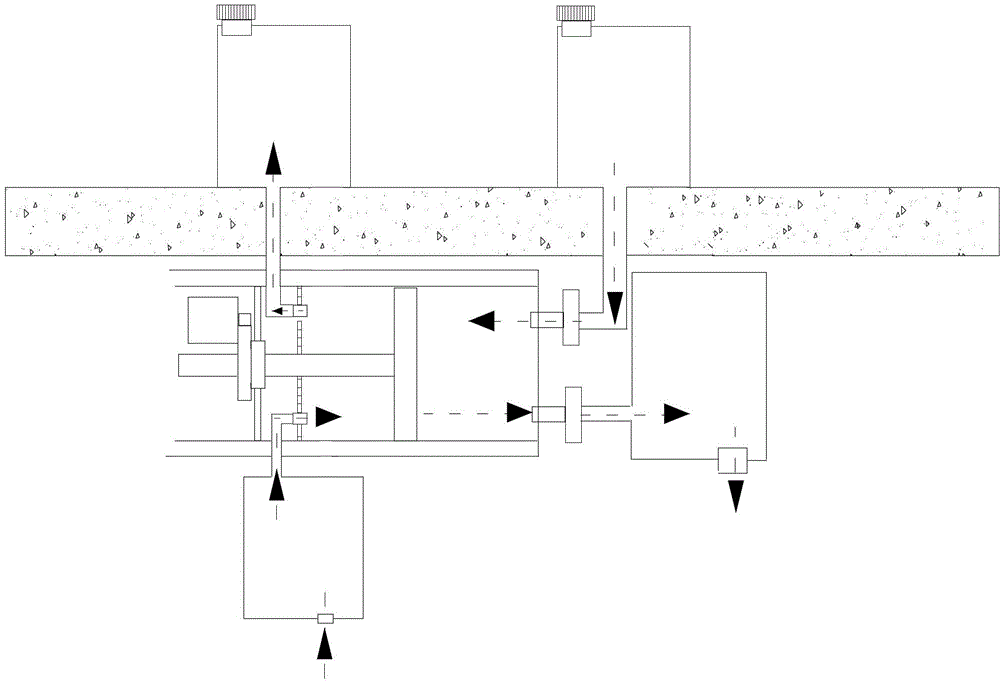

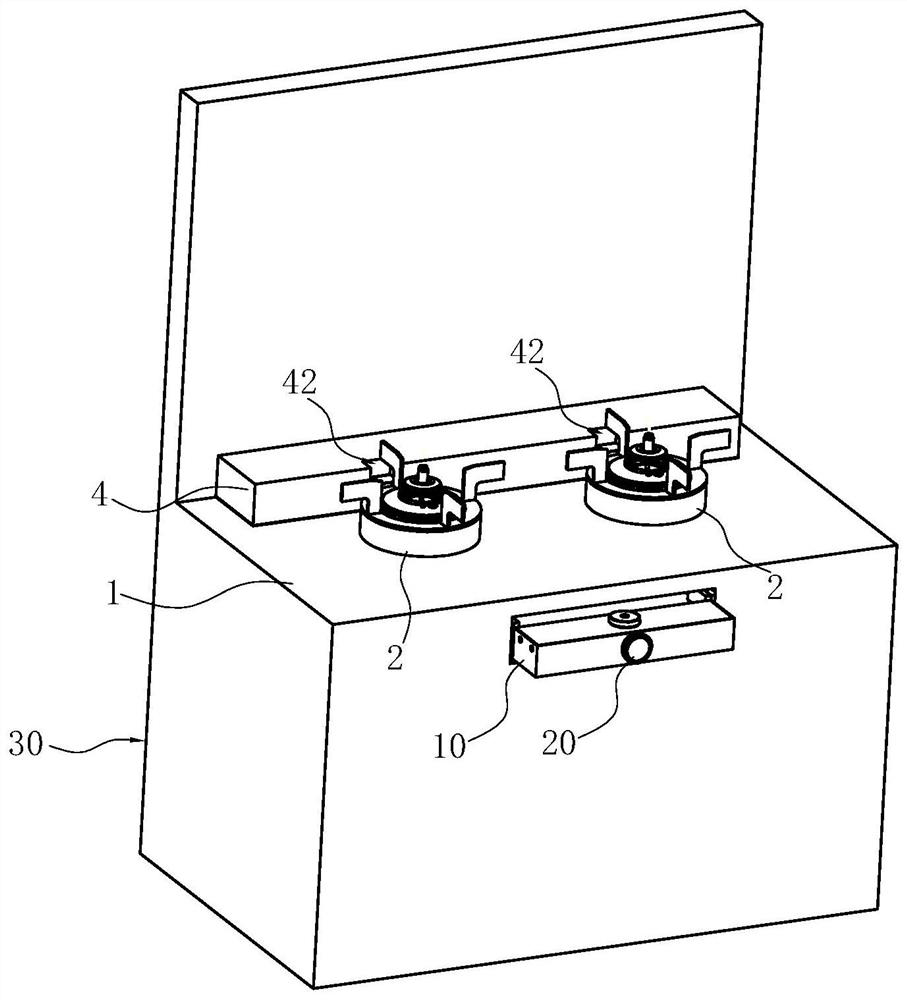

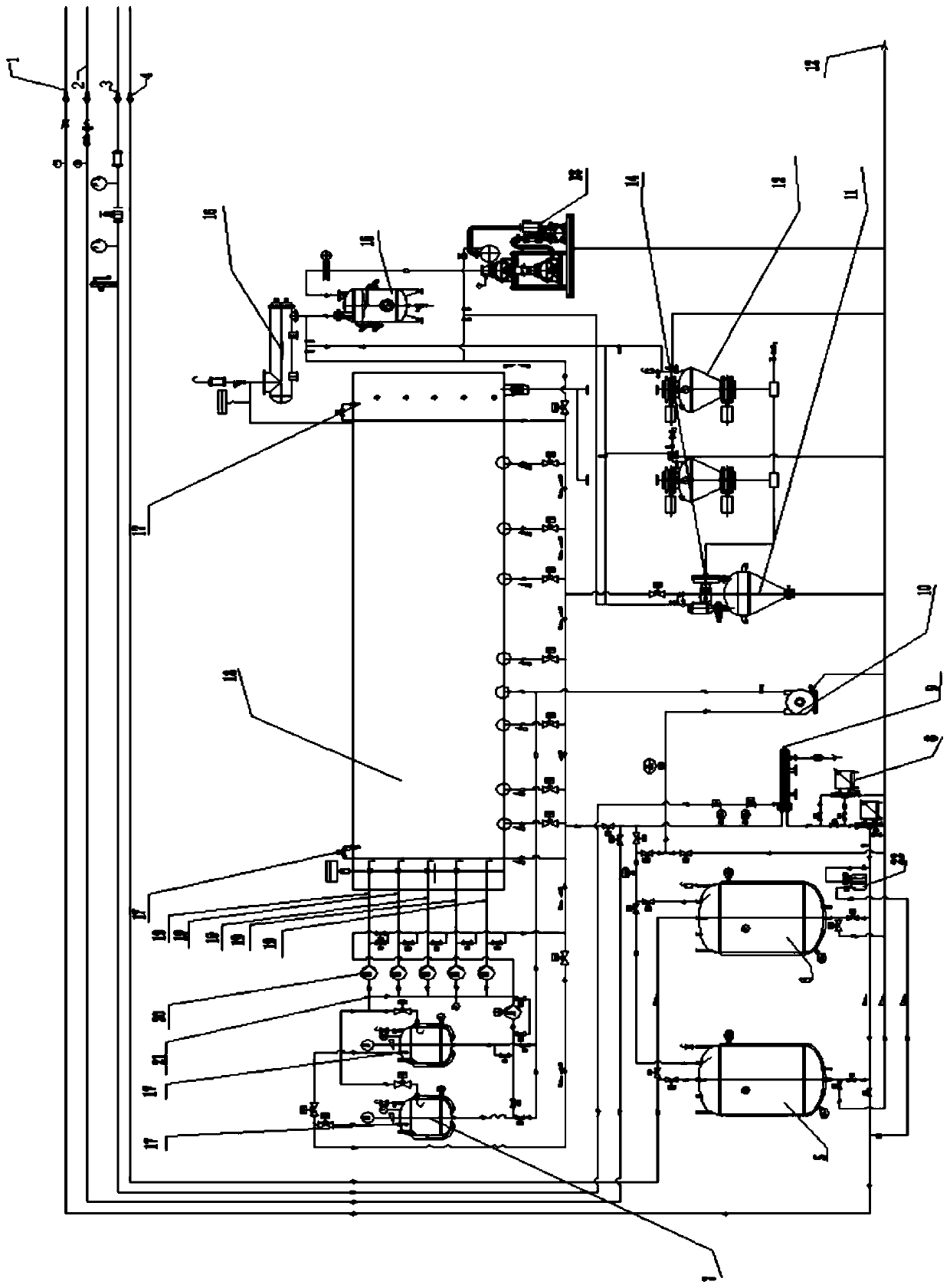

Cleaning and sterilizing equipment of vacuum belt drying unit and cleaning and sterilizing step method

ActiveCN109513679AEasy to drainEasy to cleanHollow article cleaningDrying gas arrangementsBuffer tankReducer

The invention discloses cleaning and sterilizing equipment of a vacuum belt drying unit. The cleaning and sterilizing equipment comprises a plurality of discharge tanks, a rotor pump, a rotor pump liquid outlet pipeline, a plurality of discharge screw pumps, a plurality of discharge pipelines, a purified water tank, a concentrated alkaline preparation tank, an alkali-washing tank, an aggregate bin, a buffer tank, a liquid collector, a condenser, a vacuumizing unit, a speed reducer, a self-priming pump, a valve, a centrifugal pump, a tubular heat exchanger and a cleaning pump, and further comprises a vacuum belt drier, wherein the vacuum belt drier comprises several layers of track conveyor belts, a case, a track bracket, a heating plate bracket, and a plurality of heating plates and cleaning tube units. According to the cleaning and sterilizing equipment, the cleaning ability is enhanced, the sanitary dead angle is reduced, and the exhaustion of residual water is facilitated, so that interior of the equipment is completely and fully cleaned, and in addition, an installation method of an original track support bracket is optimized to facilitate disassembly; and with adoption of thecleaning and sterilizing equipment, a cleaning standard for the production is improved, pollution and cross pollution are simultaneously prevented and the product quality is guaranteed.

Owner:温州市金榜轻工机械有限公司

Method and device for rolling and folding dough blocks

PendingCN108208057ARich ripenessPromote rapid formationDough-sheeters/rolling-machines/rolling-pinsDough processingEngineeringConveyor belt

The present invention relates to a method for rolling and folding dough blocks. The method comprises the following steps: (1) firstly, dough blocks are conveyed through a lower conveyor belt to conduct a first rolling process; after the first rolling process, dough belts are formed; and then the dough belts are subjected to a first folding process; (2) after the dough belts are subjected to the first folding process in the step (1), the stacked dough belts are conveyed by an upper conveyor belt to conduct a second rolling process; then a second folding process is conducted; and then the treated dough belts are conveyed by the lower conveyor belt; and (3) the first rolling process and first folding process in the step (1) and the second rolling process and second folding process in the step(2) are conducted repeatedly. Advantages are as follows: a cross-type mechanical structure can automatically conduct vertical and cross-type repeated folding and rolling of the dough, and automatically export the dough belts with rich network and high ripening degree.

Owner:QINGDAO HAIKEJIA ELECTRONCE EQUIP MFG

Extractor hood

PendingCN109990336AEasy to cleanLarge amount of solutionDomestic stoves or rangesLighting and heating apparatusEngineeringL# .NET

The invention discloses an extractor hood. The extractor hood comprises a shell, a smoke absorbing port is formed in the shell, the extractor hood comprises an oil net installed on the smoke absorbingport, the oil net is inclined and fixed relative to the smoke absorbing port, the oil net is a flat plate body, and at least one side of the oil net is separated from the edge of the smoke absorbingport and forms a gap with the smoke absorbing port. The extractor hood well solves the problem that the oil smoke is large and urgent in the oil net through oil discharge gaps formed in the oil net and the smoke absorbing port, greatly reduces the oil pollution accumulation on the lowest surface of the oil net, and solves the problem that oil droplet particles are large and form a concentrated problem in a short period of time on the lowest surface of the oil net, so that most of the oil droplets can smoothly flow into an oil cup as soon as possible, oil pollution overflowing is not caused, the sanitary dead corner is reduced, and the extractor hood is easier to clean.

Owner:QINGDAO HAIER WISDOM KITCHEN APPLIANCE CO LTD

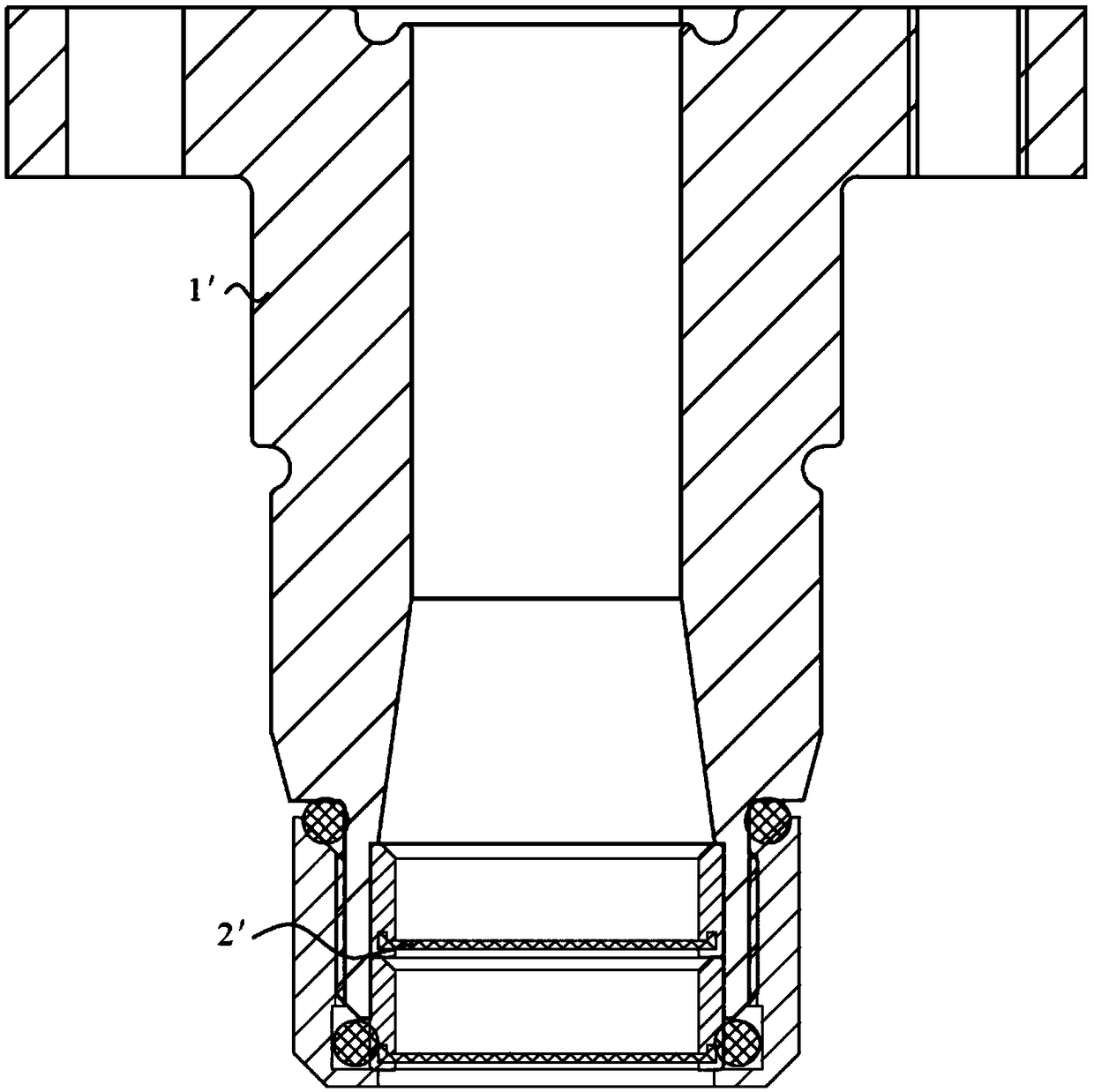

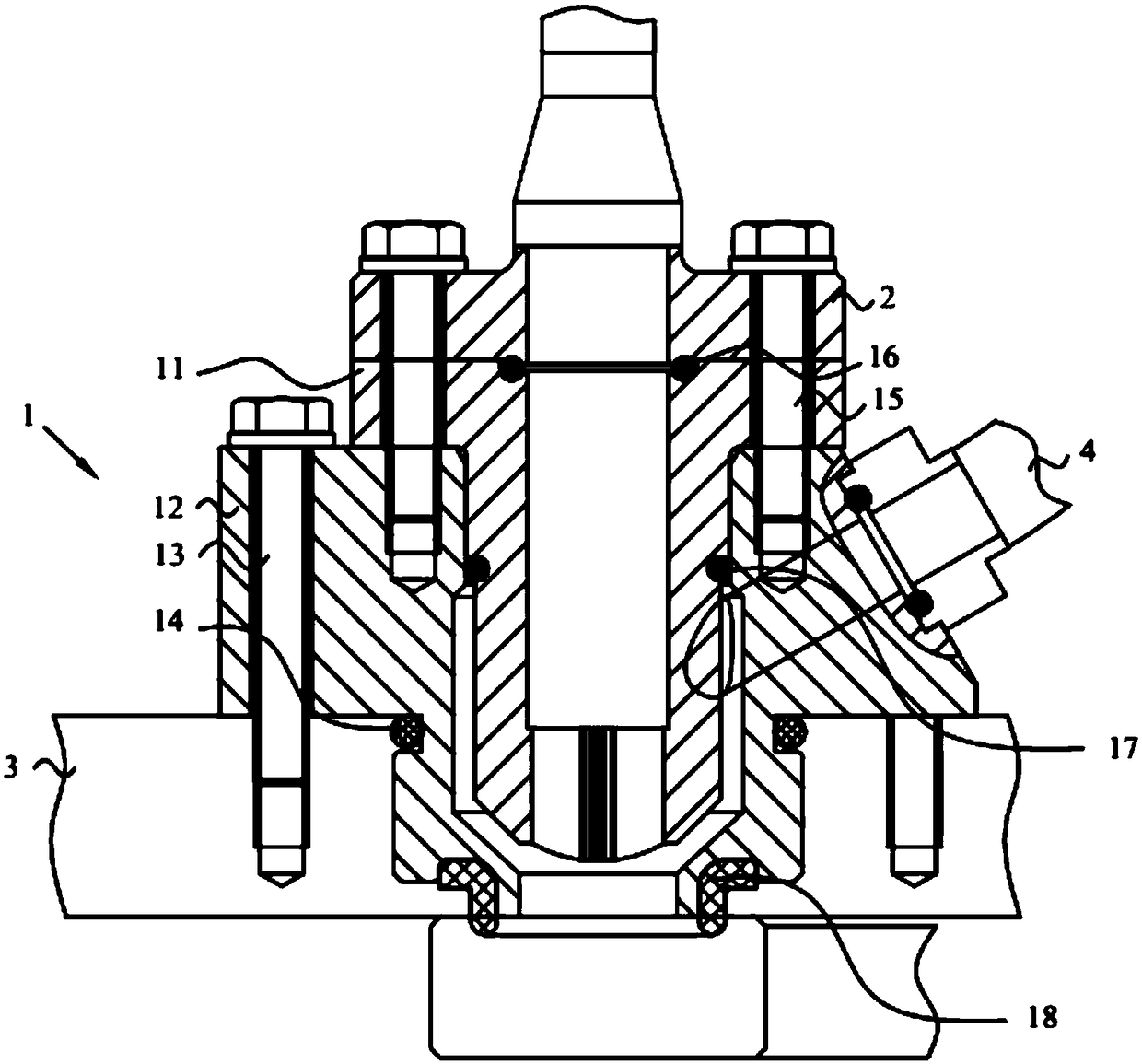

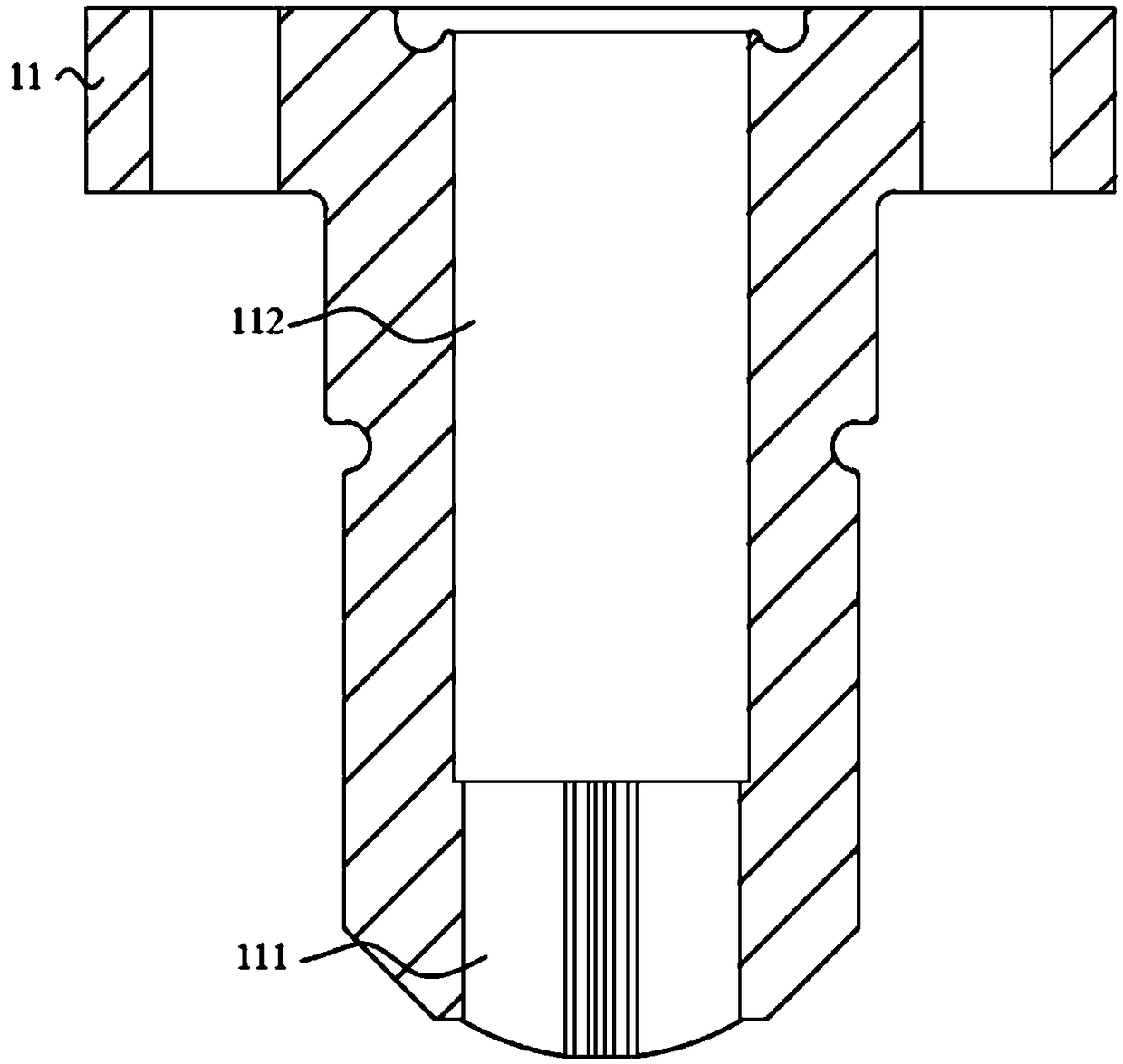

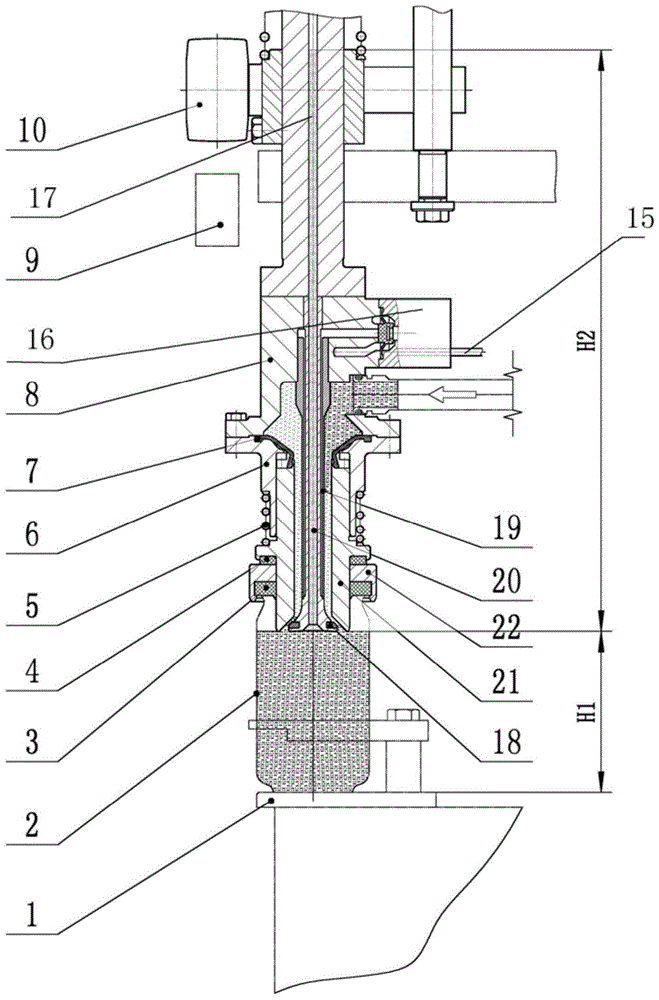

Filling valve and filling device

PendingCN109205537AReduce sanitary cornersReduce health risksFilling device cleaningEngineeringFill device

The invention relates to the technical field of filling equipment, particularly to a filling valve and a filling device. The filling valve provided by the invention comprises a valve core; the valve core is provided with a filling channel and a plurality of throttling channels; the filling channel communicates with each of the throttling channels; and the throttling channels are arranged on the tail end of the valve core. The filling valve provided by the invention can divert liquid in the filling channel through the plurality of throttling channels, thereby ensuring the uniformity and stability of a filling liquid column; and additional installation of a filter screen is not needed, so sanitary dead angles are effectively reduced, sanitary risks are greatly decreased, and the filling valve is applicable to aseptic filling and to occasions with high sanitary requirements. Through usage of the filling valve, the filling device provided by the invention does not need additional installation of a filter screen, can effectively reduce sanitary dead angles and greatly decrease sanitary risks and is applicable to aseptic filling and to occasions with high sanitary requirements.

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

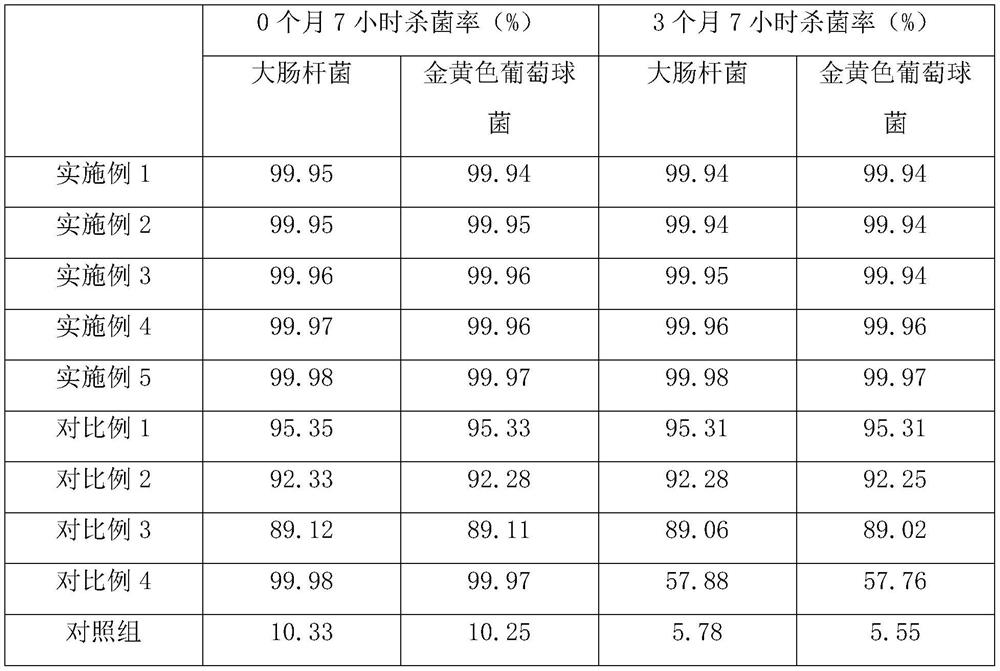

A kind of antibacterial toothbrush and manufacturing method thereof

ActiveCN108359236BExtend the life cycleWill not polluteDomestic articlesAntimicrobial actionPolymer science

Owner:杭州纳美智康科技有限公司

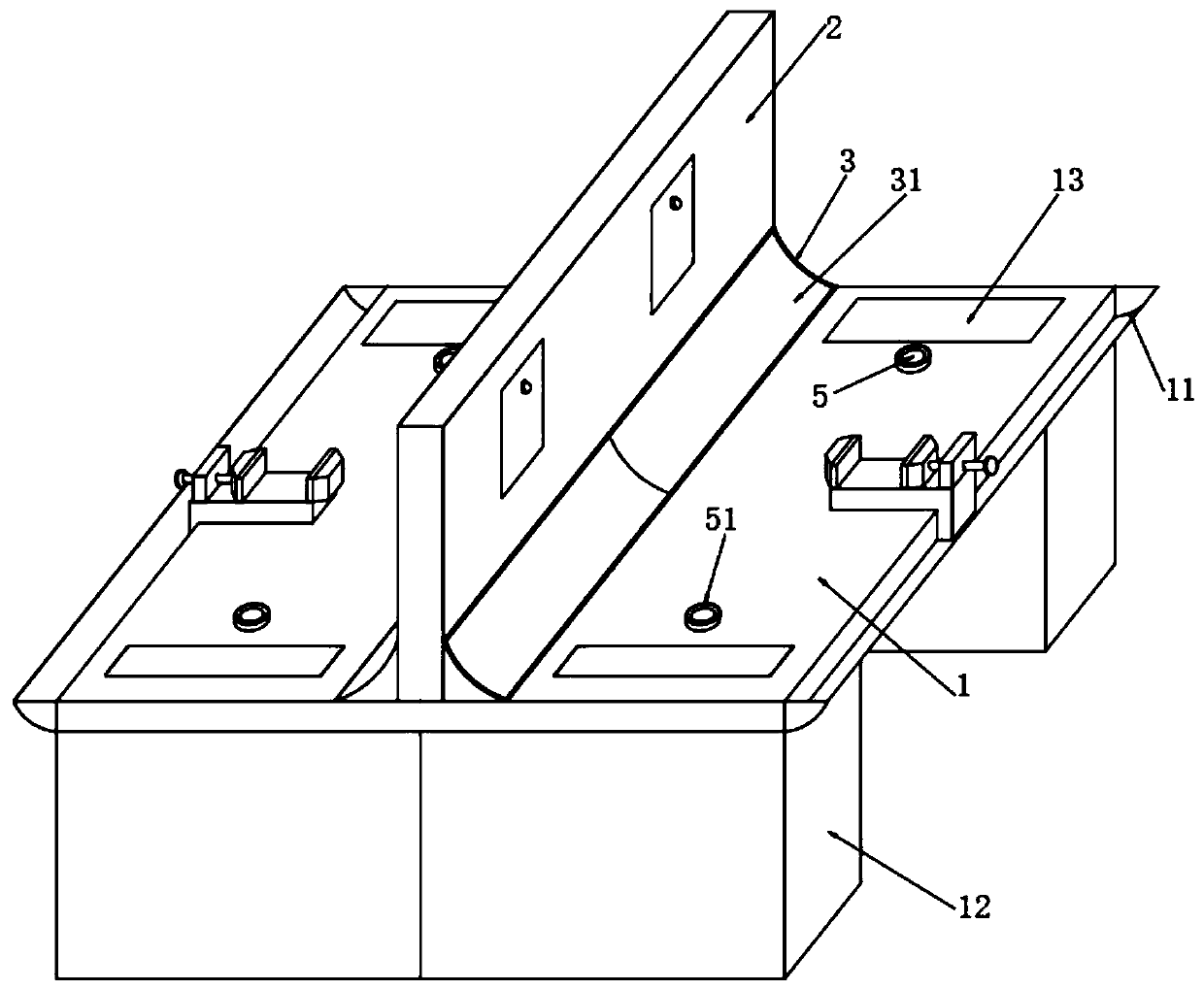

Machining worktable

InactiveCN111015603AAvoid high impactReduce space consumptionWork benchesMachine buildingEngineering

The invention belongs to the technical field of mechanical manufacturing, and particularly discloses a machining worktable. The machining worktable comprises two worktable plates and a separating plate fixedly connected between the two worktable plates, the separating plate is located on the upper end faces of the worktable plates, a storage box is fixedly connected with the upper end faces of theworktable plates, the storage box is located on the corners of the worktable plates and the separating plate, an observing cover is hinged to the upper end face of the storage box, two symmetrically-distributed supporting storage boxes are fixedly connected to the bottom faces of the worktable plates, through a control switch, a tool box and a document box are controlled to ascend and descend, anoperator is prevented from being affected by the height of the worktable, during object taking, the operator does not need to stoop down or crouch for seeking for, tools used during work are placed in the storage box, the user can intuitively observe the conditions of the tools, and at the moment, on the premise of reducing space occupying of a table board, taking convenience is improved.

Owner:嘉兴博立螺丝有限公司

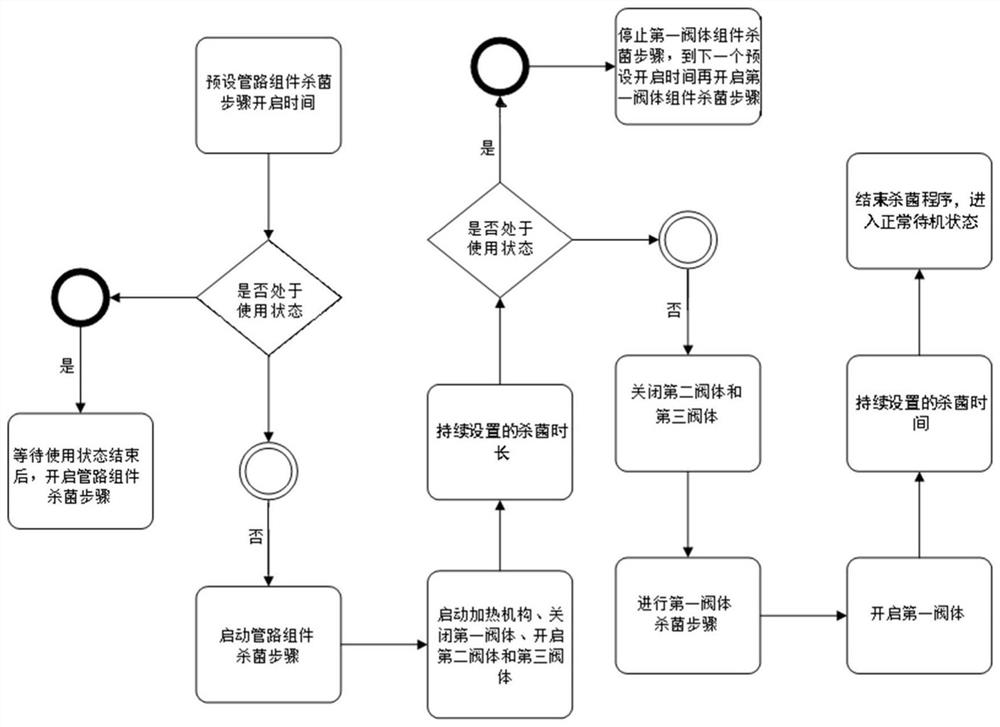

Water purification device and control method thereof

PendingCN114149132AReduce sanitary cornersImprove health and safetyTreatment involving filtrationWater/sewage treatment bu osmosis/dialysisWater flowProcess engineering

The invention provides a water purifying device and a control method thereof, and relates to the technical field of water outlet equipment, the water purifying device comprises a pure water outlet, a pipeline assembly and a first valve body assembly; when the water purifying device is sterilized, the outlet of the first pipeline and the outlet of the second pipeline are communicated through the first valve body assembly, the heating mechanism is started, pure water prepared by the water purifying device flows into the second pipeline and then is heated by the heating mechanism to prepare heated water, and the heated water can circularly flow in the first pipeline and the second pipeline; the first pipeline and the second pipeline are sterilized; after sterilization of the first pipeline and the second pipeline is completed, the outlet of the second pipeline can be opened through the first valve body assembly, so that the heated water flows to the first valve body assembly from the outlet of the second pipeline and flows out of the first valve body assembly, and therefore the first valve body assembly is sterilized. According to the water purifying device provided by the invention, sanitary dead angles of the water purifying device can be reduced, and the sanitary safety of the water purifying device is improved.

Owner:HANGZHOU ROBAM APPLIANCES CO LTD

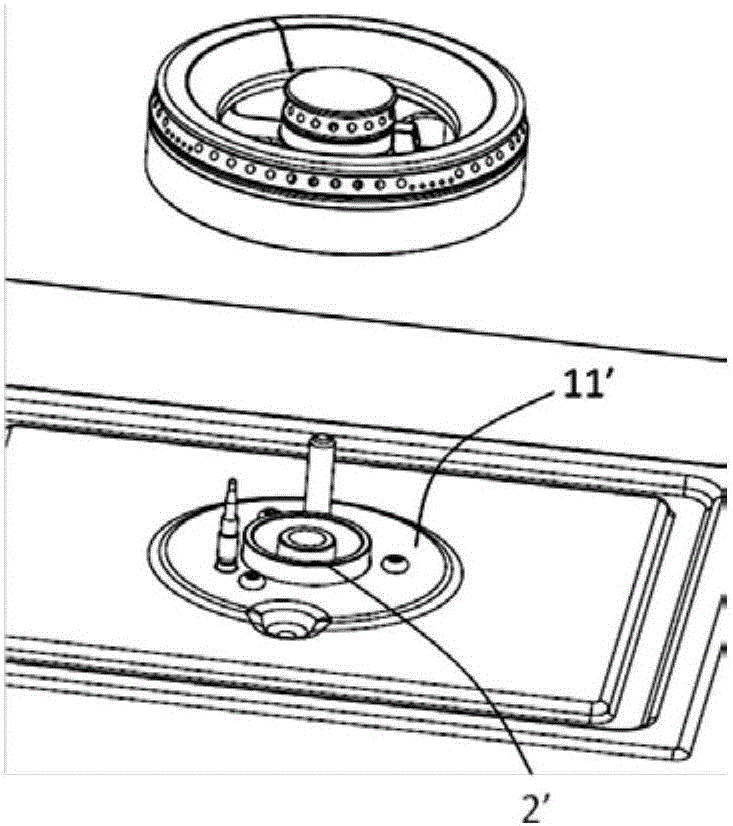

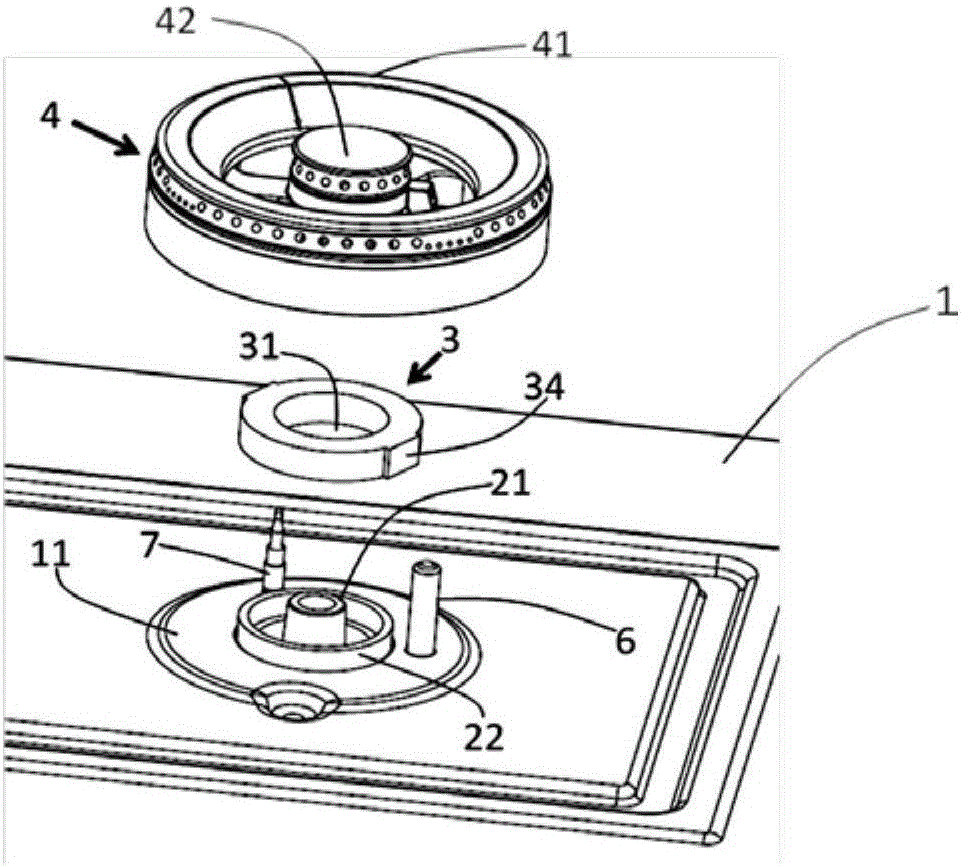

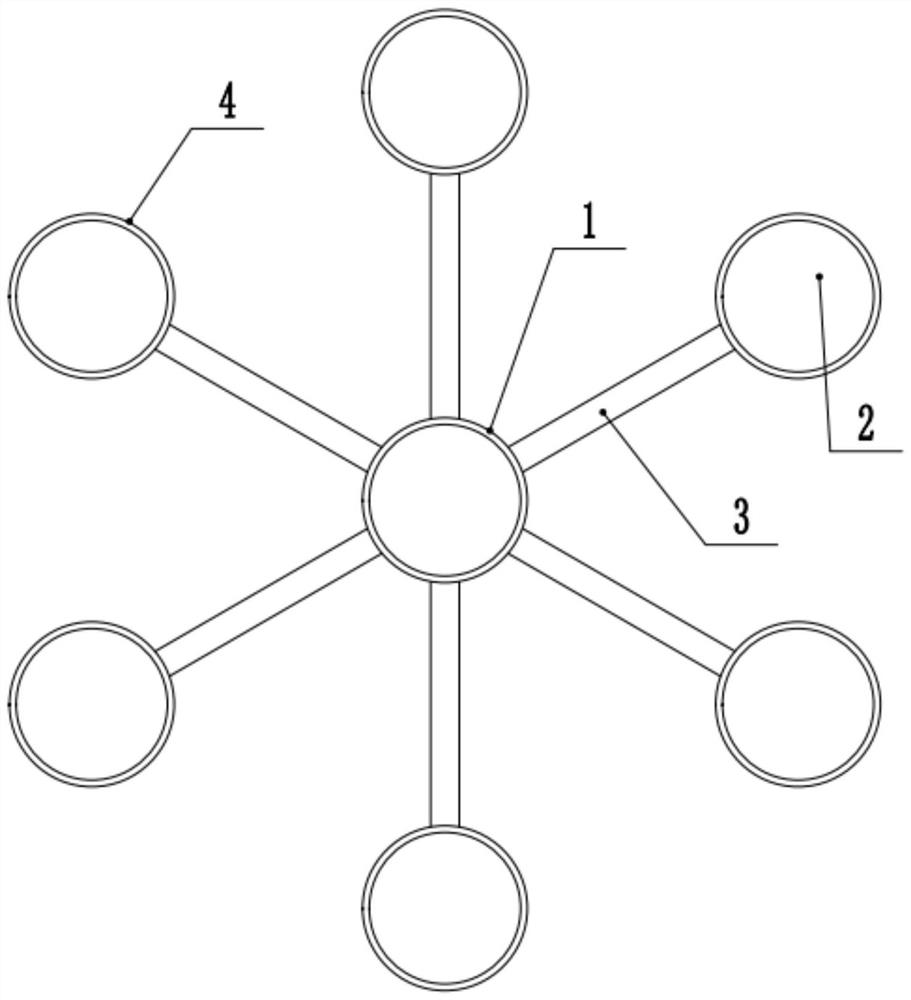

Gas stove and assembly thereof

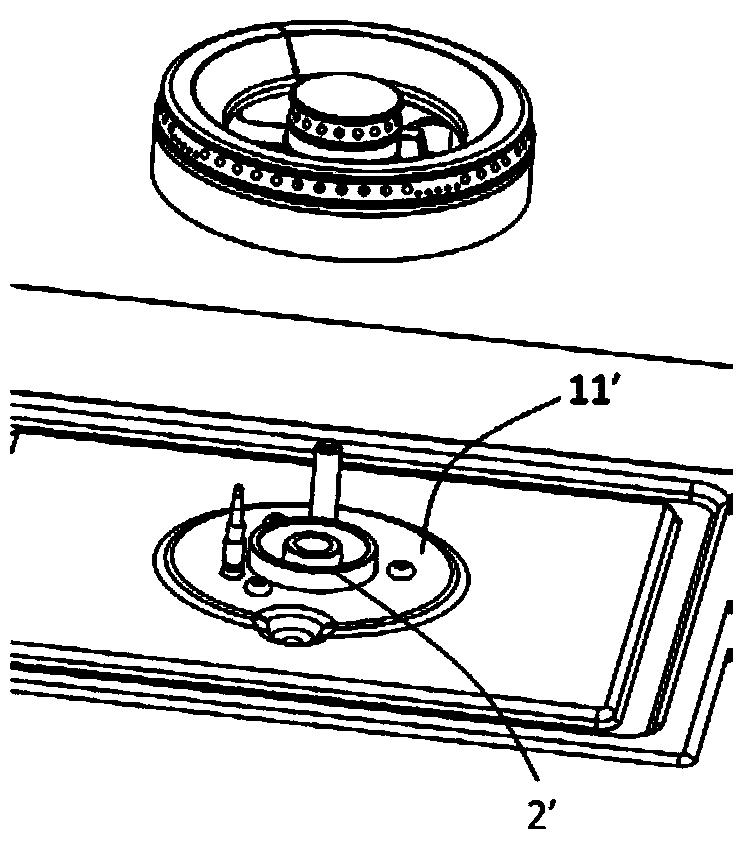

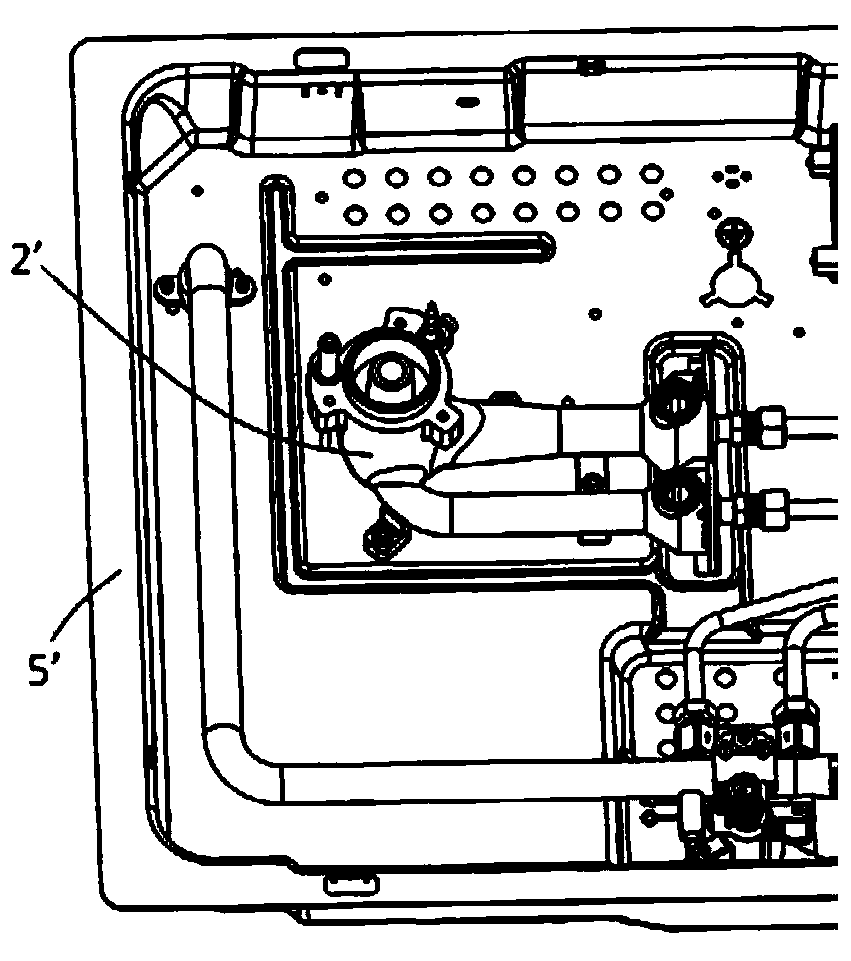

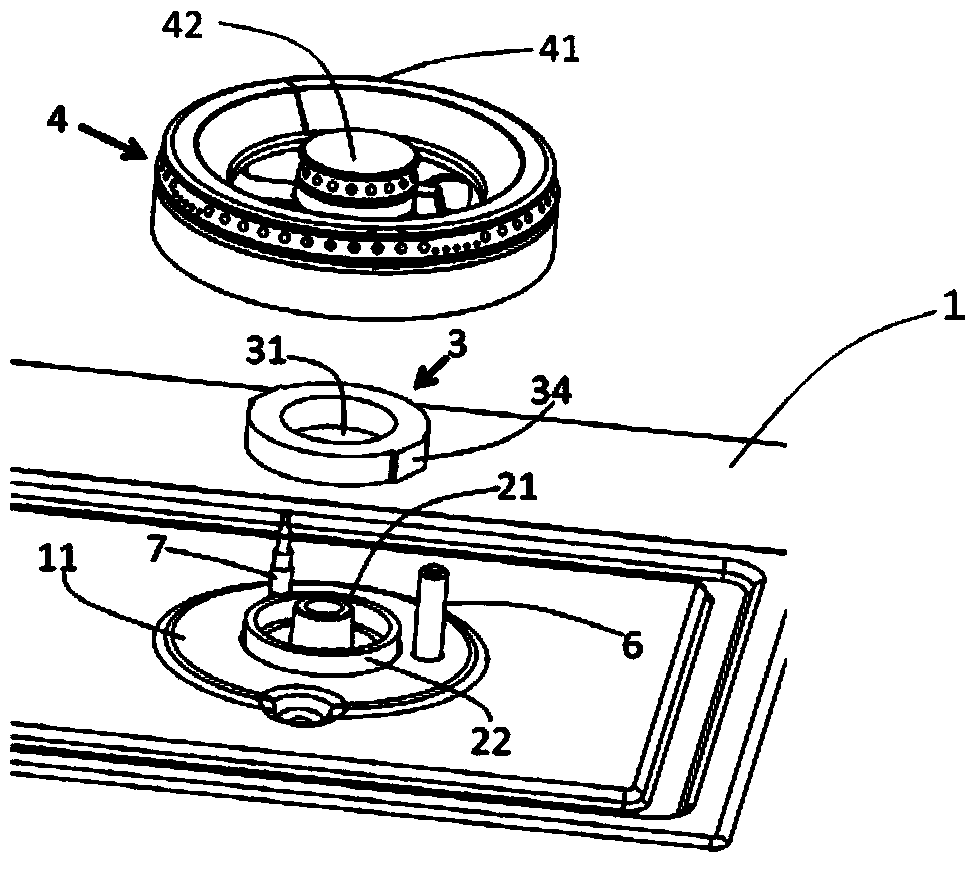

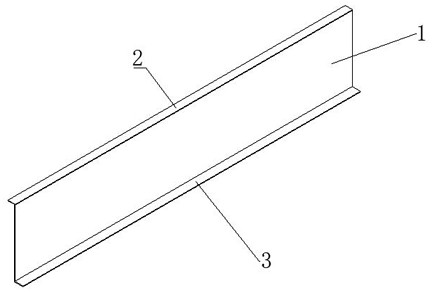

ActiveCN106322445ALow costReduce sanitary cornersDomestic stoves or rangesLighting and heating apparatusEngineeringSurface plate

The invention provides a new improvement for a gas stove and an assembly thereof. The provided gas stove assembly comprises a panel (1) and a burner base (2). The panel (1) is provided with a through hole part. The gas stove assembly further comprises a fixing piece (3). The fixing piece (3) and the gas outlet end of the burner base (2) are provided with matched threads correspondingly. The fixing piece (3) is fixed to the gas outlet end of the burner base (2) from top to bottom in a threaded connection manner. An edge (12) of the through hole part is extruded and fixed between the gas outlet end of the burner base (2) and the fixing piece (3). By the adoption of the technical scheme, it becomes possible that no screw is arranged on the panel any more, and panel is conveniently cleaned.

Owner:BSH ELECTRICAL APPLIANCES JIANGSU +1

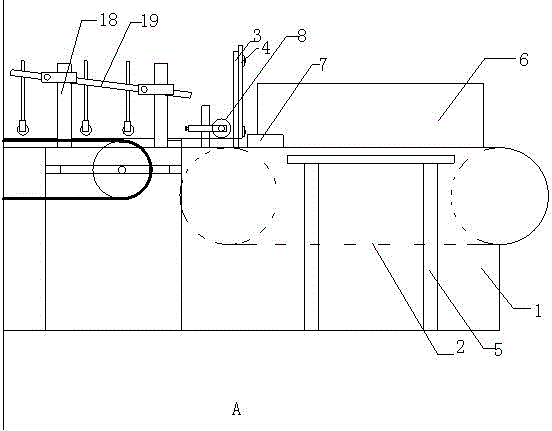

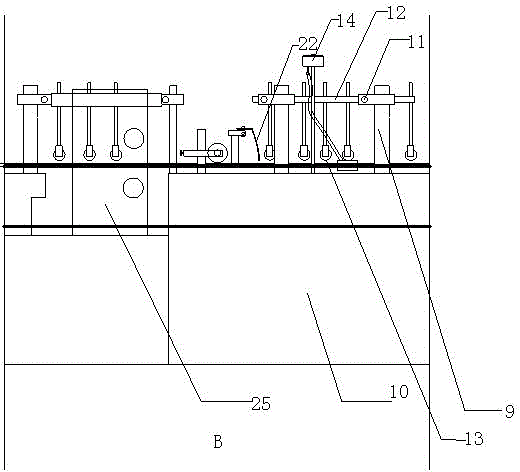

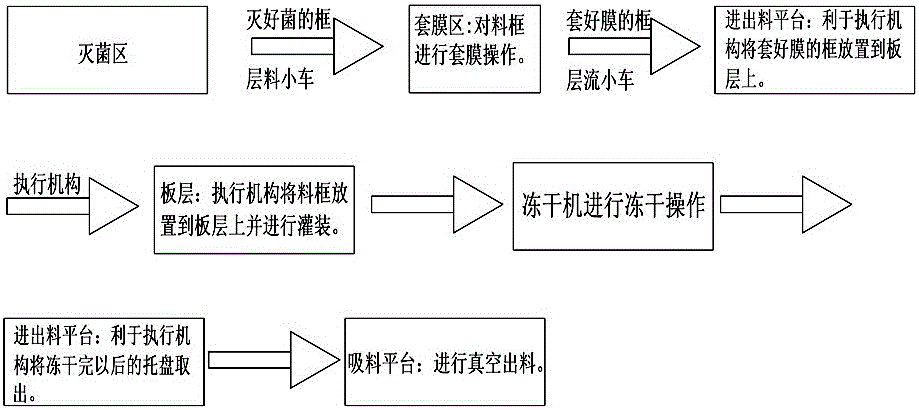

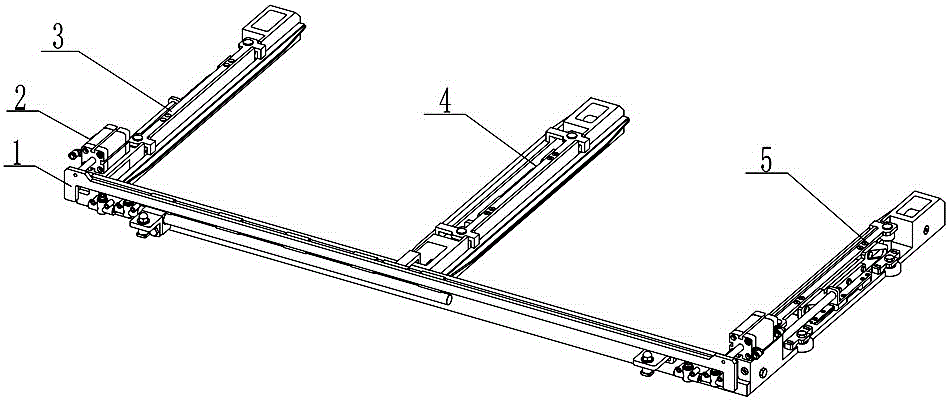

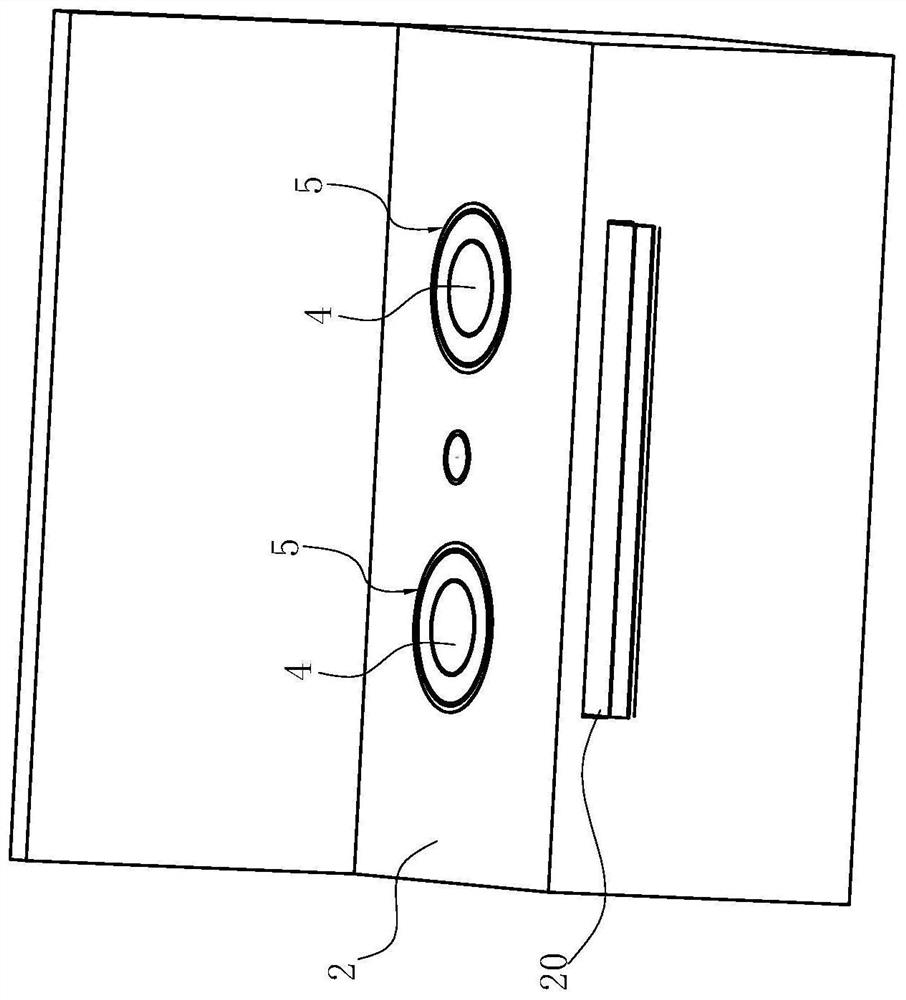

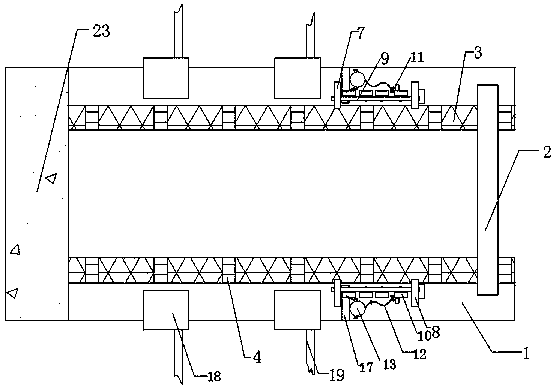

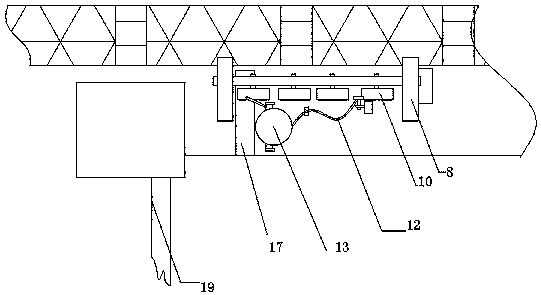

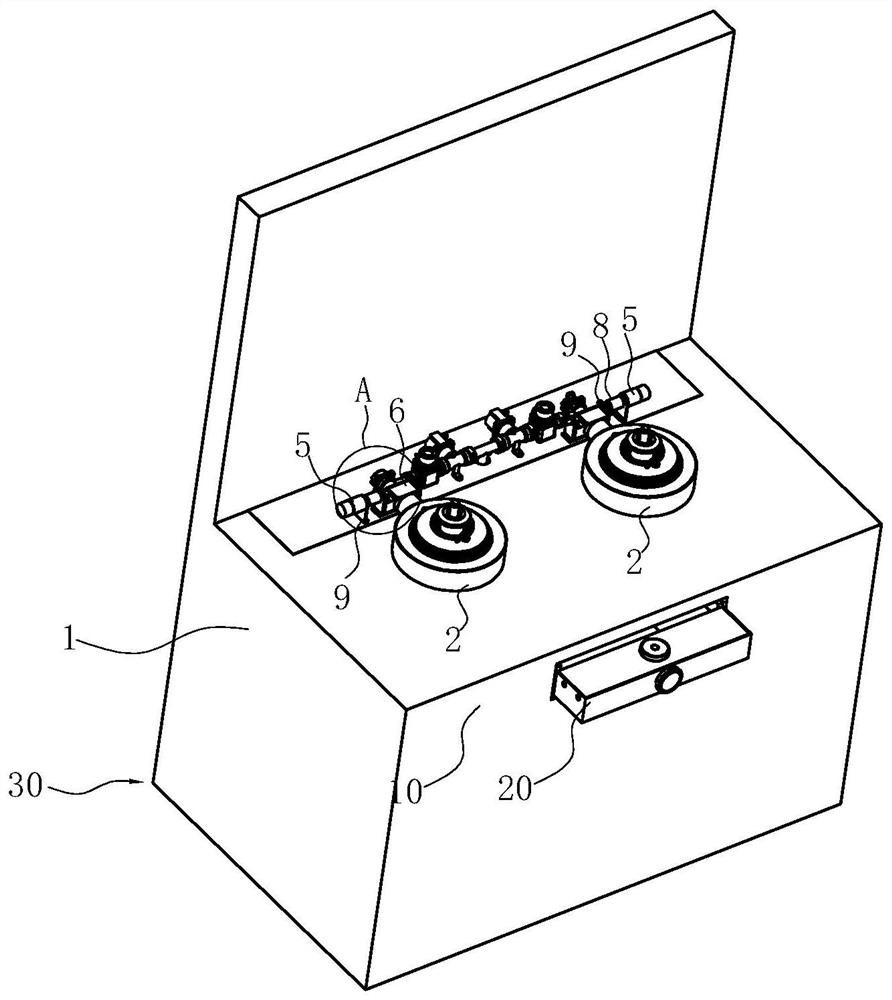

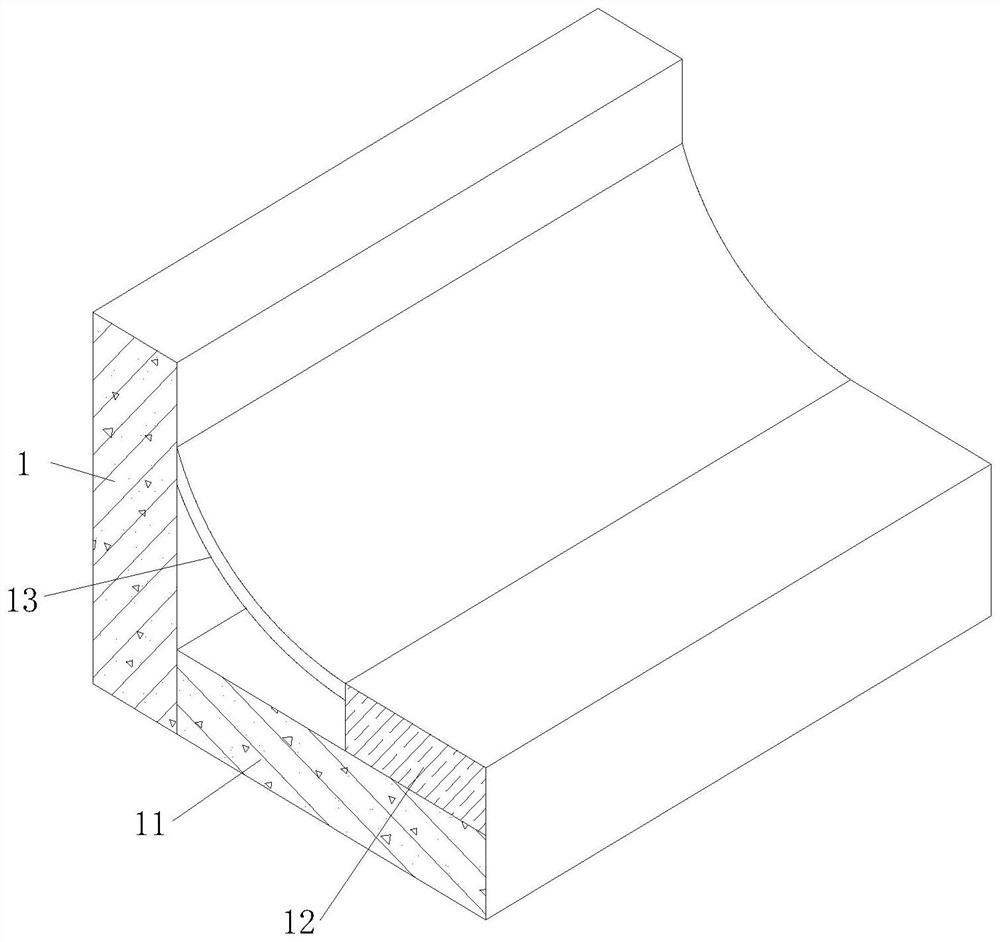

A method for controlling the feeding and discharging of raw materials on a freeze-drying machine

ActiveCN103759524BEasy to operateIncrease the level of automationDrying solid materialsEngineeringMechanical engineering

Owner:TRUKING TECH LTD

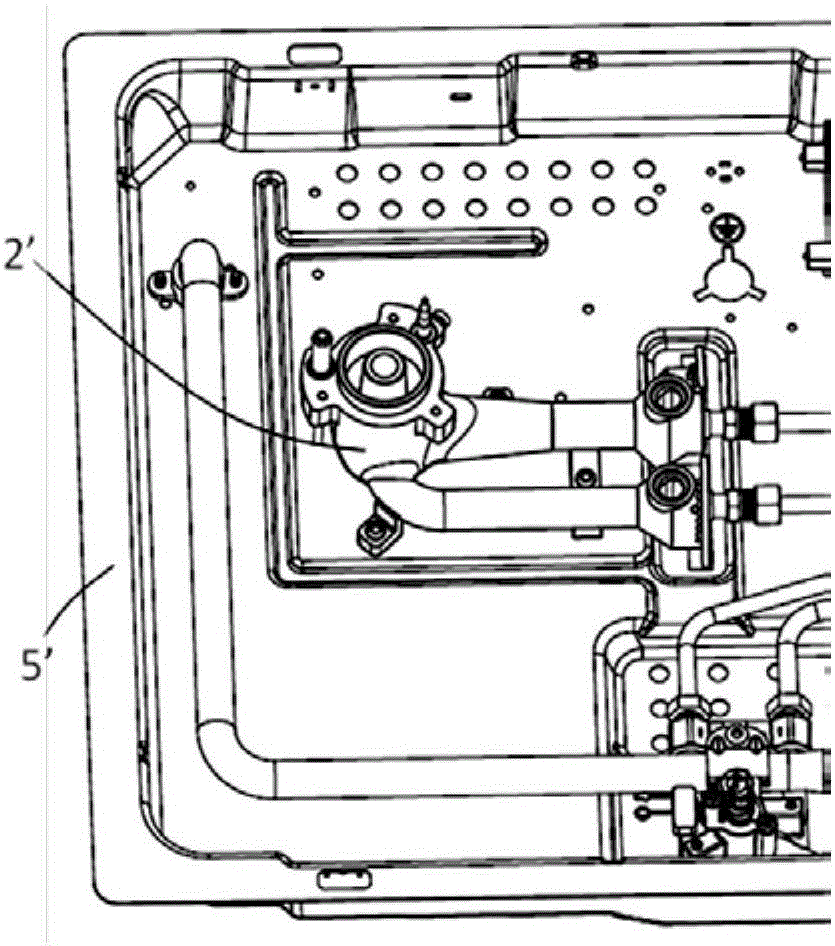

A gas stove and a cabinet using the gas stove

ActiveCN111351072BImprove aestheticsReduce sanitary cornersDomestic stoves or rangesLighting and heating apparatusEngineeringCupboard

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

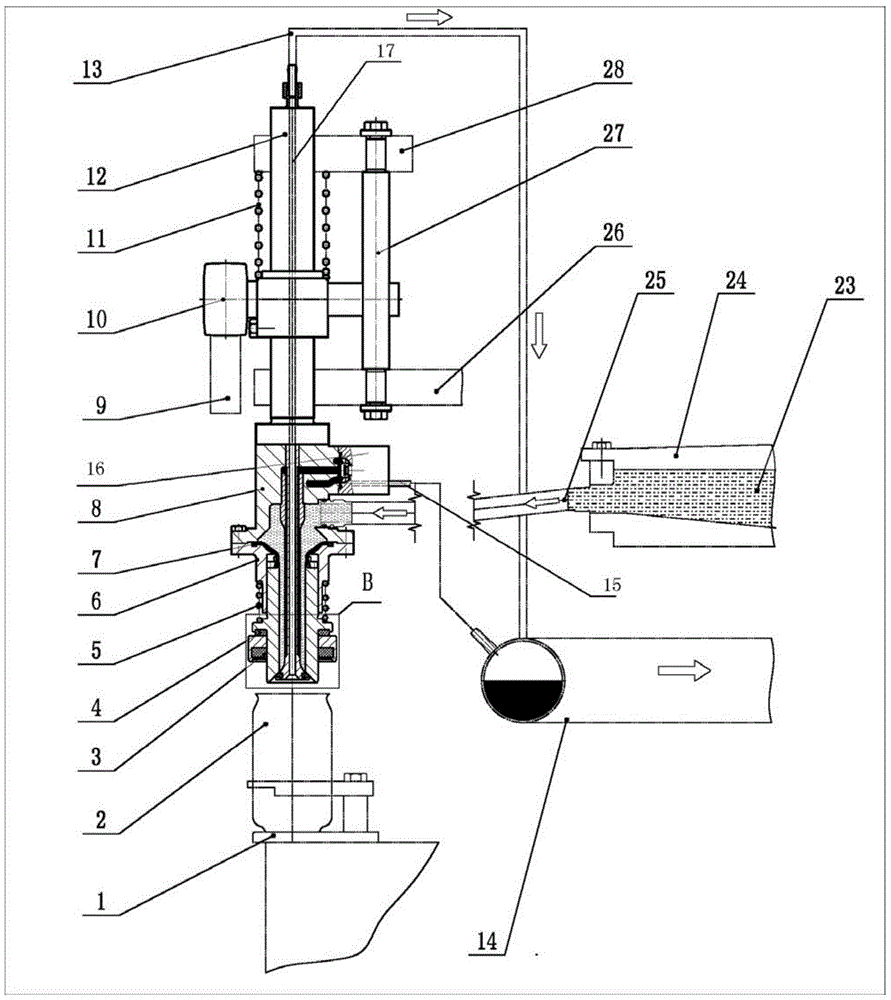

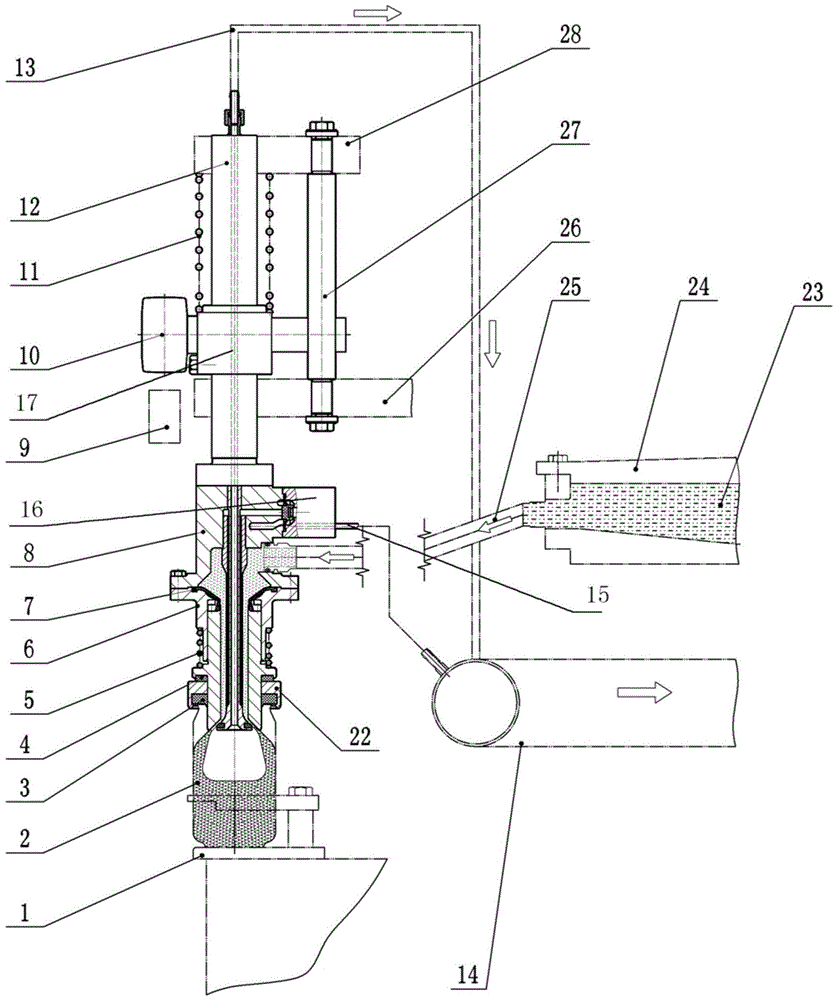

A hot filling valve

ActiveCN104085843BAvoid heatingPrecise control of return flowLiquid bottlingControl valvesReturn channel

The invention discloses a hot filling valve. The hot filling valve comprises a valve seat, a valve element, a material cylinder, an outer sliding sleeve and a sealing base, wherein the valve seat is arranged on a supporting rotating disk in a vertical lifting manner and is driven by a valve seat lifting driving mechanism, a central gas return hole which penetrates through the whole valve element axially and is communicated with a gas return pipe is formed in the valve element, a valve element sleeve pipe is arranged outside the valve element in a sheathing manner, a reflux gap is left between the valve element sleeve pipe and the valve element, the outer sliding sleeve is arranged on the valve seat in a lifting manner, a filling channel is arranged between the outer sliding sleeve and the valve element sleeve, the reflux gap is communicated with the filling channel, the sealing base is fixed on the outer sliding sleeve, the material cylinder is communicated with a filling liquid inlet by a filling branched pipe, and a reflux opening is communicated with a reflux container by a control valve. According to the hot filling valve, a gas return channel is completely separated from a reflux channel, the reflux quantity is controllable, the defects such as unstable production capacity, and large liquid level precision fluctuation caused by a phenomenon that gas and liquid are mixed in the same channel are avoided, and the nutrition of beverage cannot be lost.

Owner:南京保立隆包装机械有限公司

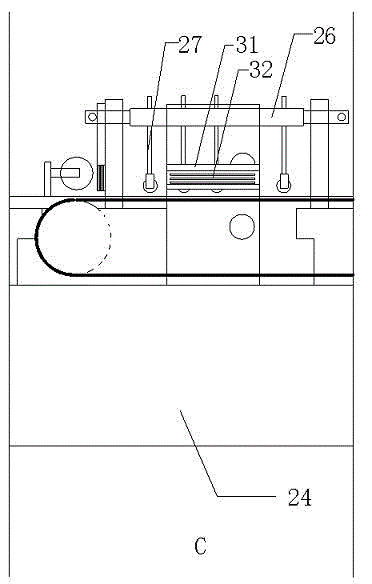

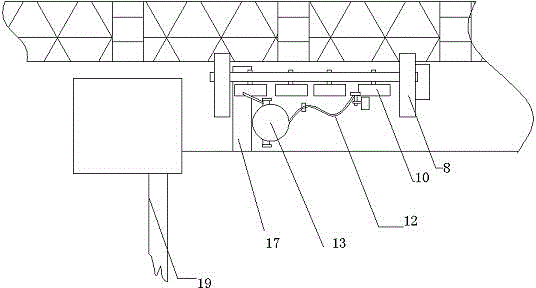

Floor short side edge chamfer painting equipment

The present invention is floor short side edge chamfer painting equipment including two boxes, the two boxes support two ends of a floor, the inner sides of the two boxes are provided with conveyor belts for driving movement of the floor, the floor is driven by the conveyor belt to enter into two painting devices arranged on the two boxes for painting, each painting device includes a left support plate and a right support plate, a pressure roller support beam is arranged between the left support plates at the same side, a pressure roller support beam is arranged between the right support plates at the same side, each pressure roller support beam is provided with a plurality of pressure rollers, the outer side of each pressure roller support beam is provided with a moving roller arranged by a bracket, the upper part of each moving roller is connected with a paint pot filled with water-based paint by a pipe, and one sides of the painting devices are respectively provided with two drying boxes. The floor short side edge chamfer painting equipment is simple in structure, easy to operate and reasonable in design, can effectively paint short sides of the floor, prevents the presence of V-grooves of the floor after splicing, and reduces health dead corners.

Owner:JIANGSU KENTIER WOOD

Gas cooker and its components

ActiveCN106322445BLow costReduce sanitary cornersDomestic stoves or rangesLighting and heating apparatusEngineeringGas stoves

The invention provides a new improvement for a gas stove and an assembly thereof. The provided gas stove assembly comprises a panel (1) and a burner base (2). The panel (1) is provided with a through hole part. The gas stove assembly further comprises a fixing piece (3). The fixing piece (3) and the gas outlet end of the burner base (2) are provided with matched threads correspondingly. The fixing piece (3) is fixed to the gas outlet end of the burner base (2) from top to bottom in a threaded connection manner. An edge (12) of the through hole part is extruded and fixed between the gas outlet end of the burner base (2) and the fixing piece (3). By the adoption of the technical scheme, it becomes possible that no screw is arranged on the panel any more, and panel is conveniently cleaned.

Owner:BSH ELECTRICAL APPLIANCES JIANGSU +1

Raw material mixing equipment for making bread and pastries

InactiveCN111871265AWell mixedEvenly distributedRotary stirring mixersTransportation and packagingElectric machineryEngineering

The invention relates to the technical field of pastry raw material mixing devices, in particular to raw material mixing equipment for bread and pastry making, which comprises a stirring barrel and asupport frame, the stirring barrel comprises a cover body, a barrel body, a water adding tank, a stirrer and a control keyboard, and the barrel body is provided with a non-stick layer inner wall; thewater adding tank includes a water outlet pipe equipped with a valve; the water outlet of the water outlet pipe is fixedly connected to the wall of the barrel; the stirrer comprises a motor, a transverse shaft and a stirring rod, wherein the right end of the transverse shaft is connected with the barrel wall of the barrel body through a bearing, the right end of the transverse shaft and the innerwall of the water outlet pipe are rotationally sealed, water outlet holes are evenly formed in the transverse shaft, and the stirring rod is fixedly connected with the transverse shaft; the supportingbracket is equipped with a top frame, wherein the bottom end of the top frame is fixedly connected with a first electric telescopic rod, and the bottom end of the first electric telescopic rod is connected with the cover body through a connecting frame. Water in the water adding tank is rotationally spun out from the water outlet holes of the transverse shaft to enter the barrel body to be evenlymixed with other raw materials, so that the mixing efficiency of water and other raw materials is improved, the mixing difficulty is reduced, and all the raw materials are evenly distributed.

Owner:黄山市胡兴堂文化发展有限公司

A floor long and short side edge painting production line

ActiveCN105436019BAvoid affecting the effect of paintingReduce impactPretreated surfacesCoatingsProduction linePaint shop

The present invention is a floor long and short side edge painting production line, the production line includes long side painting equipment, short side painting equipment and a transition device, the long side painting equipment and the short side painting equipment are vertically arranged, The long-side painting equipment includes a feeding device, a long-side painting device, and a drying device. After the floor is loaded, it passes through the long-side painting device and the drying device, and then the floor is sent to the short-side painting equipment through a transition device. One end of the short-side painting equipment is also provided with a material receiving device, and the material borrowing device includes a material receiving frame, and several springs are arranged inside the material receiving frame. The invention has the advantages of simple structure, convenient operation and reasonable design, effectively paints the long side and short side of the floor, prevents V-shaped grooves in the spliced floor, and reduces hygienic dead ends.

Owner:JIANGSU KENTIER WOOD

A kind of equipment for chamfering and painting the short edge of the floor

ActiveCN105436024BReduce impactReduce frictionLiquid surface applicatorsCoatingsWater basedEngineering

The present invention is floor short side edge chamfer painting equipment including two boxes, the two boxes support two ends of a floor, the inner sides of the two boxes are provided with conveyor belts for driving movement of the floor, the floor is driven by the conveyor belt to enter into two painting devices arranged on the two boxes for painting, each painting device includes a left support plate and a right support plate, a pressure roller support beam is arranged between the left support plates at the same side, a pressure roller support beam is arranged between the right support plates at the same side, each pressure roller support beam is provided with a plurality of pressure rollers, the outer side of each pressure roller support beam is provided with a moving roller arranged by a bracket, the upper part of each moving roller is connected with a paint pot filled with water-based paint by a pipe, and one sides of the painting devices are respectively provided with two drying boxes. The floor short side edge chamfer painting equipment is simple in structure, easy to operate and reasonable in design, can effectively paint short sides of the floor, prevents the presence of V-grooves of the floor after splicing, and reduces health dead corners.

Owner:JIANGSU KENTIER WOOD

Multifunctional water-saving closestool

ActiveCN103835359BExtended service lifeOvercoming the pitfalls of early retirementWater closetsBathroom coversInterference fitWater saving

The invention belongs to the field of sanitary ware, and particularly relates to a multifunctional water-saving closestool. The multifunctional water-saving closestool comprises a closestool body, a closestool cover, a closestool cushion, a purified water inlet pipe, a urinal and a blow-off pipe, a blow-off pipe connector is connected into a pipe cavity in the lower portion of the blow-off pipe in a sleeved mode, a defecating hose connector is connected into the blow-off pipe connector in a sleeved mode and is a diameter-changing connector, the upper portion of the defecating hose connector is placed in the blow-off pipe connector and in interference fit with the blow-off pipe connector, the lower portion of the defecating hose connector is a shrinking and diameter changing structure and sleeved with a defecating hose and a sewer pipe connector sequentially from interior to exterior in a connected mode, the sewer pipe connector is also a diameter changing connecter, the upper portion of the sewer pipe connector is arranged outside the defecating hose connector in a sleeved mode and matched with the defecating hose connector in a tensioning mode, the lower portion of the sewer pipe connector is the shrinking and diameter changing structure and arranged in a sewer pipe and matched with the sewer pipe in a tensioning mode, and the pipe wall of the lower portion of the defecating hose is a self-suction sheet structure and placed in the sewer pipe. The multifunctional water-saving closestool is simple in structure, low in cost, obvious in water-saving effect, diversified in function and ideal.

Owner:高建国

Time delay type efficient noise elimination and air changing device and method

ActiveCN103206761BNoise is reduced by prolonging the residence time of air in the unitReduce noiseLighting and heating apparatusNoise suppressionTime delaysAir change

Owner:国检测试控股集团京诚检测有限公司

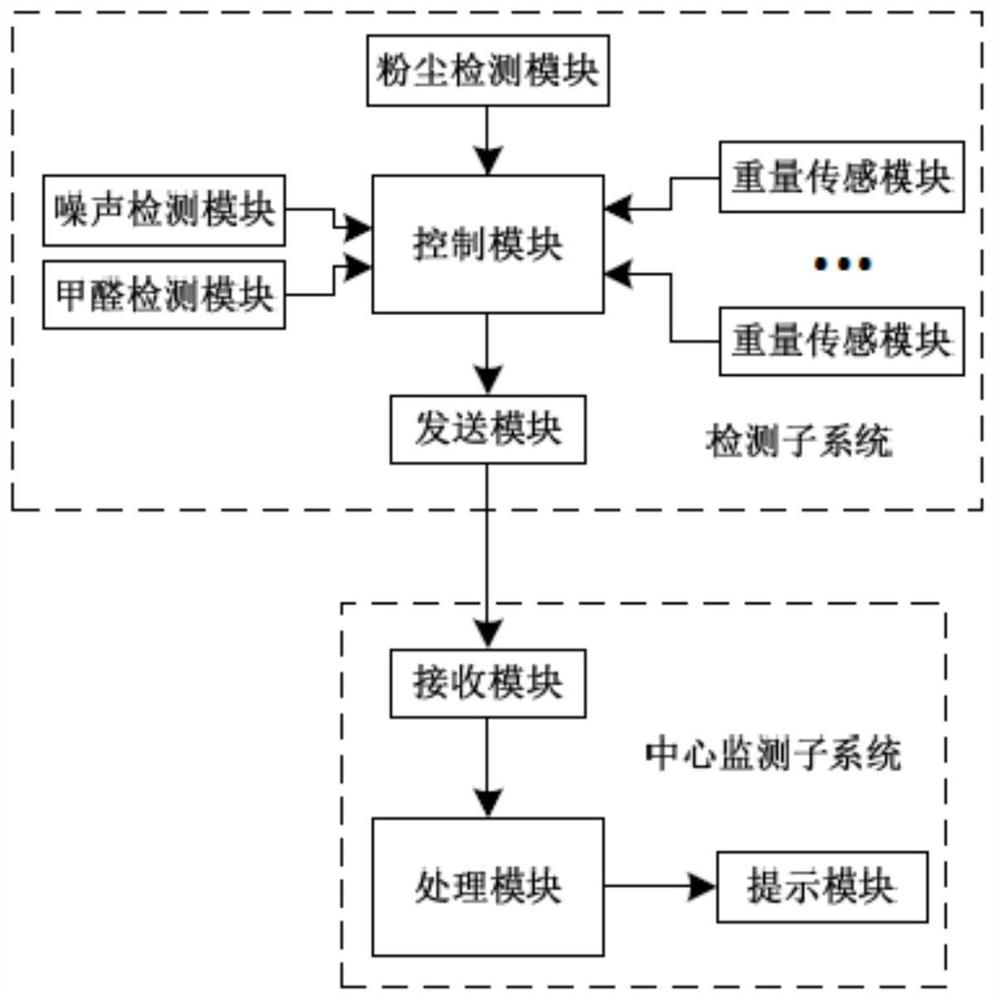

Indoor Environmental Monitoring System Based on Internet of Things

ActiveCN108872038BUniform detection coverageIncrease dust weightSubsonic/sonic/ultrasonic wave measurementParticle suspension analysisMonitoring systemEngineering

Owner:杭州非相科技有限公司

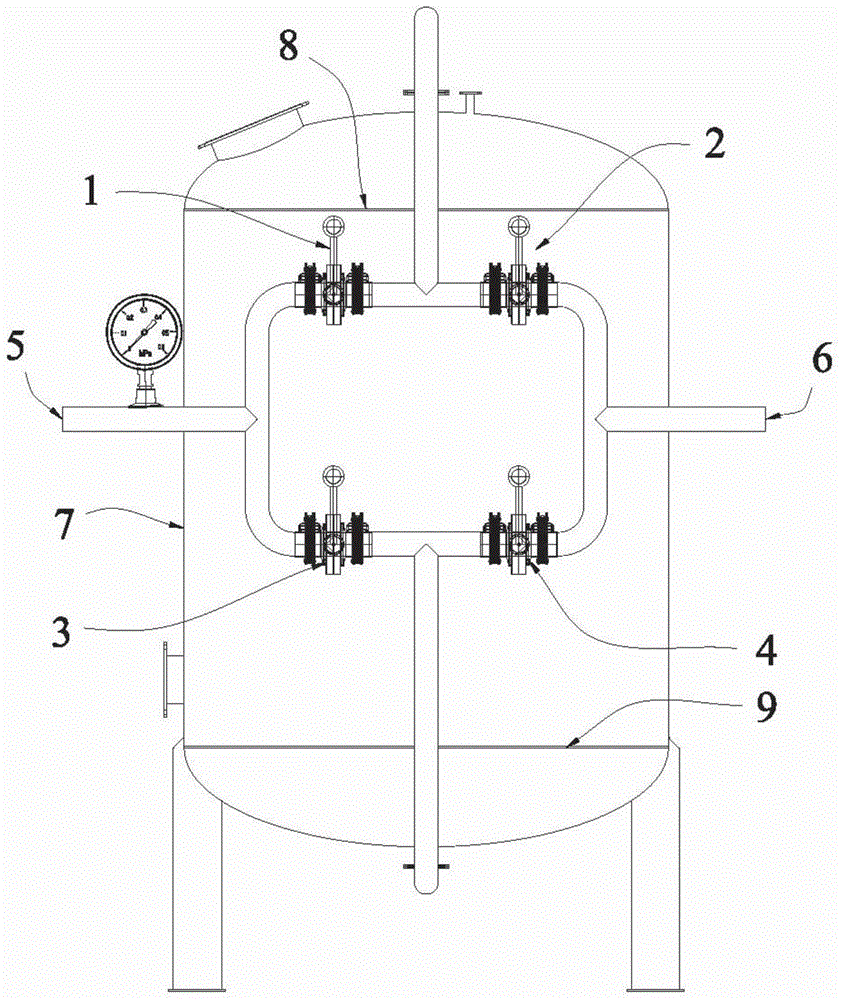

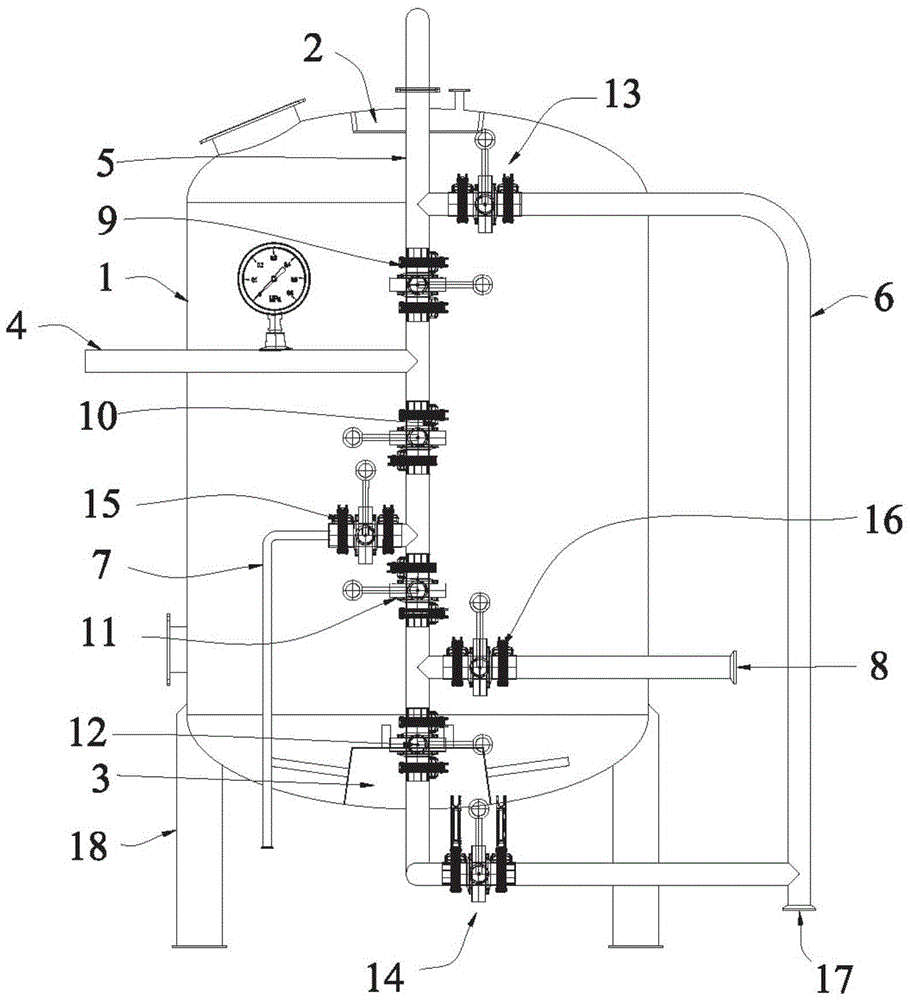

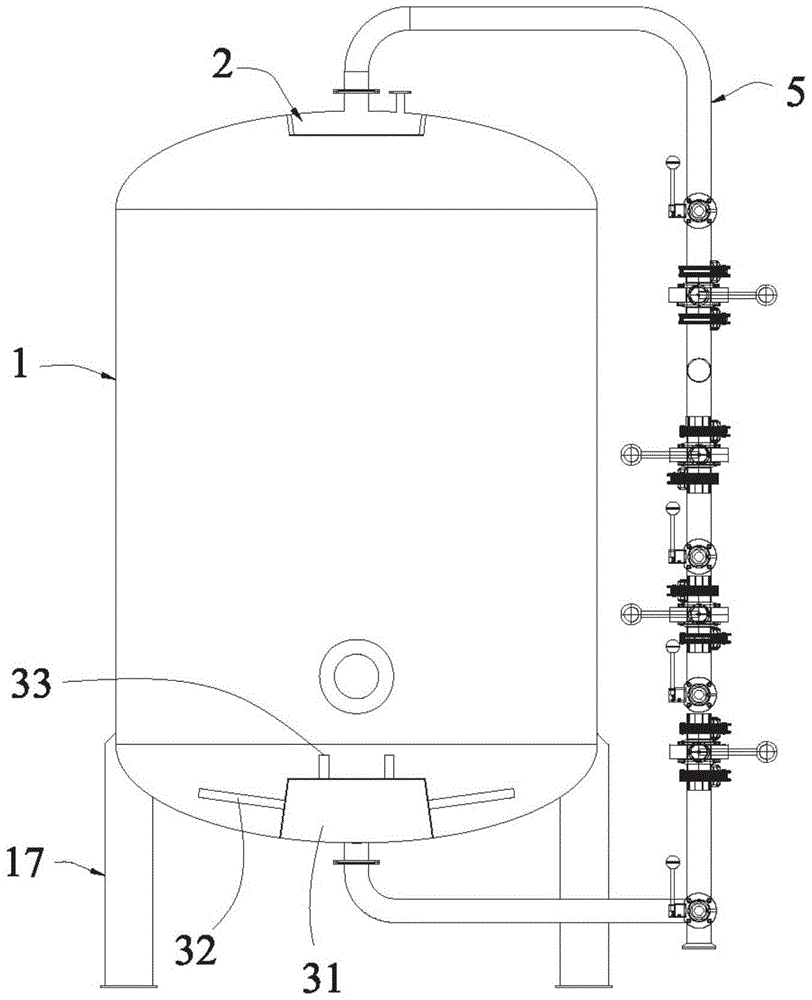

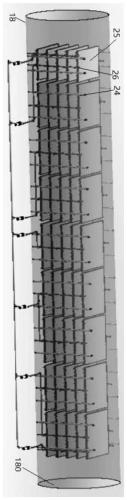

Mechanical Filter Panel Piping Connection Structure

InactiveCN104689629BOvercome leaksReduce the probability of water leakageFiltration separationLeaking waterWater discharge

The invention discloses a novel mechanical filter panel pipeline connection mode which comprises a tank body, a water distributor, a water collector, a water feeding pipe body, a main pipe body, a backwashing pipe body, a leakage detection pipe body, a filtering water discharging pipe body and valve bodies from A to H, wherein the water distributor is arranged at the top in the tank body; the water collector is positioned at the bottom position in the tank body; the valve bodies from A to D are arranged on the main pipe body at intervals in sequence from top to bottom. The novel mechanical filter panel pipeline connection mode is reasonable in structural design, and the problem of water leakage of a key valve is effectively solved; furthermore, the probability of water leakage of the key valve is greatly reduced; even if the valve body B and the valve body C leak water simultaneously, the phenomenon that filtered water is mixed with non-filtered water can not occur, so that the water quality is guaranteed; the contact area between the water distributor and the water collector as well as the tank body is relatively small, and the sanitary dead corners are greatly reduced; meanwhile, the water distributor is ingeniously arranged at the top of the tank body, so that water can be uniformly distributed on filtering substances, and the filtering effect is enhanced; furthermore, the operation is simple, and the wide popularization and application are facilitated.

Owner:4R WATER TREATMENT SYST

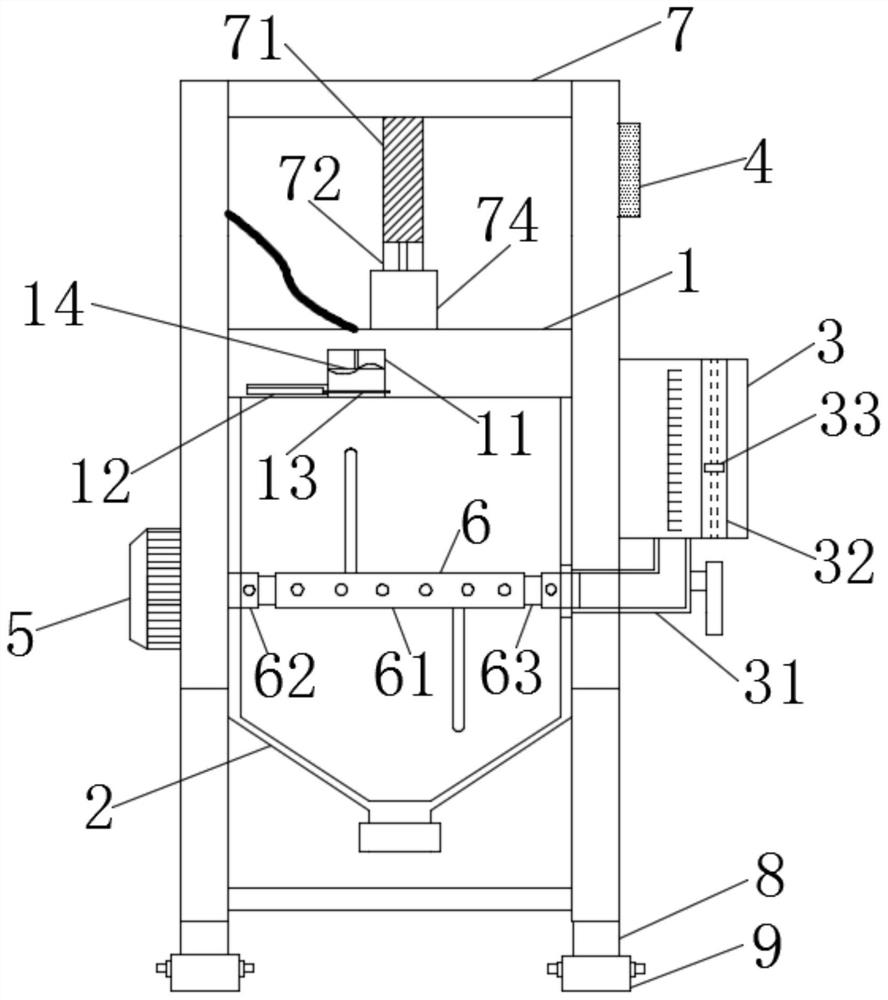

Gas stove and cabinet applying same

PendingCN111720861AImprove aestheticsReduce sanitary cornersStoves/ranges foundationsDomestic stoves or rangesCupboardEngineering

The invention relates to a gas stove and a cabinet applying the same. The gas stove comprises a panel, a burner main body and an injection pipe used for providing mixed gas for the burner main body, and the burner main body can laterally rotate relative to the panel. The gas stove is characterized in that the panel is provided with a mounting seat, and a driving mechanism for driving a burner to rotate laterally, and a gas supply passage concentric with the gas inlet end of the injection pipe are arranged in the mounting seat. Compared with the prior art, the gas stove has the advantages thata burner can laterally rotate relative to the panel so that the burner can laterally rotate relative to the panel in a non-cooking state, the panel of the gas stove is in a pure plane state, and the effects of dust prevention and attractiveness are achieved while a storage plane is formed. Meanwhile, the invention further provides the cabinet applying the gas stove. The cabinet surface of the cabinet is directly used as the panel of the gas stove, so that the gas stove and the cabinet surface of the cabinet can be integrated, the overall attractiveness of the cabinet is improved, and meanwhile, sanitary dead corners of the cabinet surface of the cabinet can be reduced.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Cleaning and sterilization equipment and cleaning and sterilization steps of vacuum belt drying unit

ActiveCN109513679BEasy to drainEasy to cleanHollow article cleaningDrying gas arrangementsBuffer tankProcess engineering

The invention discloses cleaning and sterilizing equipment of a vacuum belt drying unit. The cleaning and sterilizing equipment comprises a plurality of discharge tanks, a rotor pump, a rotor pump liquid outlet pipeline, a plurality of discharge screw pumps, a plurality of discharge pipelines, a purified water tank, a concentrated alkaline preparation tank, an alkali-washing tank, an aggregate bin, a buffer tank, a liquid collector, a condenser, a vacuumizing unit, a speed reducer, a self-priming pump, a valve, a centrifugal pump, a tubular heat exchanger and a cleaning pump, and further comprises a vacuum belt drier, wherein the vacuum belt drier comprises several layers of track conveyor belts, a case, a track bracket, a heating plate bracket, and a plurality of heating plates and cleaning tube units. According to the cleaning and sterilizing equipment, the cleaning ability is enhanced, the sanitary dead angle is reduced, and the exhaustion of residual water is facilitated, so that interior of the equipment is completely and fully cleaned, and in addition, an installation method of an original track support bracket is optimized to facilitate disassembly; and with adoption of thecleaning and sterilizing equipment, a cleaning standard for the production is improved, pollution and cross pollution are simultaneously prevented and the product quality is guaranteed.

Owner:温州市金榜轻工机械有限公司

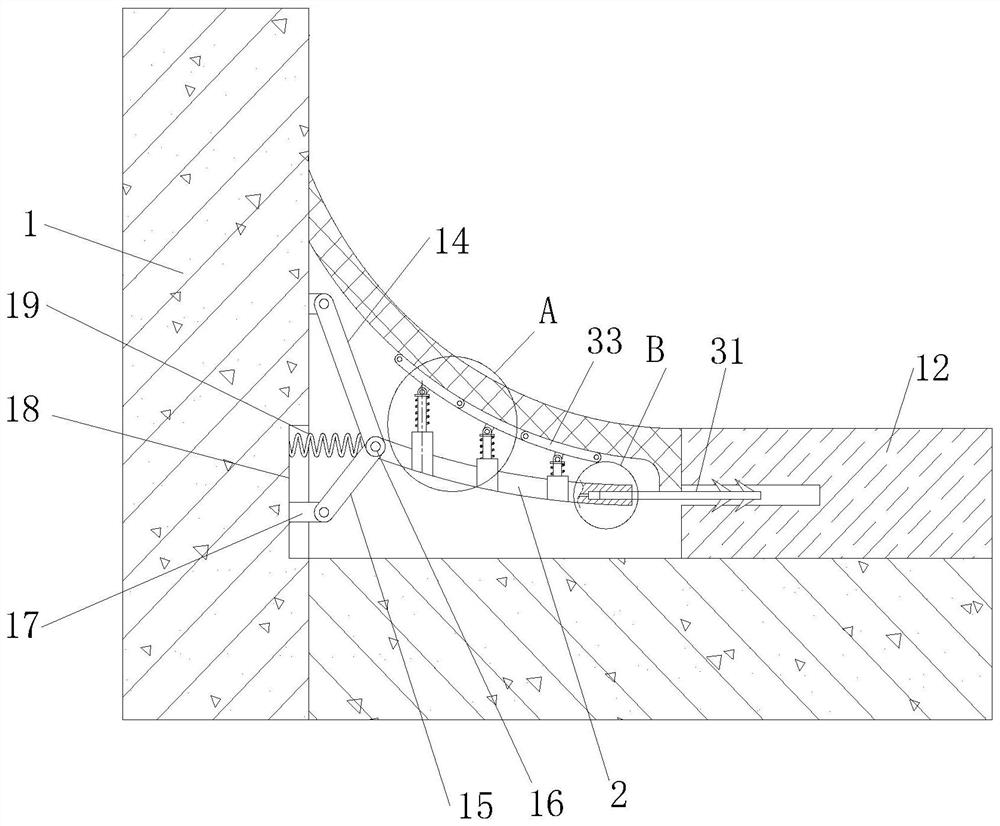

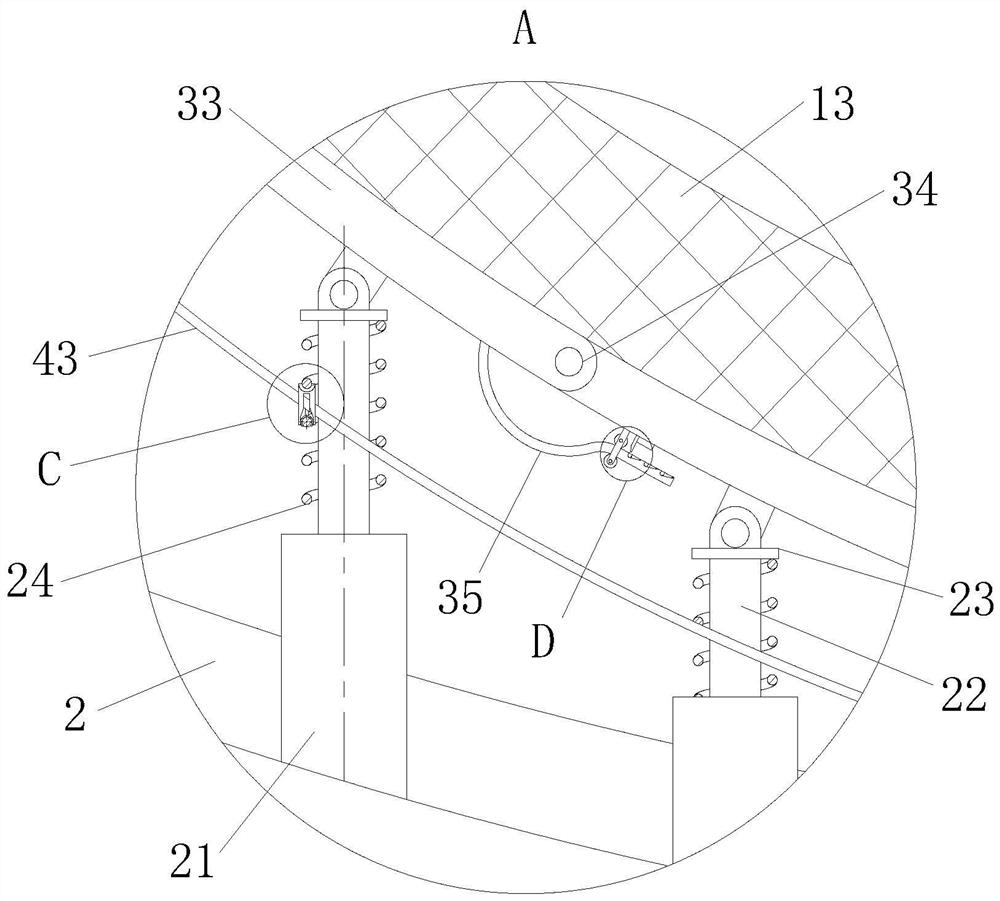

Environment-friendly epoxy floor

PendingCN114263327AIncrease the quality of cleaning and sterilizationMake up for shrinkageFlooringStructural engineeringComposite material

The invention belongs to the technical field of terraces, and particularly relates to an environment-friendly epoxy terrace which comprises a wall body, a substrate layer and an epoxy material surface, the epoxy material surface is brushed on the top of the substrate layer; the wall body is arranged on the side surface of the substrate layer; an arc-shaped wear-resistant elastic film is arranged at the included angle between the epoxy material surface and the wall body, and one side of the elastic film is fixedly connected with the wall body; a first rod and a second rod are arranged on one side of the wall. The ends, away from the wall, of the first rod and the second rod are hinged through a first rotating pin. A pressure spring is fixedly connected between the first rotating pin and the wall body; a supporting rod is fixedly connected to the side, close to the wall body, of the epoxy material face and is elastic, and the end, close to the first rotating pin, of the supporting rod is hinged to the first rotating pin. The side, away from the wall, of the elastic film is connected with the portion, close to the epoxy material face, of the supporting rod. When the epoxy material surface shrinks, the compression spring pushes the first rod to be matched with the second rod and the sliding block, so that the elastic film deforms, expands and moves along with the epoxy material surface, the shrinkage amount of the epoxy material surface is compensated, and the cleaning and sterilizing quality of the floor is improved.

Owner:张淑敏

Novel skirting line and installation method thereof

PendingCN114165025AAvoid enteringImprove cleanlinessBuilding constructionsStructural engineeringMechanical engineering

The novel skirting line comprises a skirting line body, a skirting line upper edge is arranged at the top of the skirting line body, a skirting line lower edge is formed at the bottom of the skirting line body, and the skirting line upper edge and the skirting line lower edge are arranged in a Z-shaped staggered mode. The skirting line has the beneficial effects that the problem that the existing skirting line cannot attach furniture to a wall surface so as to cause difficulty in cleaning is solved, and compared with the existing skirting line, after the skirting line is installed, sanitary dead angles at home are greatly reduced; the problems that dust is prone to being accumulated on the upper edge of a common skirting line and cleaning is difficult are solved. The skirting line is simple and convenient to install and operate, fast in installation progress, low in cost, little in dust in the installation process, easy to clean and cleaner and more sanitary compared with an existing installation mode due to the change of the skirting line structure.

Owner:王聚业

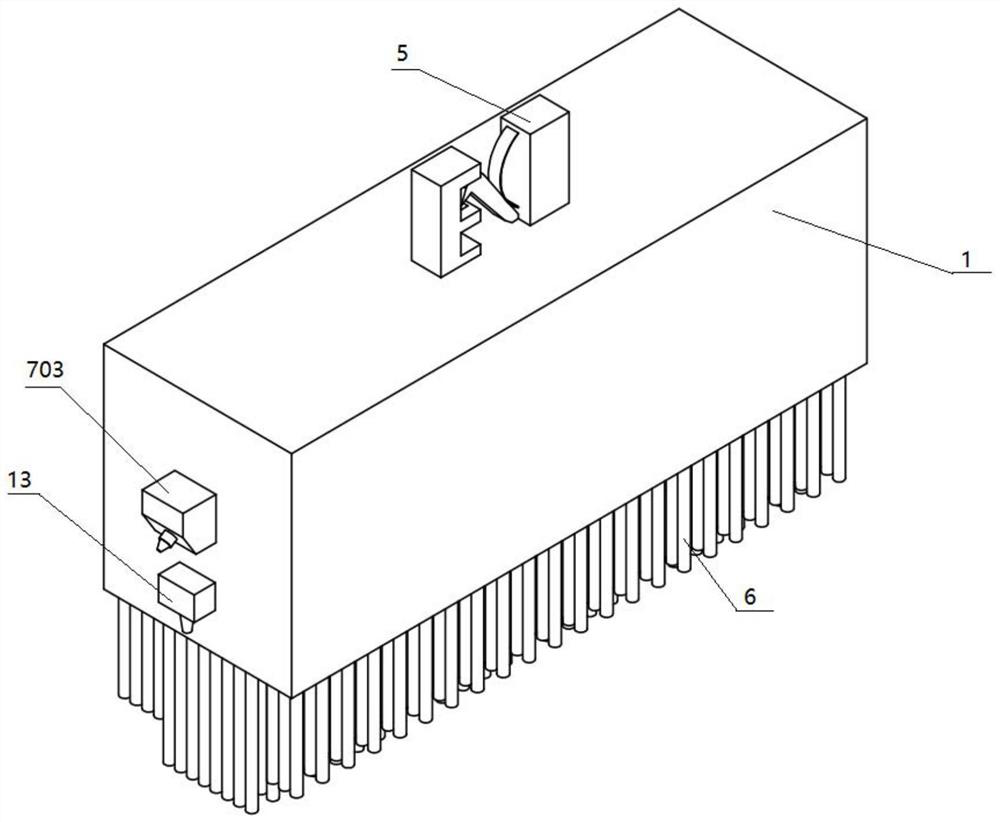

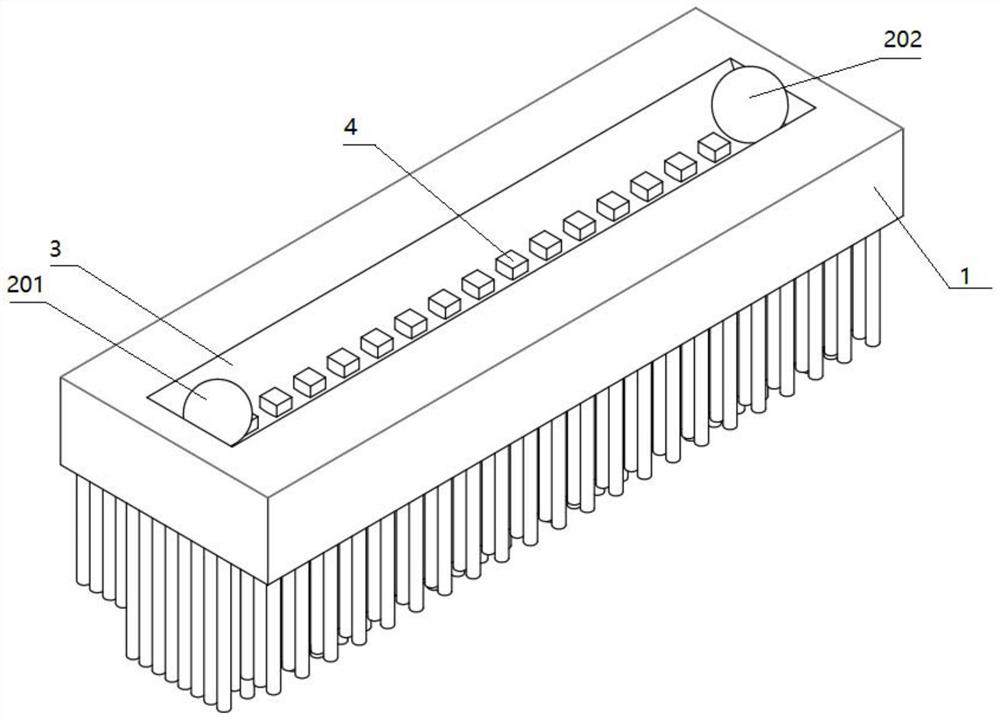

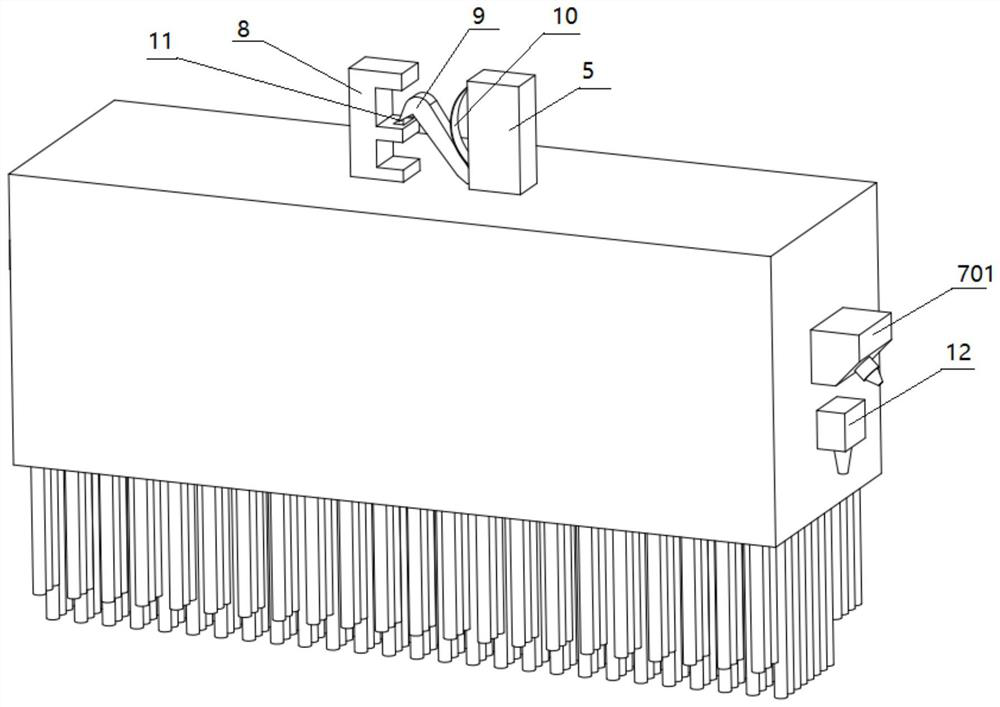

Gap cleaning brush for ultrasonic cavitation and cleaning method thereof

PendingCN114521732AResidue reductionReduce sanitary cornersBrush bodiesBristleUltrasonic cavitationBristle

The invention relates to the technical field of brushing appliances, in particular to a gap cleaning brush for ultrasonic cavitation and a cleaning method of the gap cleaning brush. Comprising a self-adaptive balance mechanism, an ultrasonic wave conversion assembly, an ultrasonic wave cleaning assembly and a brush base, the self-adaptive balance mechanism is composed of a rolling ball and a groove, the groove is located in the brush base, the rolling ball is located in the groove and can roll along the groove under the action of gravity, protruding points are evenly distributed at the bottom of the groove, and the bottom of the groove is provided with an ultrasonic wave conversion assembly. The ultrasonic wave conversion assembly comprises an ultrasonic transducer, the ultrasonic transducer is installed outside the brush base, the ultrasonic wave cleaning assembly comprises bristles and an atomization spray gun, the bristles are arranged at the bottom of the brush base, and the atomization spray gun is used for spraying liquid to the contact face of the bristles and gaps. According to the invention, the application of the ultrasonic cavitation technology in the field of gap cleaning is realized, and the cleaning effects of energy conversion and cavitation are realized; hygienic dead angles are reduced, and the cleaning effect is better.

Owner:GUANGZHOU UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com