Gap cleaning brush for ultrasonic cavitation and cleaning method thereof

An ultrasonic and gap technology, applied in the direction of brushes, brush bodies, bristles, etc., can solve the problems of uneven objects that are difficult to clean, bulky, and cannot be used in the field of gap cleaning. Residual reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

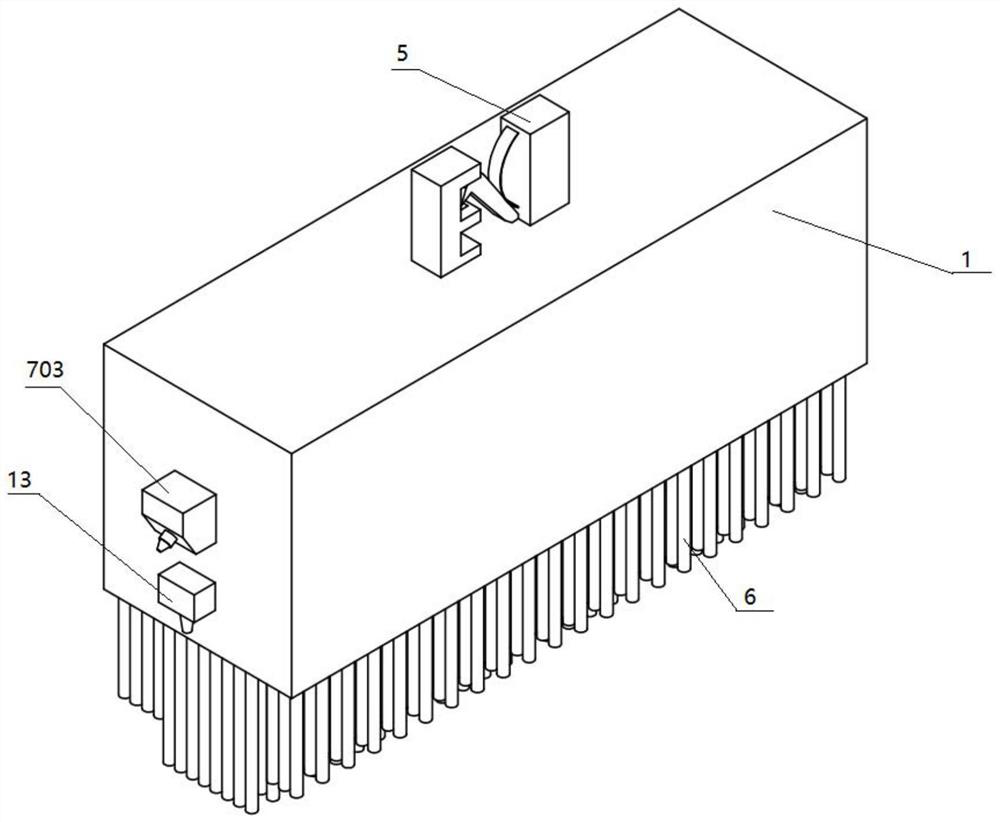

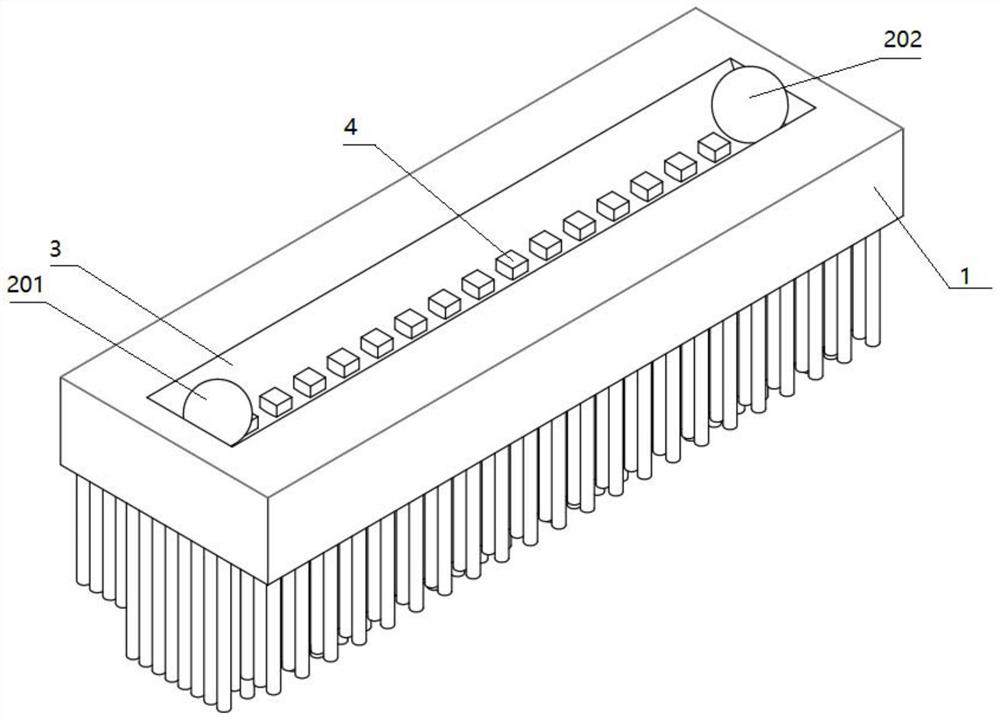

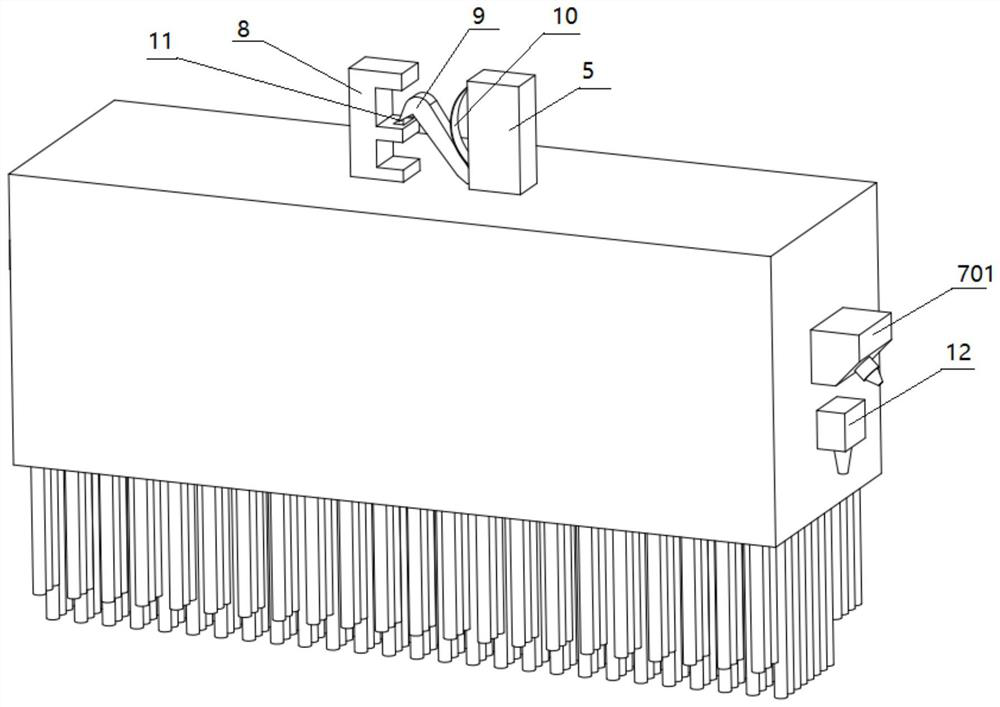

[0029] A crevice cleaning brush for ultrasonic cavitation, comprising an adaptive balancing mechanism, an ultrasonic conversion assembly, an ultrasonic cleaning assembly and a brush seat 1, the adaptive balancing mechanism is composed of a rolling ball and a groove 3, the middle of the two sides of the brush seat 1 is There are also ultrasonic distance sensors 12 and 2 13 at the positions. The groove 3 is a U-shaped groove and is located inside the brush holder 1. The length of the groove 3 is 10cm, and the bottom of the groove 3 is provided with protrusions every 1-3cm Starting point, rolling ball 1 201 and rolling ball 2 202 are located on the left and right sides of groove 3, and they are all solid balls with a weight of 100-150 grams and a diameter of 3-5 cm. Groove 3 rolls. The ultrasonic conversion assembly includes an ultrasonic transducer 5, and the ultrasonic transducer 5 is installed on the outside of the brush holder 1. The ultrasonic cleaning assembly includes bris...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com