Gas stove and assembly thereof

A technology of gas stoves and components, which is applied in the field of gas stoves, and can solve the problems that it is difficult to clean, and the screw is easy to become a hygienic dead corner.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

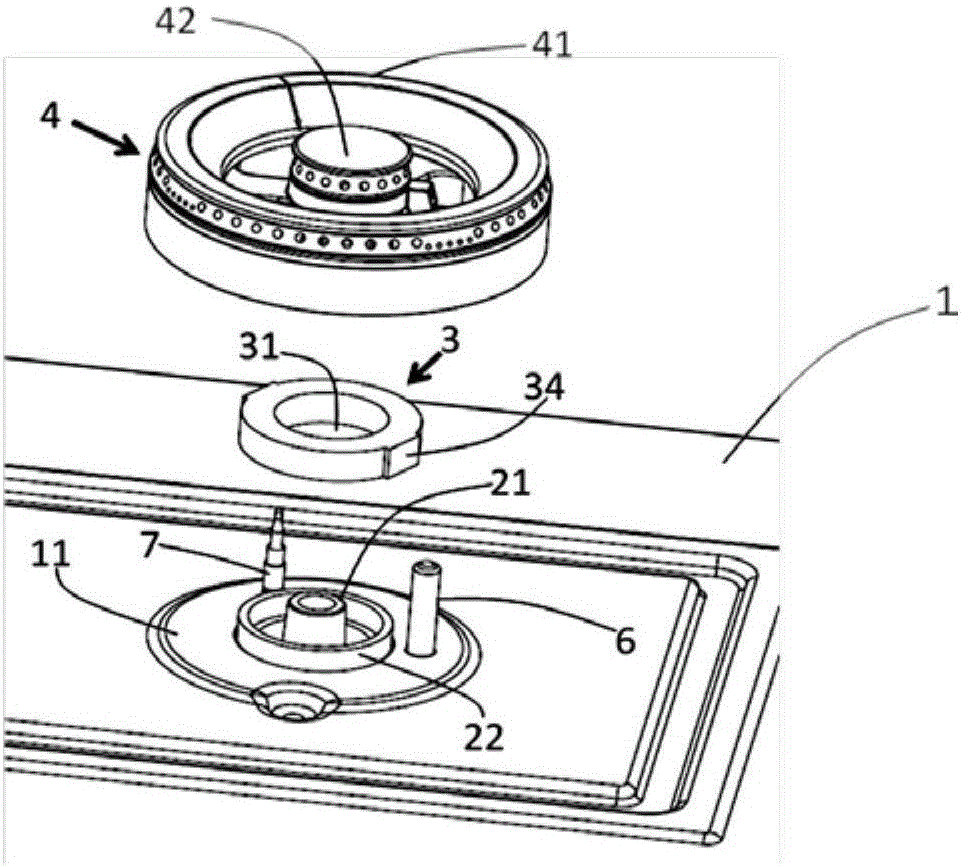

[0047] The present invention proposes an embodiment of a gas stove, including a gas stove assembly, an ignition needle 6 and a thermocouple 7 .

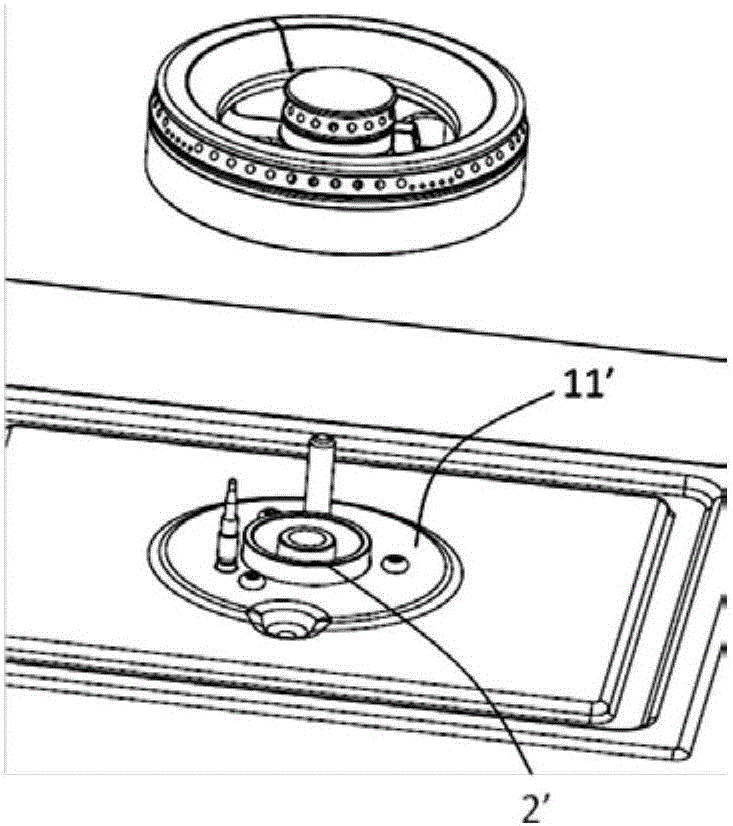

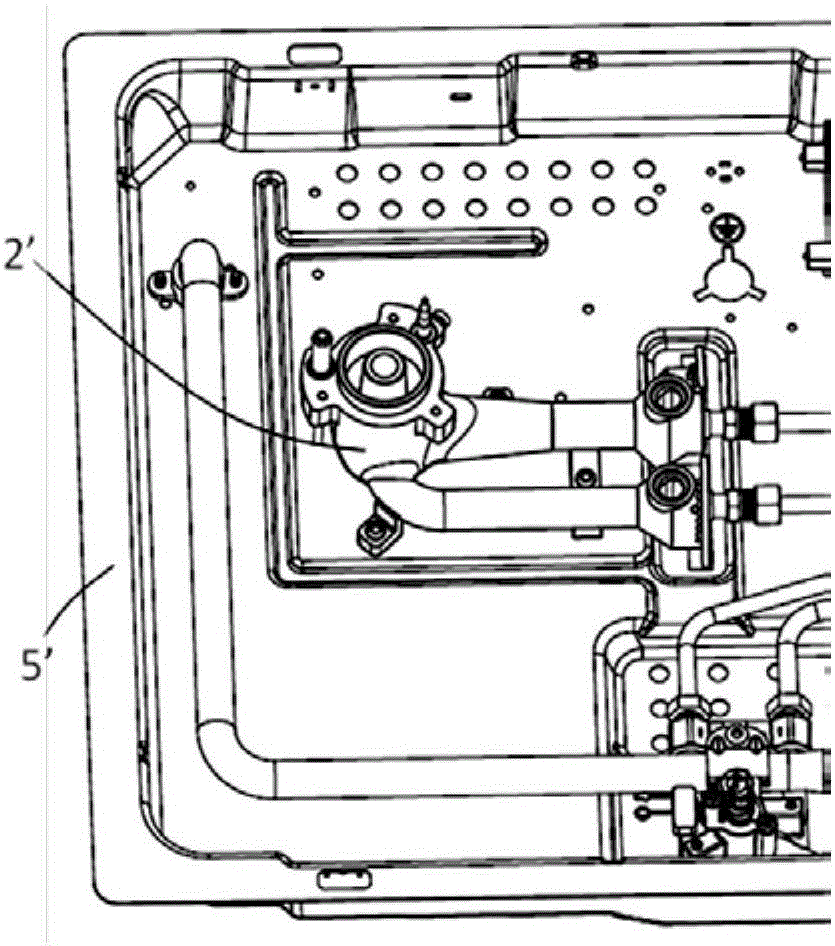

[0048] A gas stove assembly, including a panel 1, a burner base 2, a fixing piece 3, a burner 4 and a bottom case, such as Figures 3 to 5 shown. The panel 1 includes a liquid pan 11 made of stainless steel, and the liquid pan 11 is provided with a through hole. The bottom of the burner base 2 is fixed to the bottom shell. Both the ignition needle 6 and the thermocouple 7 are fixed on the burner base 2 , and the liquid pan 11 is provided with holes for respectively passing the ignition needle 6 and the thermocouple 7 .

[0049] The fixing part 3 has a ring-shaped structure and adopts an integrally formed structure. The fixing part 3 includes a hollow part 31, a ring-shaped groove 32 and two symmetrically arranged clamping parts 34, such as Figure 6 and 7 shown. The clamping part 34 adopts a raised structure, such as Figure 6 ...

Embodiment 2

[0057] The present invention also proposes another gas stove embodiment 2, which is further improved on the basis of the gas stove embodiment 1 above. The main differences between the second embodiment of the gas stove and the first embodiment of the gas stove are as follows.

[0058] The fixing part 3 of the gas cooker assembly of the gas cooker embodiment 2 is a nut structure, such as Figure 8 and 9 shown. The protrusion 24 of the outer tube 22 is provided with an external thread. The fixing member 3 is provided with an internal thread 33 matched with the external thread of the protruding portion 24 , and the internal thread 33 surrounds the hollow portion 31 . The fixing part 3 is fixed on the protruding part 24 from top to bottom by means of threaded connection, the edge 12 of the through hole part is squeezed and fixed between the fixing part 3 and the stop part 23 of the outer tube 22, the top end of the fixing part 3 The top end of the protrusion 24 is at the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com