Mechanical Filter Panel Piping Connection Structure

A technology of mechanical filter and connection structure, applied in the field of filters, can solve the problems such as the inability to drain the liquid in the filter tank, the inability to know the leakage of the key valve, the uneven distribution of the liquid, etc., so as to ensure the water quality, the overall structure is simple, and the structural design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

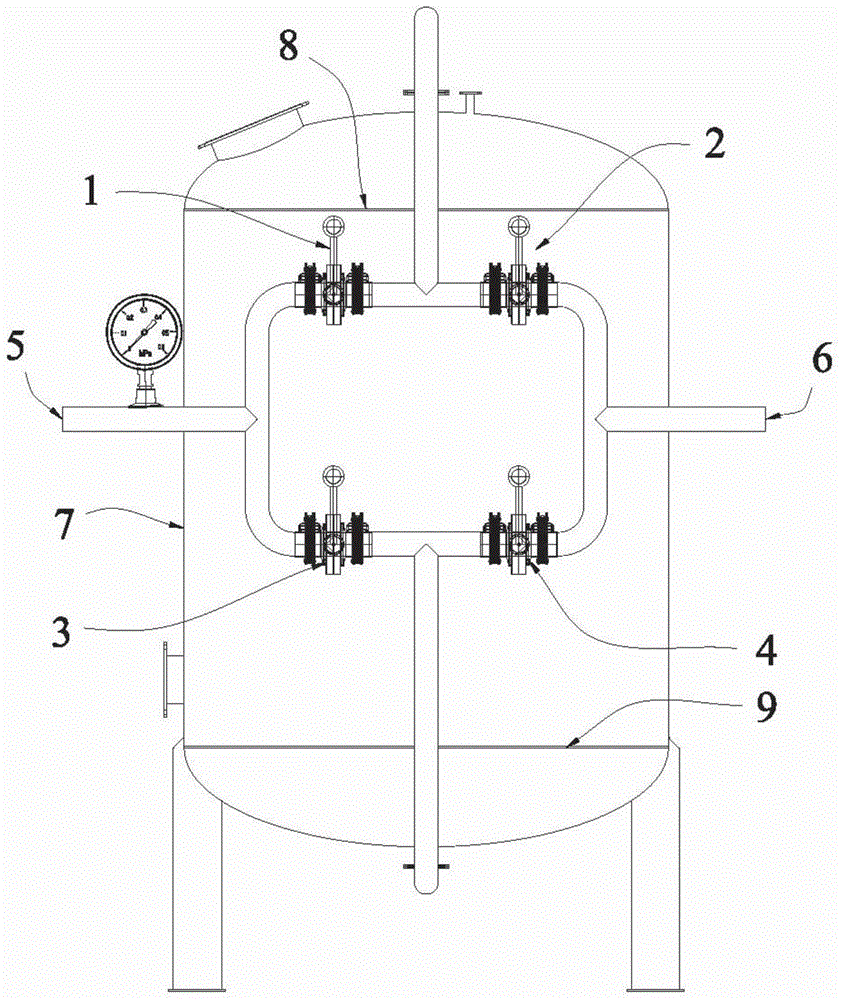

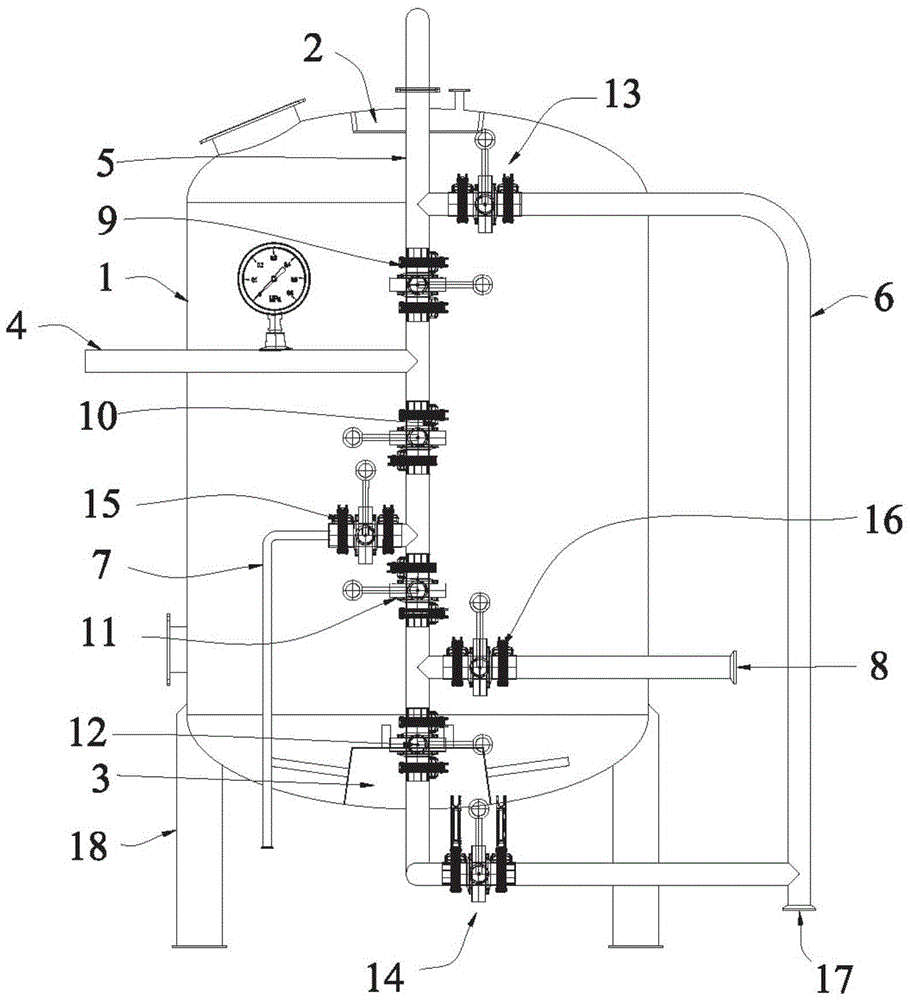

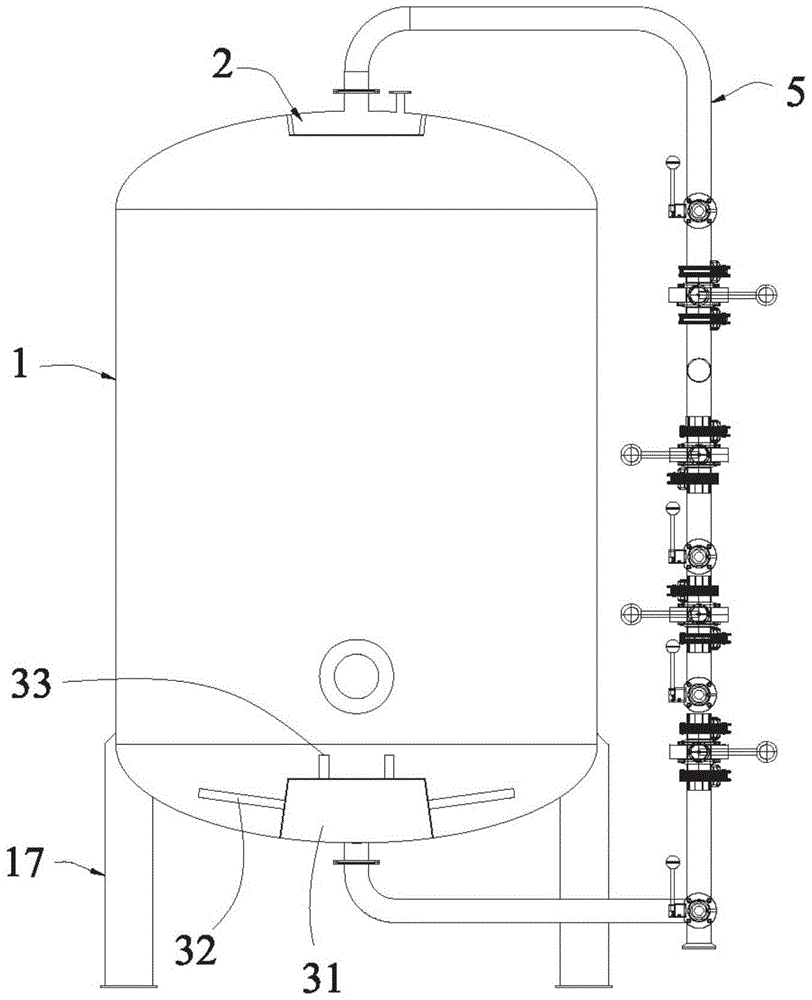

[0023] see figure 2 and image 3 , a mechanical filter panel pipe connection structure provided in this embodiment, which includes a tank body 1, a water distributor 2, a water collector 3, a water inlet pipe body 4, a main pipe body 5, a backwash pipe body 6, and a leak detection pipe Body 7, filter outlet pipe body 8 and valve body A9, valve body B10, valve body C11, valve body D12, valve body E13, valve body F14, valve body G15, valve body H16.

[0024] Specifically, the water distributor 2 is located at the top position in the tank body 1, the water collector 3 is located at the bottom position in the tank body 1, and the main body 5 is located at a side position of the tank body 1, preferably Yes, the main body 5 is parallel to the central axis of the tank body 1 . The upper end of the main body 5 extends into the tank body 1 to be connected with the water distributor 2, and the lower end extends into the tank body 1 to be connected to the water collector 3. The valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com