Four-sided valve

A four-sided valve and valve cavity technology, applied to valve details, diaphragm valves, valve devices, etc., can solve the problems of short service life of the four-sided valve, valve leakage, and easy damage of the rubber tympanic membrane.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

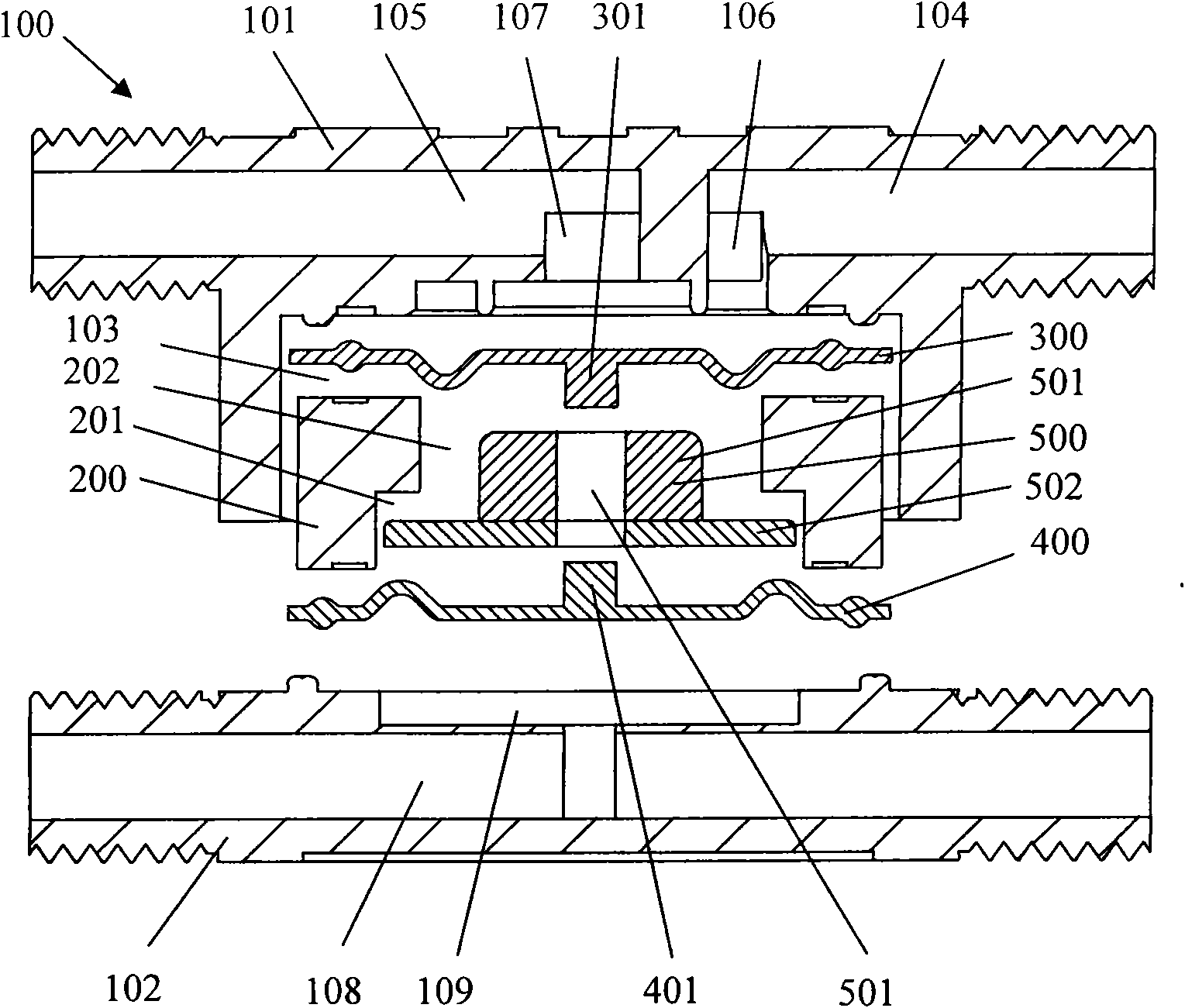

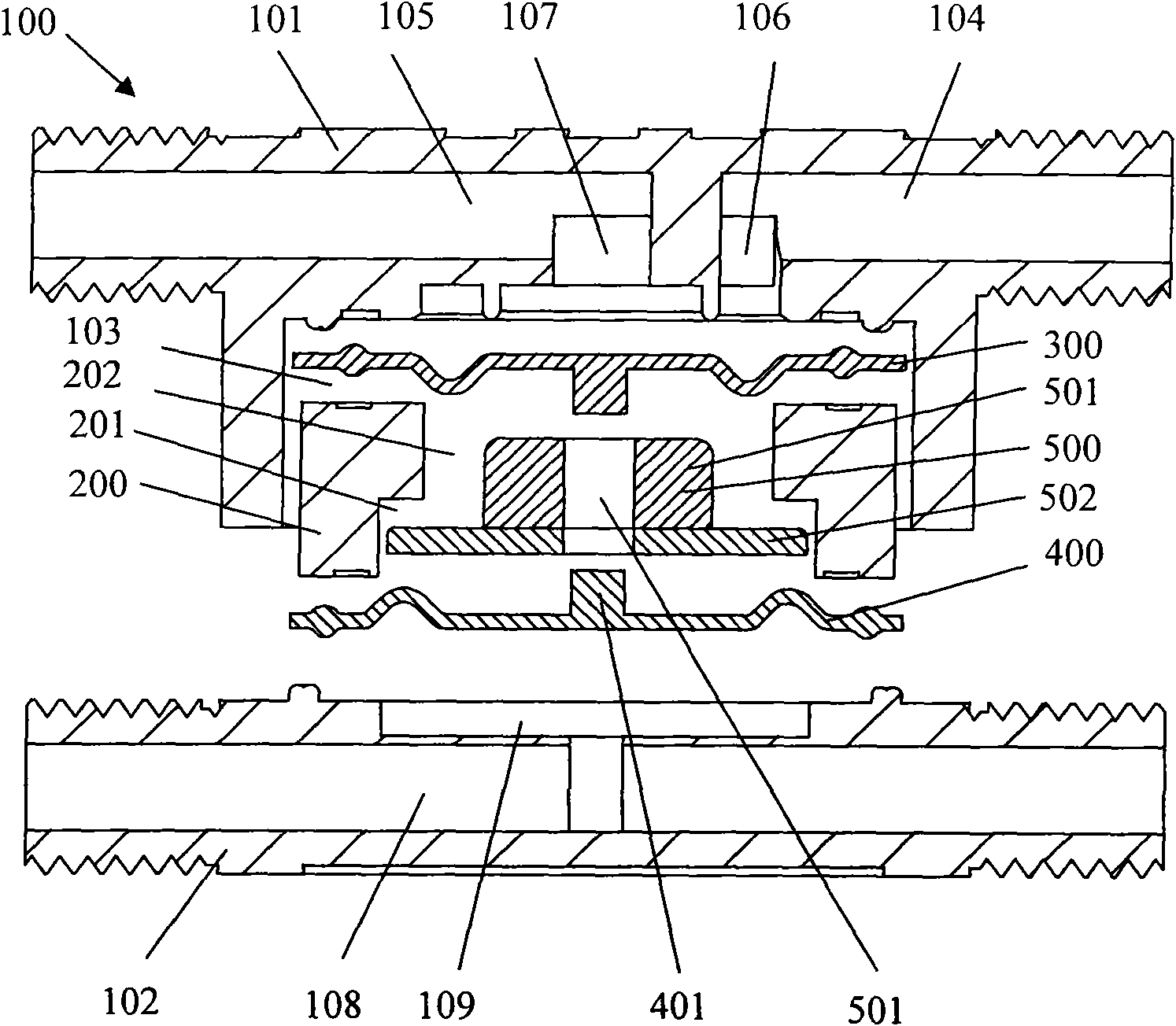

[0017] Such as figure 1 As shown, the four-sided valve of the present invention includes a valve body 100 , an inner ring 200 , an upper rubber tympanic membrane 300 , a lower rubber tympanic membrane 400 , and a piston 500 .

[0018] The valve body 100 is composed of an upper cover 101 and a lower cover 102, and the valve body 100 formed by combining the upper cover 101 and the lower cover 102 has a valve chamber 103, and the upper cover 101 has a separated water inlet channel 104 and a water outlet channel. 105 , the water inlet passage 104 and the water outlet passage 105 have two through holes 106 , 107 communicating with the valve chamber 103 at positions close to the center of the valve chamber 103 . The lower cover 102 has a pressure applying channel 108 inside, and above the pressure applying channel 108 there is a water chamber 109 communicating with the pressure applying channel 108 and also communicating with the valve cavity 103 .

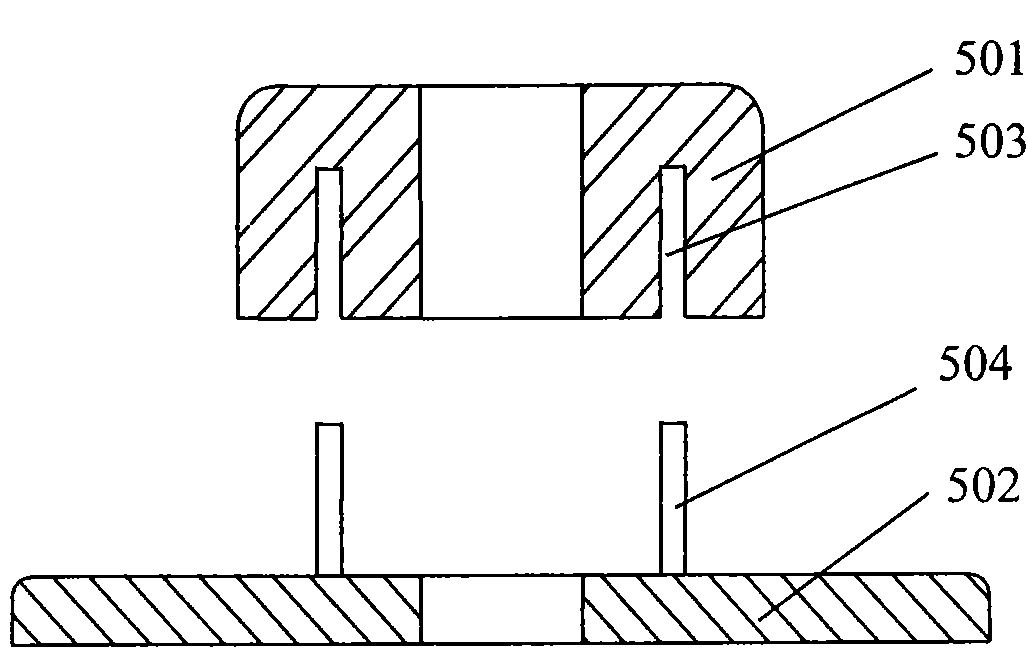

[0019] The inner ring 200 , the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com