Directly-connected oil pump for dump truck

A dump truck, direct connection technology, applied to pump components, rotary piston type/swing piston type pump components, machines/engines, etc., can solve the problems of large space occupation, high failure rate, low efficiency, etc., and achieve weight The effect of lightening, improving transmission efficiency and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

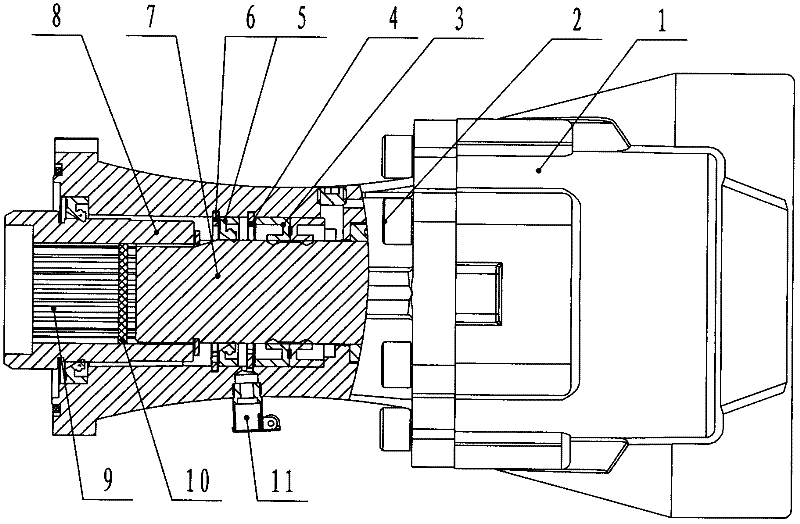

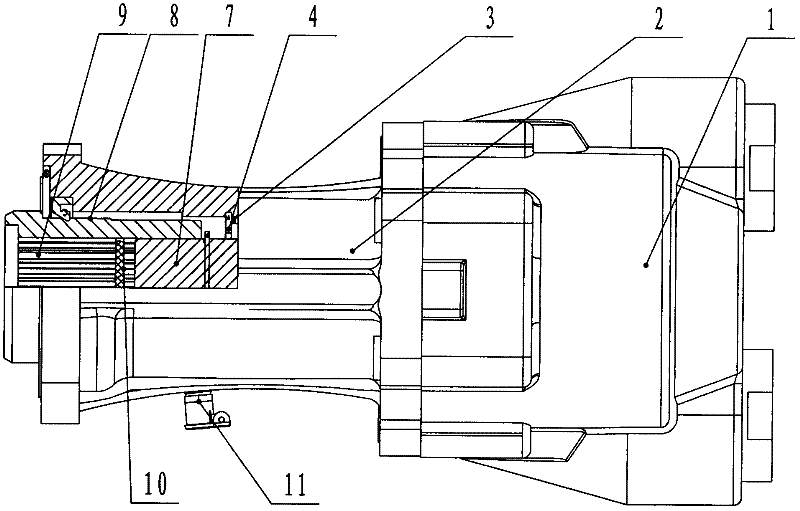

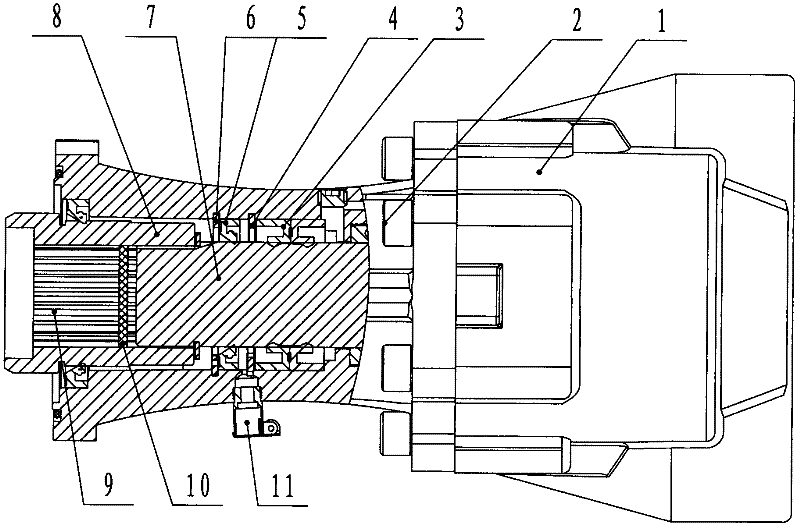

[0007] The structure and use of the present invention will be described in detail below in conjunction with the embodiments given in the accompanying drawings. Refer to attached figure 1 Or 2, this kind of dump truck direct-connected oil pump has a pump body (1) and a pump cover (2) matched with it and the gear shaft (7) of the transmission gear, which is characterized in that the input end of the gear shaft (7) The sleeve is connected with a spline sleeve (8) with a spline (9), and the pump cover is extended to be able to close the connection between the gear shaft and the spline sleeve, and can be reasonably connected with the installation end of the power take-off of the original dump truck. The sealing ring (3) between the gear shaft and the pump cover is fixed and positioned by the retaining ring (4), and there is a spacer (10) at the part where the gear shaft (7) is connected with the spline sleeve, and the pump cover (2) There is an oil drain observation hole (11) betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com