Baffle plate of flue

A flue baffle and baffle technology, which is applied in the treatment of combustion products, combustion methods, exhaust gas devices, etc., can solve the problems of high heating temperature of the bearing, unattended consideration, and difficulty in opening and closing the flue baffle. Increase the reliability of use and overcome the effect of affecting the sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

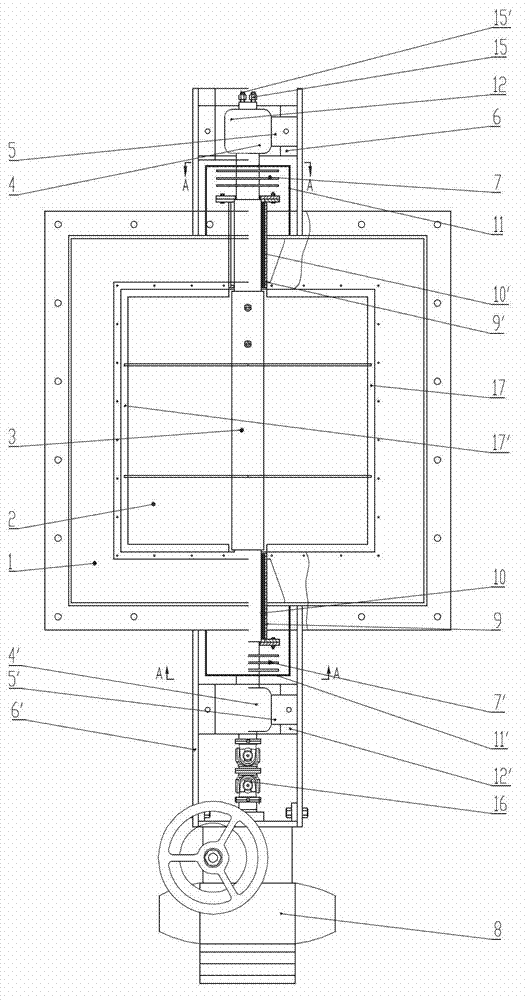

[0030] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the drawings in the embodiments of the present invention:

[0031] A flue damper such as figure 2 mainly includes:

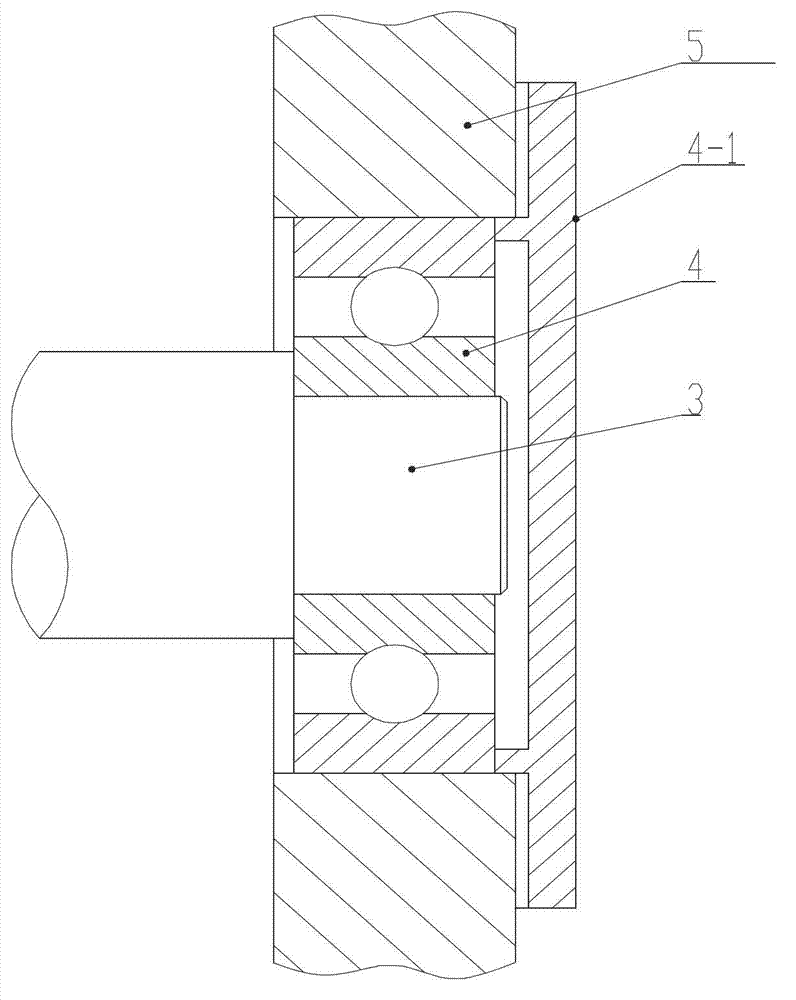

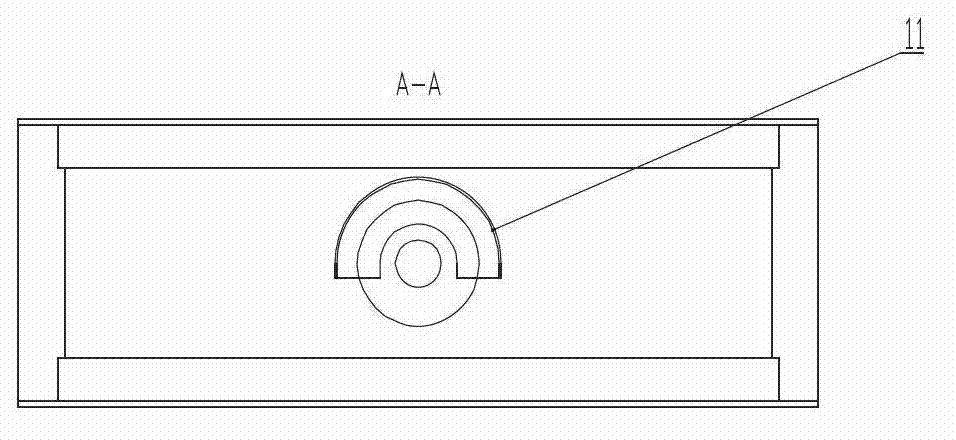

[0032] The shell 1 connected with the flue, the shape of the shell 1 can be set to be circular or square or other shapes according to the shape of different flues. Supports 6 and 6' are respectively fixed on both sides of the opening on the housing 1 . A baffle 2 that can rotate with the shaft is provided on the shaft inside the housing 1 , and the length and width of the baffle 2 are smaller than the inner diameter of the housing 1 , so as to reserve an expansion margin for the baffle. The baffle plate 2 is fixedly connected to the shaft 3 . The baffle seats 17 , 17 ′ are fixed on the inner wall of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com