Neutron small angle scattering loading device for studying metal surface hydrogen corrosion

A small-angle scattering, metal surface technology, used in measuring devices, material analysis using wave/particle radiation, instruments, etc., can solve problems such as inability to meet, destroy, and do not consider hydrogen loading, and achieve reduced size, simple sealing structure, The effect of reducing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

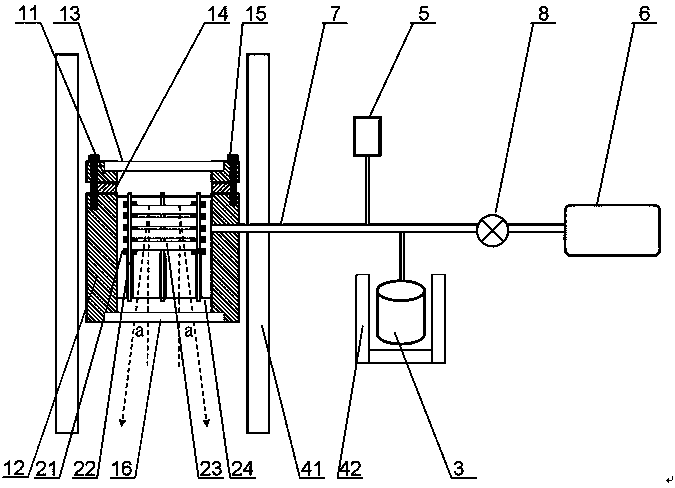

[0039]The neutron beam size used in the small-angle neutron scattering experiment of this implementation example is 8mm, and the fluence rate is 2*10 5 cm -2 .s -1 .

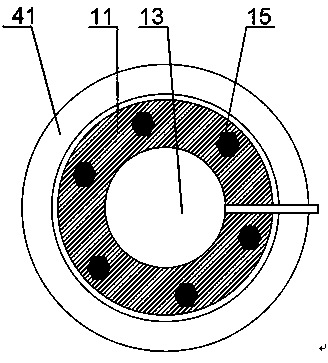

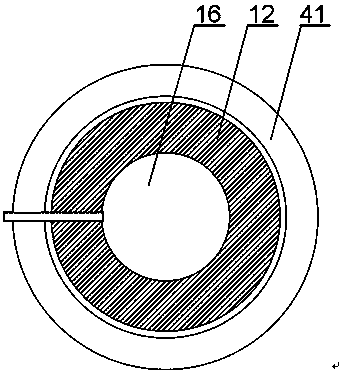

[0040] In this implementation example, the inner diameter of the front shell 11 and the rear shell 12 of the hydrogen loading chamber is 20 mm, the outer diameter is 30 mm, and the material is made of hydrogen-resistant stainless steel; the diameter of the scattering window I13 and the scattering window II16 is 24 mm, and the material is selected Sapphire is connected to the front shell 11 and the rear shell 12 respectively by metal welding; the inner diameter of the metal gasket 14 is 20 mm, the outer diameter is 25 mm, and the material is copper; the total length of the inside of the hydrogen loading chamber along the direction of the neutron beam It is 5mm and the volume is about 1.6ml.

[0041] The diameter of the annular support frame 24 of the multi-piece sample holder in this embodiment is 19.9mm; the ...

Embodiment 2

[0047] The structure of this embodiment is the same as that of Embodiment 1, except that the material of the scattering window I13 and II16 is quartz; the total length of the inside of the hydrogen loading chamber along the direction of the neutron beam is 15mm, and the volume is about 7.4ml.

[0048] After the above implementation, the scattering signal of the hydride can be increased by 20 times during the neutron scattering experiment, and the scattering signal of the metal itself is obviously suppressed. Usually greater than 100mm), the interference signal generated by hydrogen drops to 13.3% during the experiment, the buffer tank has enough hydrogen to keep the experiment going on, and there will be no hydrogen leakage problem under high temperature and high pressure loading, and the selected material is When it is warm, it will not decompose and release gas, which will interfere with the reaction of metal and hydrogen.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com