Pre-treatment method of nickel hydrogenation catalyst

A technology for hydrogenation catalysts and nickel-based catalysts, applied in chemical instruments and methods, catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, etc. Bed hot spots, catalyst activity and selectivity decline, etc., to achieve excellent hydrogenation activity and selectivity, easy control of bed temperature rise, and excellent hydrogenation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

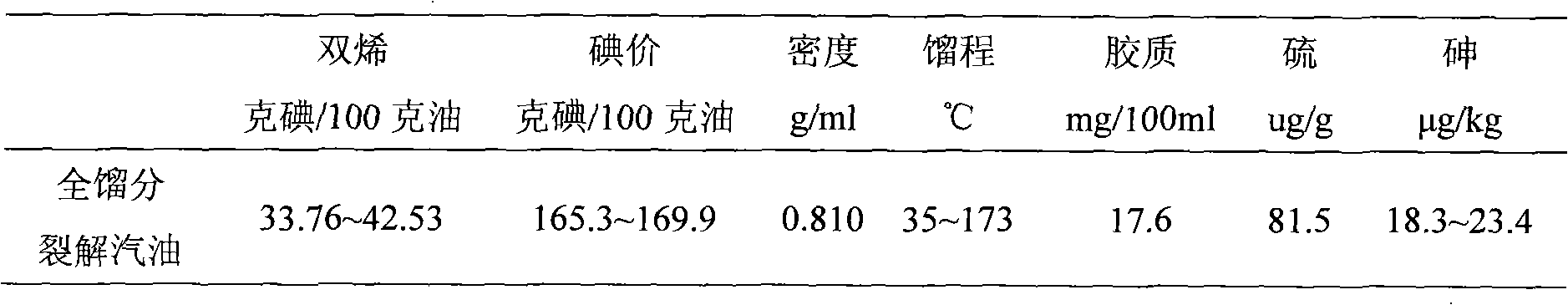

Examples

preparation example Construction

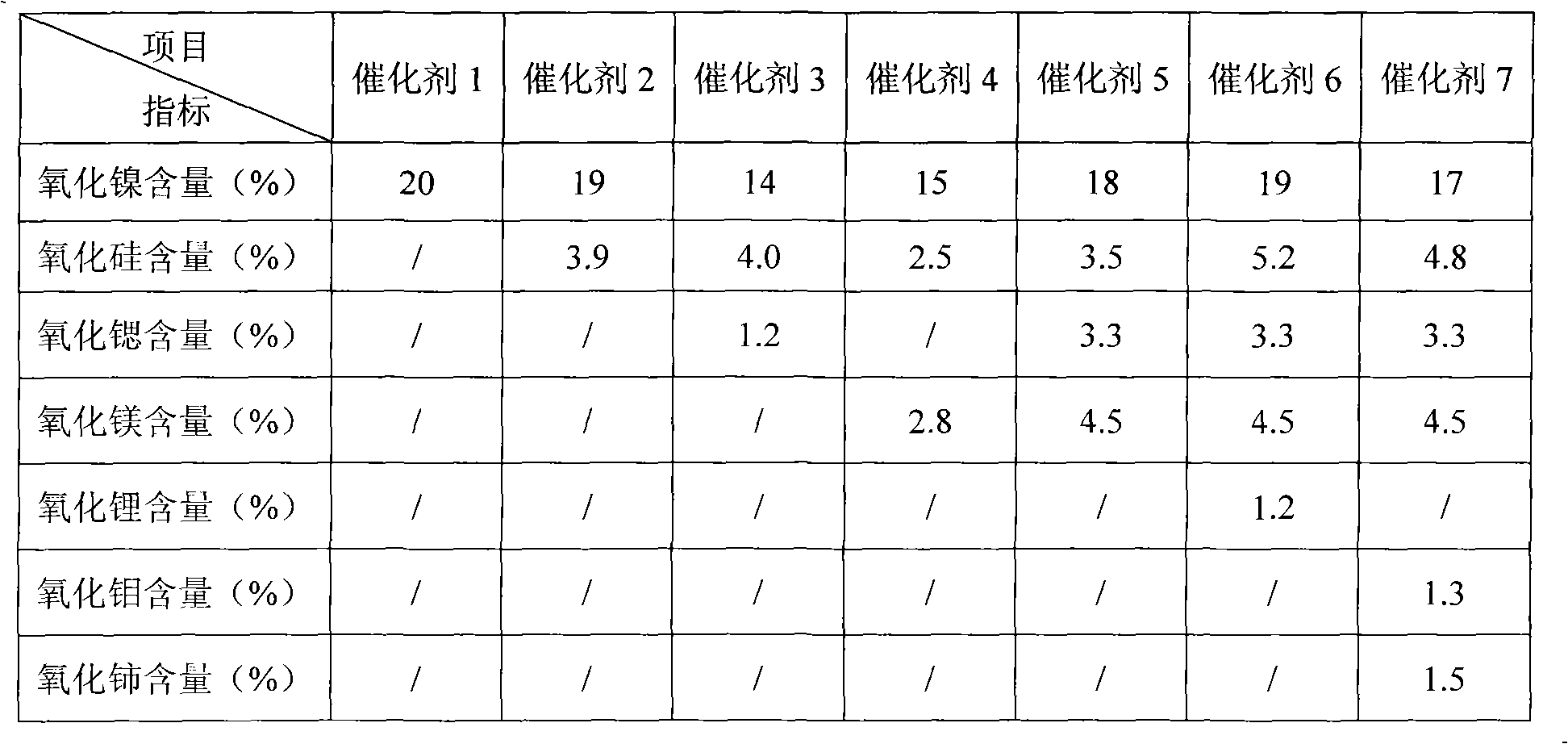

[0034] Preparation of Catalyst 1:

[0035] Add 140L of water and 5L of nitric acid (content 60%) to 300kg of pseudoboehmite alumina powder, knead and extrude into strips, dry at 120°C in the air, and roast at 900-1100°C to obtain Al 2 o 3 carrier. Add nickel nitrate to 200L-300L water, stir and dissolve, adjust the pH value to 4, then impregnate on 100kg carrier, age for 12 hours, dry at 120°C, and roast at 400°C for 4 hours to prepare the catalyst. The physical and chemical properties of the catalysts obtained are shown in Table 2.

[0036] Preparation of Catalyst 2:

[0037] Add 140L of water, 5L of nitric acid (content 60%), silica sol (containing 40% silicon dioxide) to 300kg of pseudo-boehmite alumina powder, knead and extrude into strips, dry in the air at 120°C, 900~ Calcined at 1100°C to obtain corresponding modified Al 2 o 3 carrier. Add nickel nitrate to 200L-300L water, stir and dissolve, adjust the pH value to 4, then impregnate on 100kg carrier, age for 12 ...

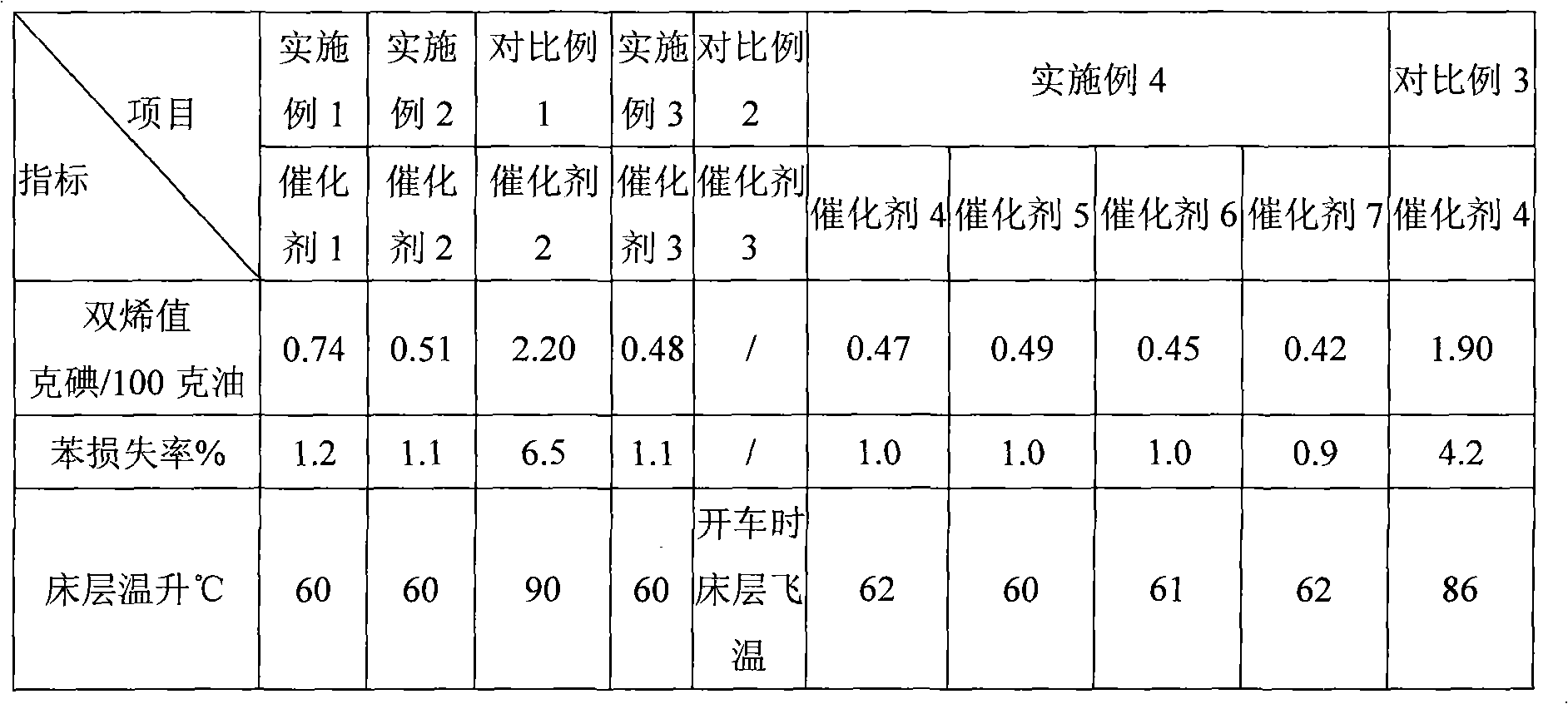

Embodiment 1

[0044] Put the catalyst 1 into the fixed bed reactor, under the pressure of 0.4MPa, the volume ratio of hydrogen to the catalyst is 500Nm 3 / m 3 / h, raise the temperature of the bed layer to 240°C at a rate of 50°C / h and maintain it for 5h, then raise the temperature to 340°C at a rate of 10°C / h, maintain it for 10h, and then raise the temperature to 400°C at a rate of 15°C / h , maintained for 5 hours; then lowered the temperature to 35°C, fed a mixture of nitrogen and air, the initial partial pressure of oxygen was 5%, and gradually increased the partial pressure of oxygen under the condition that the temperature rise of the reactor did not exceed 5°C until the partial pressure of oxygen was 20%, maintained for 5 hours, a pre-reduced / oxidized catalyst was obtained.

[0045] Put the catalyst into an adiabatic bed reactor, raise the temperature of the bed to 150°C at a rate of 50°C / h under the hydrogen pressure of 2.0MPa and maintain it for 10h, then cool down the catalyst bed ...

Embodiment 2

[0047] Put the catalyst 2 into the adiabatic bed hydrogenation reaction device, under the pressure of 0.8MPa, feed the helium-hydrogen mixed gas with the hydrogen content of 10%, and the volume ratio of the reducing gas to the catalyst is 1000Nm 3 / m 3 / h, raise the temperature of the bed layer to 250°C at a rate of 40°C / h and maintain it for 4h, then raise the temperature to 350°C at a rate of 8°C / h, maintain it for 8h, and then raise the temperature to 390°C at a rate of 12°C / h , maintained for 4 hours; then cooled to 25°C, under the hydrogen pressure of 2.5MPa, naphtha with a sulfur content of 450ug / g and an olefin content of 1.2% passed through the catalyst bed at a space velocity of 12 hours -1 , The passivation time is 3 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com