Method for synthesizing methyl glycollate and ethylene glycol by dimethyl oxalate hydrogenation

A technology of dimethyl oxalate and methyl glycolate, which is applied to the preparation of carboxylic acid esters, the preparation of organic compounds, chemical instruments and methods, etc., can solve the problem of low dispersion of active components, low-temperature activity to be improved, catalyst ratio Low surface area and other issues, to achieve the effect of low payload, high activity at low temperature, and increase conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

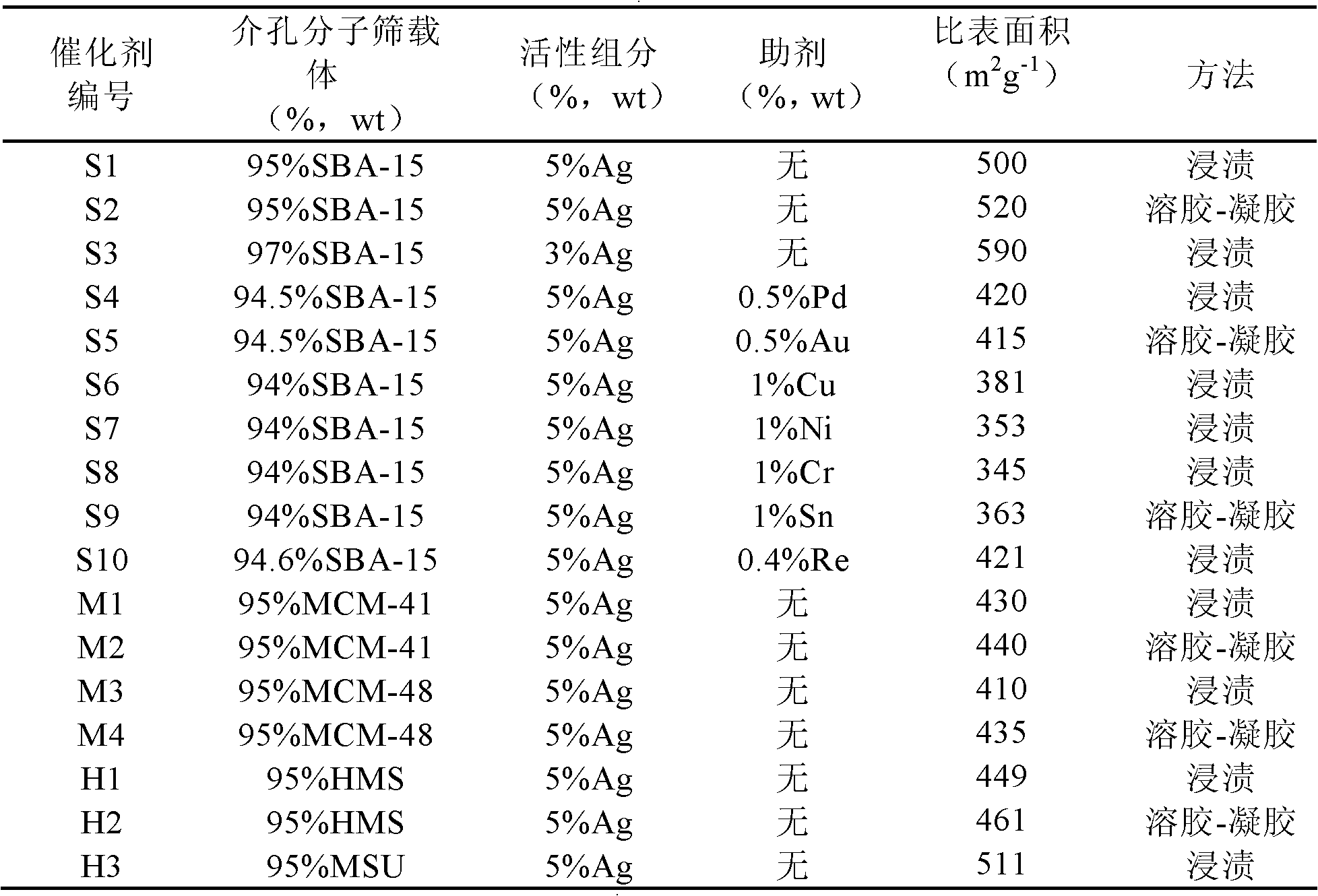

[0024] Embodiment 1 Preparation of silver-containing SBA-15 mesoporous molecular sieve catalyst S1

[0025] Weigh 3.0 grams of SBA-15 molecular sieve after pretreatment at 200°C for 2 hours, impregnate it in equal volume in an aqueous solution containing 0.23 grams of silver nitrate for 12 hours, and then dry it at 80°C. The dried silver-containing SBA-15 is baked in a muffle furnace at 500°C for 5 hours, then pressed into tablets, and then reduced for reaction. The reduction temperature is 350°C, the reduction pressure is 2.5Mpa, and the hydrogen space velocity is 1000h -1 , the reduction time is 6 hours. The obtained catalyst is numbered S1.

Embodiment 2

[0026] Embodiment 2 Preparation of silver-containing SBA-15 mesoporous molecular sieve catalyst S2

[0027] Using orthoethyl silicate (TEOS) as silicon source, silver lactate (C 3 h 5 AgO 3 ) is the silver source, and the three-stage copolymer P123 is the template agent, and the silver-containing SBA-15 is synthesized under acidic (hydrochloric acid) conditions, and the static synthesis temperature in the autoclave is 100 ° C, and the corresponding raw material molar ratio is: P123: HCl: TEOS : C 3 h 5 AgO 3 :H 2 O=0.017:5.88:1:0.03:197. After 3 days of crystallization in the kettle, the synthesized silver-containing SBA-15 was washed with water, washed with alcohol, and dried. After drying, bake the silver-containing SBA-15 in a muffle furnace at 500°C for 5 hours, then press it into tablets, and reduce it for reaction. The reduction temperature is 350°C, the reduction hydrogen pressure is 2.5MPa, and the hydrogen space velocity is 1200h -1 , the reduction time is 7 ...

Embodiment 3

[0028] Example 3 Preparation of silver-containing MCM-41 mesoporous molecular sieve catalyst M1

[0029] The preparation method is the same as that of Example 1, except that the mesoporous molecular sieve used is MCM-41. The obtained mesoporous molecular sieve catalyst is coded as M1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com