Filling valve and filling device

A filling valve and filling technology, which is applied in the direction of filling device cleaning, packaging, bottle filling, etc., can solve the problems of unfavorable cleaning, incomplete positioning and cleaning, and prone to hygienic dead ends, so as to reduce hygienic dead ends and reduce hygienic risks. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

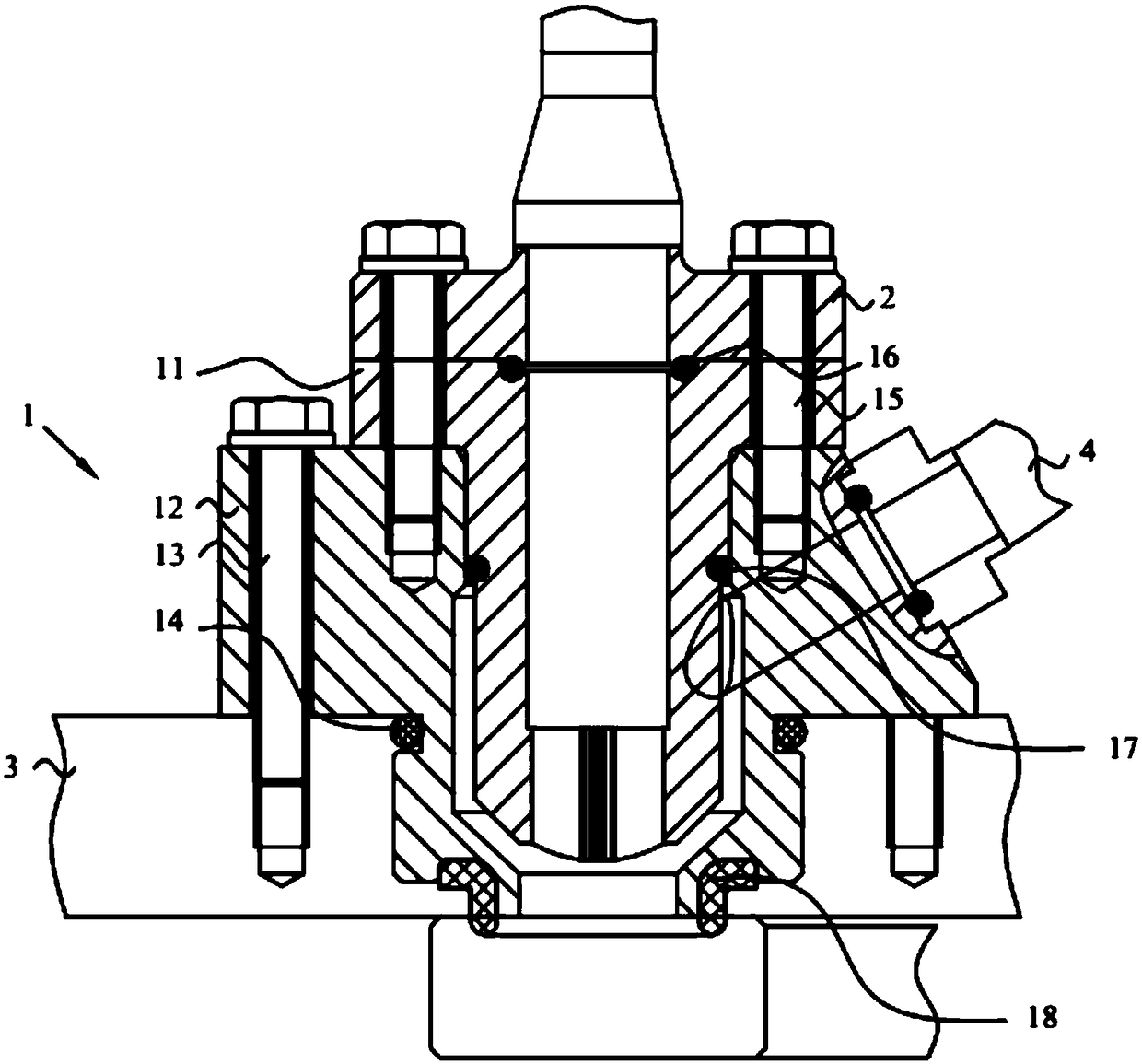

[0036] In order to enable those skilled in the art to better understand the technical solution of this embodiment, the technical solution of this embodiment will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0037] Filling valve is one of the core components in aseptic filling equipment, which directly affects the safety and quality of products.

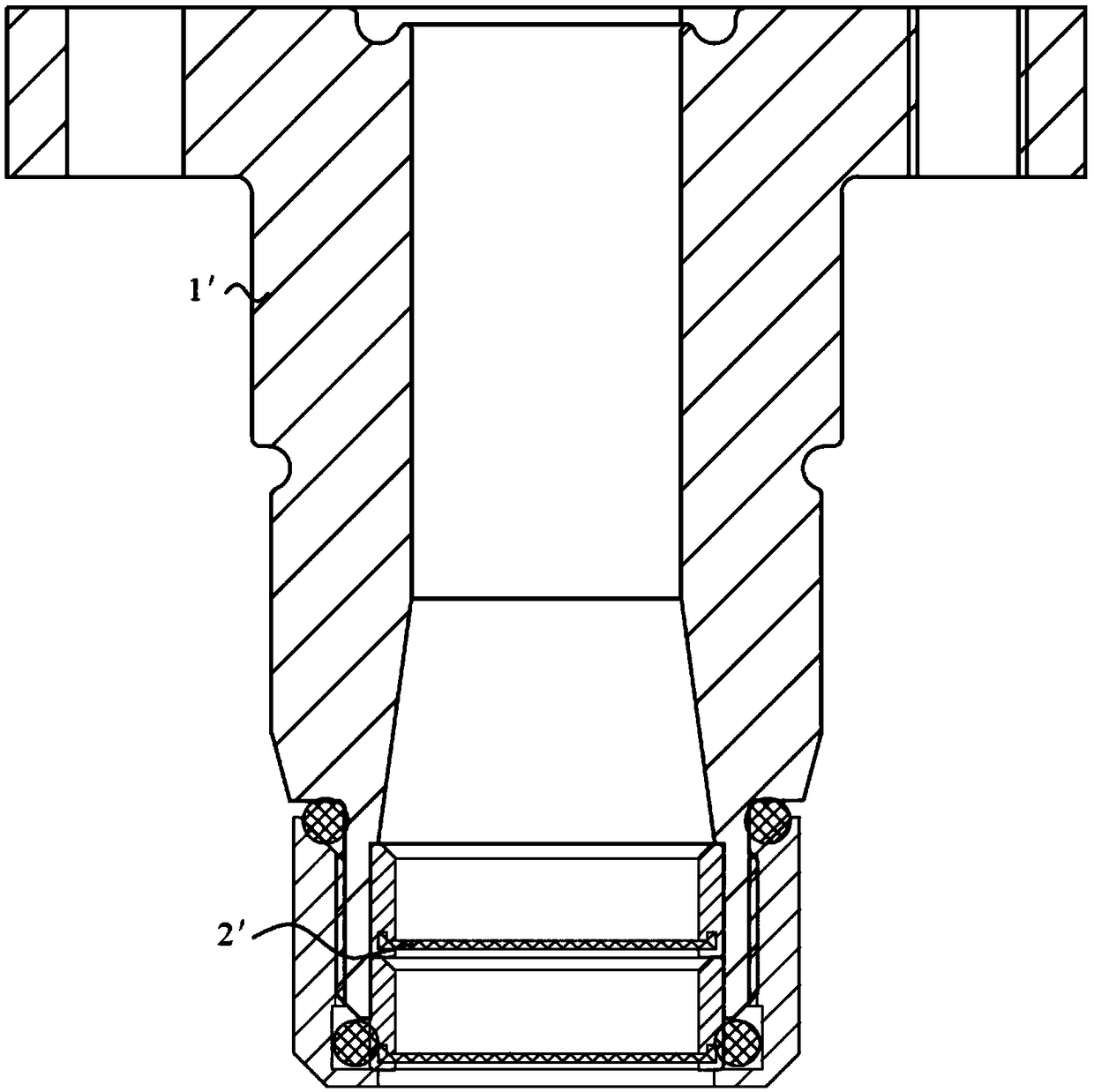

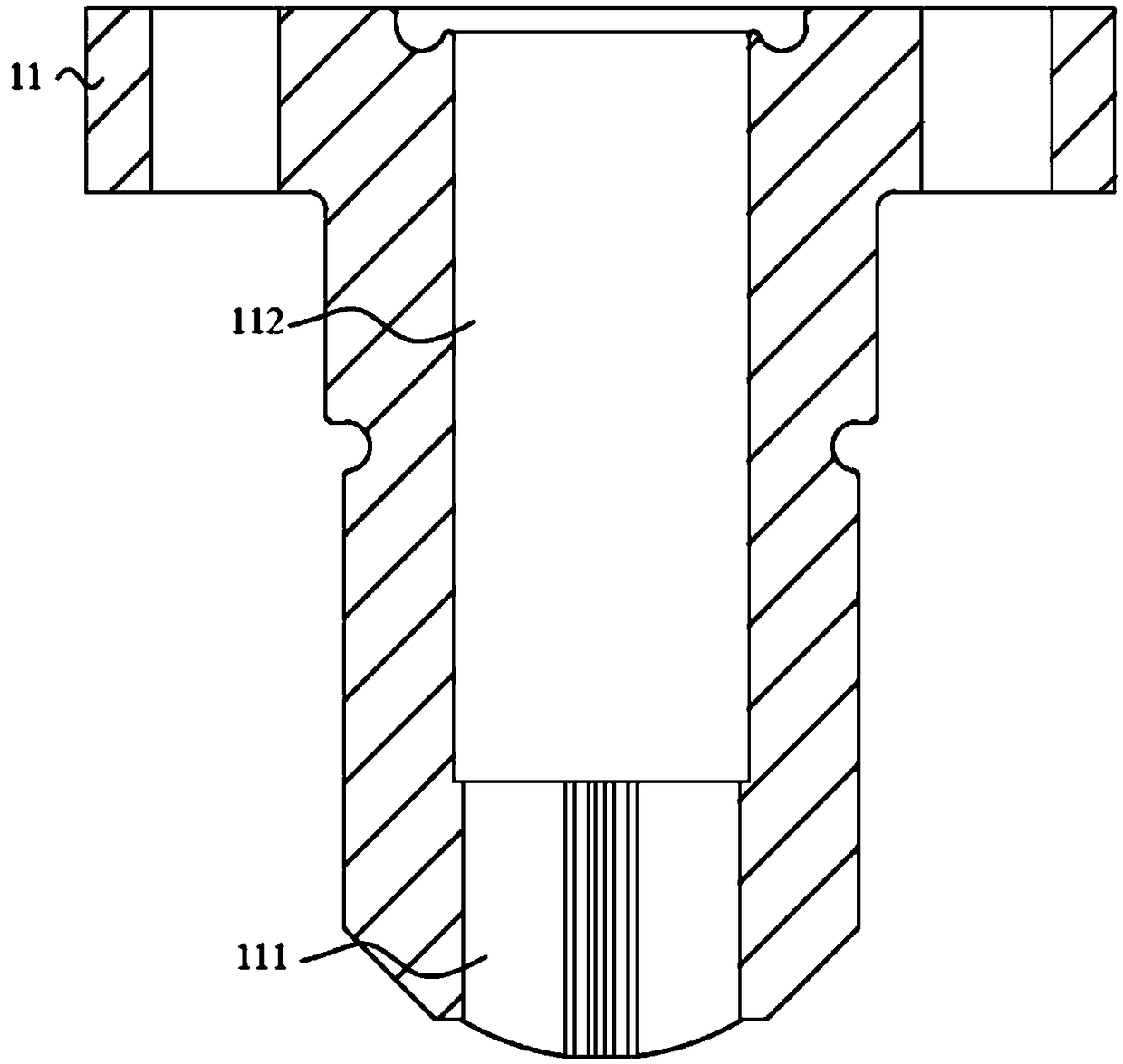

[0038] like figure 2 and image 3 As shown, the filling valve 1 provided in this embodiment includes a valve core 11, and a filling channel 112 and a plurality of throttle channels 111 are opened on the valve core 11, and the filling channel 112 communicates with each throttle channel 111, and They are arranged from top to bottom along the axial direction of the spool 11 . The filling valve 1 provided in this embodiment can divide the liquid in the filling channel 112 through a plurality of throttling channels 111 to ensure the uniformity and stability of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com