Cleaning and sterilizing equipment of vacuum belt drying unit and cleaning and sterilizing step method

A vacuum belt drying and sterilizing equipment technology, which is applied in the direction of liquid cleaning methods, cleaning methods and utensils, dryers, etc., can solve the problems of welding slag residue, unfavorable cleaning, and many dead ends in pipelines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

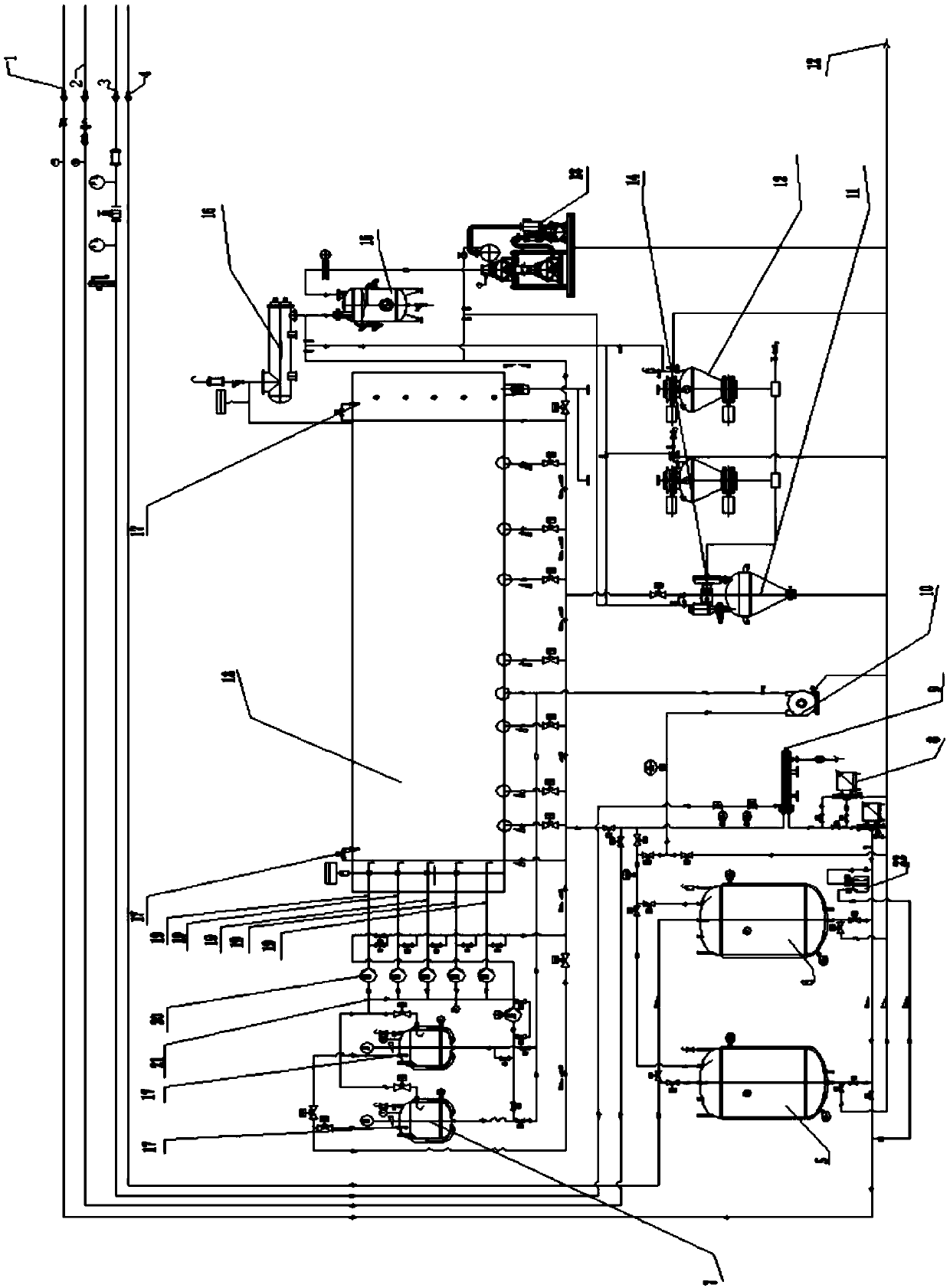

[0048] In order to make up for the above deficiencies, the present invention provides a cleaning and sterilization equipment for a vacuum belt drying unit and a cleaning and sterilization procedure to solve the above-mentioned problems in the background technology.

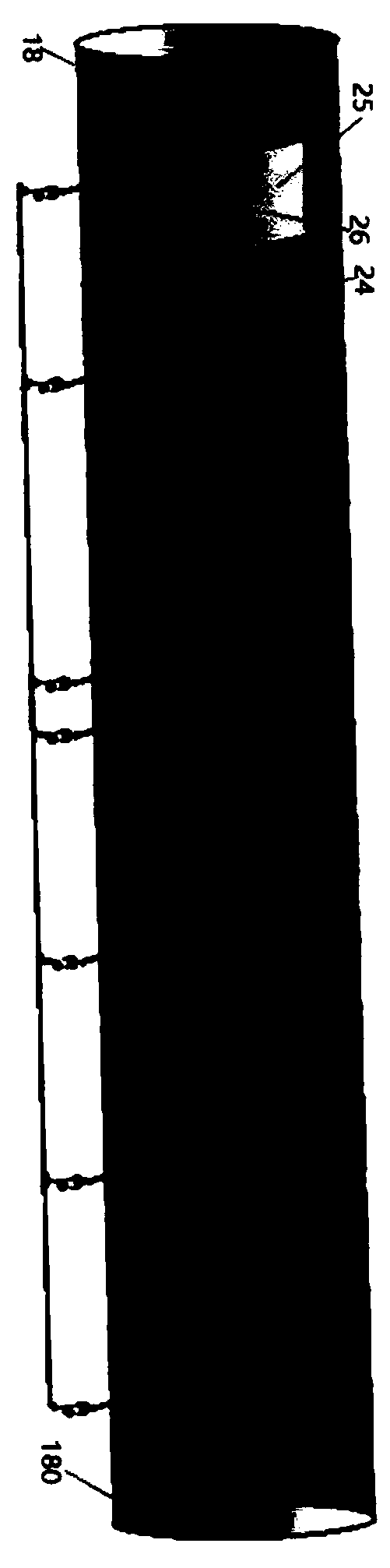

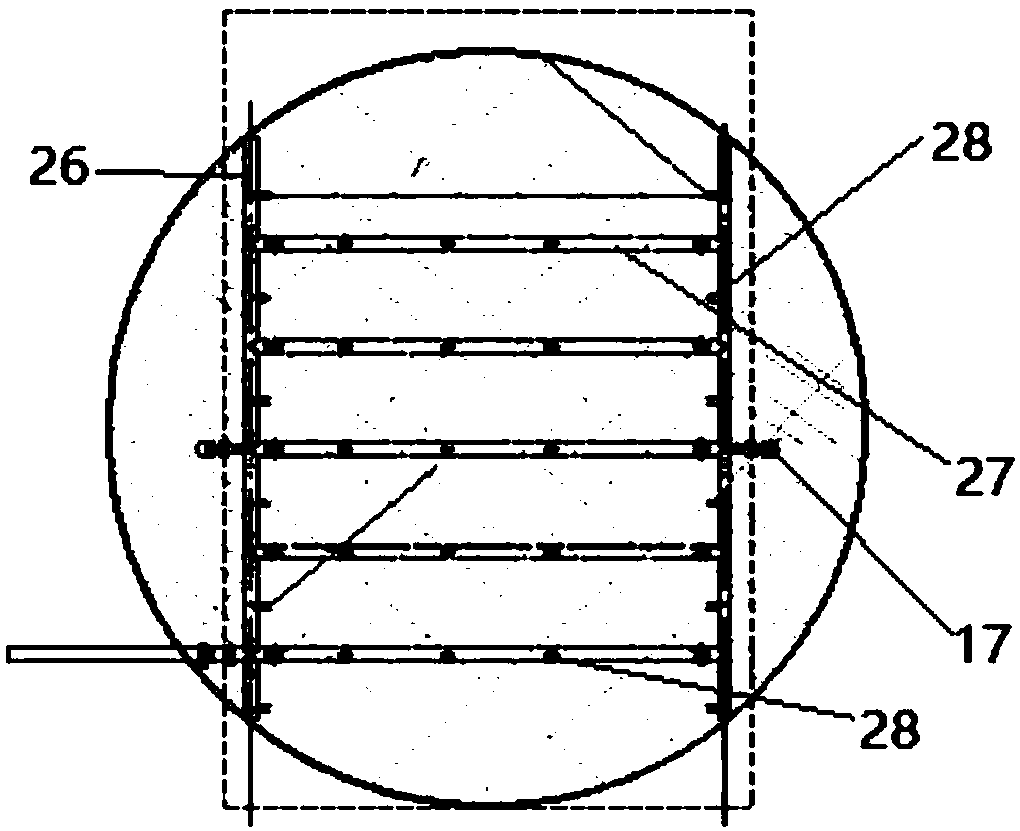

[0049] A vacuum belt drying unit cleaning and sterilization equipment, including several discharge tanks, rotor pumps, rotor pump discharge pipes, several discharge screw pumps, several discharge pipes, purified water tanks, concentrated alkali preparation tanks, and alkali washing tanks , collection bin, buffer tank, liquid receiver, condenser, vacuum group, reducer, self-priming pump, valve, centrifugal pump, tubular heat exchanger and cleaning pump, etc., the discharge port of the discharge tank The rotor pump is communicated with the rotor pump outlet pipeline, and the rotor pump outlet pipeline is respectively communicated with several so-called discharge screw pumps;

[0050] It also includes a vacuum belt d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com