Fermentation equipment for bread processing

A technology for fermentation equipment and bread, which is applied in the field of fermentation equipment for bread processing, and can solve the problems of increasing the complexity of operation, taking up a large space for equipment, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

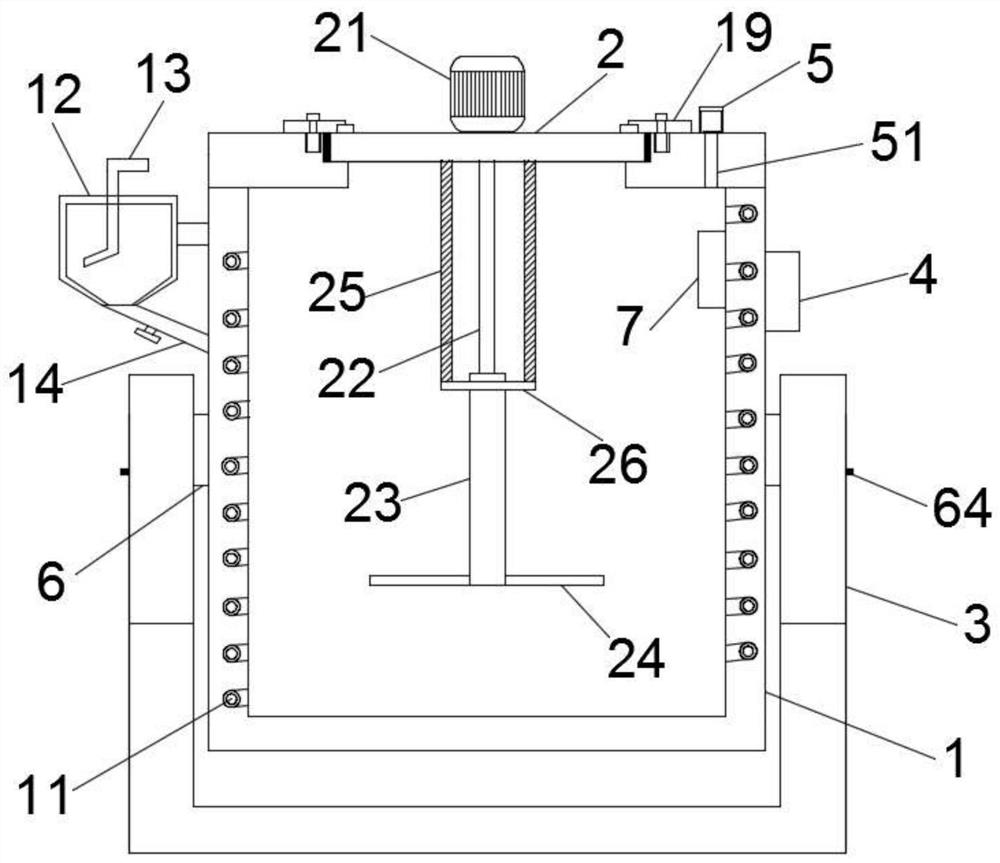

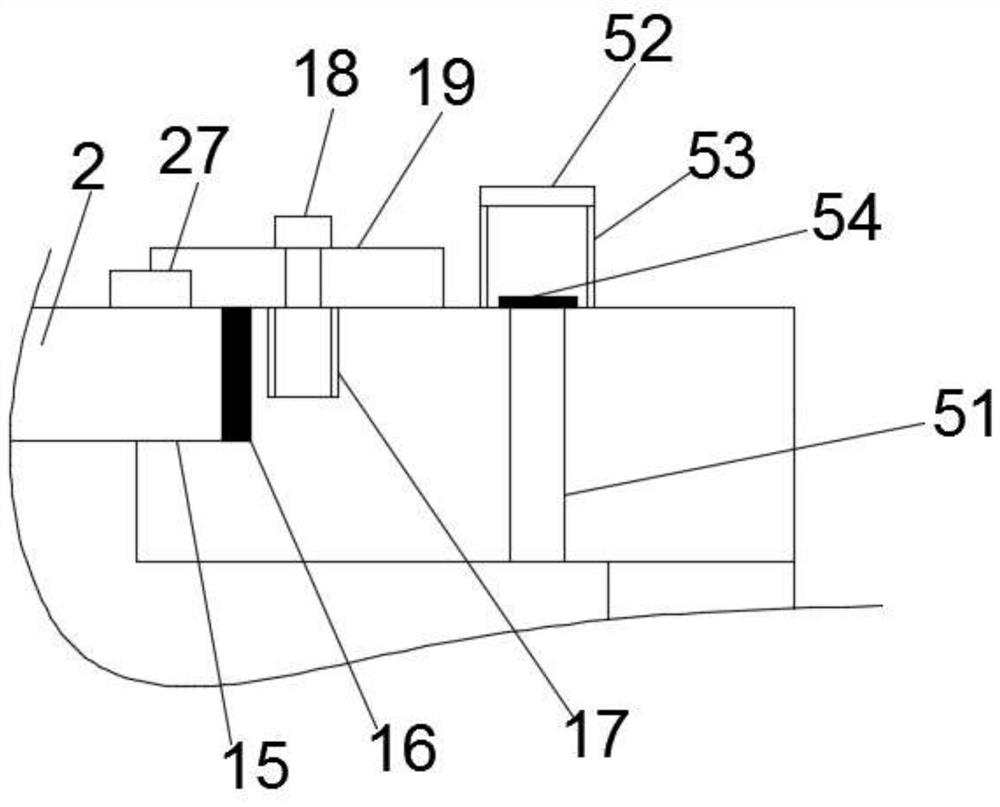

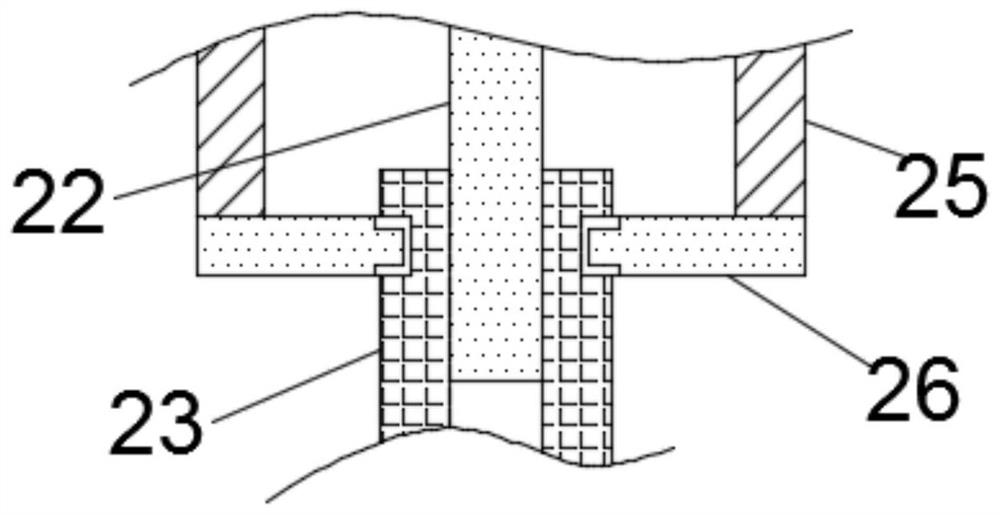

[0028] see Figure 1 to Figure 3 , the present invention provides a technical solution: a fermentation equipment for bread processing, comprising a fermentation chamber 1, a top cover 2 and a support frame 3, the top cover 2 is equipped with a stirring motor 21 and a stirring shaft, the output end of the stirring motor 21 is connected to the stirring The shaft is connected, the stirring shaft is fixedly connected with the stirring rod 24, the fermentation chamber 1 includes a jacket, a buffer chamber, an exhaust valve 5 and a pressure device 7, a spiral heating coil 11 is installed in the jacket, and the spiral heating coil 11 is connected with a temperature controller 4. The buffer chamber includes a feeding hopper 12, a hand crank 13 and a discharge pipe 14. The hand handle 13 is rotationally sealed with the feed hopper 12. The discharge pipe 14 is provided with a valve. The exhaust valve 5 includes an exhaust hole 51 and a limit position. Sheet 52, the bottom surface of the...

Embodiment 2

[0032] see figure 1 , Figure 4 and Figure 5 , the present invention provides a technical solution: a fermentation equipment for bread processing, comprising a fermentation chamber 1, a top cover 2 and a support frame 3, the top cover 2 is equipped with a stirring motor 21 and a stirring shaft, the output end of the stirring motor 21 is connected to the stirring The shaft is connected, the stirring shaft is fixedly connected with the stirring rod 24, the fermentation chamber 1 includes a jacket, a buffer chamber, an exhaust valve 5 and a pressure device, a spiral heating coil 11 is installed in the jacket, and the spiral heating coil 11 is connected with a temperature controller 4 , the buffer chamber includes a hopper 12, a hand handle 13 and a discharge pipe 14, the hand handle 13 is rotationally sealed with the hopper 12, the discharge pipe 14 is provided with a valve, and the exhaust valve 5 includes an exhaust hole 51 and a limit piece 52 , the bottom surface of the li...

Embodiment 3

[0038] see figure 1 , figure 2 and Figure 6 , the present invention provides a technical solution: a fermentation equipment for bread processing, comprising a fermentation chamber 1, a top cover 2 and a support frame 3, the top cover 2 is equipped with a stirring motor 21 and a stirring shaft, the output end of the stirring motor 21 is connected to the stirring The shaft is connected, the stirring shaft is fixedly connected with the stirring rod 24, the fermentation chamber 1 includes a jacket, a buffer chamber, an exhaust valve 5 and a pressure device, a spiral heating coil 11 is installed in the jacket, and the spiral heating coil 11 is connected with a temperature controller 4 , the buffer chamber includes a hopper 12, a hand handle 13 and a discharge pipe 14, the hand handle 13 is rotationally sealed with the hopper 12, the discharge pipe 14 is provided with a valve, and the exhaust valve 5 includes an exhaust hole 51 and a limit piece 52 , the bottom surface of the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com