Patents

Literature

91results about How to "Reduce the space required" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

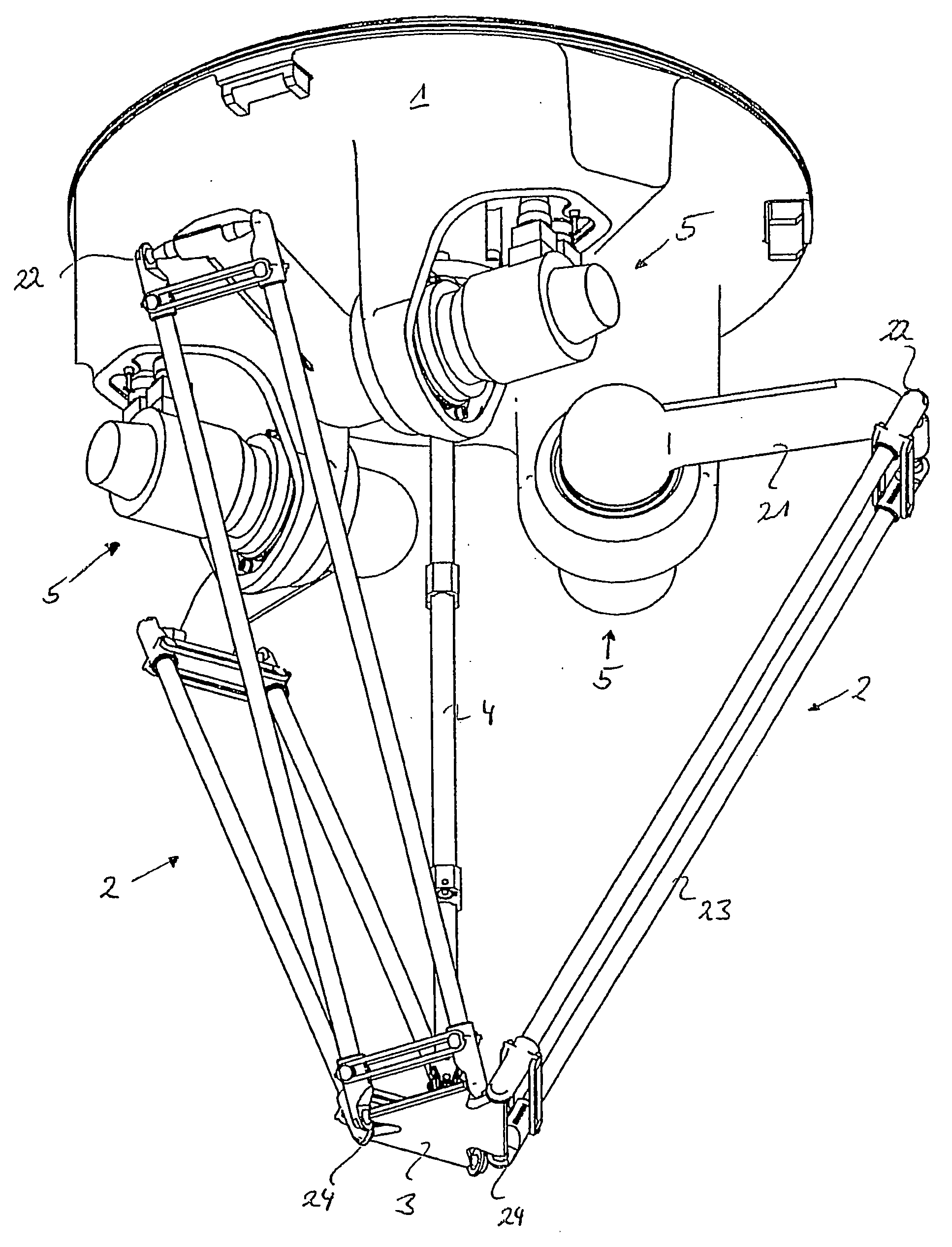

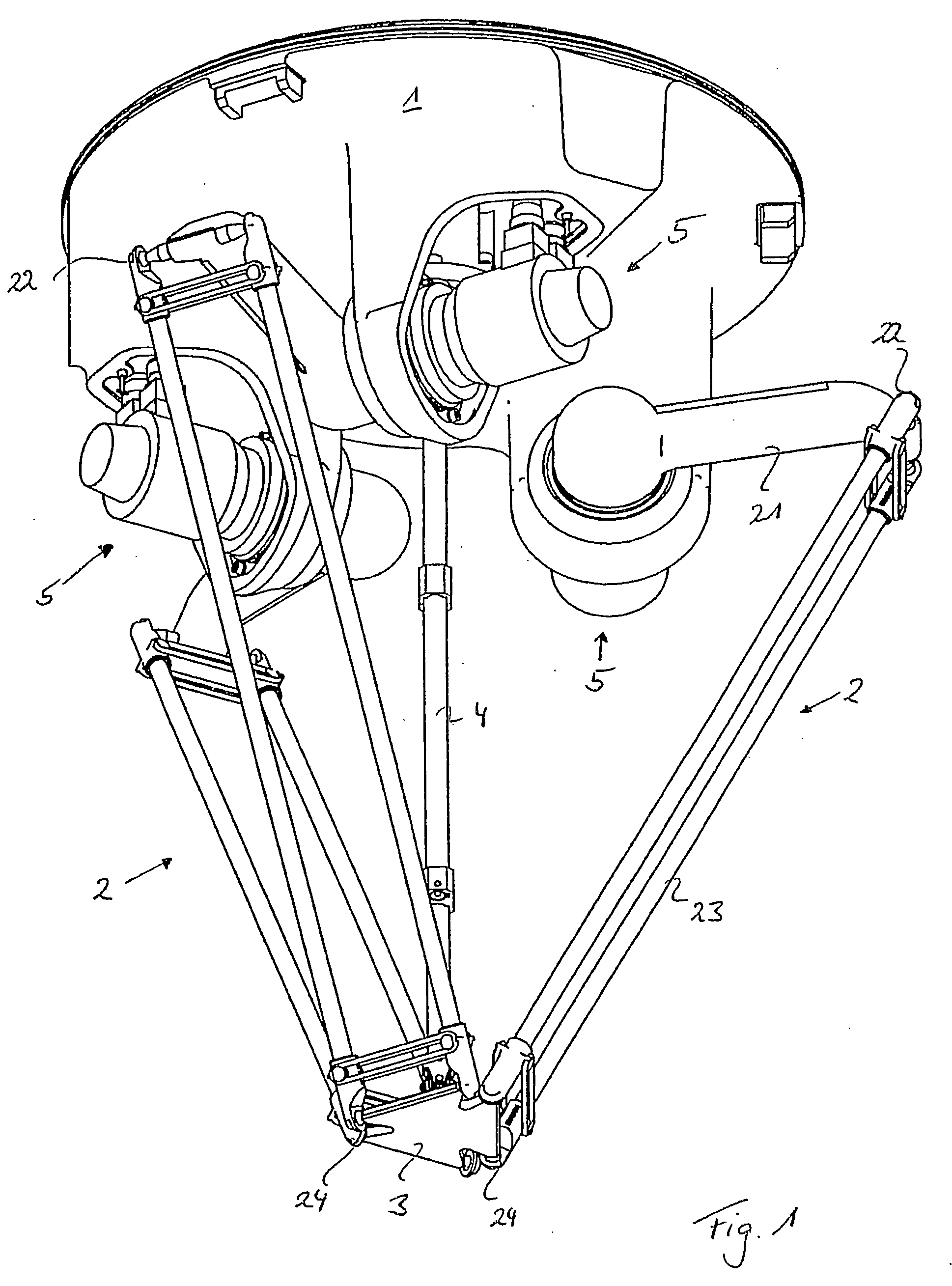

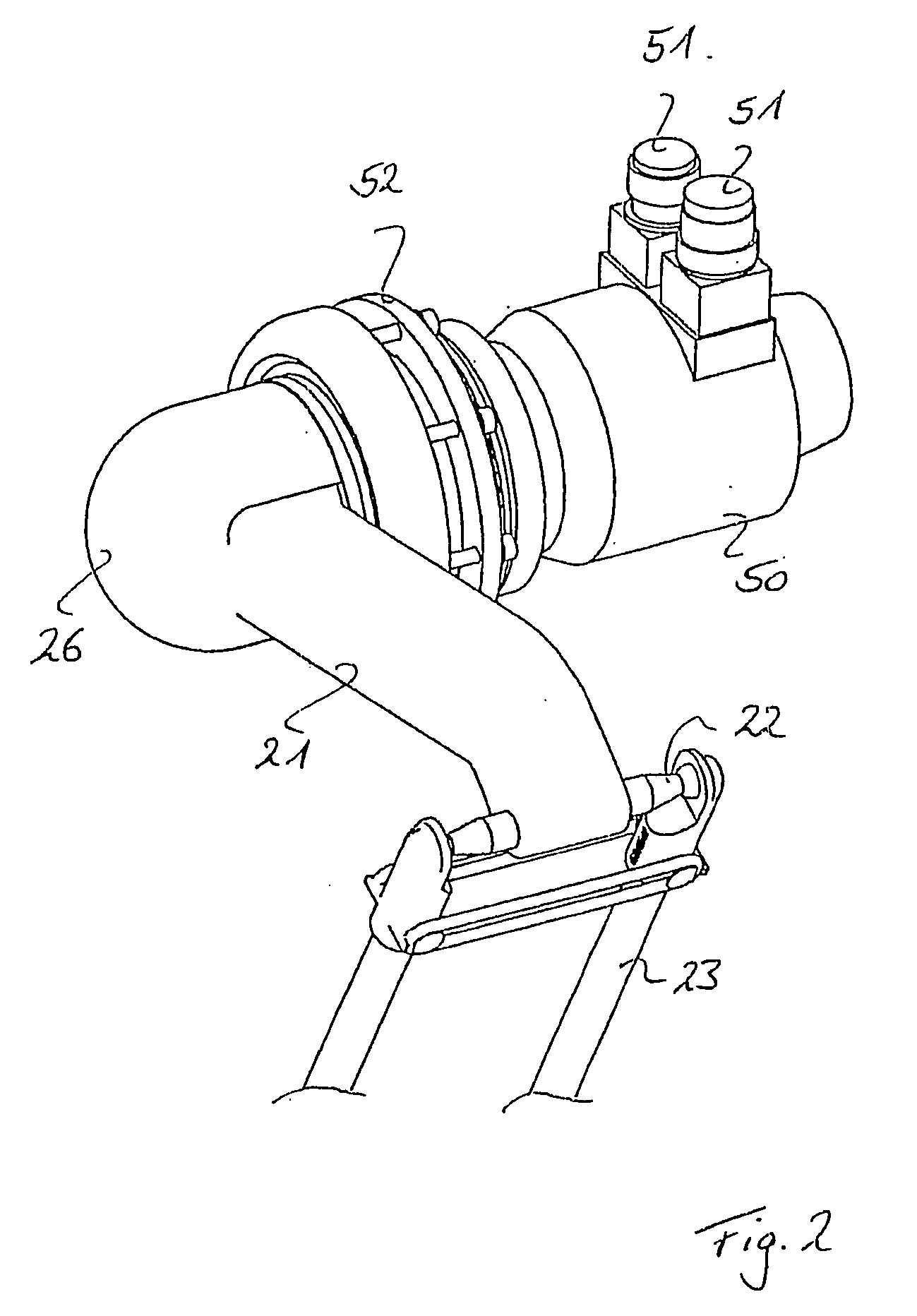

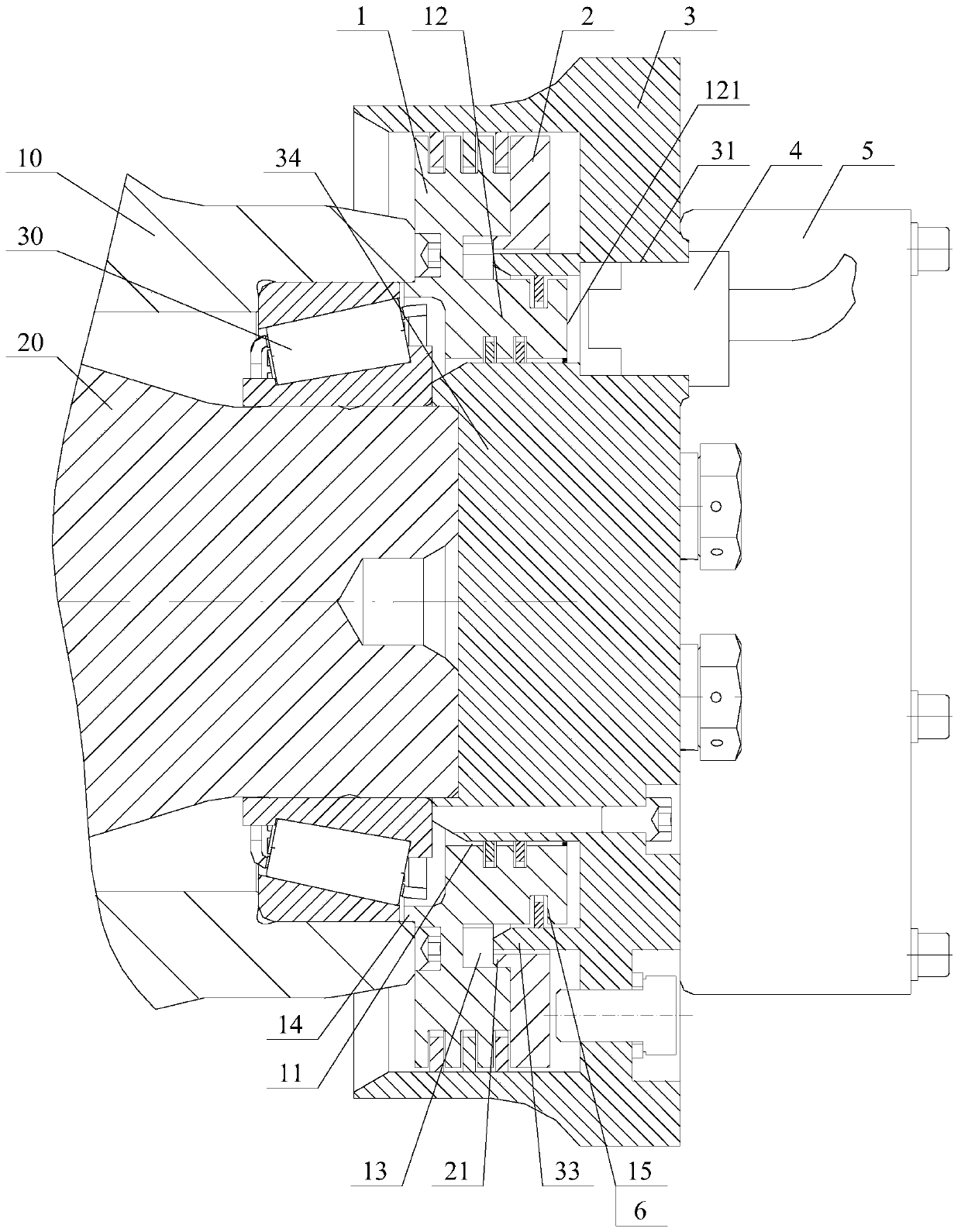

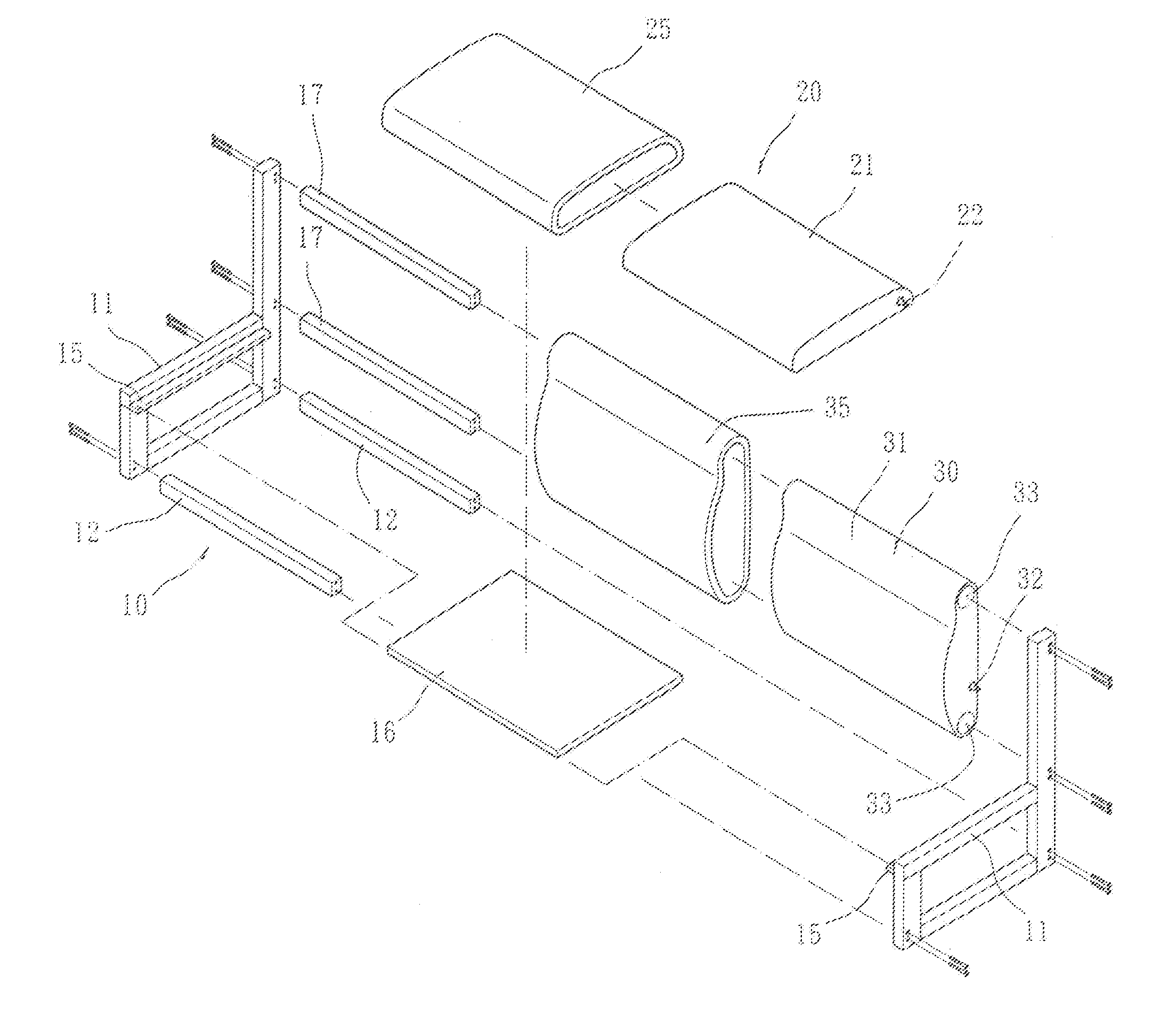

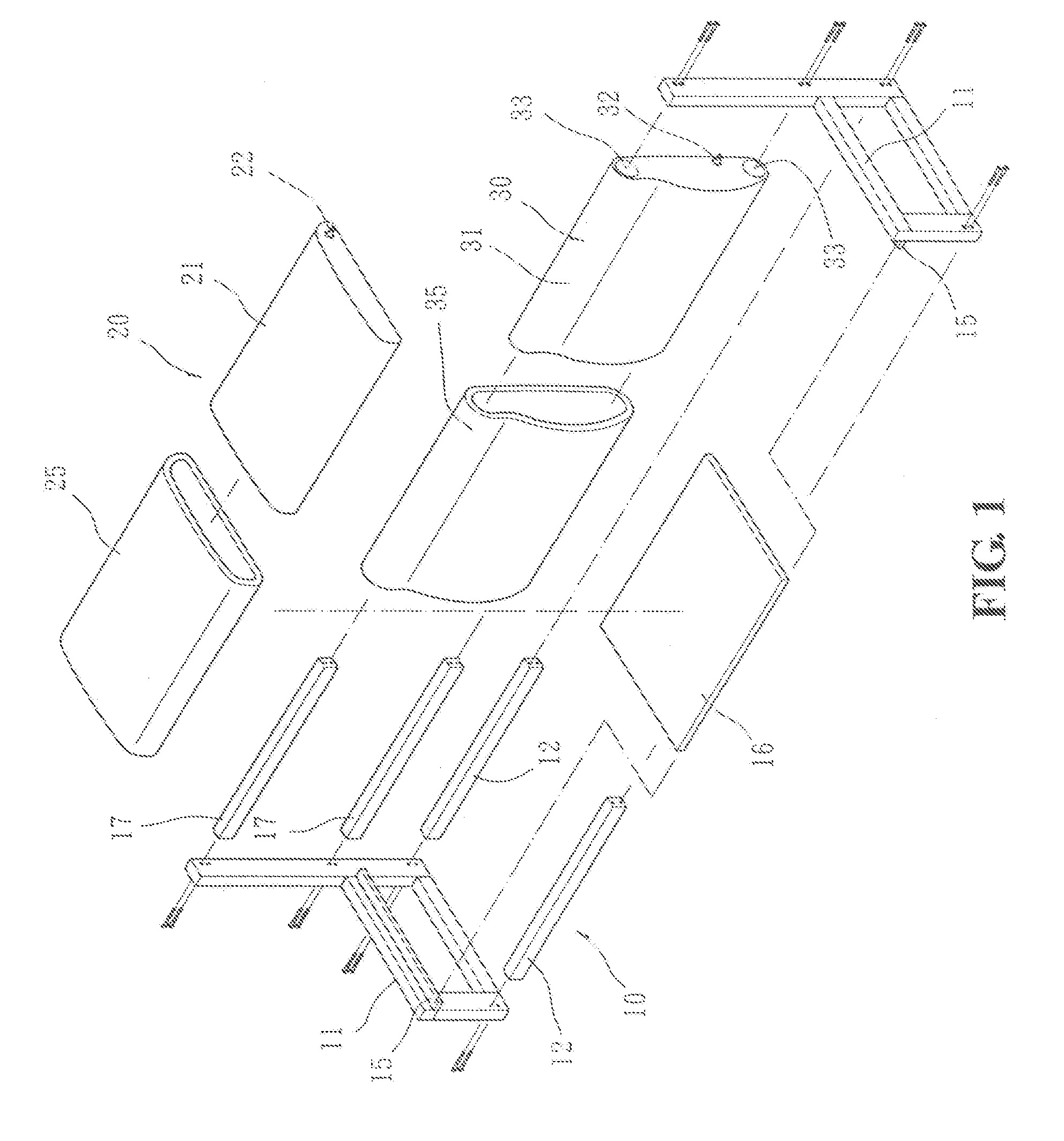

Parallel manipulator having backlash-free gearnings

InactiveUS20060182602A1Improve rigidityEasy to controlProgramme-controlled manipulatorJointsEngineeringParallel manipulator

A delta robot has motor / gearing units, which are respectively assigned to an arm and which are disposed on one side each of a triangle. Each motor / gearing unit has a gearing, by virtue of material-locking and / or positive-locking connection of gearing components, is free from backlash over the whole of the motional range of the gearing, allowing virtually all aspects fundamental to the delta robot to be optimized, especially the rigidity, the control characteristics, the spatial requirement, the speed and the positioning accuracy.

Owner:SIG TECH AG +1

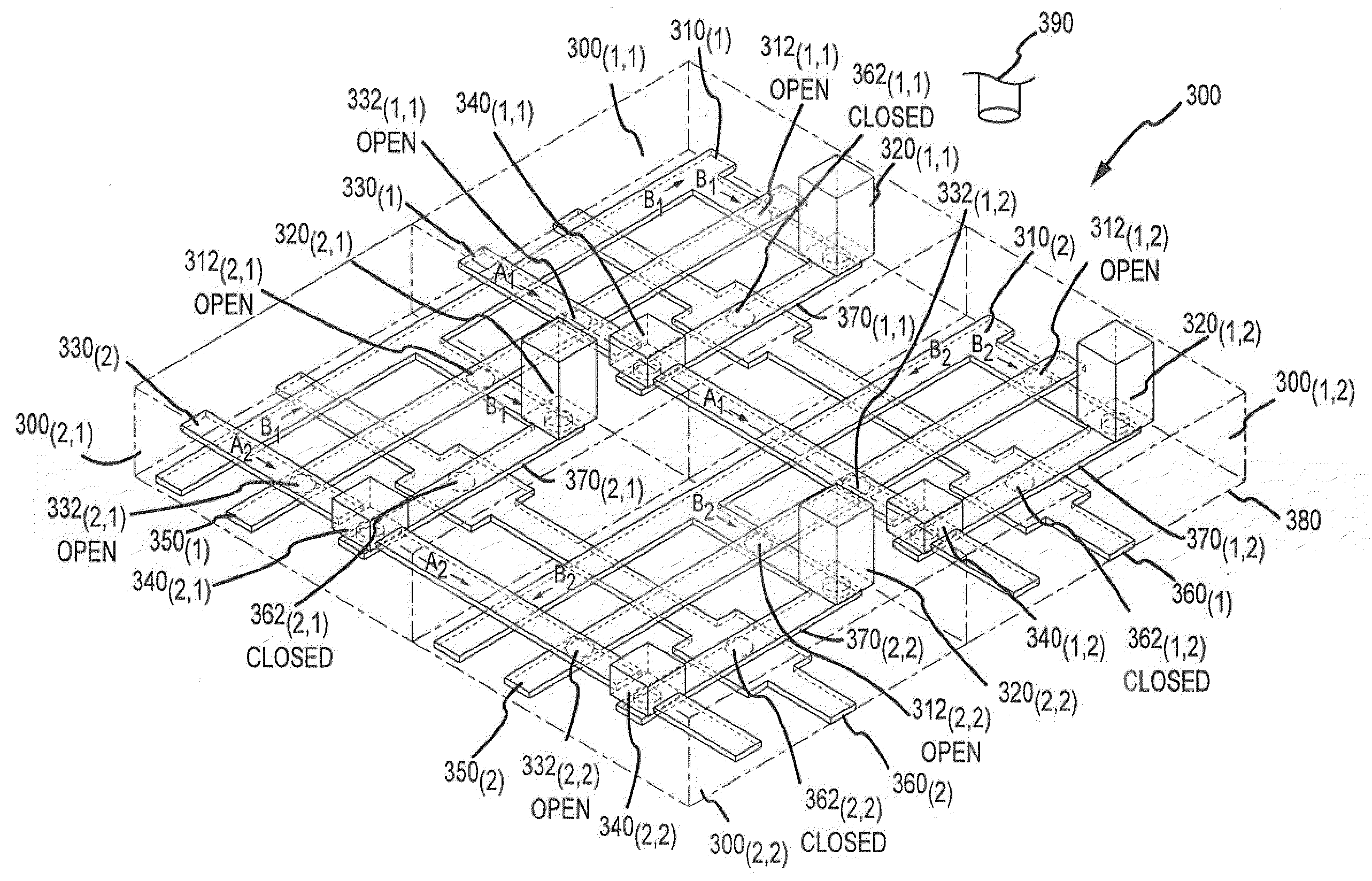

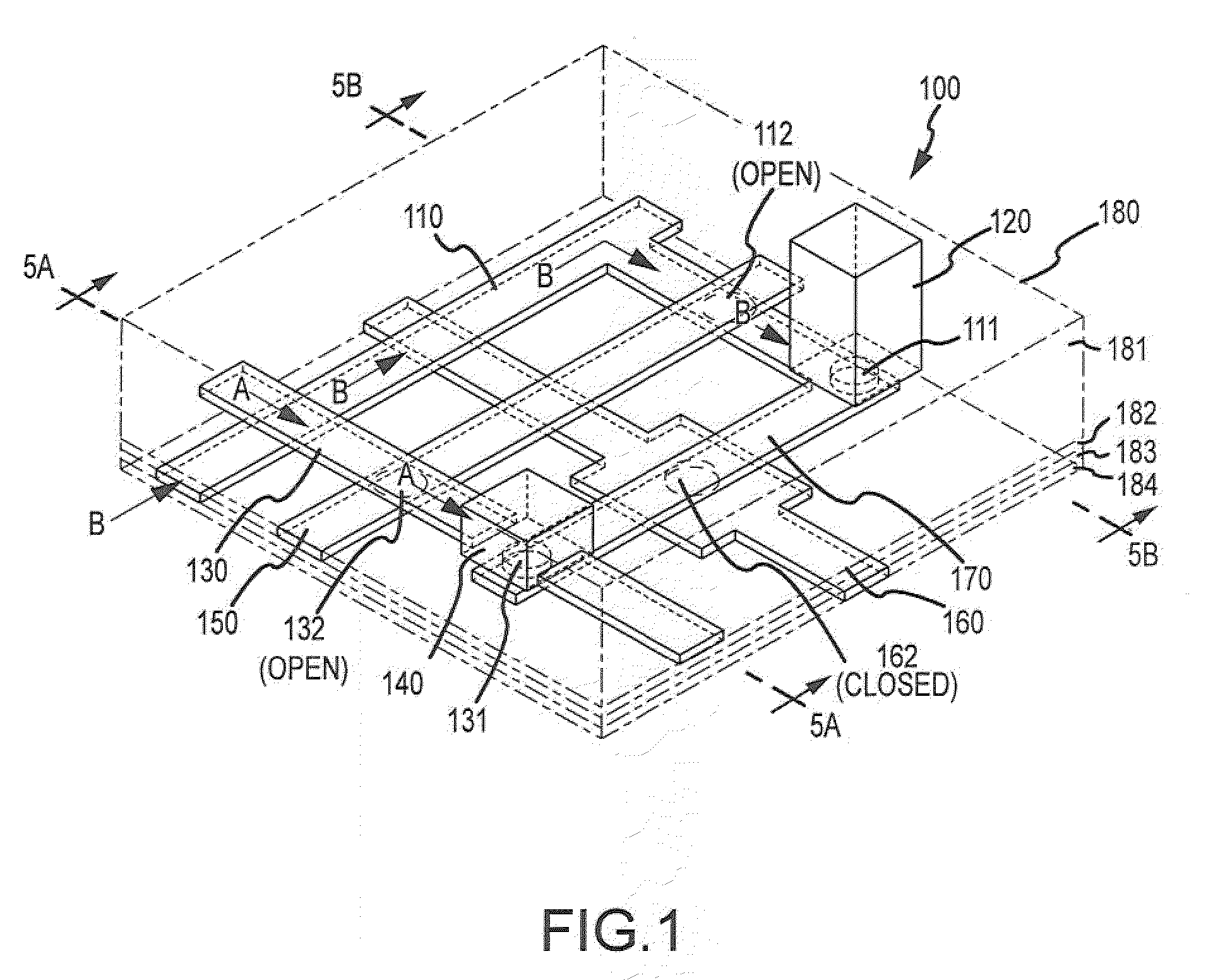

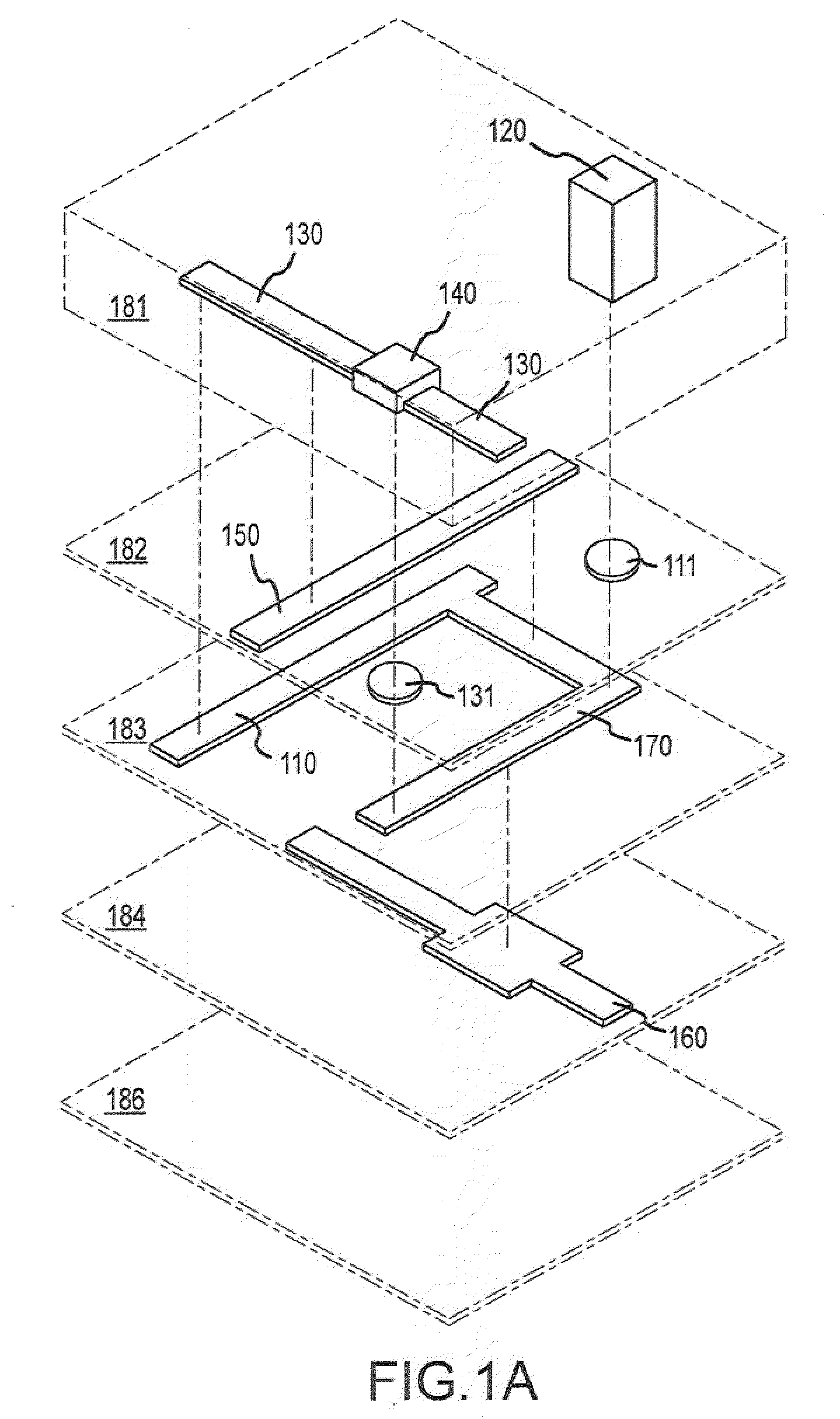

Multilevel microfluidic systems and methods

ActiveUS20090257920A1High densityImproved performance characteristicsFlow mixersCircuit elementsControl lineEngineering

Multilevel microfluidic devices include a control line that can simultaneously actuate valves for both sample and reagent lines. Microfluidic devices are configured to contain a first reagent in a first chamber and a second reagent in a second chamber, where either or both of the first and second reagents are contained at a desired or selected pressure. Operation of a microfluidic device includes transmitting second reagent from the second chamber to the first chamber, for mixing or contact with the first reagent. Microfluidic device features such as channels, valves, chambers, can be at least partially contained, embedded, or formed by or within one or more layers or levels of an elastomeric block.

Owner:STANDARD BIOTOOLS INC

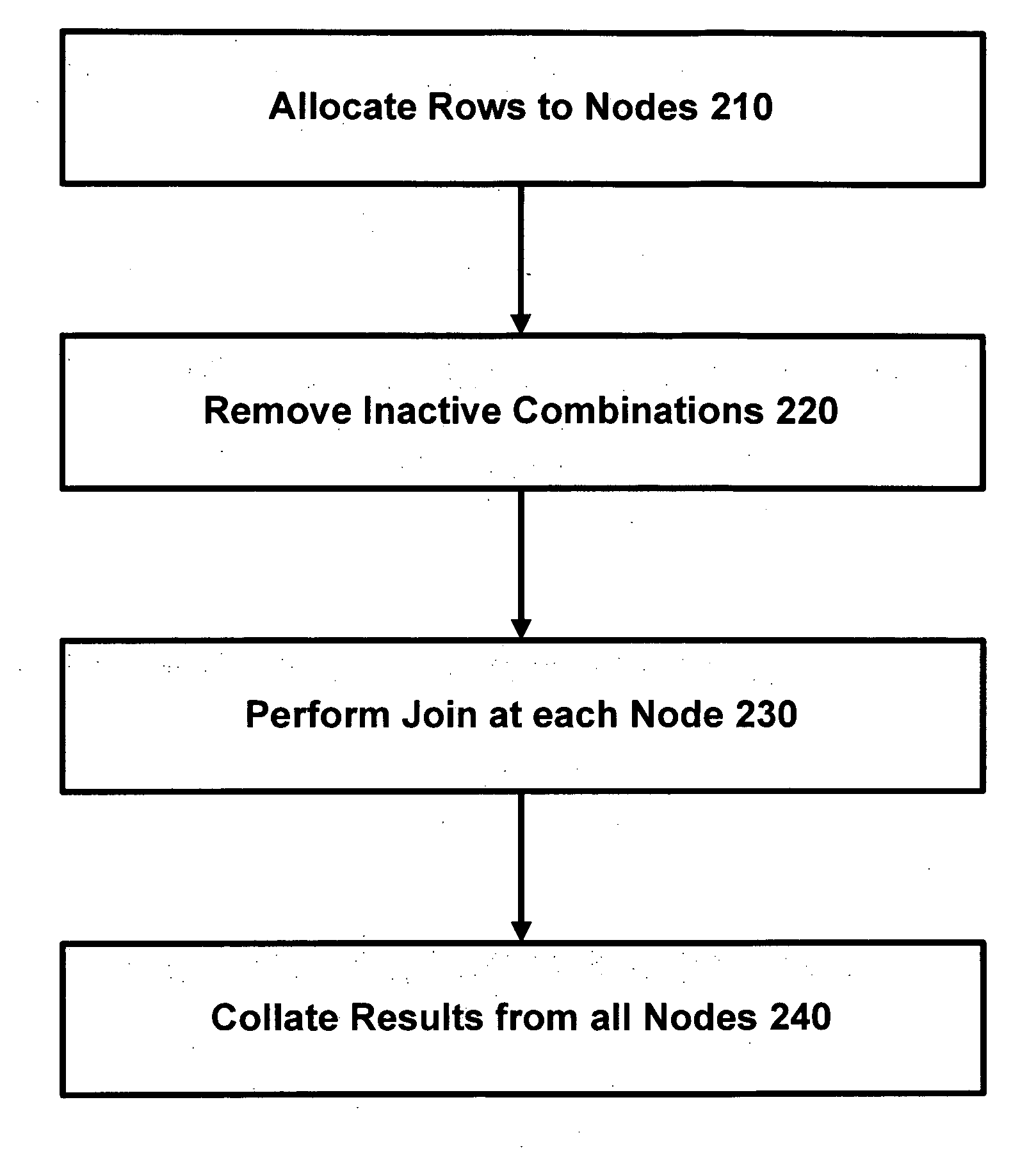

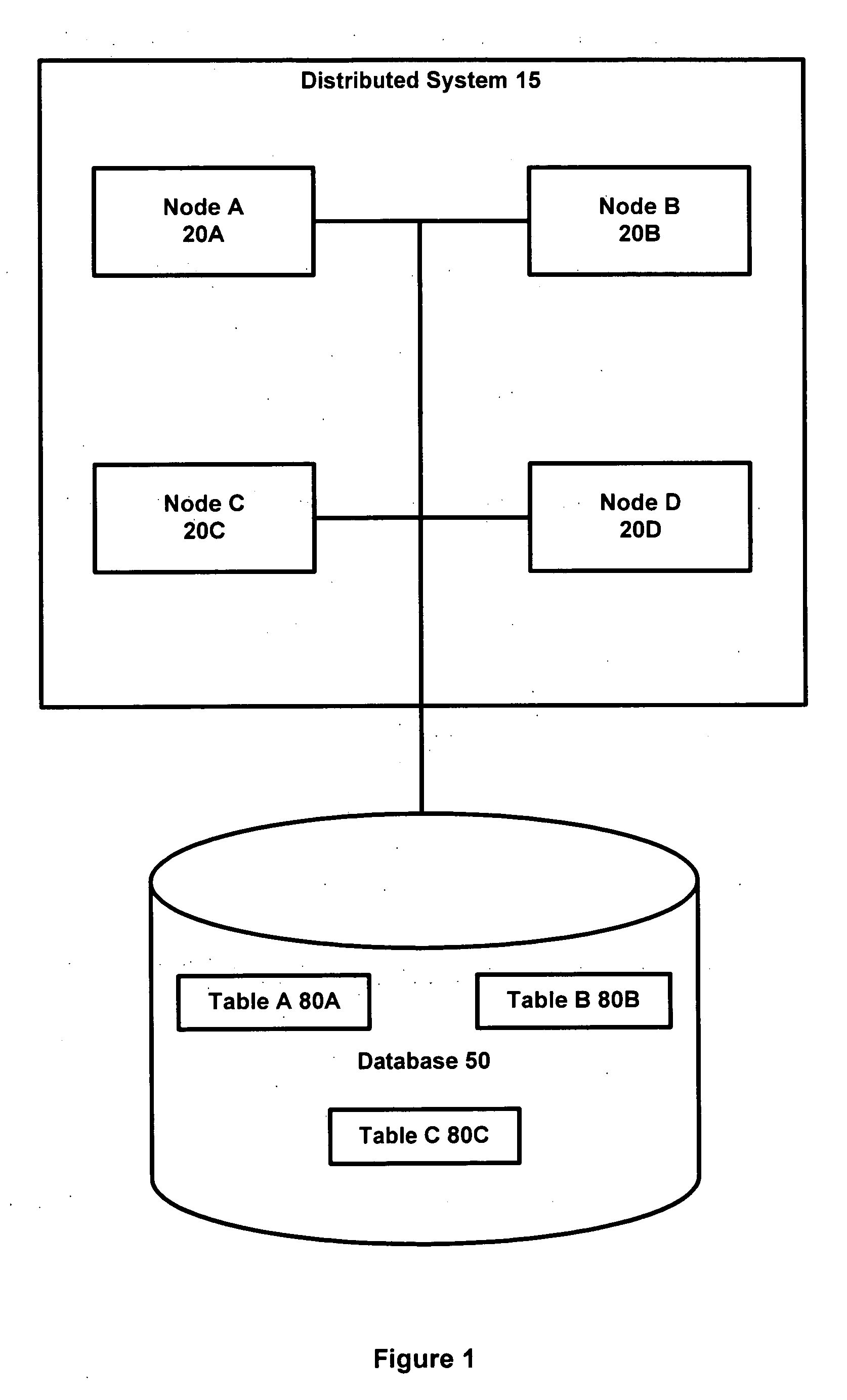

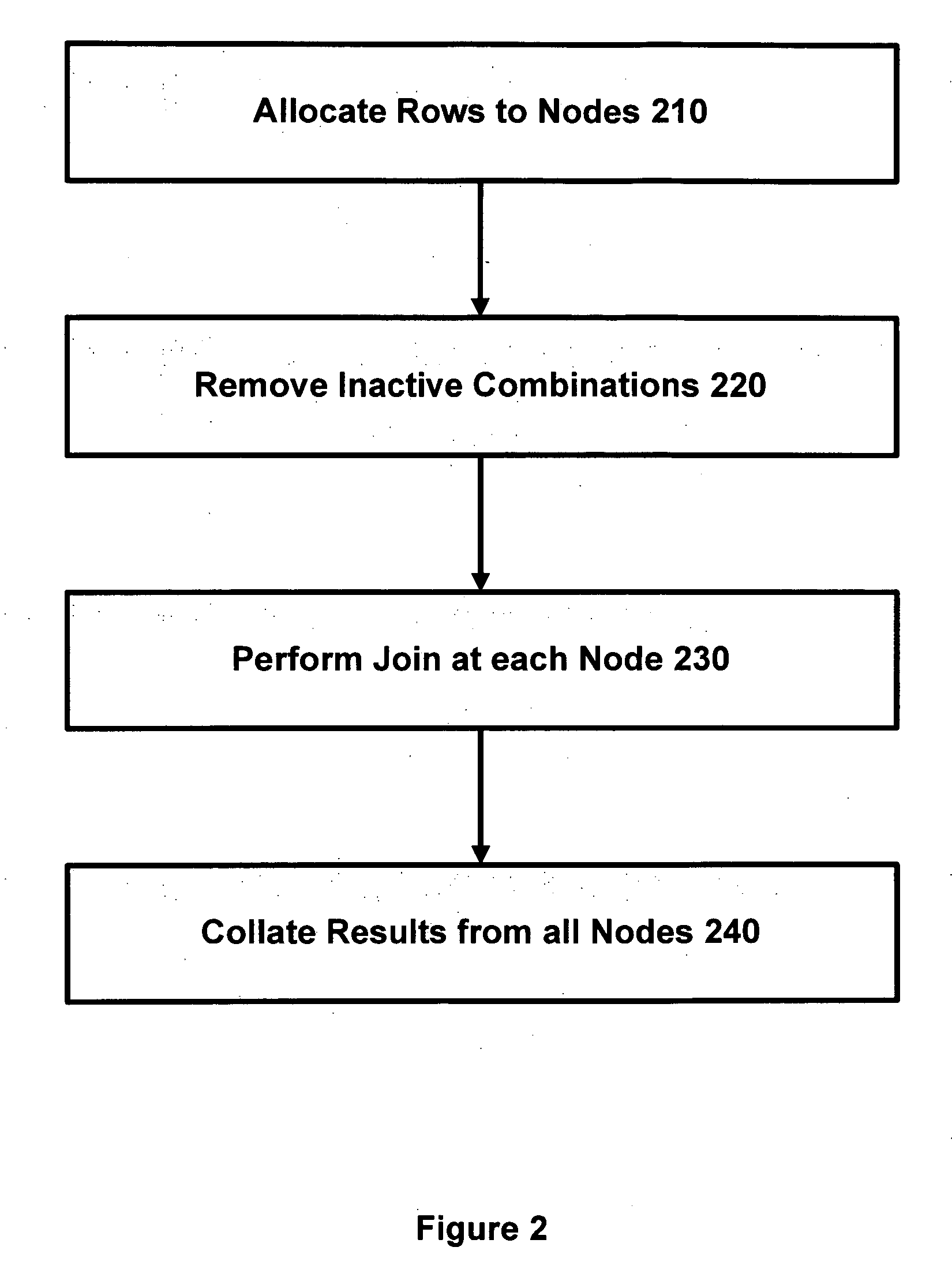

Database system with multiple processing nodes

InactiveUS20070276788A1Reduce the space requiredReduced time requirementsDigital data information retrievalDigital data processing detailsDatabase

A method and apparatus are provided for distributing a database join operation across a plurality of processing nodes. The database join operation is performed between a first table having M1 rows and a second table have M2 rows and involves forming M1×M2 combinations of rows from the first and second tables. The method includes allocating across the plurality of processing nodes the M1×M2 combinations of rows from the first and second tables. Each of the M1×M2 combinations is present on one of the nodes, and each node stores combinations corresponding to a subset of the M1 rows from the first table and a subset of the M2 rows from the second table. The method further comprises performing for each processing node the join operation in respect of all combinations of rows allocated to that processing node and collating results across all the processing nodes to complete the join operation.

Owner:KOGNITIO

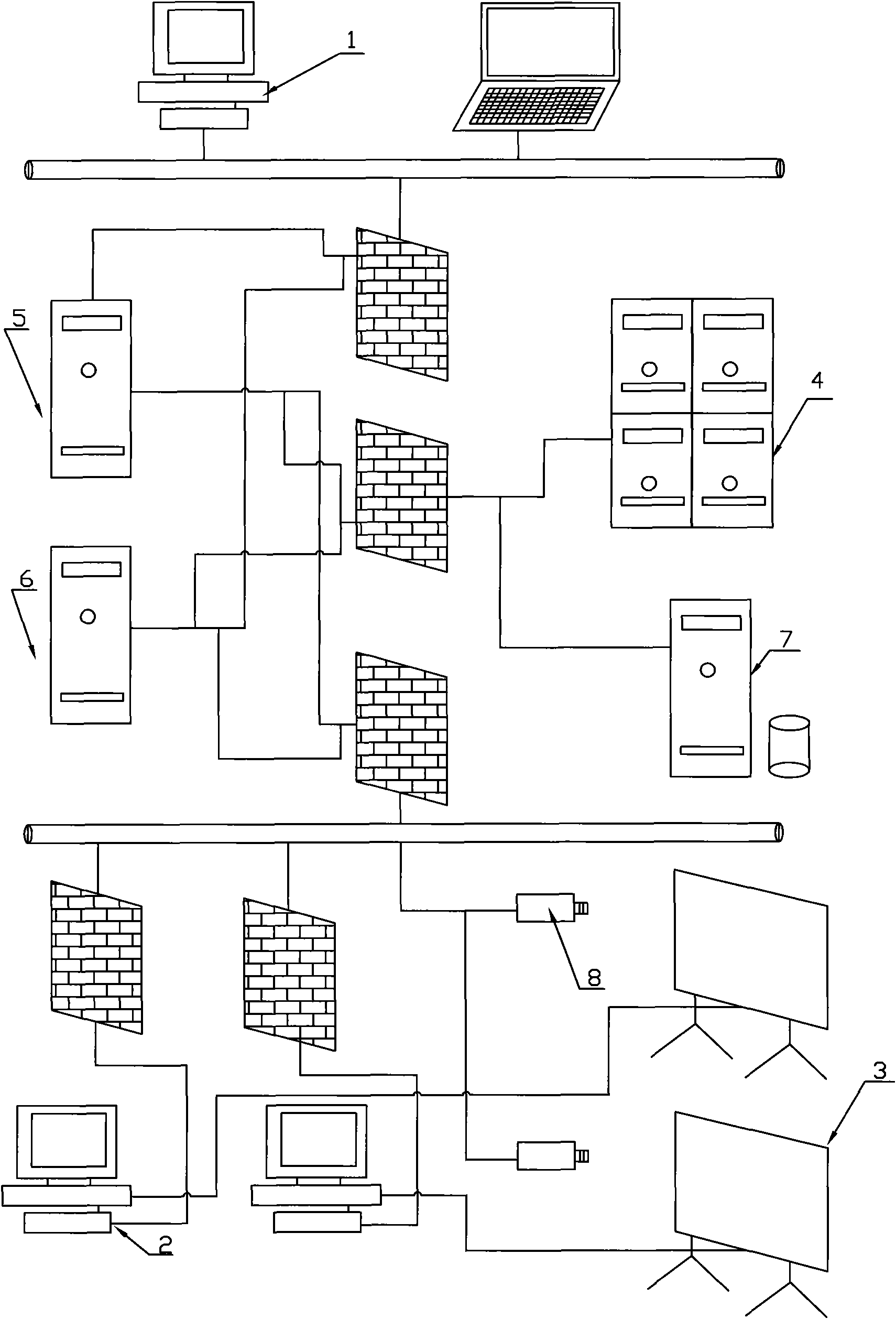

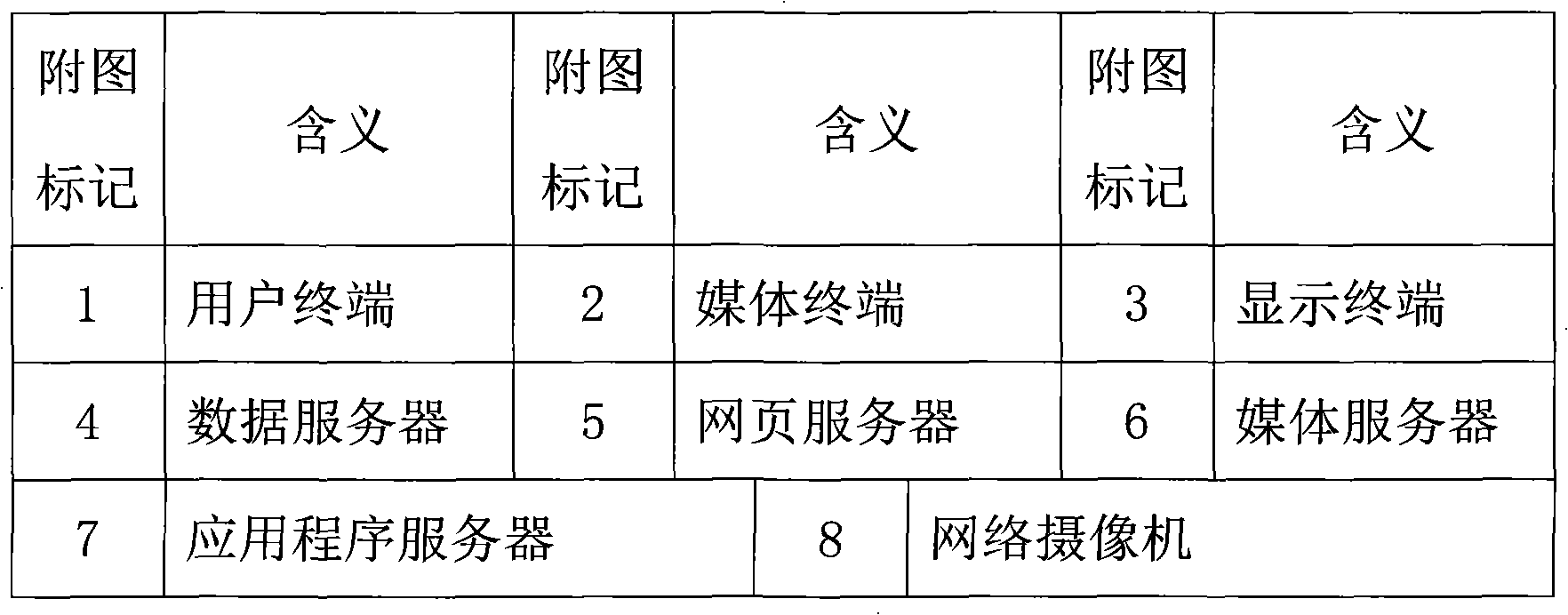

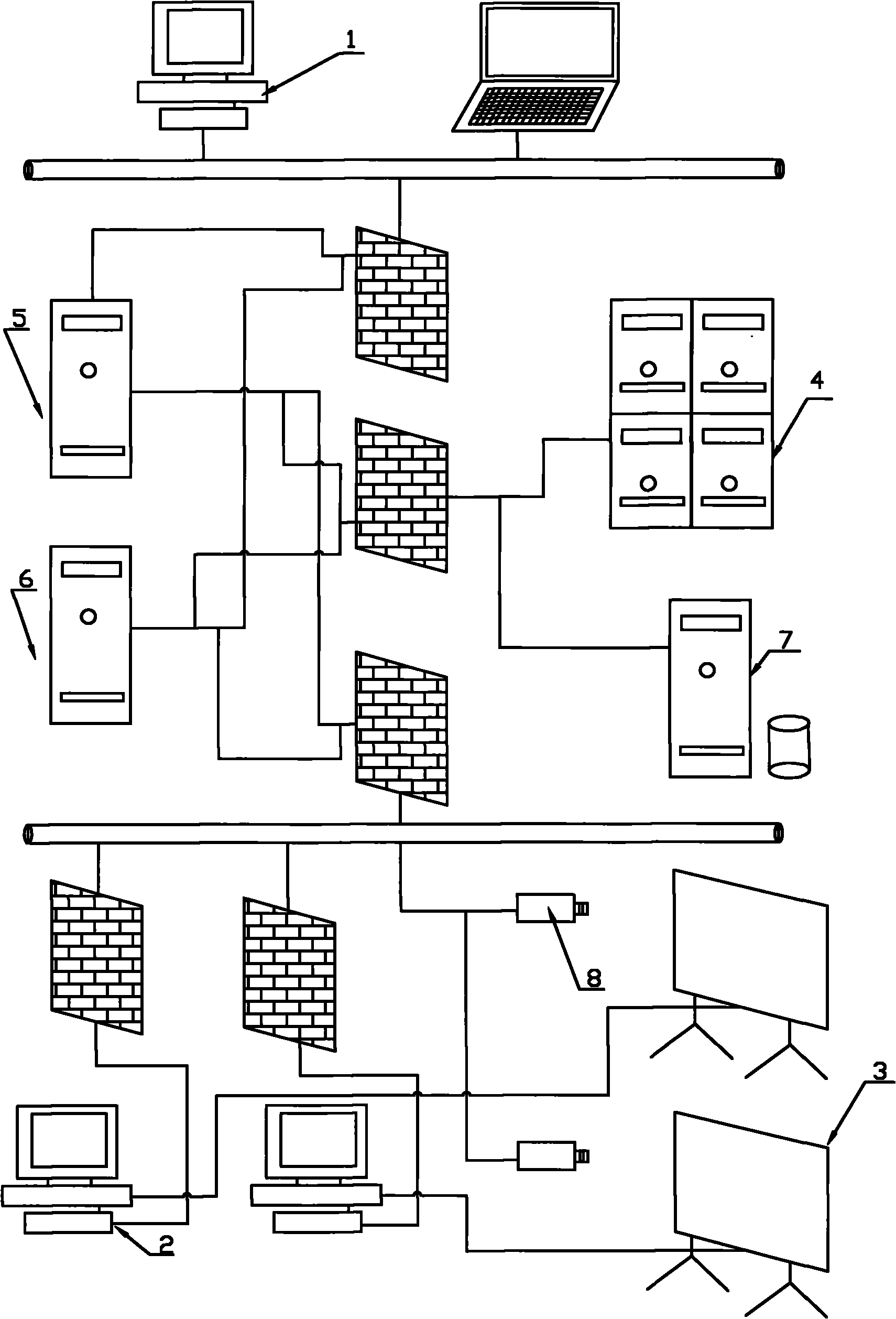

Remote information issuing and monitoring system based on wide area network and control method thereof

ActiveCN101888409AImprove technical effectOvercome the conditions of the harsh natural environmentClosed circuit television systemsTransmissionMonitoring siteGraphics

The invention provides a remote information issuing and monitoring system based on a wide area network and a control method thereof. As the wide area network remotely controls (a local area network or the wide area network) to issue caution, publicity, rebroadcasting and other information, such as display text, characters and graphics, video, and the like according to user instructions, the system can realize that remote broadcasting control, field monitoring and playing content feedback are carried out on a display screen at any online websites, can provide real-time display situations of all websites for user viewing; and the invention greatly reduces the manufacturing, operation and maintenance cost of system hardware, has simple management and convenient use, is a new-generation LED networking multimedia control playing system management tool and can be widely applied to display and issue various media information at the real time.

Owner:JIANGSU HANDSON INTELLIGENT TECH CO LTD

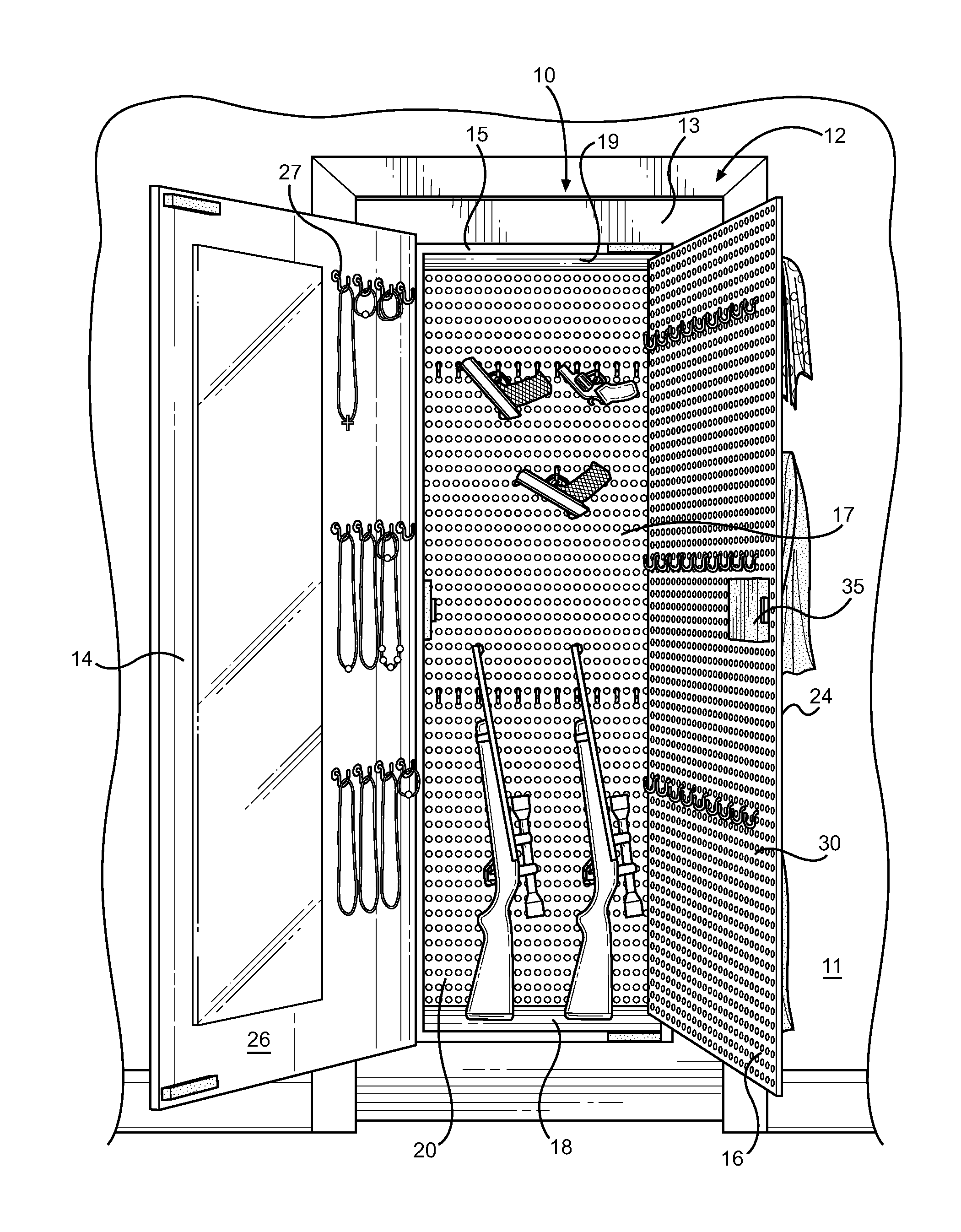

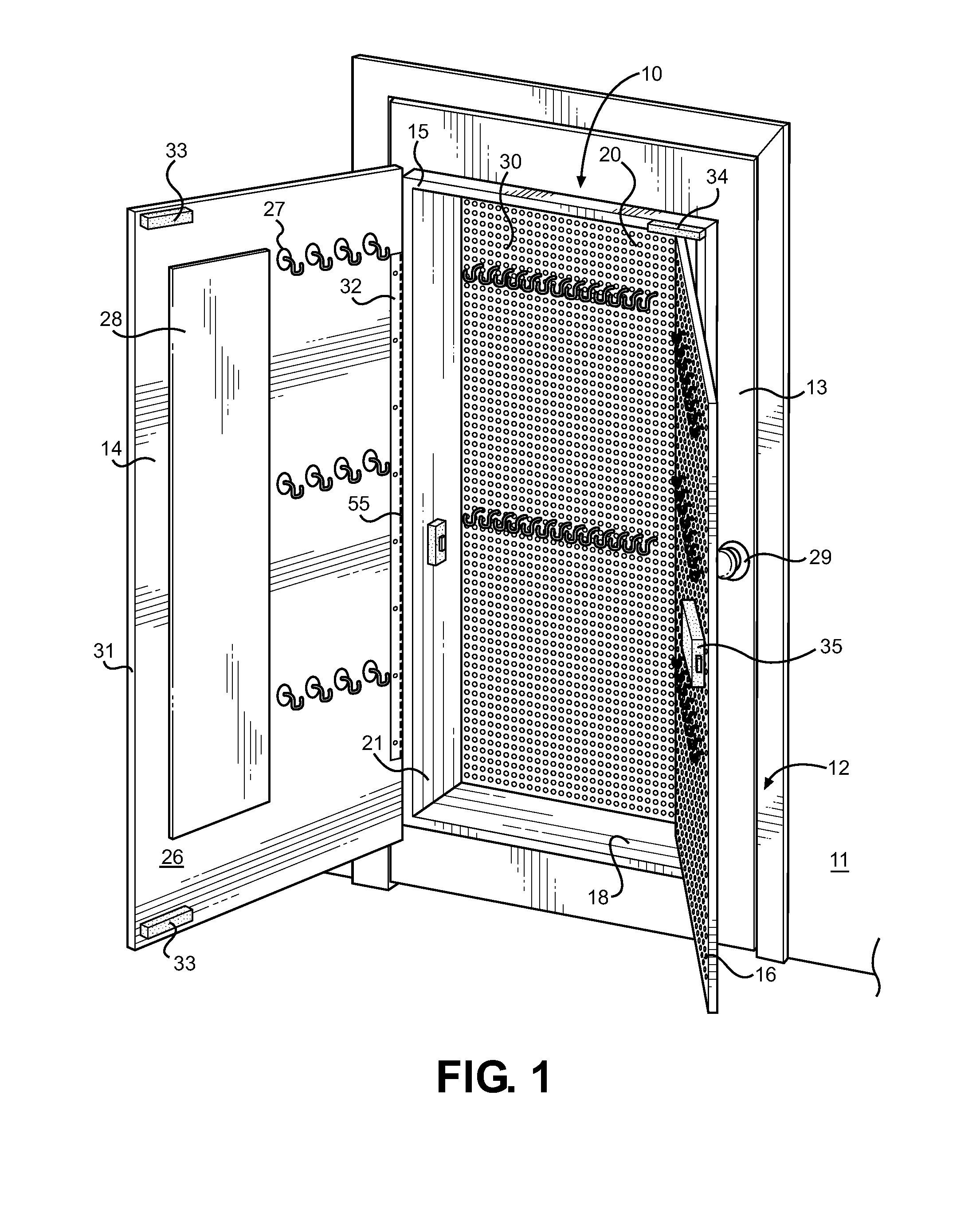

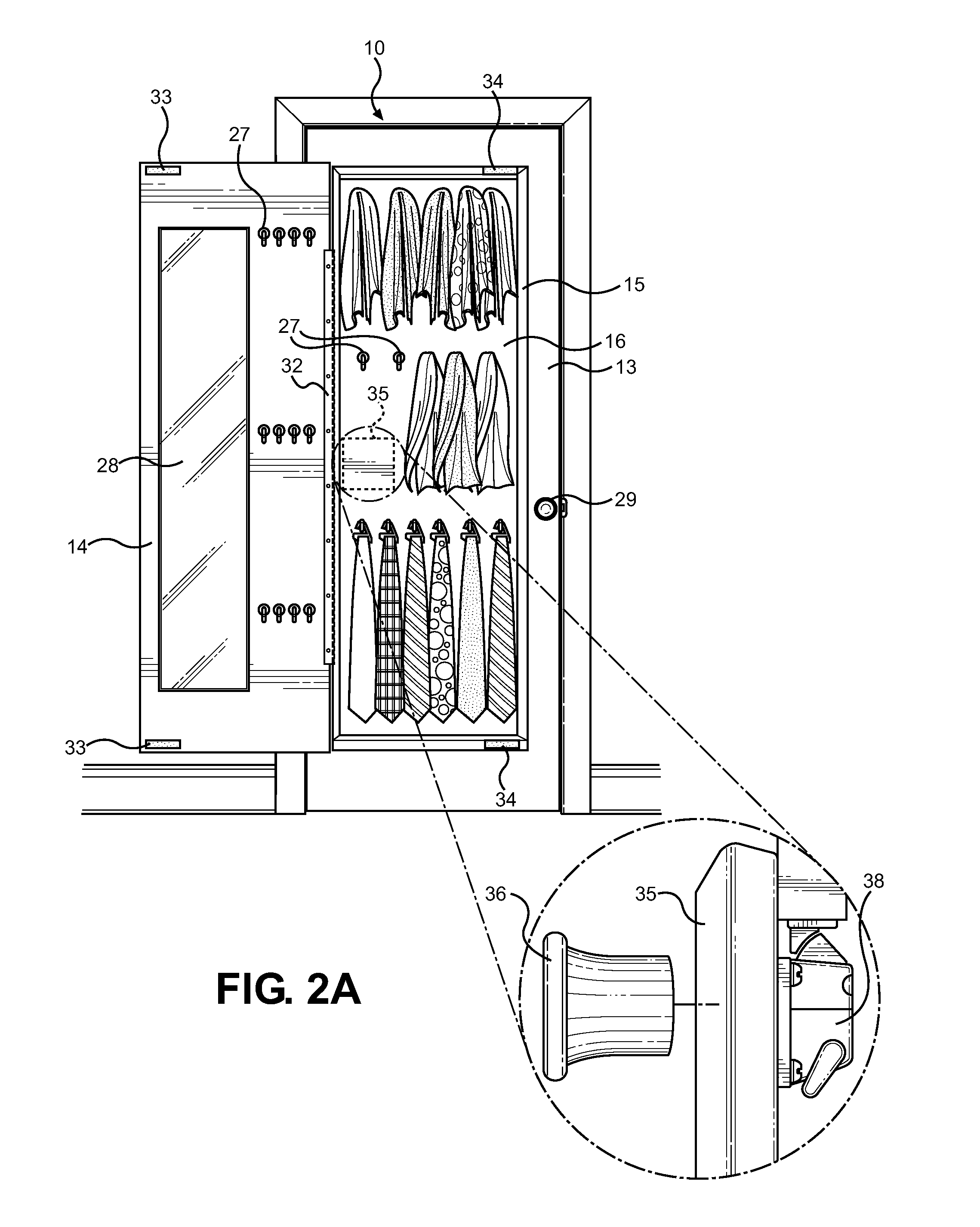

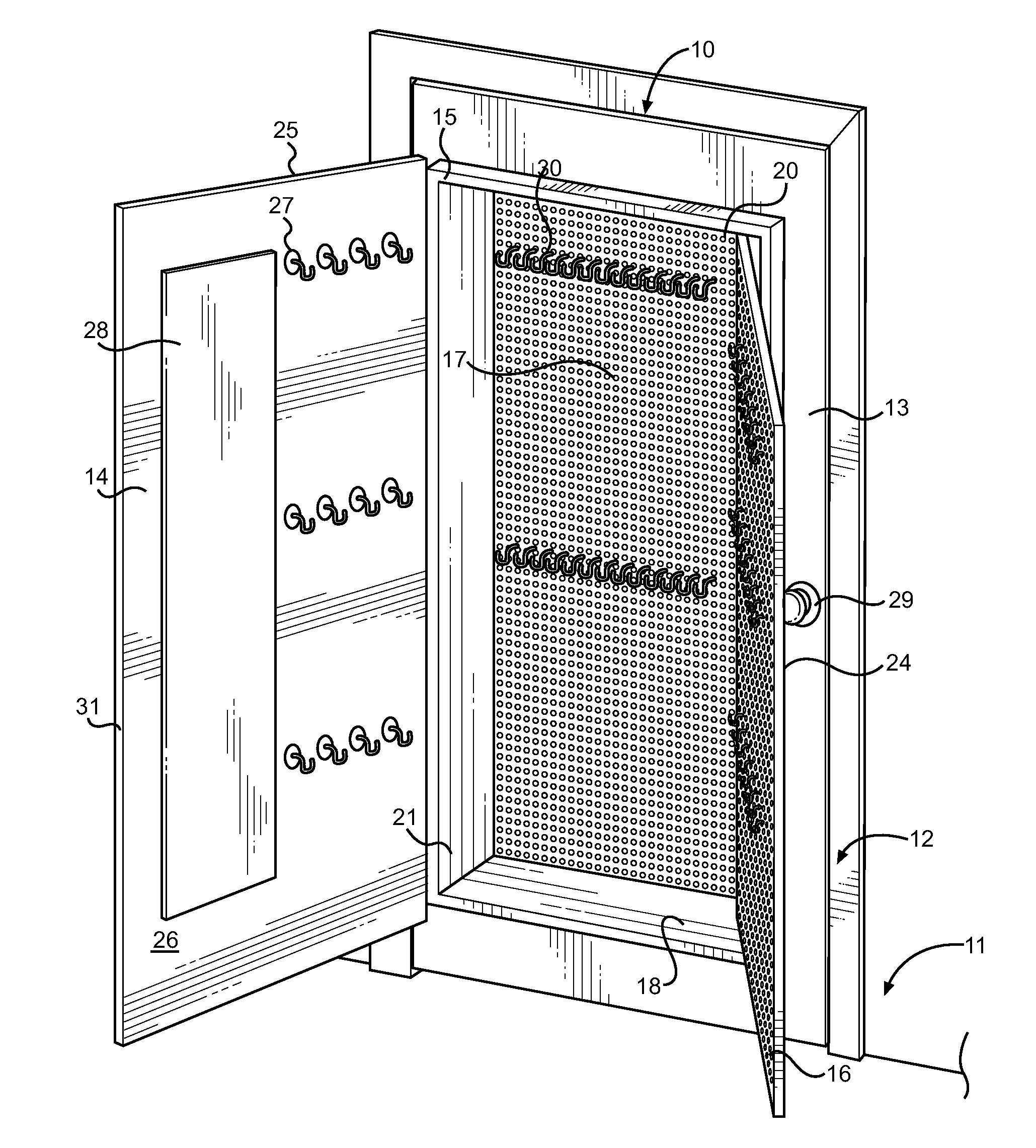

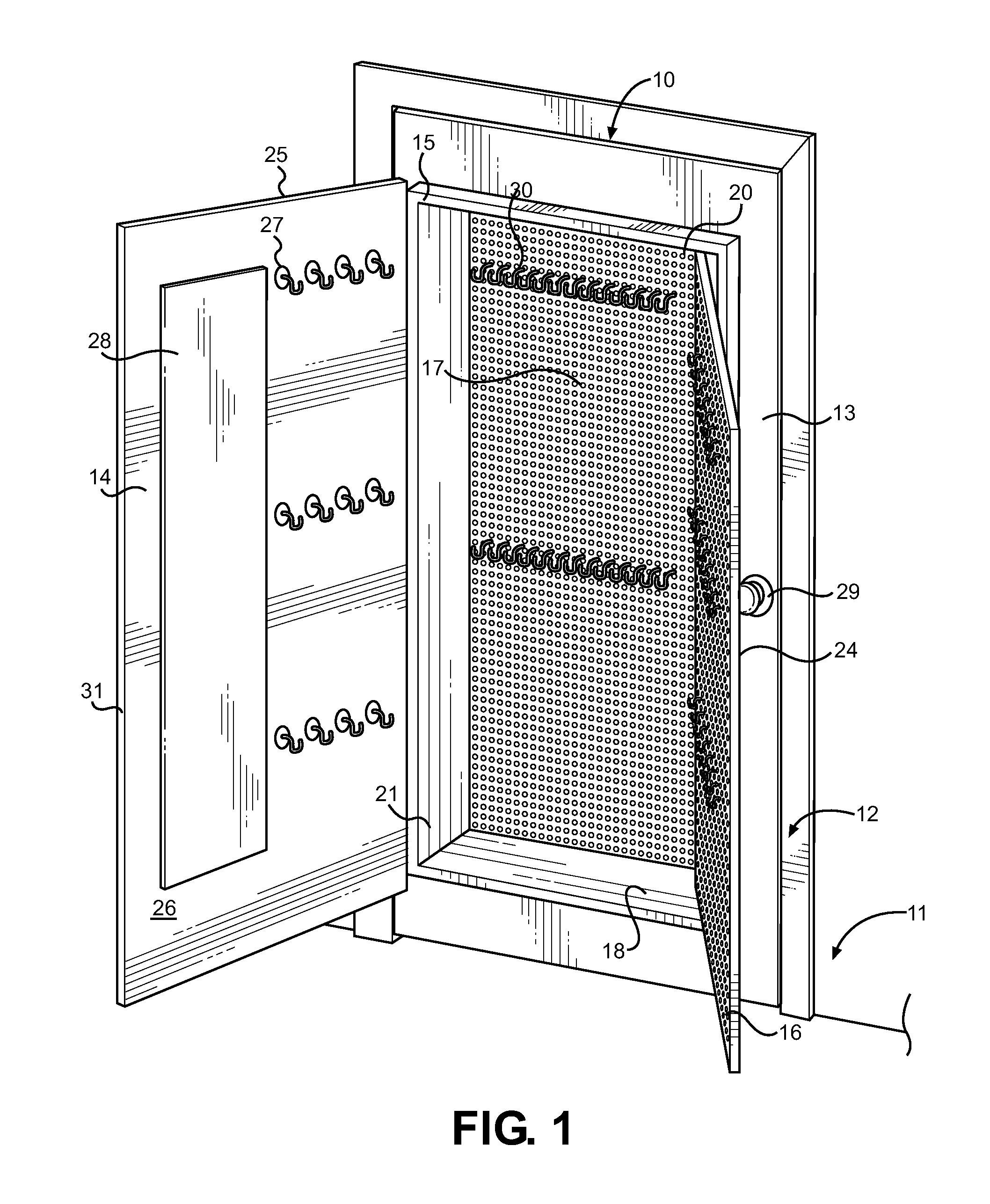

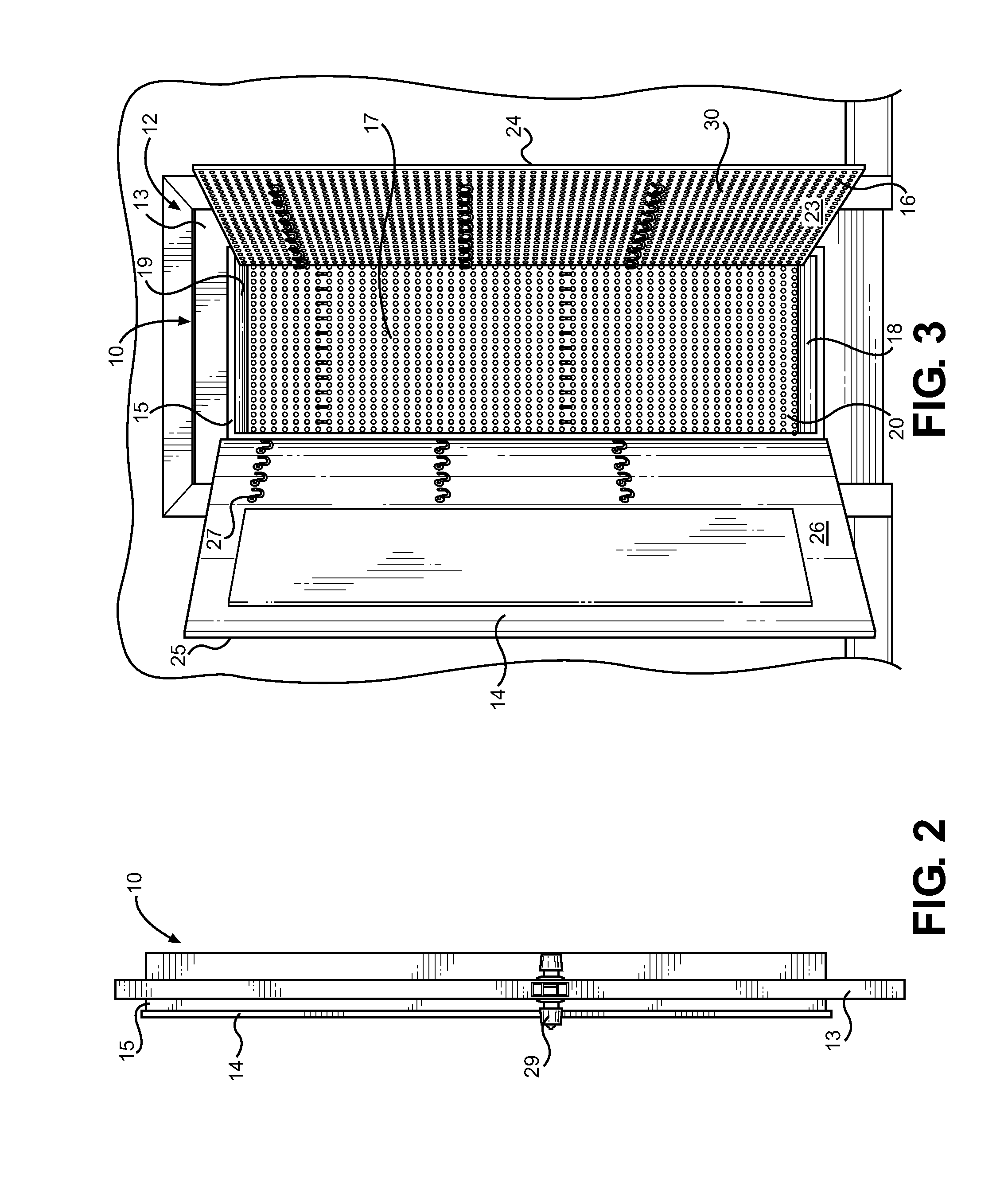

Fashion Accessory Internal Door Storage Cavity

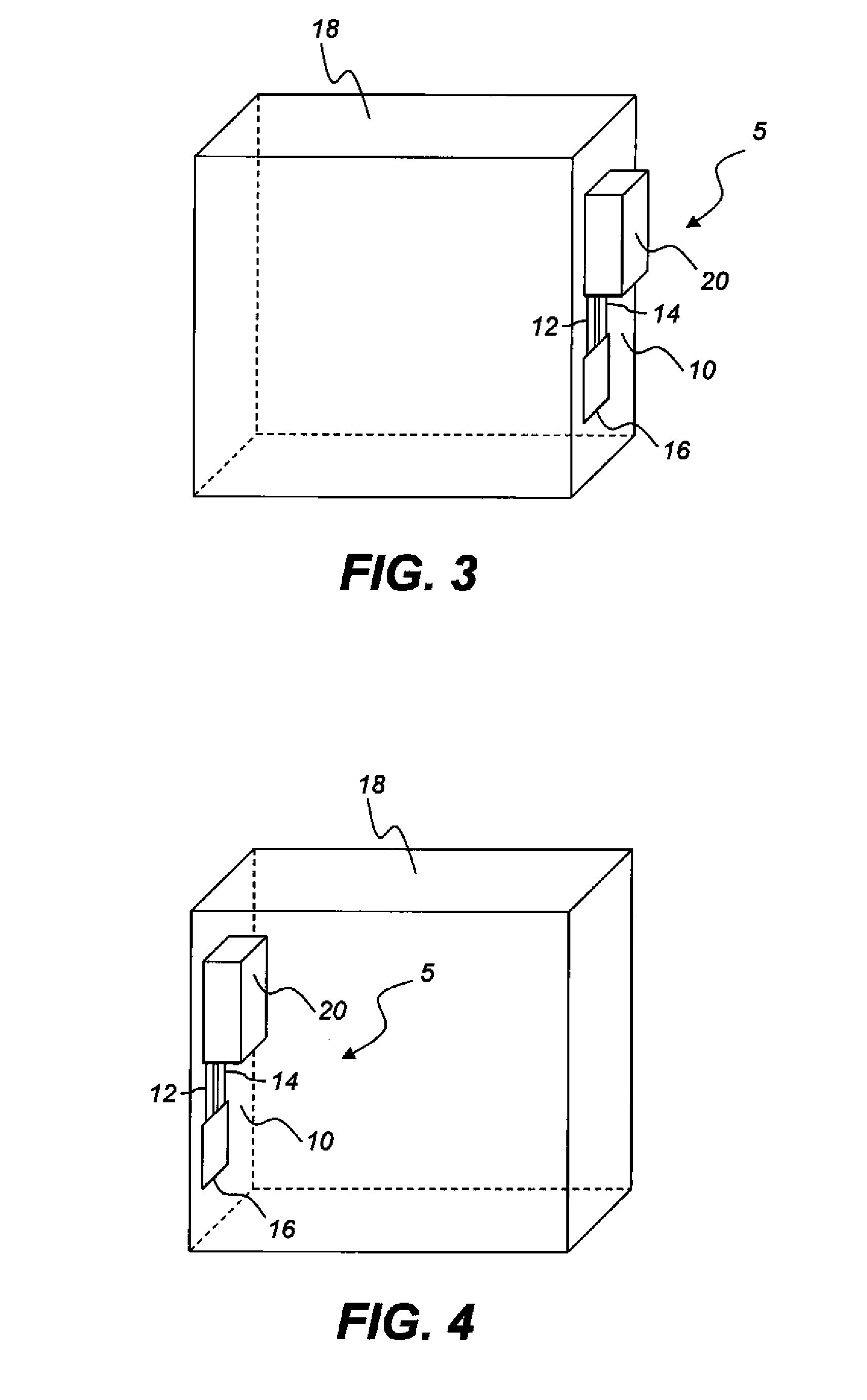

InactiveUS20140132131A1Minimizing utilized floor spaceReduce the space requiredBuilding locksOther accessoriesLocking mechanismEngineering

A storage device mounted within a door frame is disclosed for storage and organization of fashion accessories or similar articles is provided. The device comprises an outer door supported by the door frame, an interior door enclosing a hollow door interior for storage of articles, and at least one interior panel within the hollow door interior to separate an interior cavity therein and limit access thereto via a hidden locking mechanism. The interior panel provides separation of the internal cavity from the hollow door interior, increases surface area of the hollow door interior, and segregates a hidden interior cavity therein. The back wall of the interior cavity also provides a location for further hooks and shelving for storage. The device may be provided within the interior of a larger door, or as a door insert adapted to be incorporated into an existing door.

Owner:THOMAS VICKY RENEE

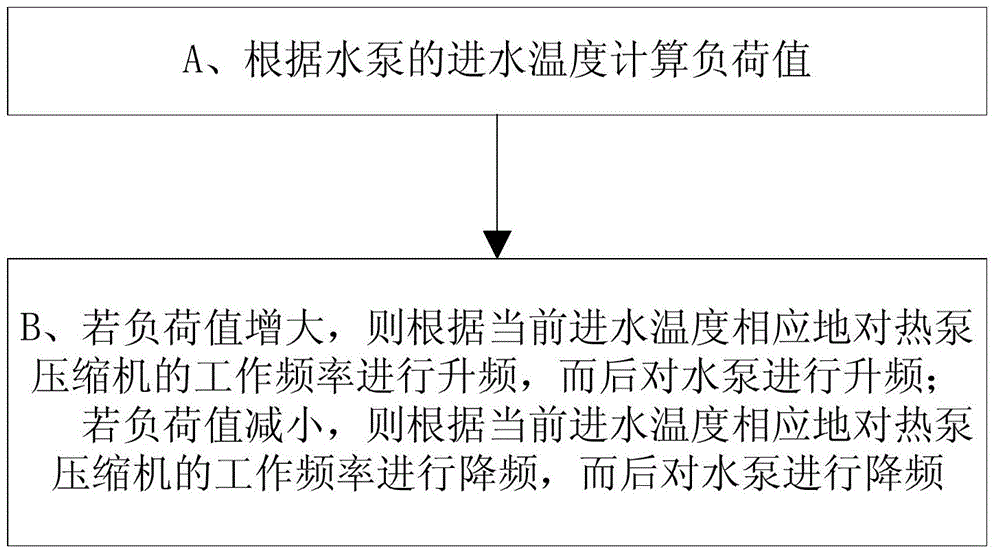

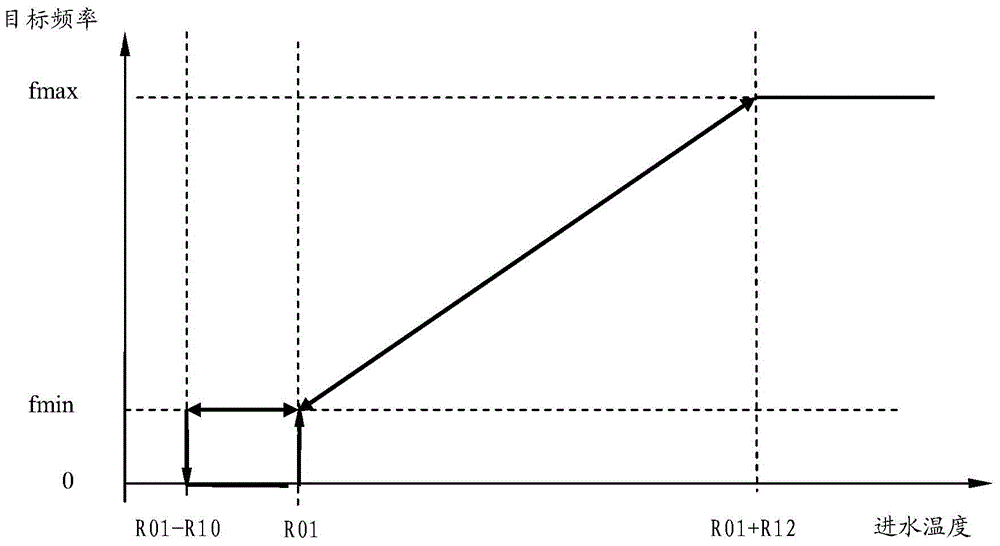

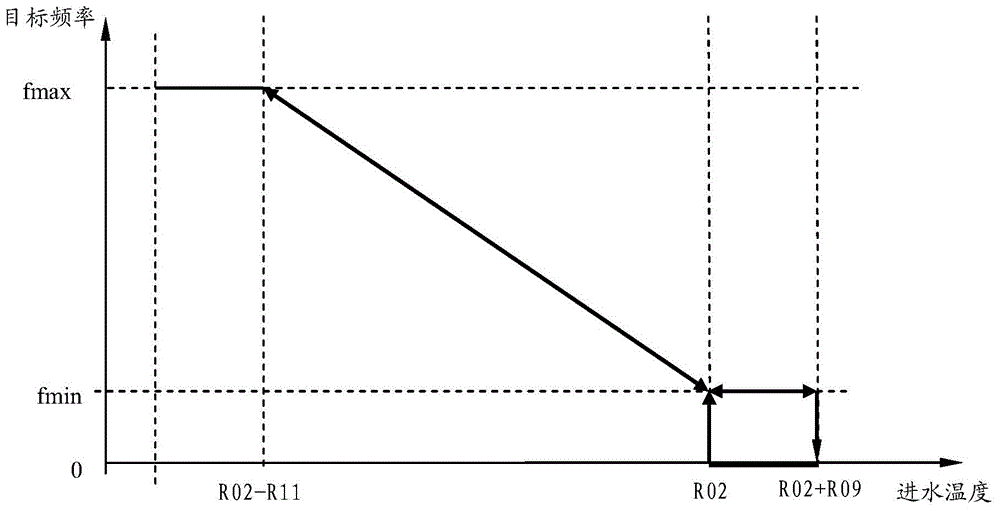

Frequency conversion control method

ActiveCN104457073AReduce investmentGood safe operationRefrigeration safety arrangementInlet temperatureFrequency conversion

The invention discloses a frequency conversion control method. The method includes the following steps that A, the load value is calculated according to the water inlet temperature of a water pump; B, if the load value increases, the working frequency of a heat pump compressor is increased according to the current water inlet temperature, and if the load value decreases, the working frequency of the heat pump compressor is decreased according to the current water inlet temperature and then the frequency of the water pump is decreased. According to the method, heat balance is achieved through the frequency conversion technology during load fluctuation, change situations of heating / refrigerating loads of a current room are judged according to water inlet temperature changes, the compressor and the water pump are controlled for frequency conversion to output proper capacity and water flow rate so that the requirement of current temperature compensation can be met, input of an energy storage water tank is effectively reduced, efficient and safe operation of a unit is guaranteed, and cost and use space are reduced. The frequency conversion control method can be widely applied to the field of heat pumps.

Owner:GUANGDONG PHNIX ECO ENERGY SOLUTION

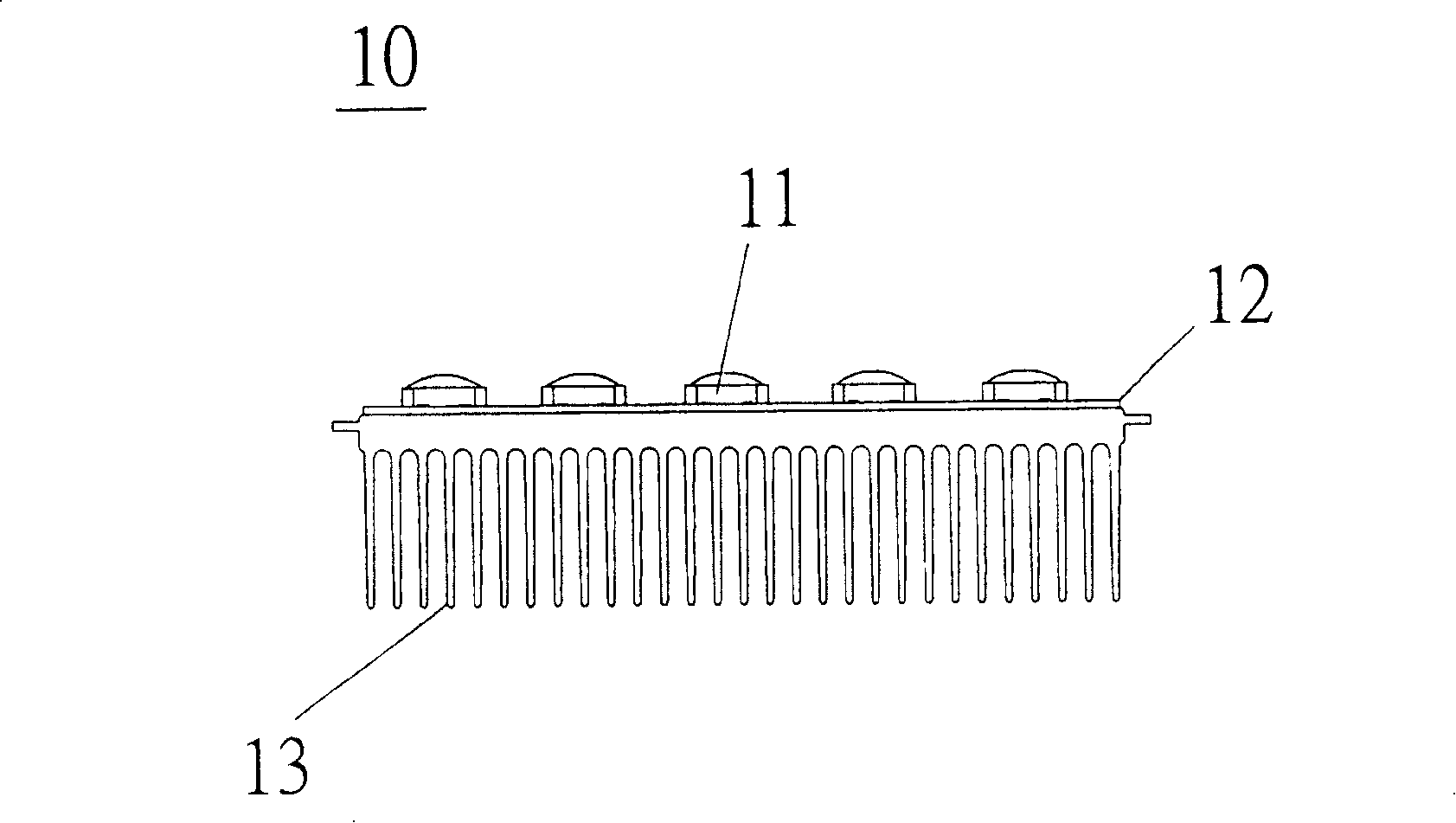

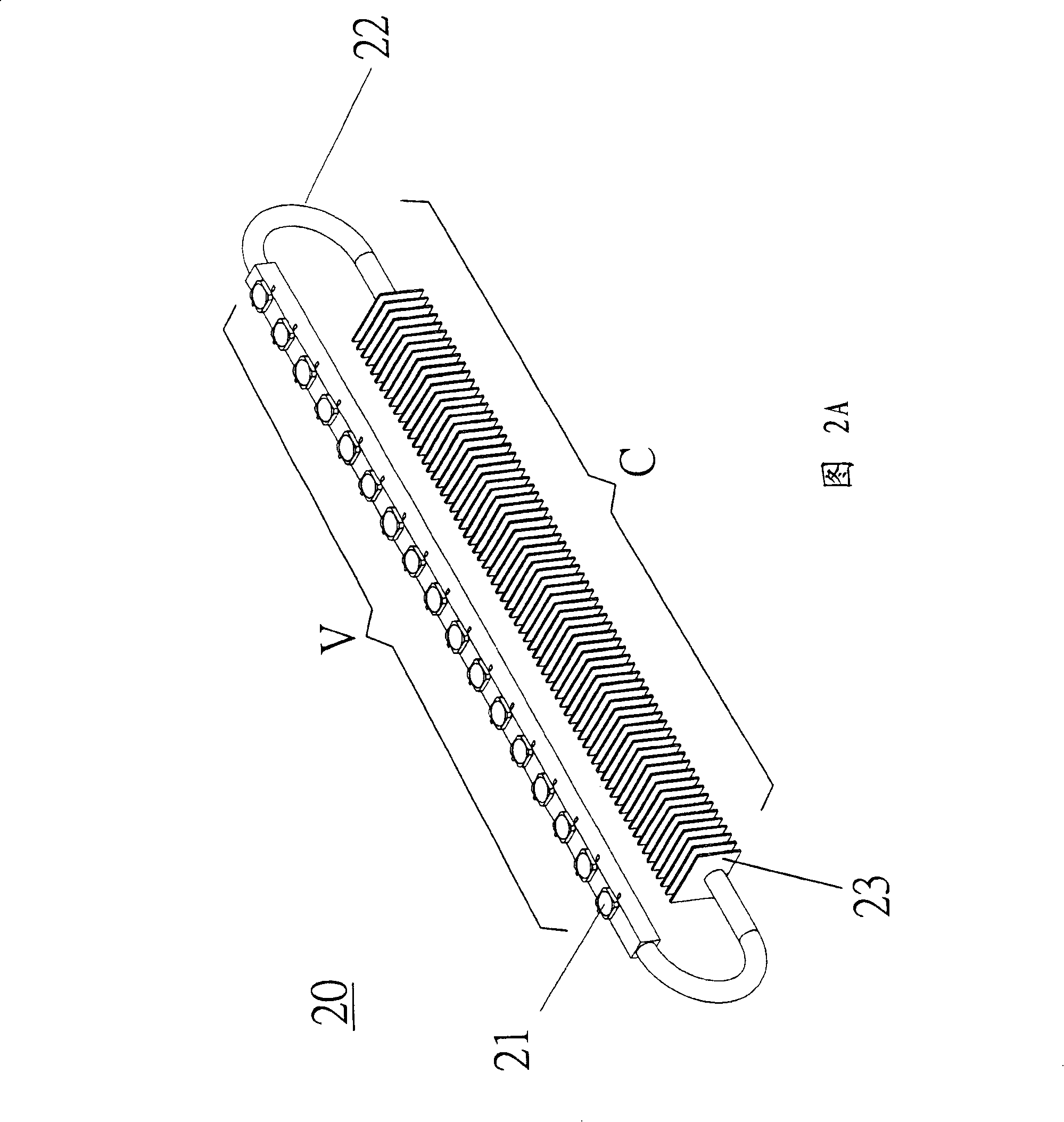

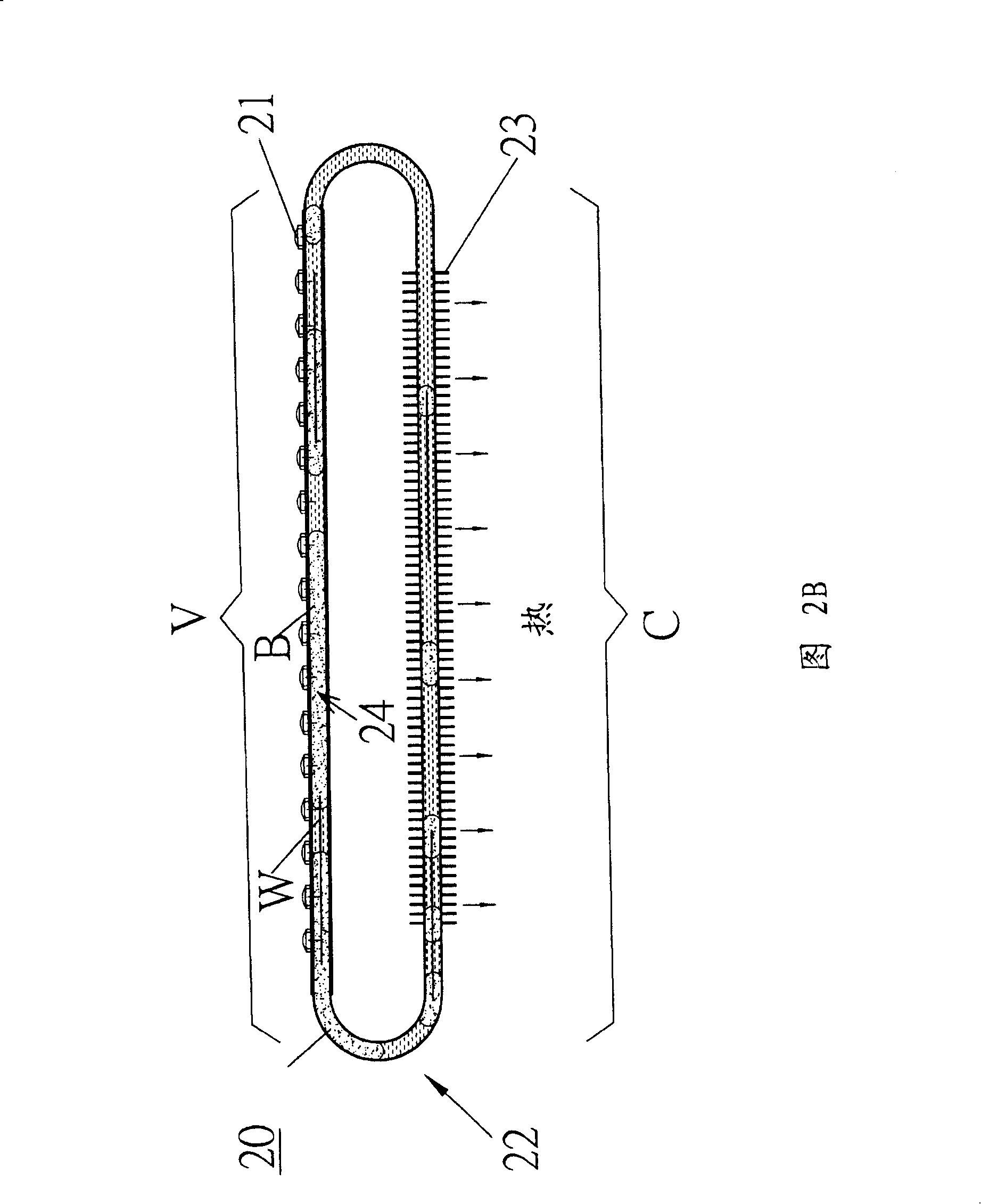

Light emitting diode radiating module and applied display apparatus

InactiveCN101207112AGuaranteed functionMaintain reliabilitySemiconductor/solid-state device detailsLighting heating/cooling arrangementsDisplay deviceLight-emitting diode

The invention relates to a display device, which comprises a casing, a displaying panel, and a plurality of light emitting diode radiating modules. The displaying panel and the casing are mutually combined, the light emitting diode radiating modules are all arranged in the casing, each light emitting diode radiating module comprises a pulse type heat pipe, a plurality of light emitting diodes, and a plurality of radiating fins, and the required light source of the displaying panel is provided by the light emitting diodes. The pulse type heat pipe has an evaporating end and an opposite condensing end, a plurality of the light emitting diodes are separately arranged on the pulse type heat pipe, and the light emitting diodes are all positioned at the evaporating end. The heat radiating fins are connected with the pulse type heat pipe, and the radiating fins are all positioned at the condensing end.

Owner:DELTA ELECTRONICS INC

Fashion Accessory Internal Door Storage Cavity

InactiveUS20120223626A1Minimizing utilized floor spaceReduce the space requiredChestsDressing tablesEngineeringElectrical and Electronics engineering

A storage device mounted within a door frame is disclosed for storage and organization of fashion accessories or similar articles. The device comprises a door having an internal cutout, wherein an internal cavity is provided for storage of articles in a condensed space, which can be accessed via a second, cutout door. A full length mirror is mounted to the interior of the second door along with peg board to allow attachment of accessory hooks for hanging items. One or more hinged panels inside of the interior cavity provide separation of the internal cavity and increased surface area to allow attachment of additional hooks or attachment means. The back wall of the interior cavity also provides a location for further hooks and shelving for storage. The device may be provided within the interior of a larger door, or as a door insert adapted to be incorporated into an existing door.

Owner:THOMAS VICKY

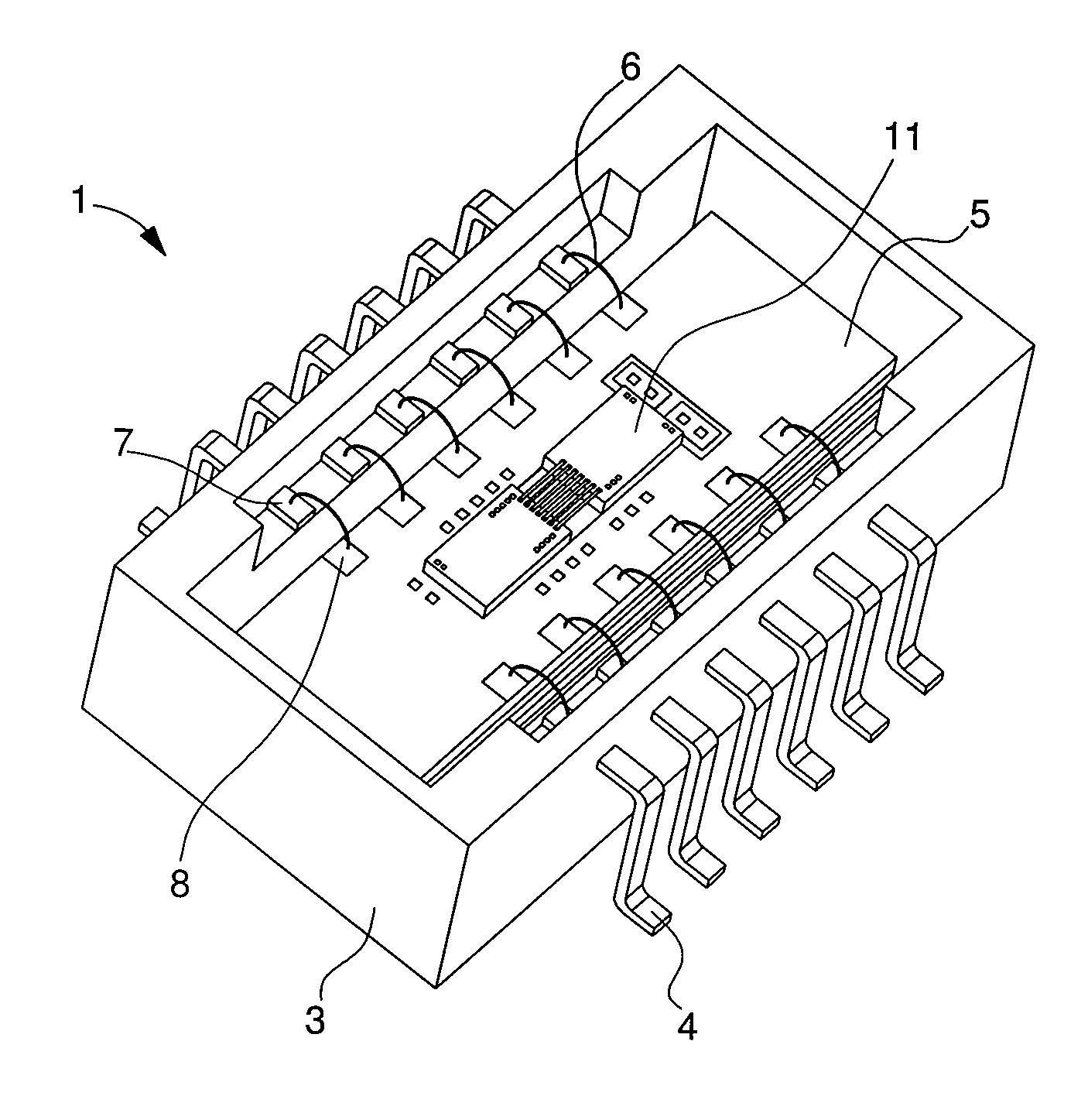

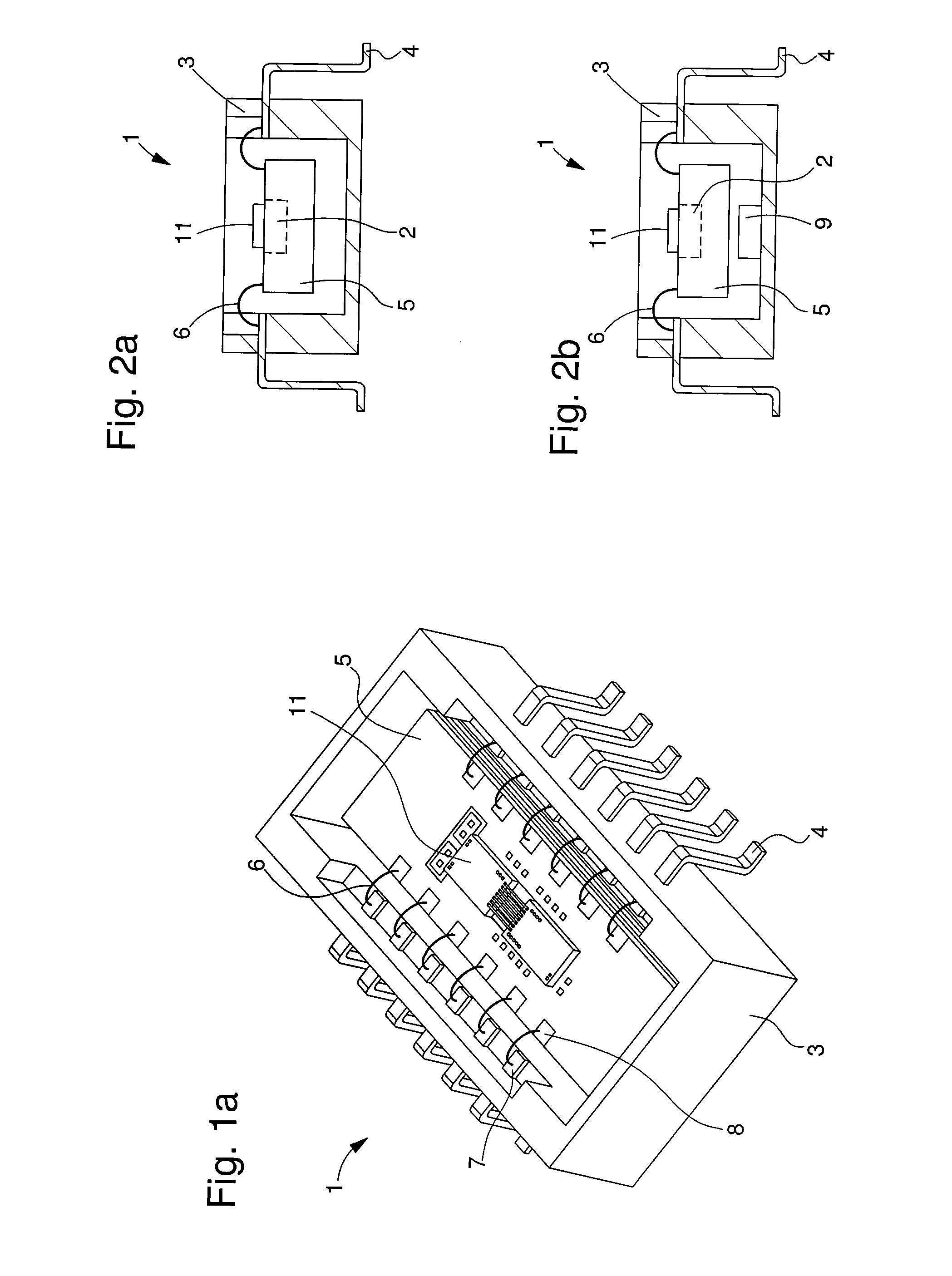

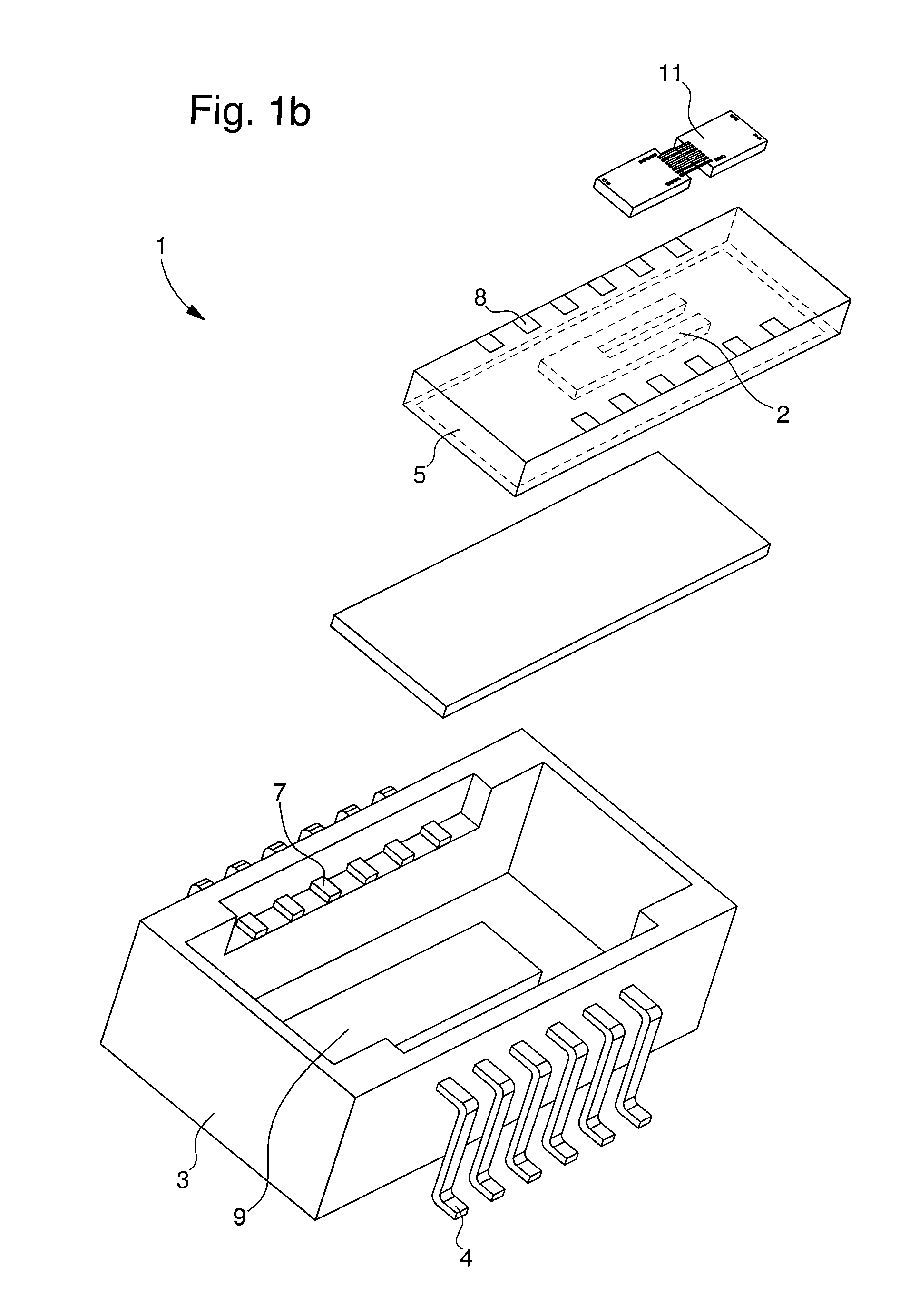

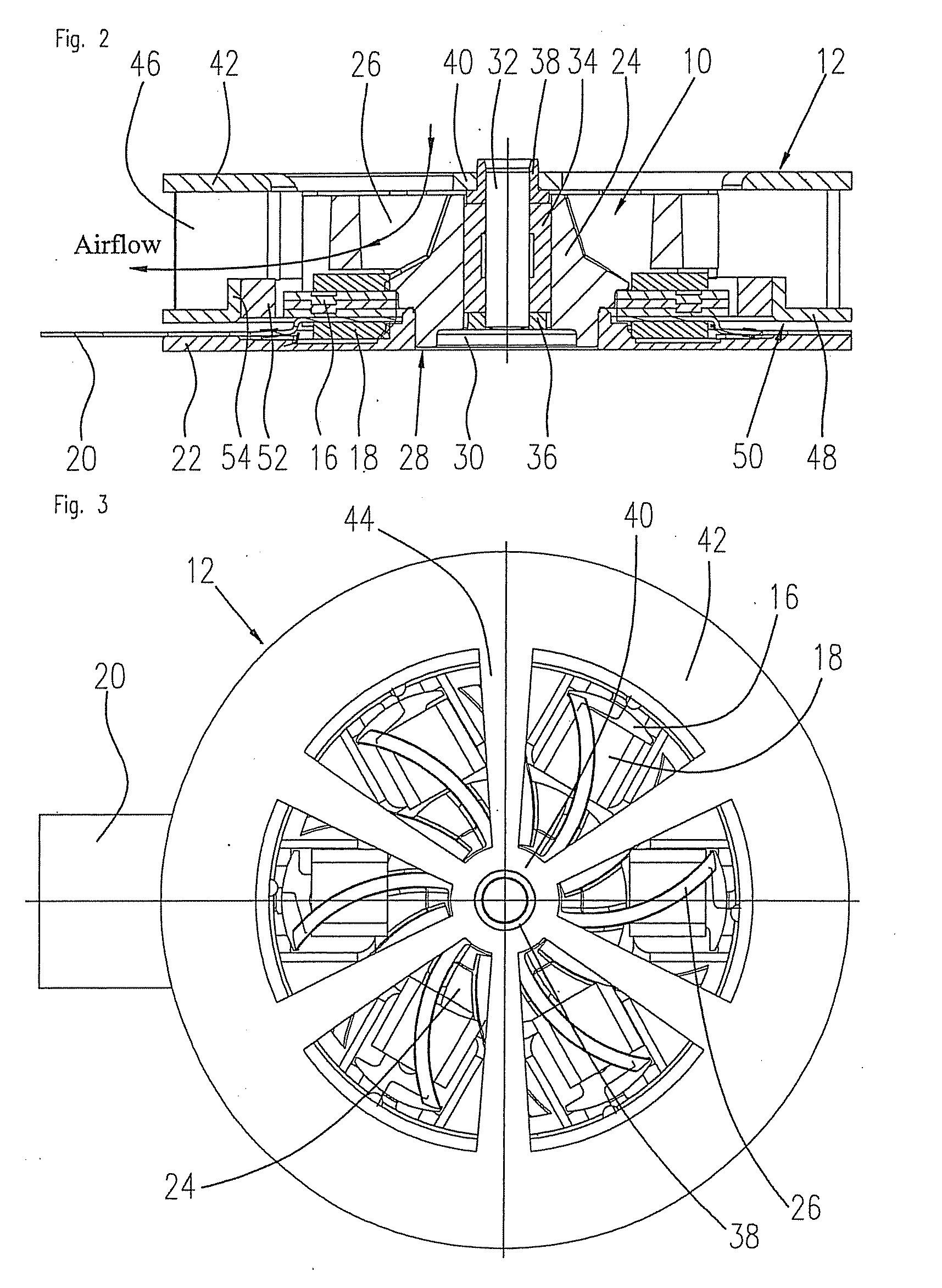

Device for assembling an electronic component

InactiveUS20090260226A1Reduce complexityReduce the space requiredMeasurement apparatus componentsImpedence networksElectricityContact pad

The invention concerns a device (1) for assembling an electronic component (2) including an outer case (3). This case is for connection to an external electric circuit via contact means (4) and is arranged for containing a support (5), to which the electronic component (2) is secured. The support is arranged for connection to the contact means of the outer case via at least one contact pad (8) placed on the support. The contact pad enables the electronic component secured to the support to be electrically connected to the contact means of the outer case via connecting means (6). In particular, the connecting means and the electronic component support are arranged such that the support is suspended by the connecting means so that the support remains mobile.

Owner:MICROCOMPONENTS AG

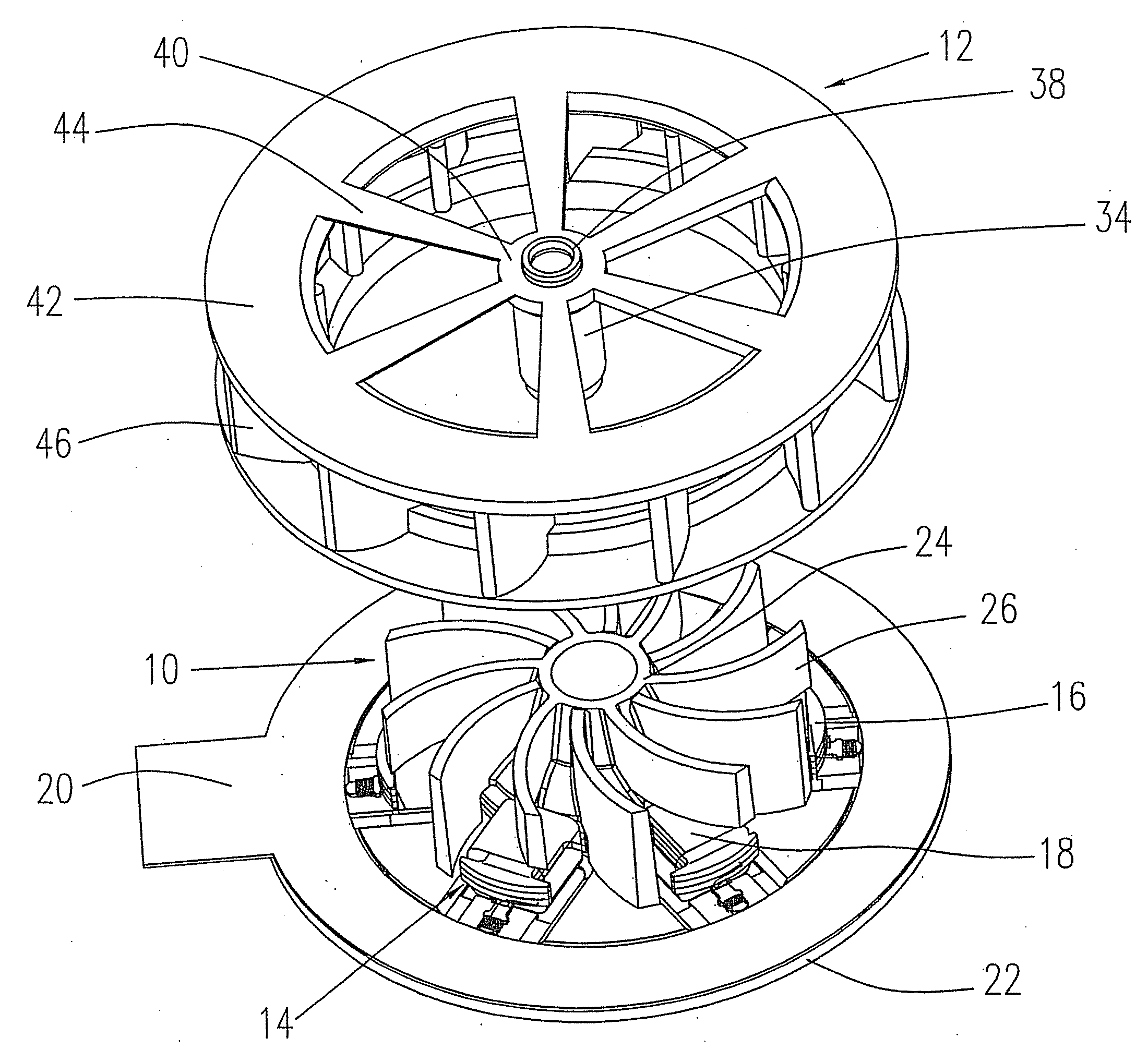

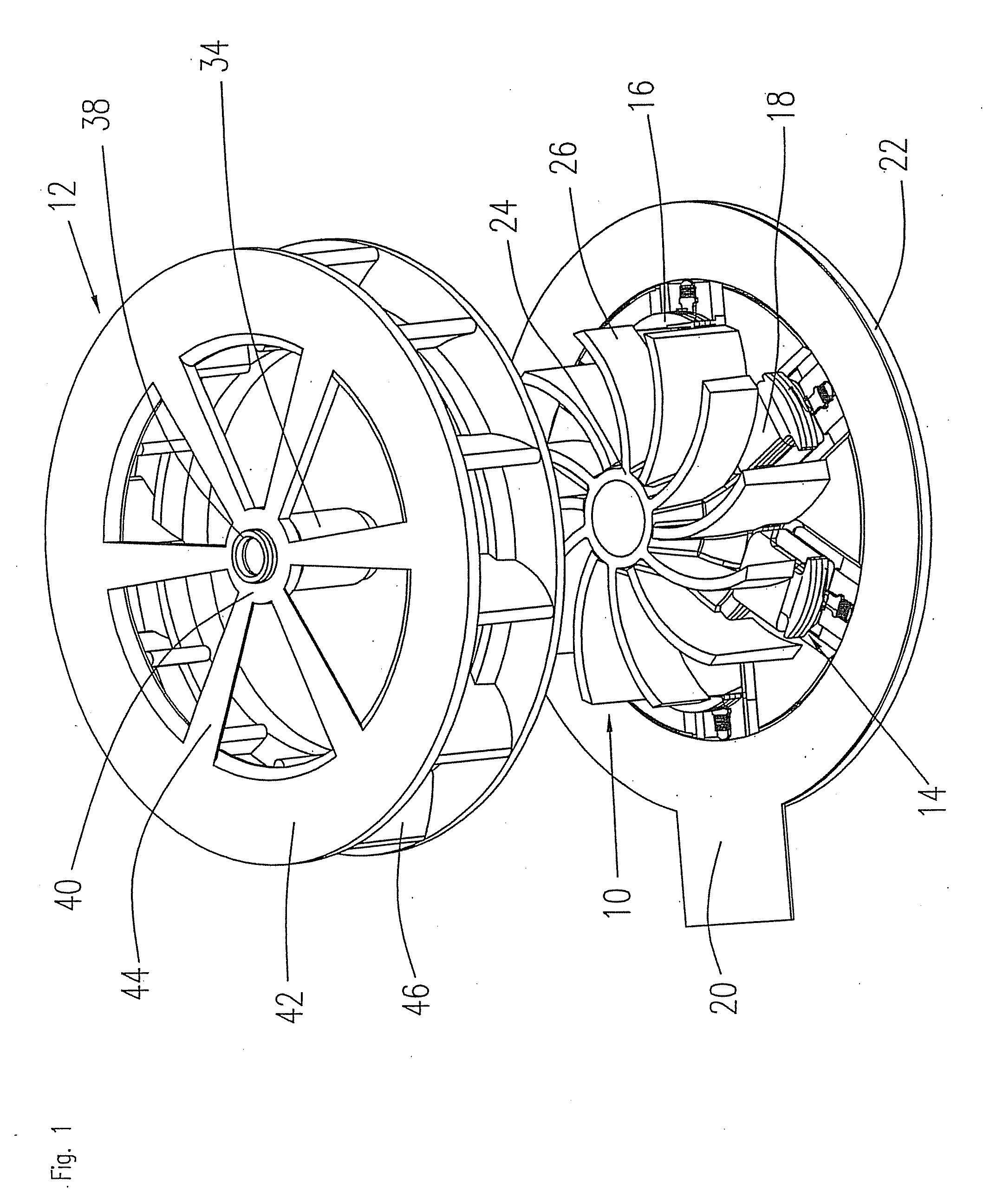

Cooling apparatus for an electronic device to be cooled

ActiveUS20080175730A1Increase airflowVolume maximizationPump componentsCooling/ventillation arrangementImpellerSpecial design

The invention relates to a cooling apparatus for an electric component such as a CPU, a memory or power semiconductor, such as transistors or LEDs, or a processor. The cooling apparatus comprises a heatsink, an impeller that coaxially encloses the heatsink, anda drive motor for the impeller. The heatsink takes the form of a stationary hub having a base for introducing heat from the electronic component that is to be cooled, the hub widening towards the base. Cooling fins are thermally coupled to the hub, the cooling fins being given a spiral-like curve similar to the blades of the impeller. Due to the special design of the hub and the cooling fins as well as the use of a radial flux motor, a highly efficient, particularly compact cooling apparatus can be realized.

Owner:MINEBEAMITSUMI INC

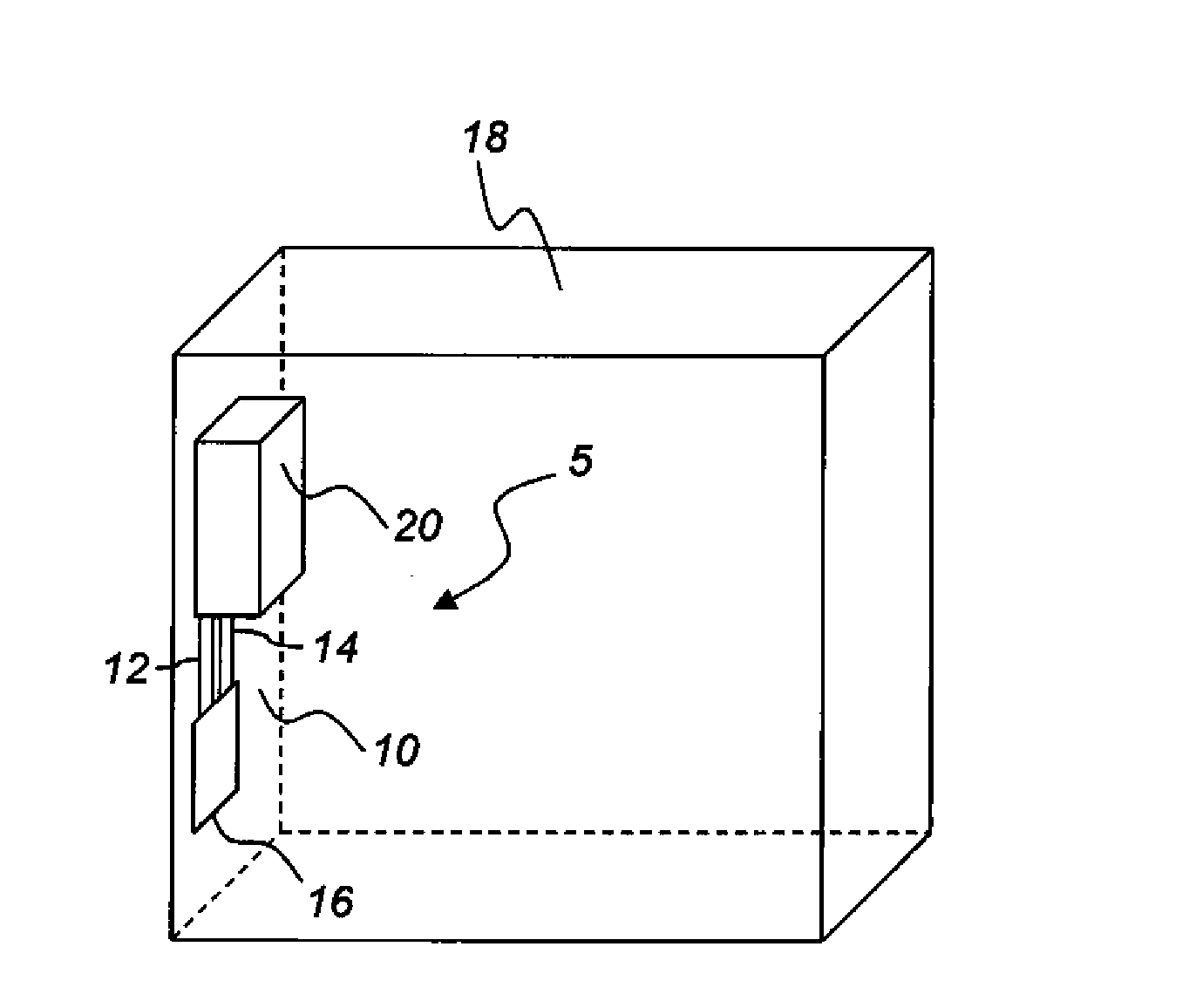

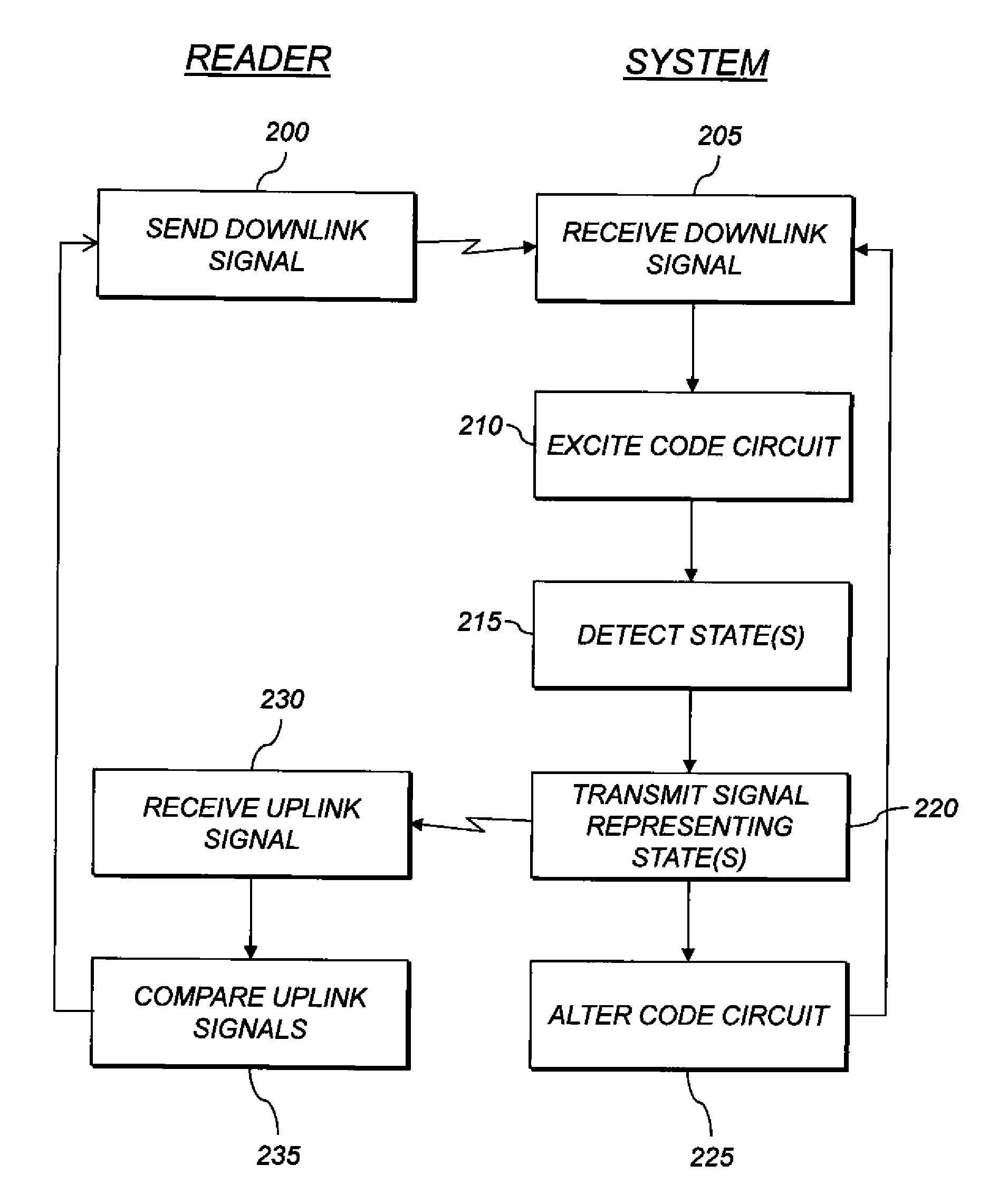

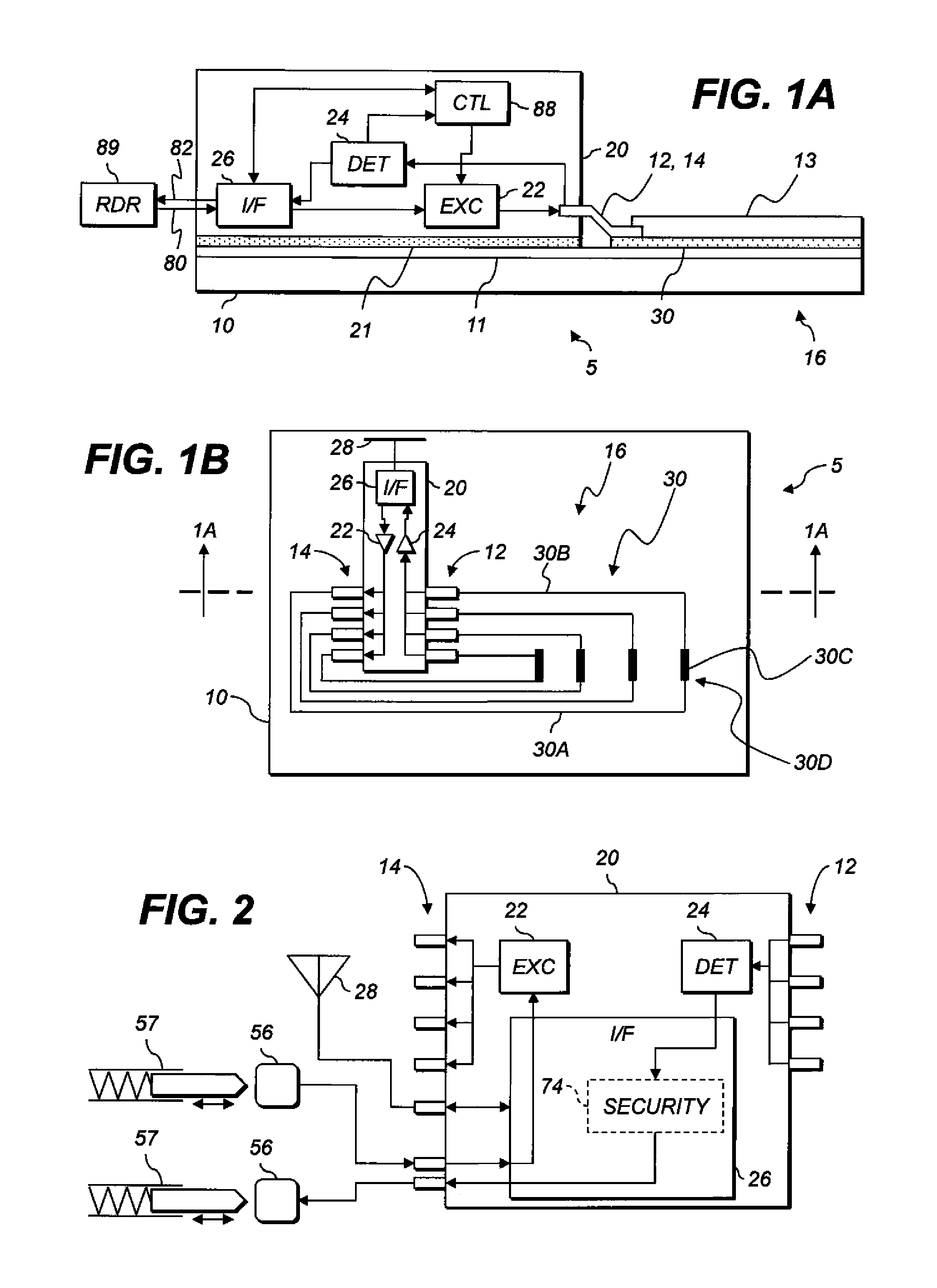

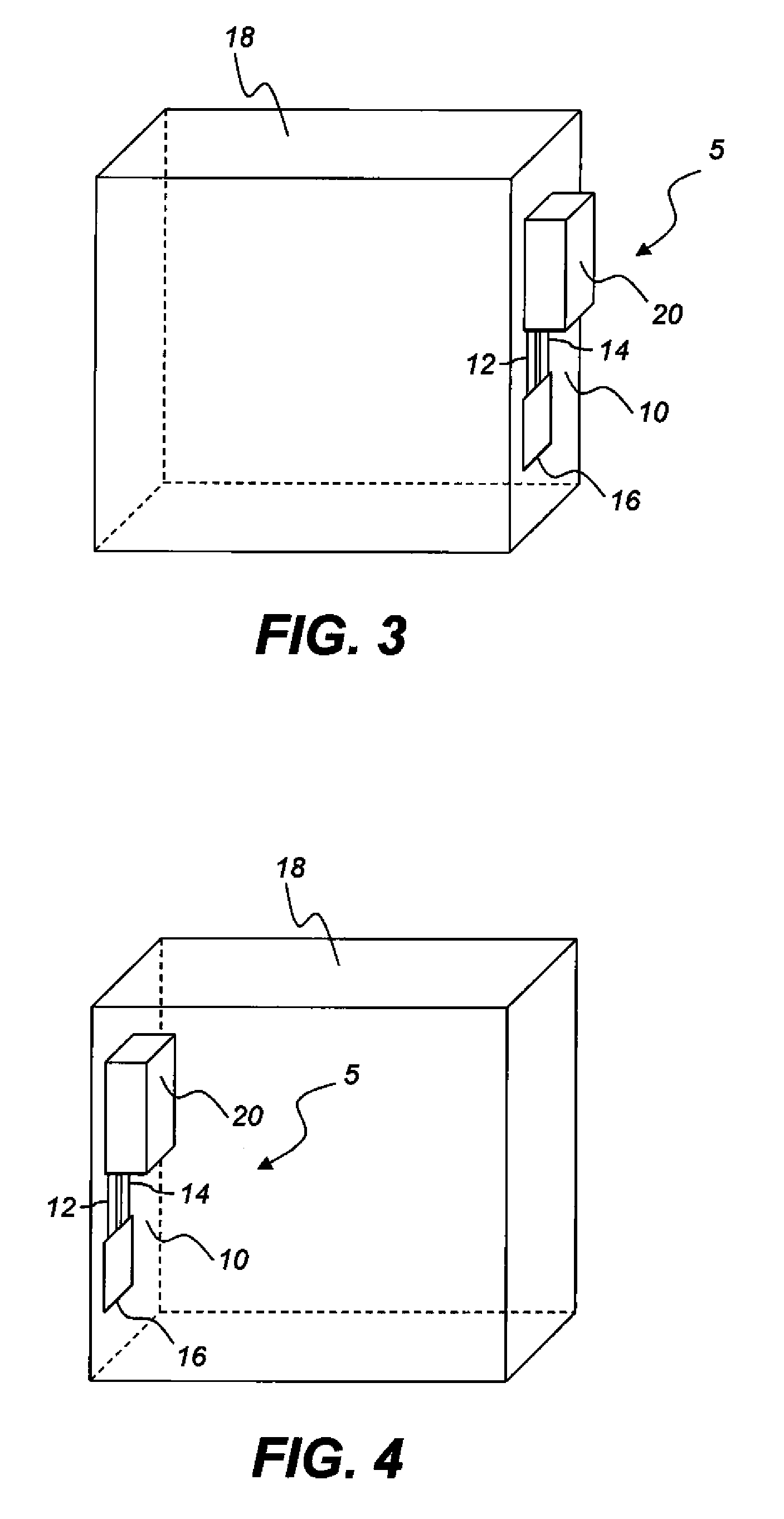

Electronic storage system with environmentally-alterable conductor

InactiveUS20130284812A1Lower-cost equipmentLow costRecord carriers used with machinesElectricityElectrical conductor

An electronic storage system includes a substrate with a detection region, a transceiver having an interface, and a code circuit separate from the transceiver and disposed over the substrate. The transceiver has an output electrical-connection pad, an excitation circuit that provides an excitation signal to the output pad, an input electrical-connection pad, and a detection circuit connected to the input pad. The code circuit connects the output pad to the input pad and includes a conductor having an electrical state and located in the detection region. The detection circuit thus detects an electrical state of the input pad in response to the excitation signal and the electrical state of the conductor. The interface is responsive to a downlink signal to transmit an uplink signal representing the electrical state of the input pad. The conductor in the detection region is adapted to change electrical state in response to an environmental factor.

Owner:EASTMAN KODAK CO

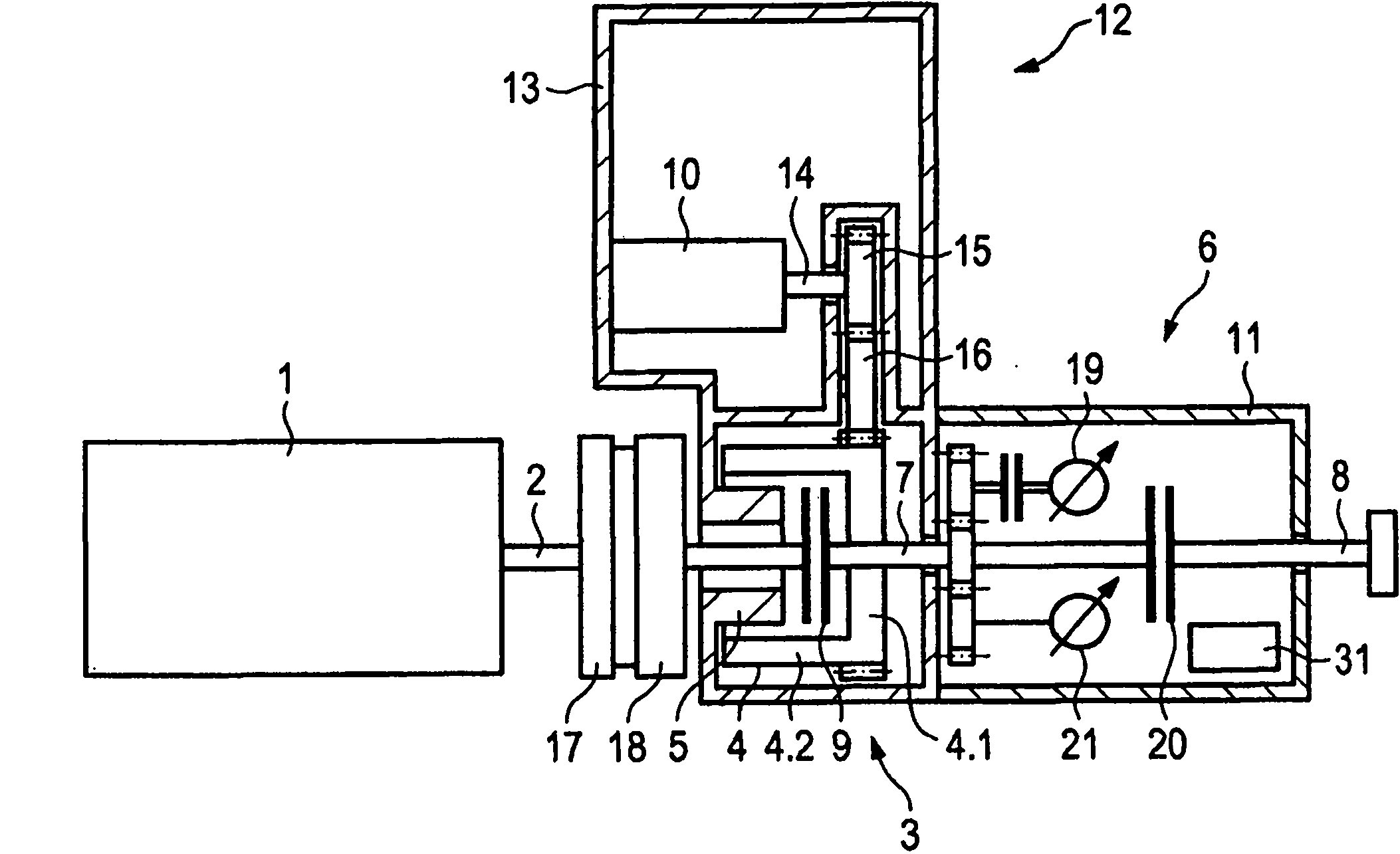

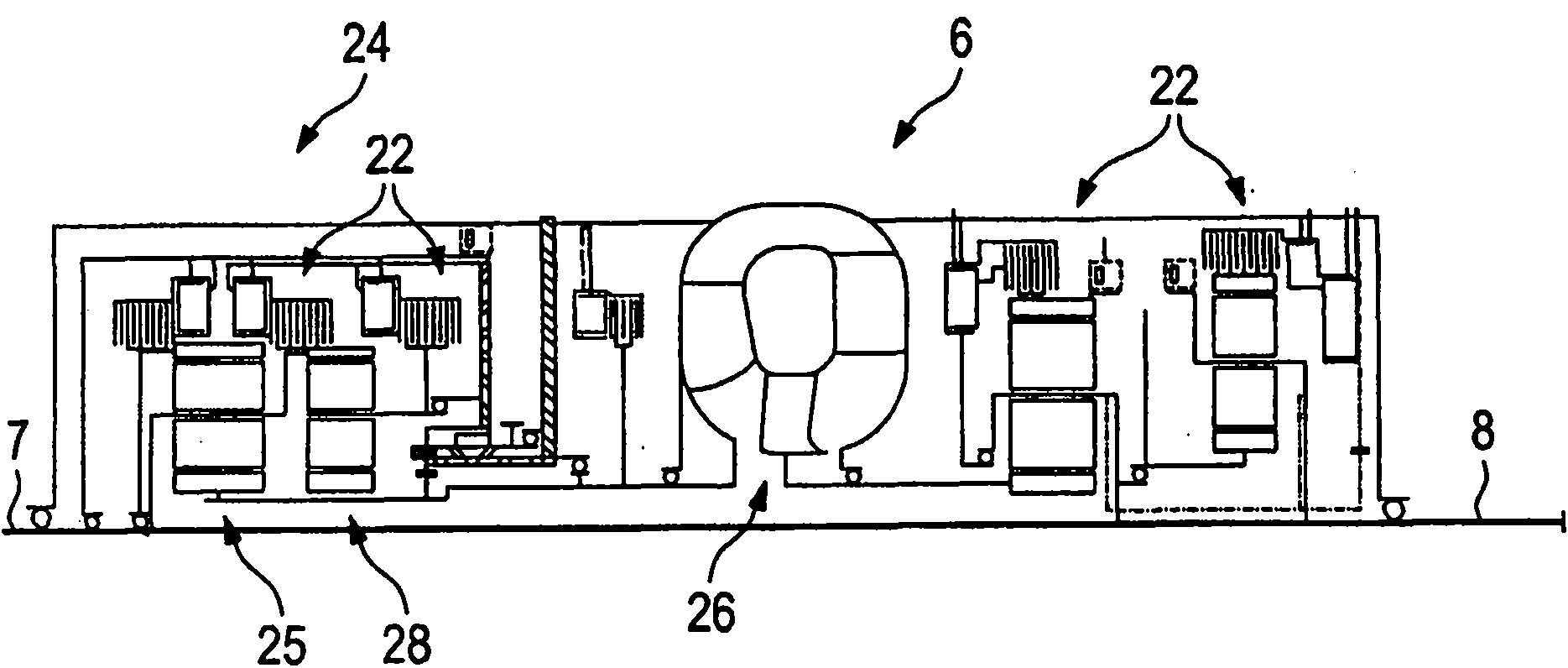

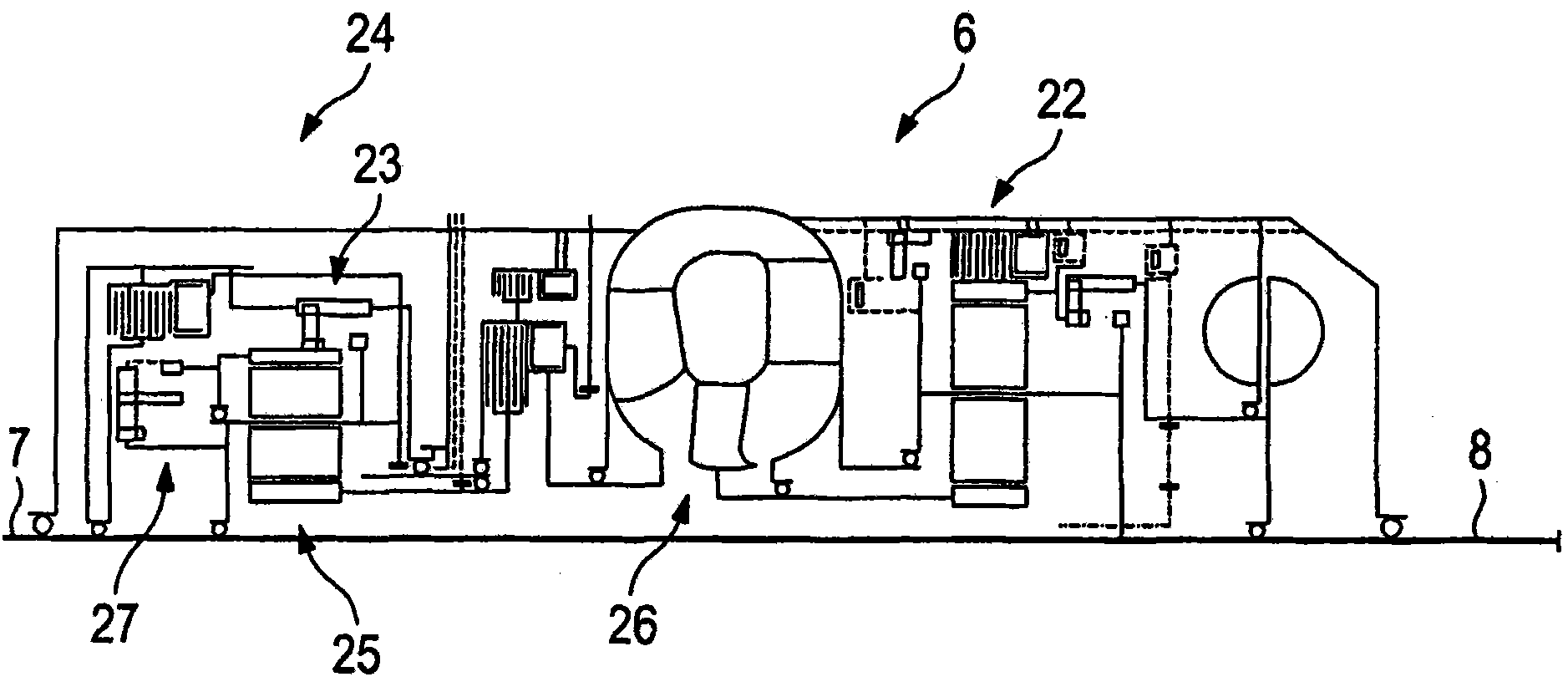

Beverage system

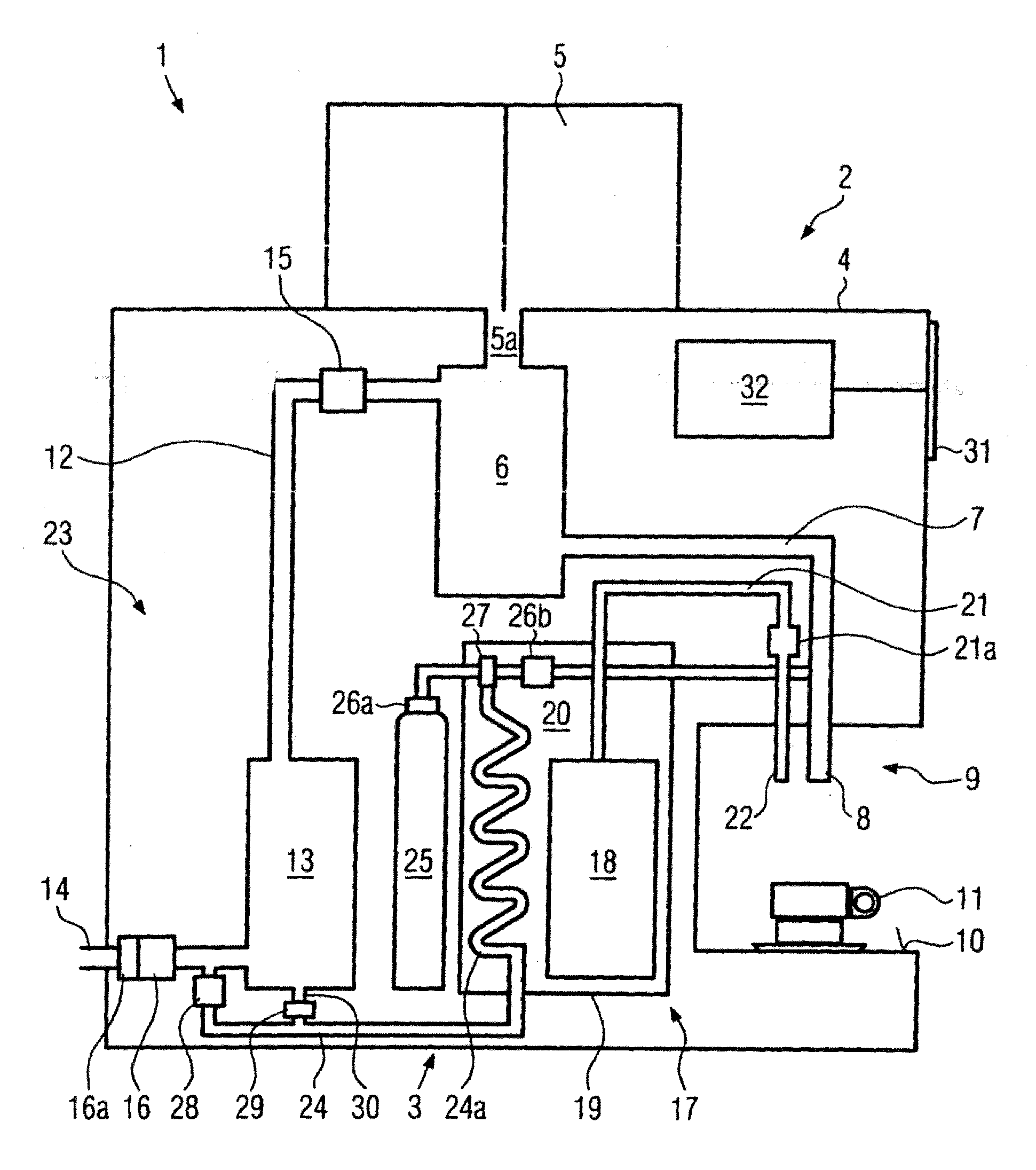

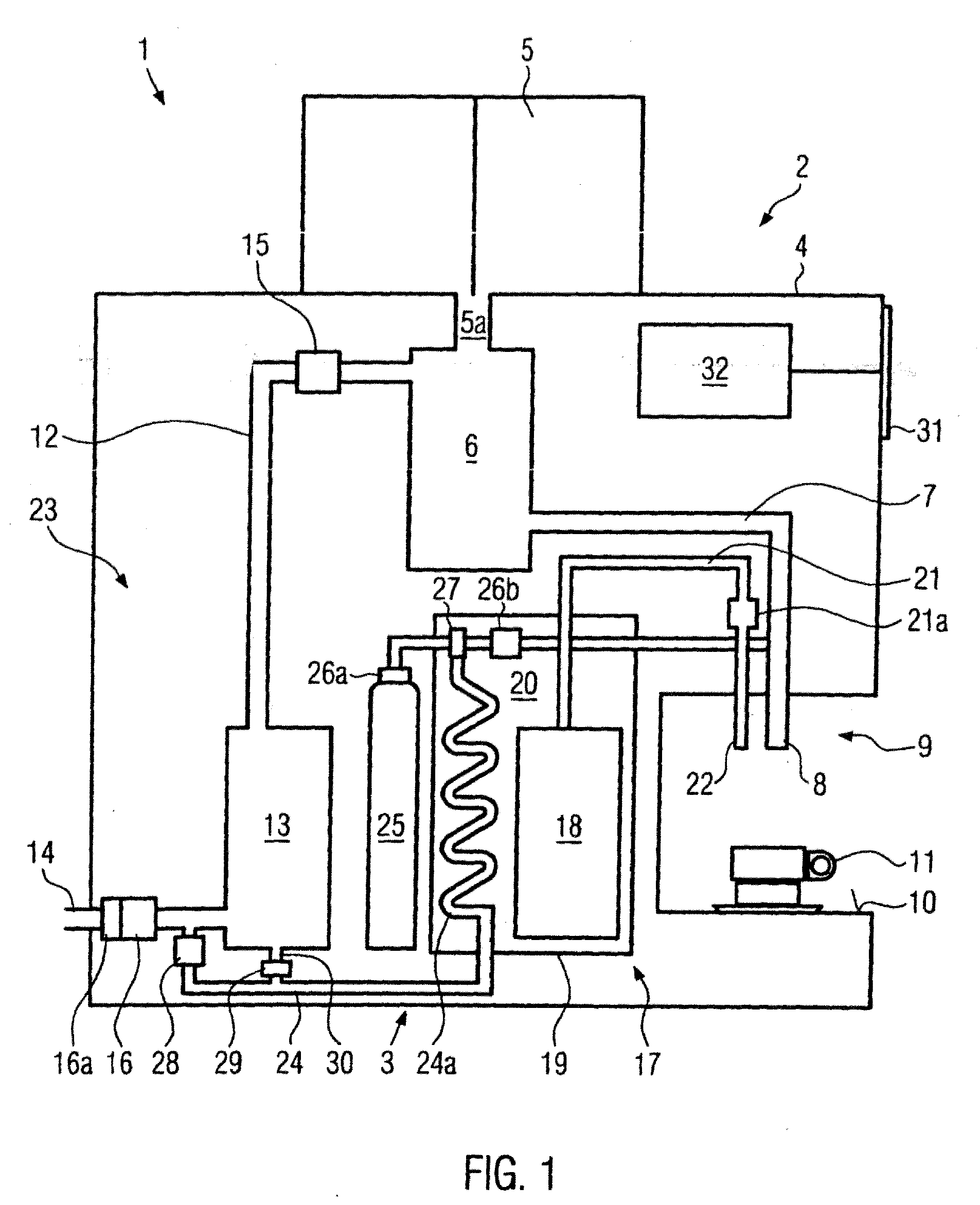

ActiveUS20090114099A1Easy to cleanLow costMixing methodsBeverage vesselsEngineeringProcess engineering

The present invention describes a beverage system (1) comprising a coffee machine (2) for preparing and dispensing hot beverages, and a water dispenser (3) for processing and dispensing drinking water; this system is inexpensive and it requires little space. To this end, it is suggested that wherein the coffee machine (2) and the water dispenser (3) should be connected to one another in such a way that at least one functional component of the coffee machine (2) or of the water dispenser (3) can be utilized both for the coffee machine (2) and for the water dispenser (3).

Owner:WMF GRP

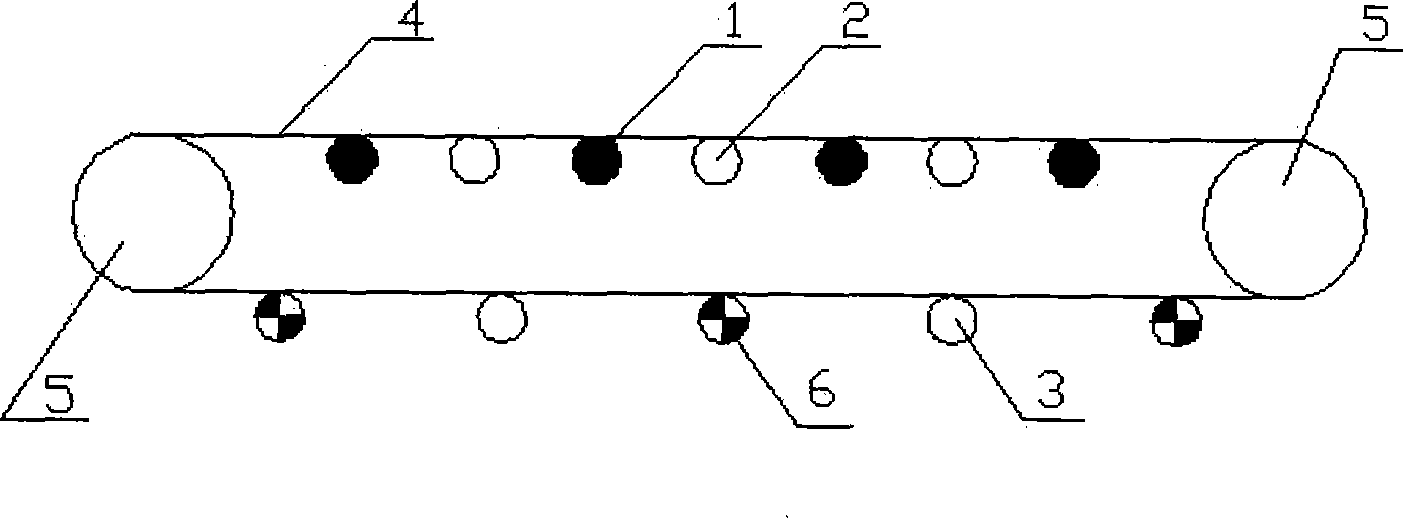

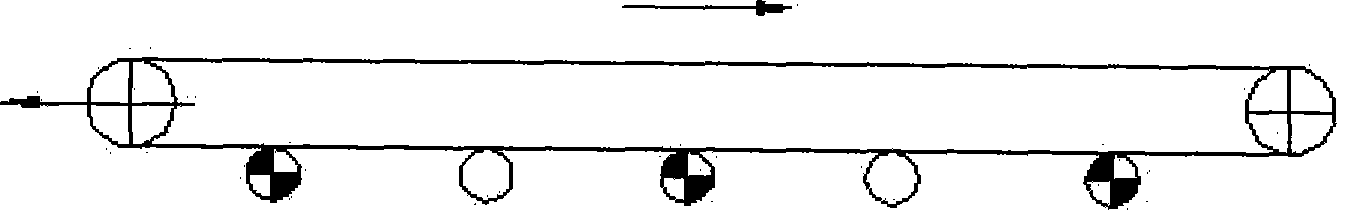

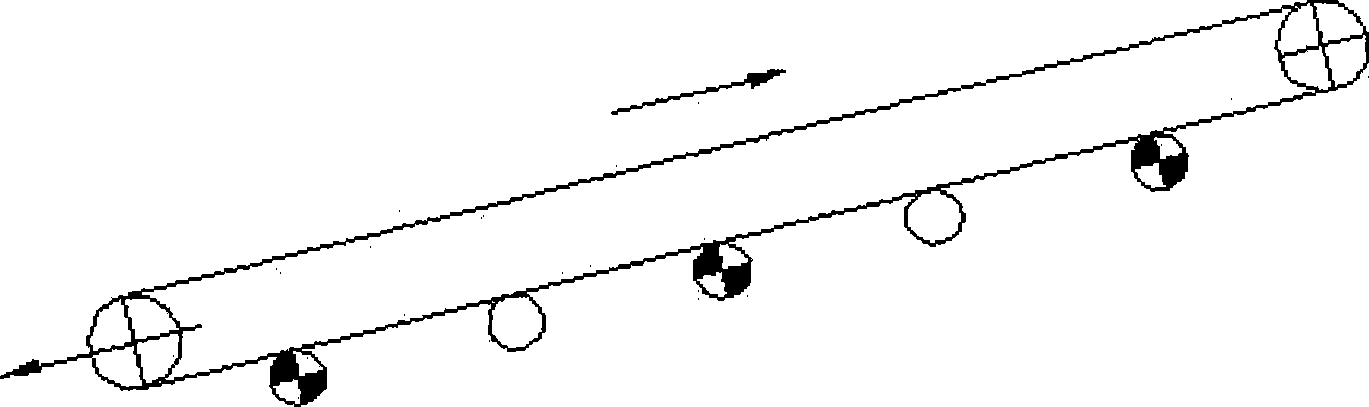

Idler roller driving belt type conveyor

InactiveCN101462634ALongitudinal stress reductionLow manufacturing costConveyorsControl devices for conveyorsElectrical controlEngineering

The invention relates to a roller driving belt conveyer, which comprises reversing rollers, bearing rollers, bearing drive rollers, return rollers, return drive rollers, a conveying belt, a structural bearing and an electric control system. The belt conveyer adopts a plurality of bearing drive rollers to directly drive the conveying belt, designs the specification, the rotating speed and the number of the required bearing drive rollers according to the carrying capacity requirement of the belt conveyer, determines whether the return rollers are required to be provided with the return drive rollers according to the design requirement of the longitudinal tension of the conveying belt, determines the number of the return drive rollers according to the design requirement of the longitudinal tension of the conveying belt, connects all the bearing drive rollers 1 and all the return drive rollers in series, and uses the electric control system to control and complete synchronized motion. The roller driving belt conveyer has the advantages of simple structure, reduction of a tension device, large reduction of the tension of the conveying belt and the cost, stable operation, long service life and so on.

Owner:张晓明

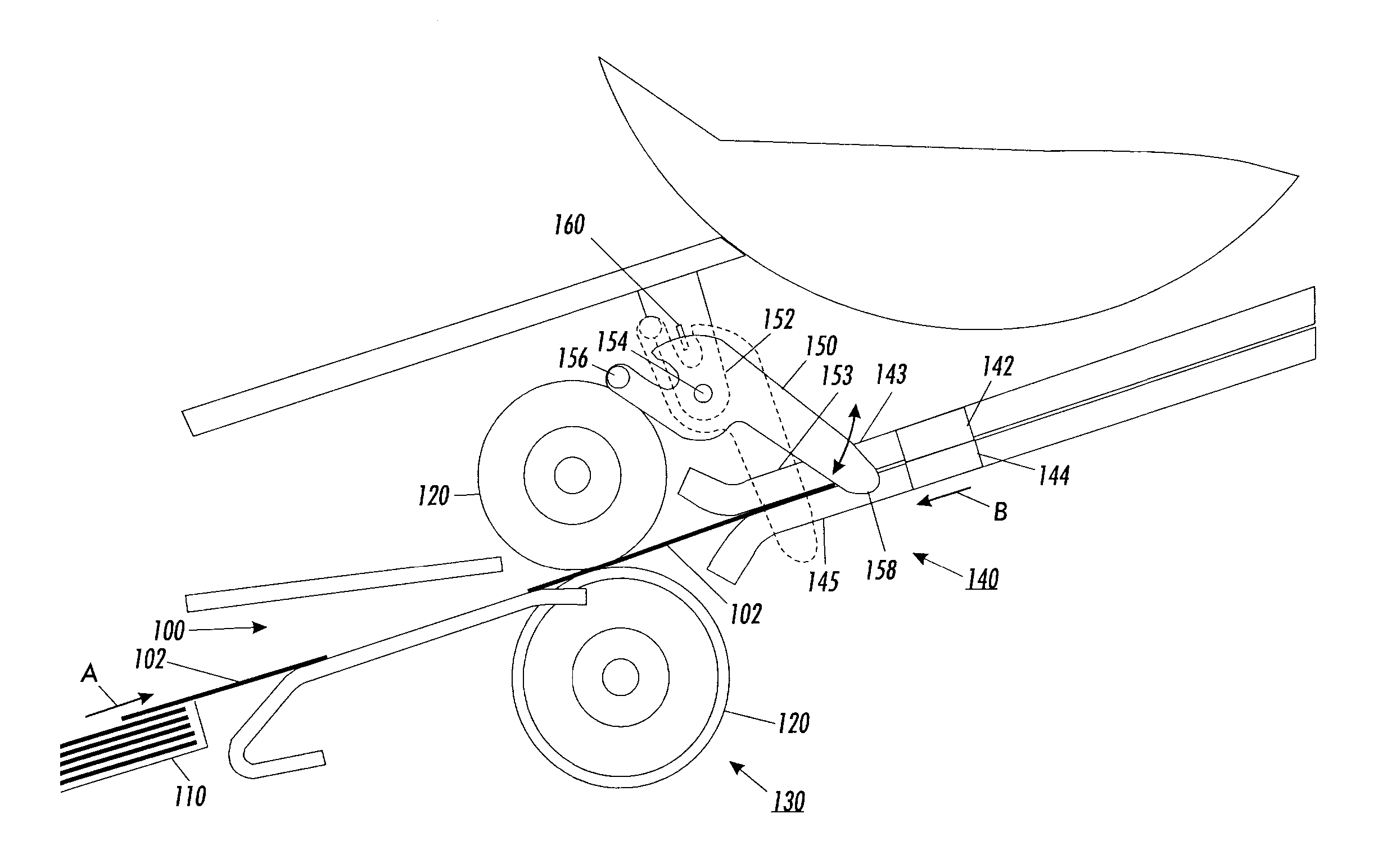

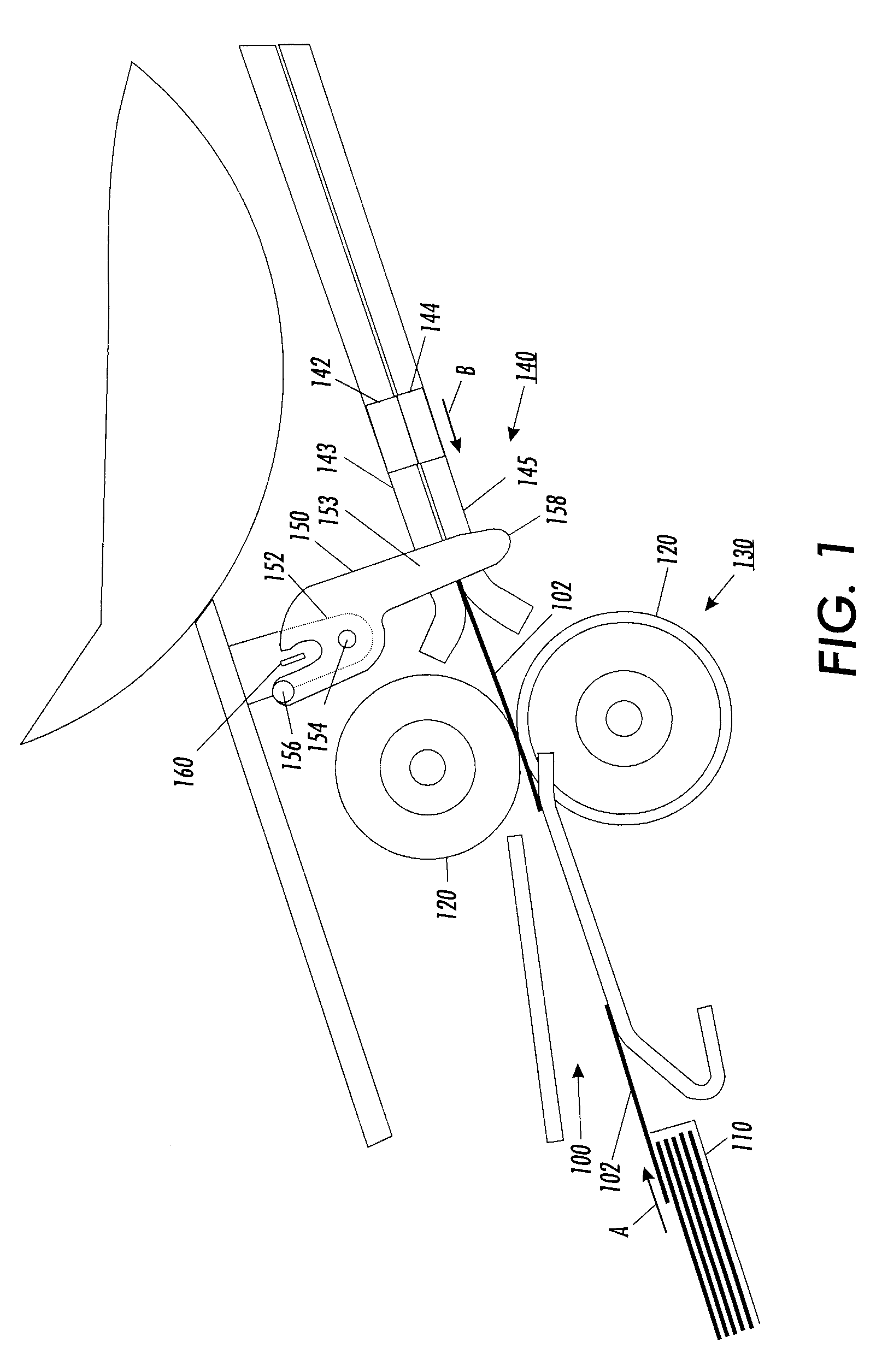

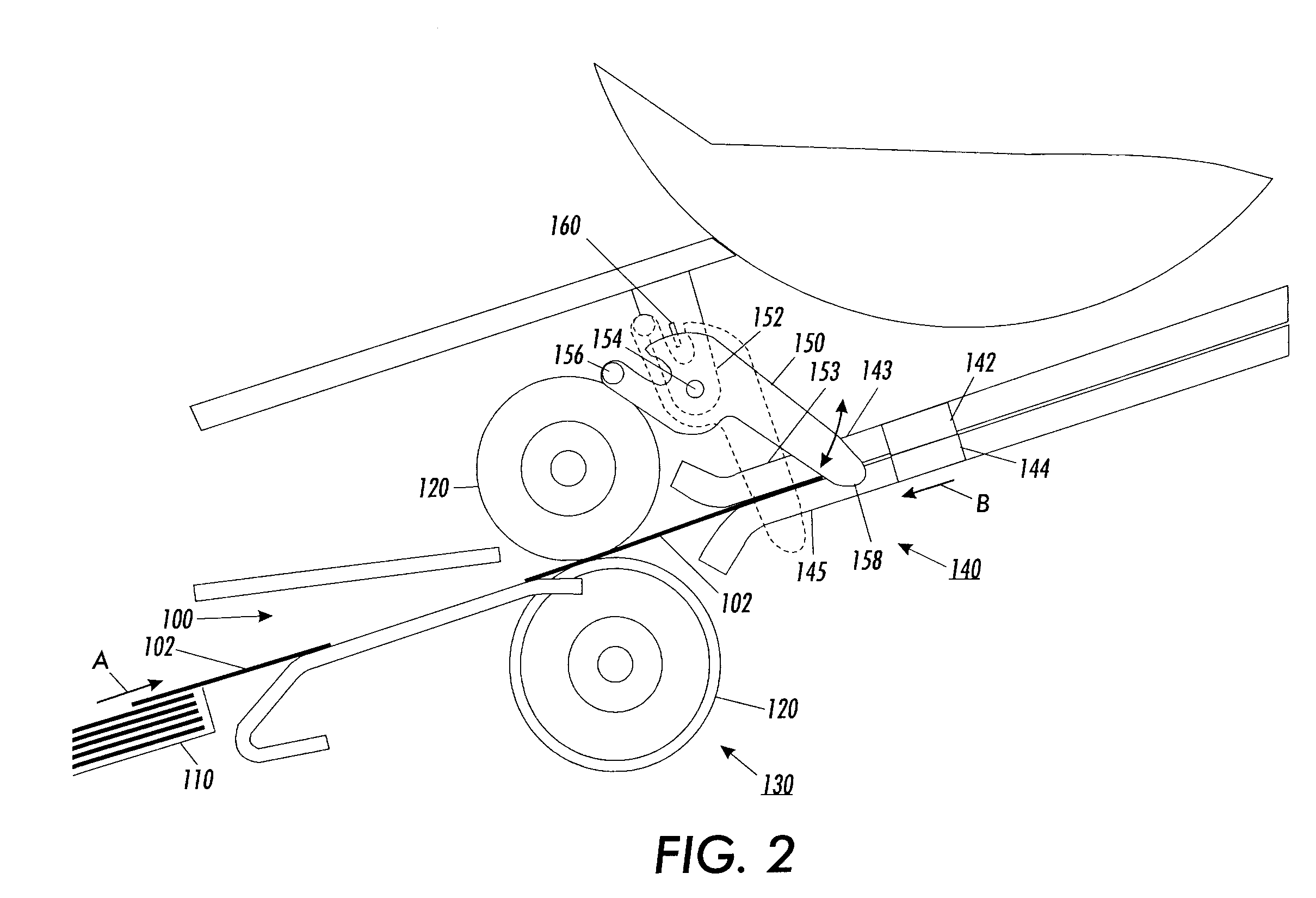

Systems and methods for detecting bi-directional passage of an object via an articulated flag member arrangement

InactiveUS20050133992A1Low costReduce the space requiredFunction indicatorsElectrographic process apparatusEngineeringDevice Sensor

Owner:XEROX CORP

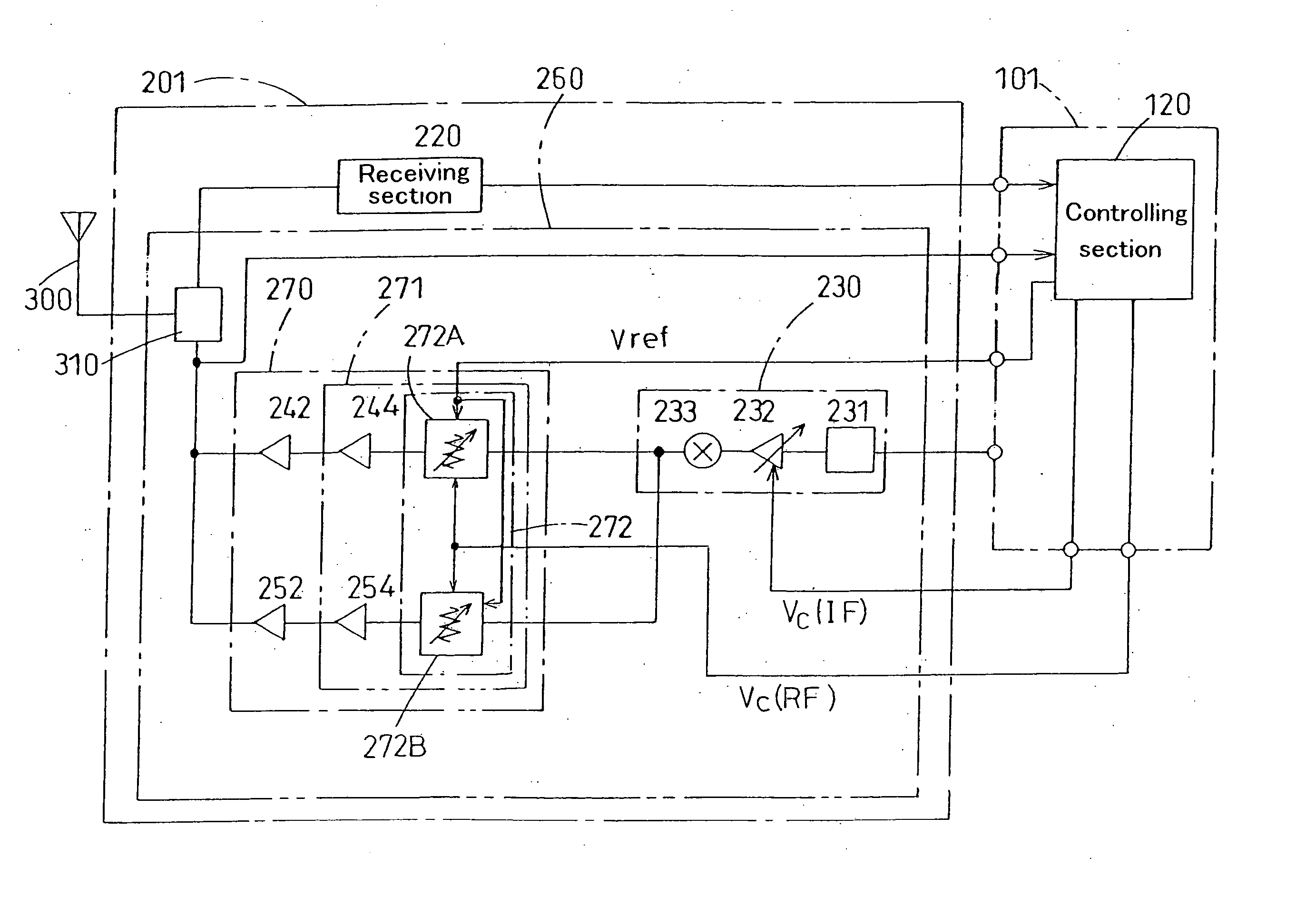

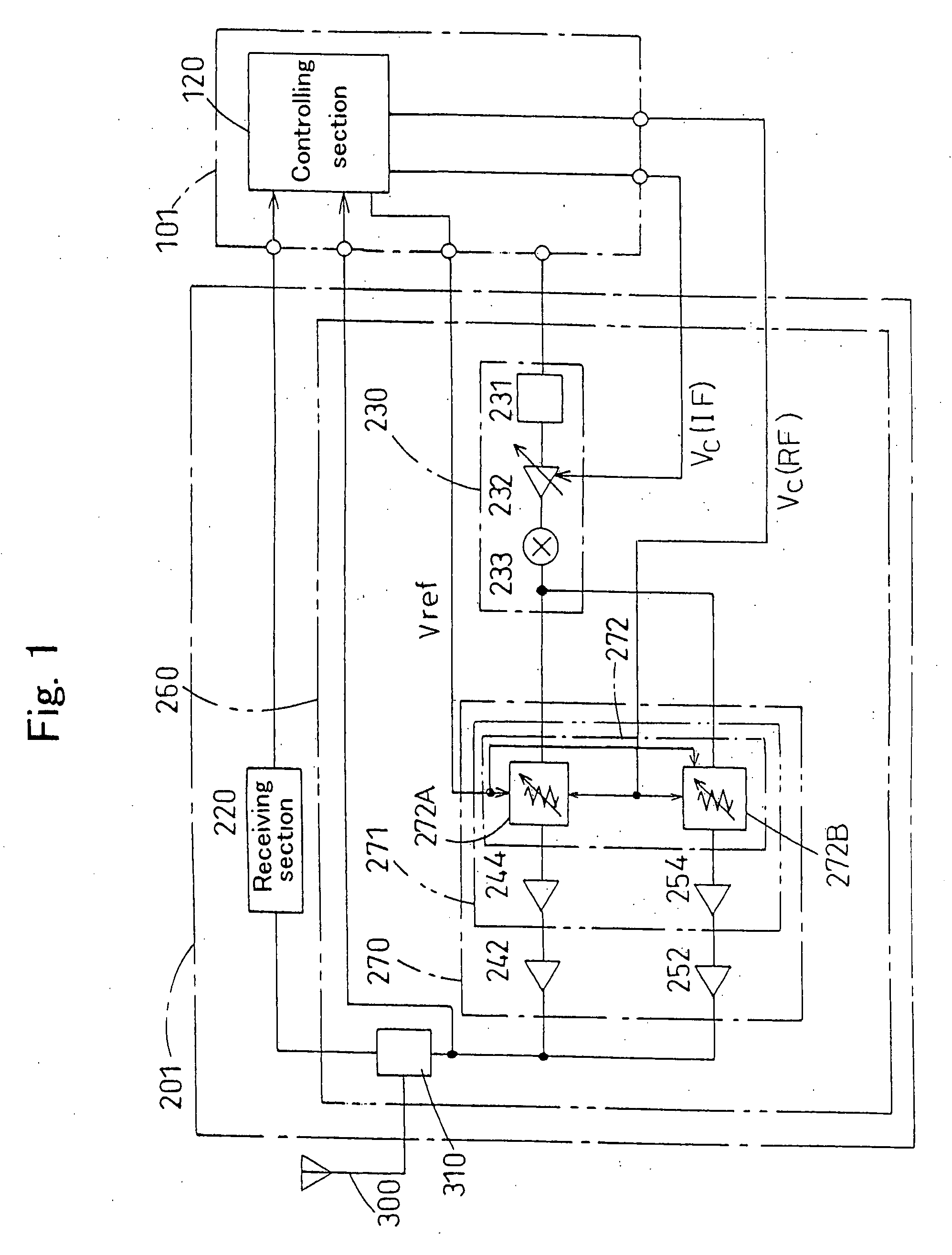

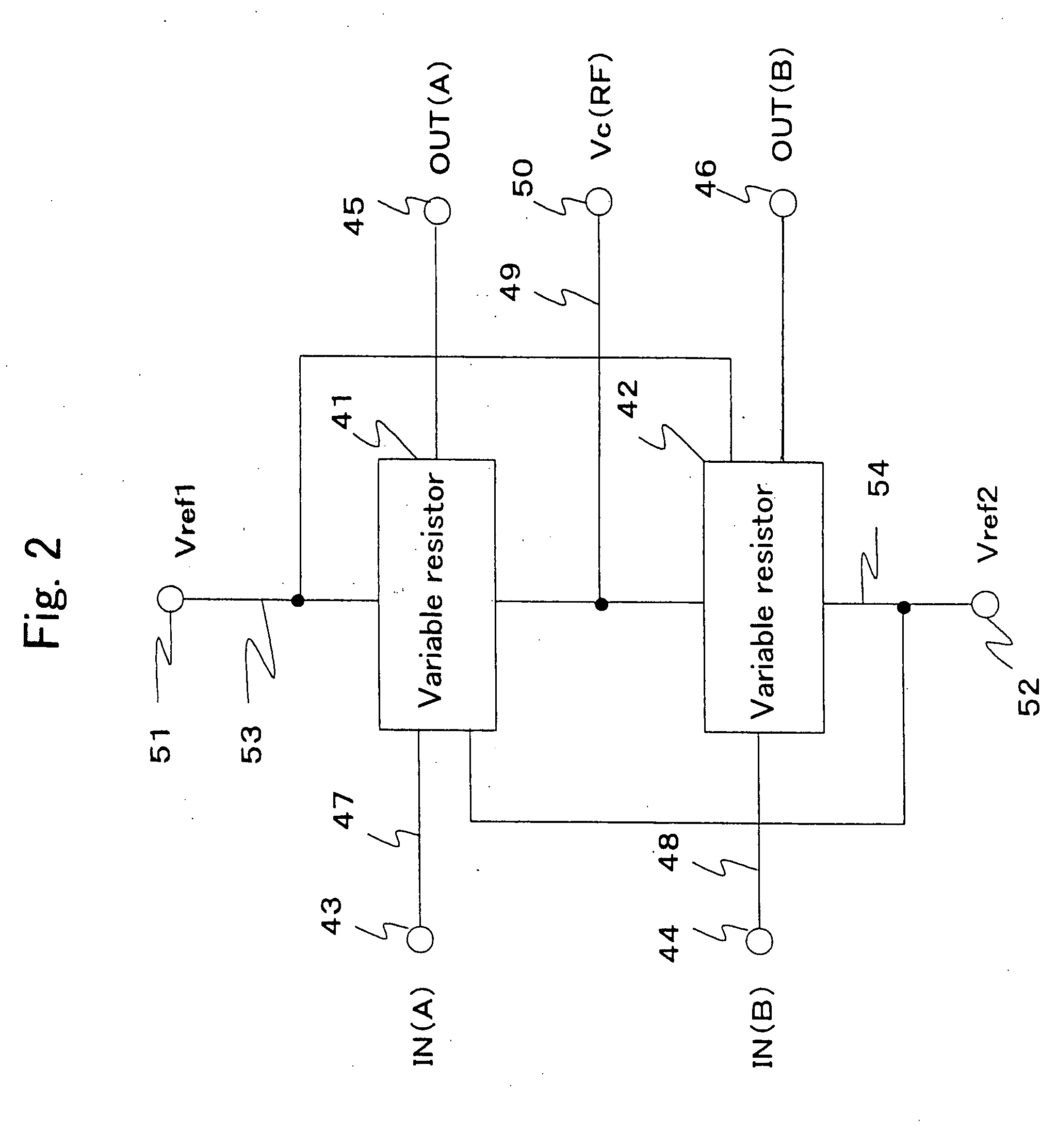

Attenuator and portable telephone terminal apparatus using the same

InactiveUS20050003784A1Improve accuracyReduce in quantityPulse automatic controlGain controlTerminal equipmentTelephone terminal

Provided are: at least one or more series variable resistors implemented by field effect transistors connected to a signal line A; and at least one or more shunt variable resistors implemented by field effect transistors connected between a signal outputting section A and a reference potential section GND. Further provided are: at least one or more series variable resistors implemented by field effect transistors connected to a signal line B arranged in parallel to the signal line A; and at least one or more shunt variable resistors implemented by field effect transistors connected between a signal outputting section B and a reference potential section GND.

Owner:COLLABO INNOVATIONS INC

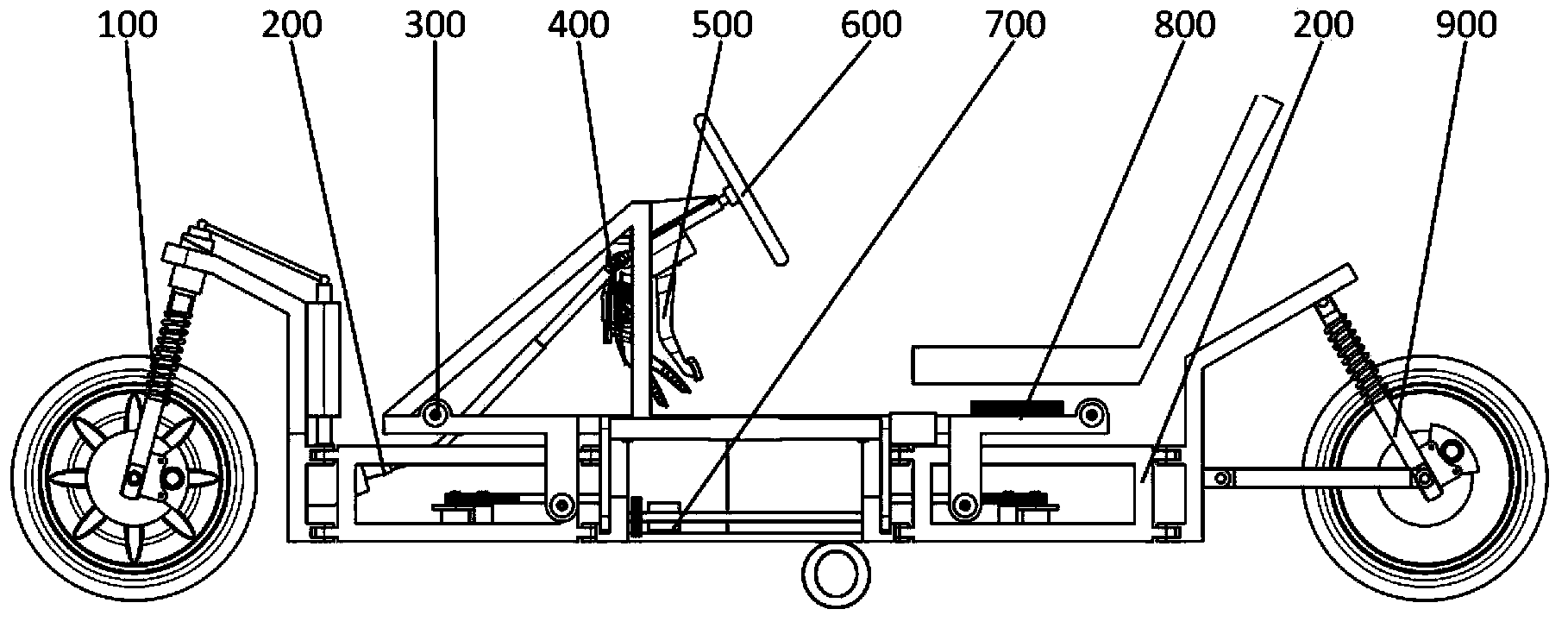

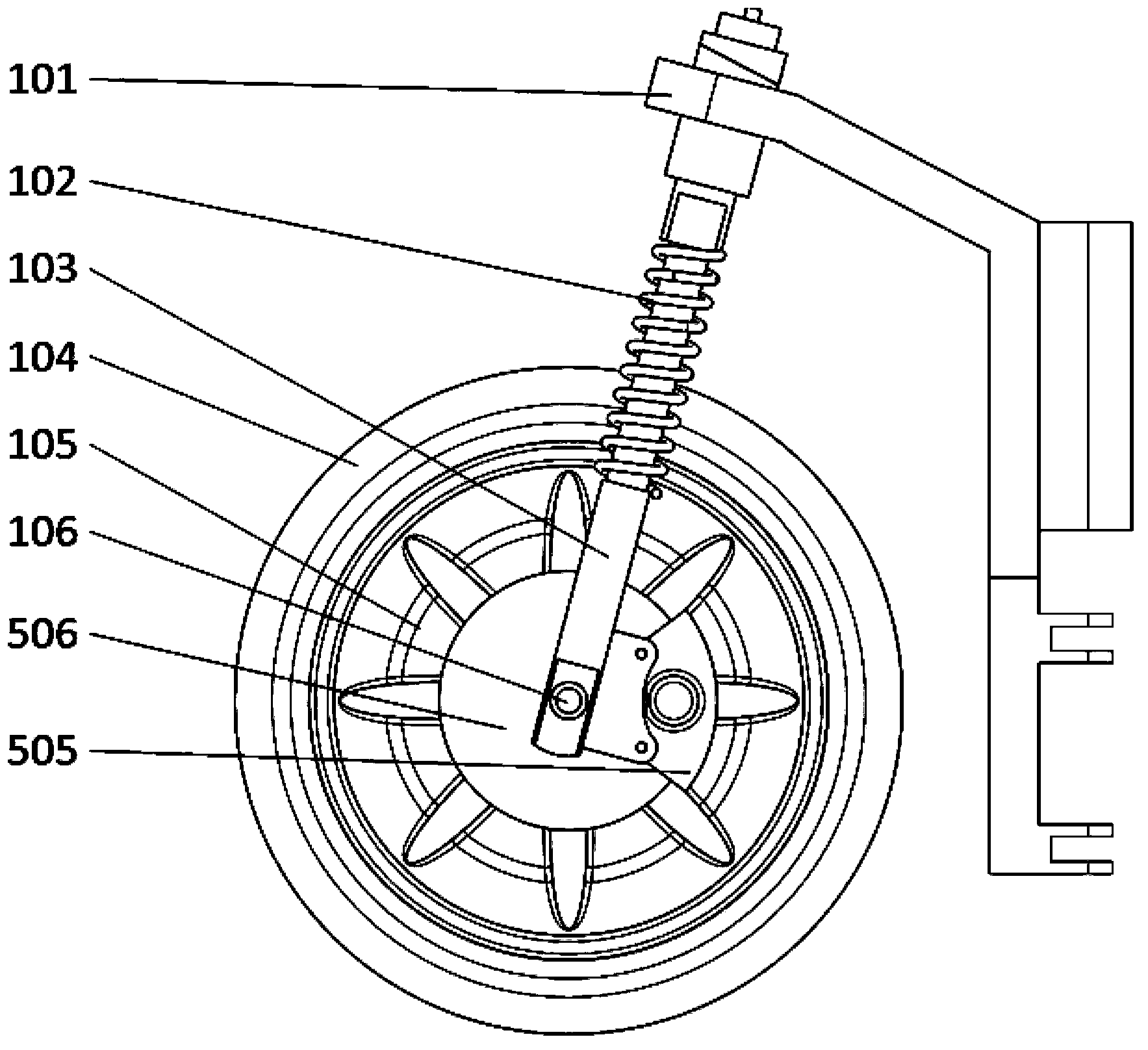

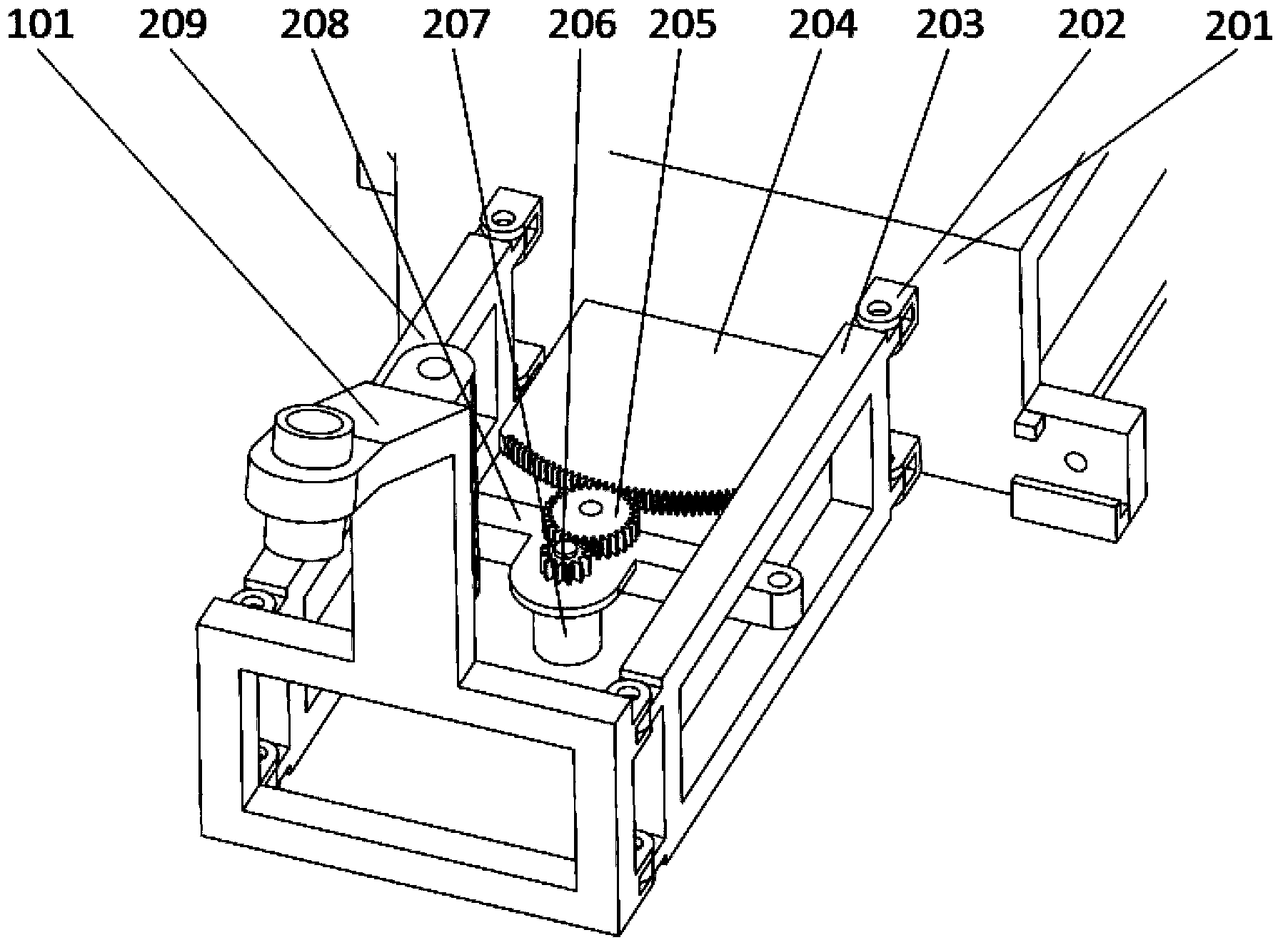

Combinable vehicle chassis device

InactiveCN103359233AIncrease profitEasy to trackConvertible cyclesAxle suspensionsEngineeringFront and back ends

The invention relates to a combinable vehicle chassis vehicle which can be operated independently. The combinable vehicle chassis comprises a front suspension system, a swinging system, a tightening system, a drive system, a brake system, a steering system, a combination system, a signal synchronous port system and a rear suspension system, and is characterized in that the front suspension system and the rear suspension system are respectively arranged on the front end and the rear end of a vehicle and respectively connected with a front single wheel and a rear single wheel, the chassis device comprises a front swinging system and a rear swinging system, the front suspension system which is arranged on the front end of the vehicle is connected with a vehicle body mechanism skeleton through the front swinging system, the rear suspension system is connected with the vehicle body mechanism skeleton through the rear swinging system, and the tightening system, the combination system and the signal synchronous port system are respectively arranged on two sides of a vehicle chassis. When a device is independently driven, due to the two-wheel structural form, the advantages of low cost, small size and high utilization rate of a battery can be realized, and the advantage for improving the market popularization rate, improving the trip convenience and flexibility and reducing the storage space and the application space can be realized.

Owner:HUNAN UNIV AISHENG AUTO TECH DEV

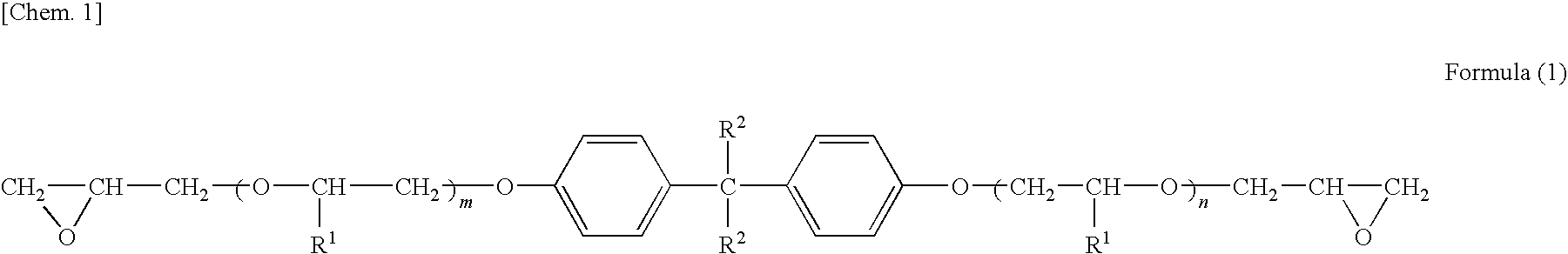

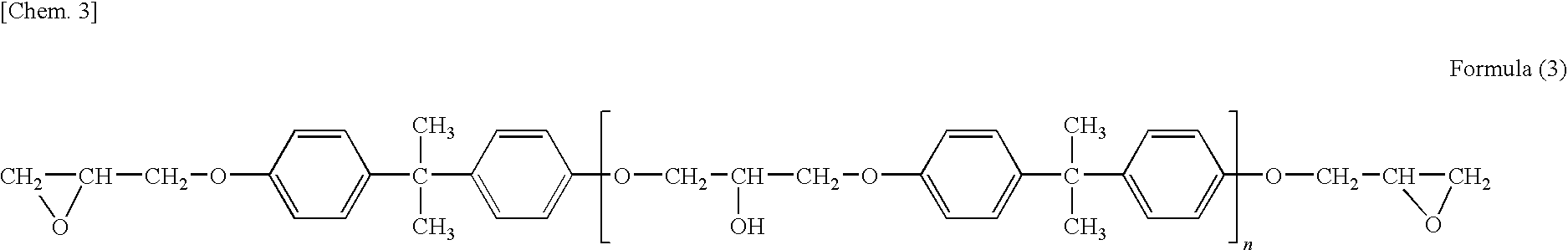

Method for forming coating film and coated article

InactiveUS20100129659A1Raise the gradeReduce energy consumptionLiquid surface applicatorsElectrolysis componentsPolymer sciencePolymer chemistry

The present invention provides a coated product having excellent corrosion resistance and excellent finish by a 3-coat 1-bake method;the method including the steps of forming cured coating film (A1) comprising cationic electrodeposition coating composition (A) on a metal object to be coated; forming first colored coated film (B1) by coating first colored aqueous coating composition (B); forming second colored coated film (C1) by coating second colored aqueous coating composition (C) on uncured first colored coated film (B1); forming clear coated film (D1) by coating clear coating composition (D) on uncured second colored coated film (C1); and simultaneously curing uncured first colored coated film (B1), uncured second colored coated film (C1), and uncured clear coated film (D1).

Owner:KANSAI PAINT CO LTD

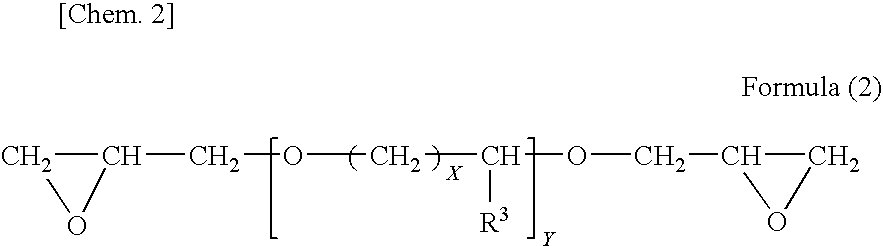

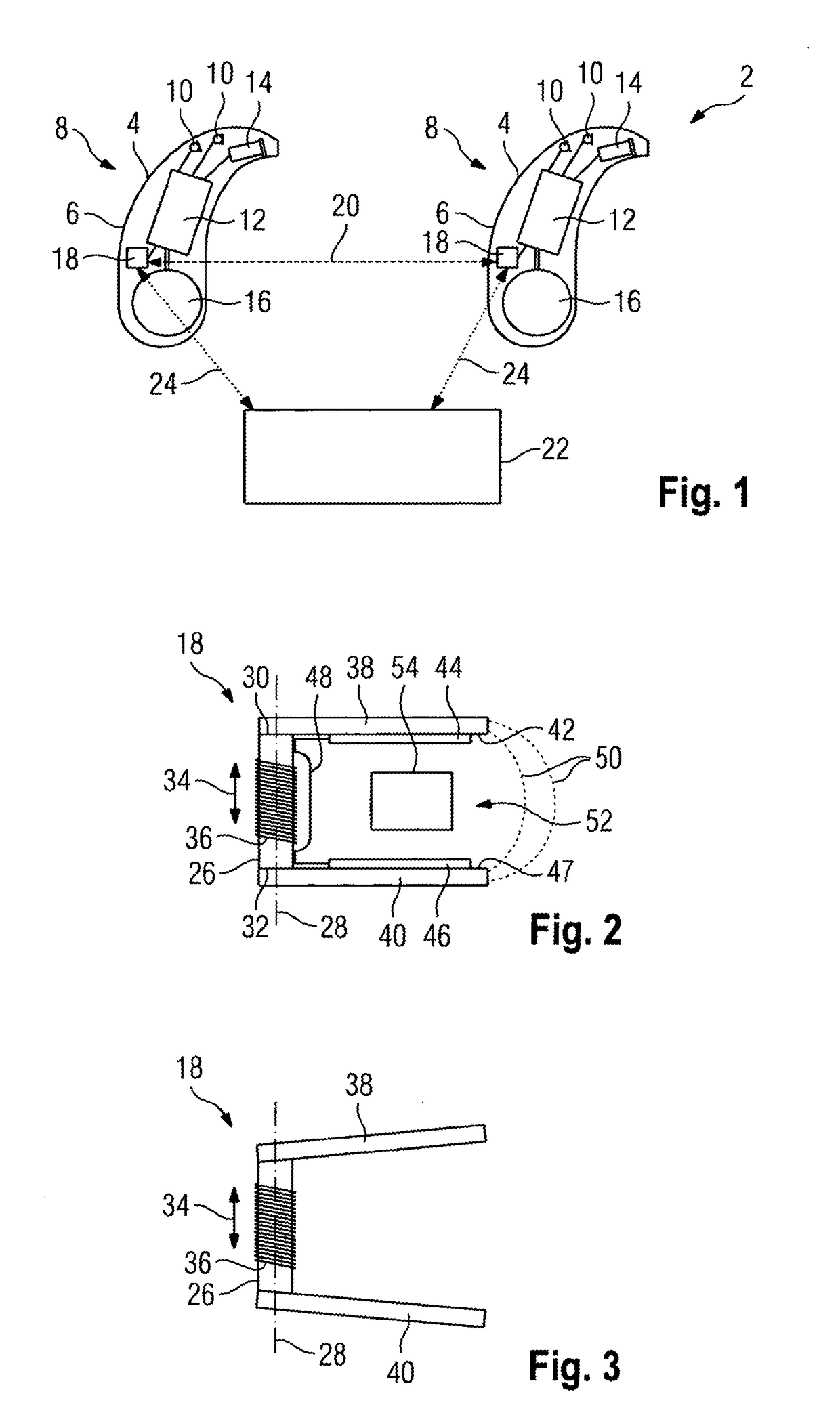

Antenna

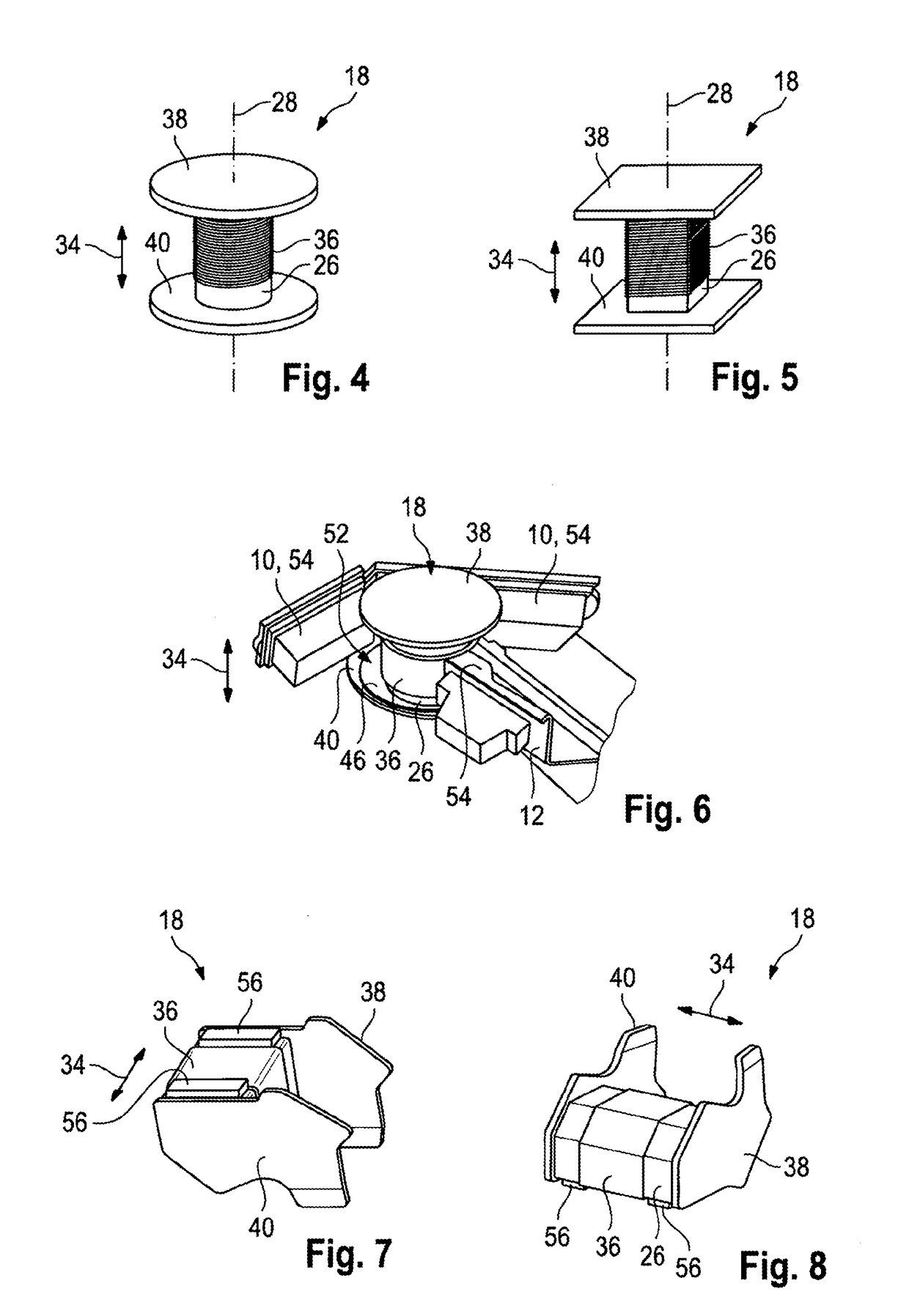

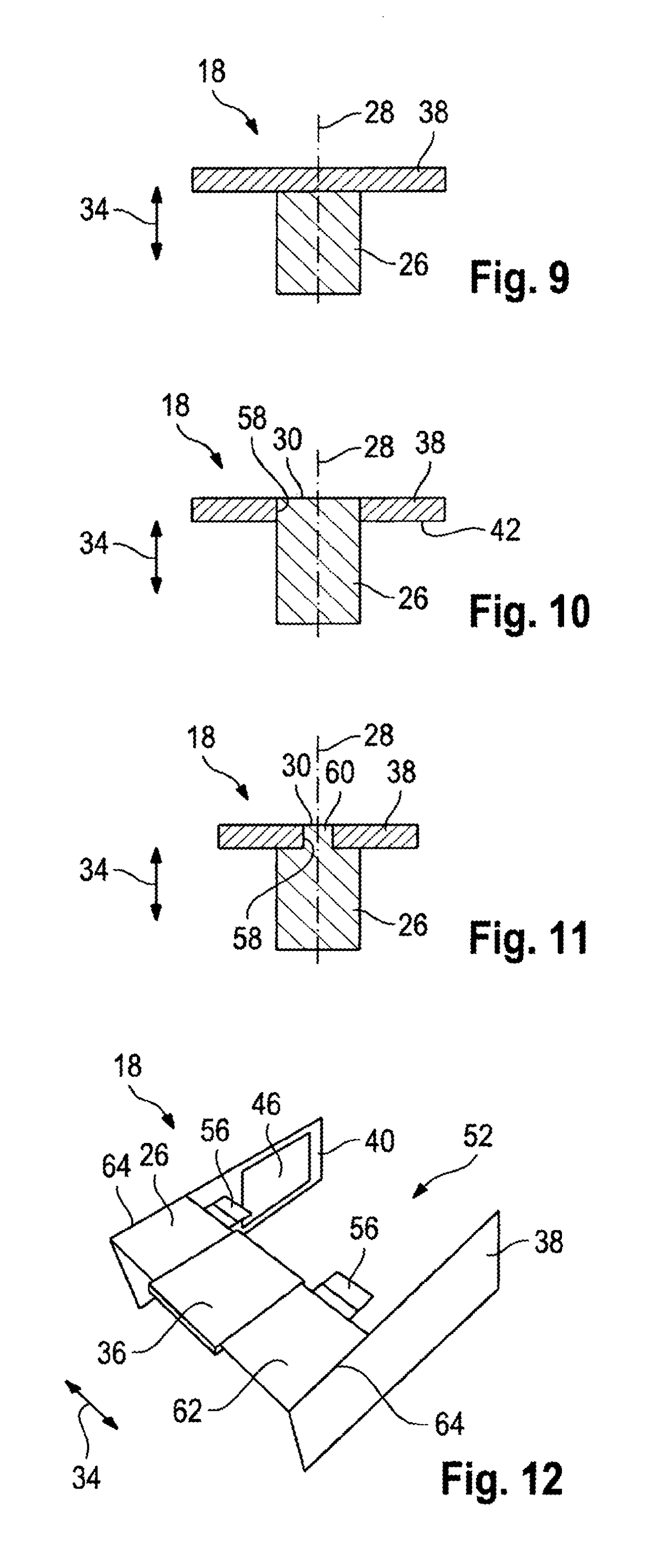

ActiveUS20190006757A1Improve reception qualityReduced Power RequirementsLoop antennas with ferromagnetic coreCompletely in canal hearing aidsHearing aidConductor Coil

An antenna, in particular for a hearing aid, for wireless radio communication, comprising a coil core which extends along a longitudinal direction and carries a number of windings, and comprising a planar first shield that is located on an end face of the coil core and is made of a ferrimagnetic and / or ferromagnetic material. The first shield extends at an angle to the longitudinal direction of the coil core. The invention further relates to a method for manufacturing an antenna as well as to a hearing aid comprising an antenna.

Owner:SIVANTOS PTE LTD

Method for culturing Metarhizium anisopliae

InactiveCN101845397ALow costReduce incubation timeFungiMicroorganism based processesSubmerged fermentationMetarhizium anisopliae

The invention discloses a method for culturing Metarhizium anisopliae, which comprises the following steps of: 1) performing liquid fermentation culture on the Metarhizium anisopliae by using a fluid nutrient medium, and marking all substances in a container as liquid fermentation products; and 2) inoculating the liquid fermentation products into a solid fermentation medium for solid fermentation culture to obtain the Metarhizium anisopliae. The method is a method for culturing the Metarhizium anisopliae by liquid-solid dual-phase fermentation, and combines liquid fermentation tank production with solid fermentation production. In liquid submerged fermentation, the medium adopted takes bagasse as a main carrier, three cheap and readily available agricultural products are taken as raw materials, and the cost is greatly reduced.

Owner:ENVIRONMENT & PLANT PROTECTION INST CHINESE ACADEMY OF TROPICAL AGRI SCI

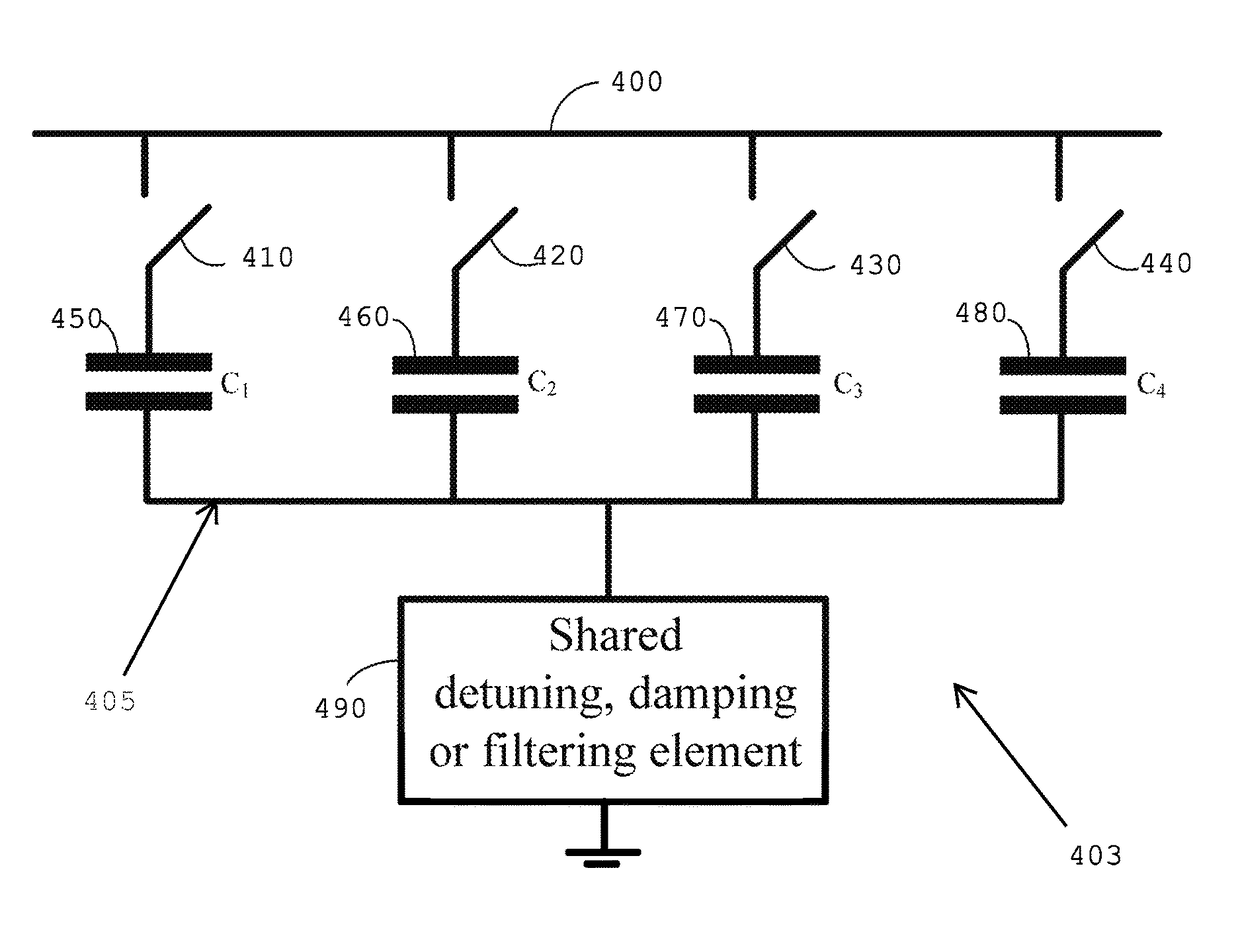

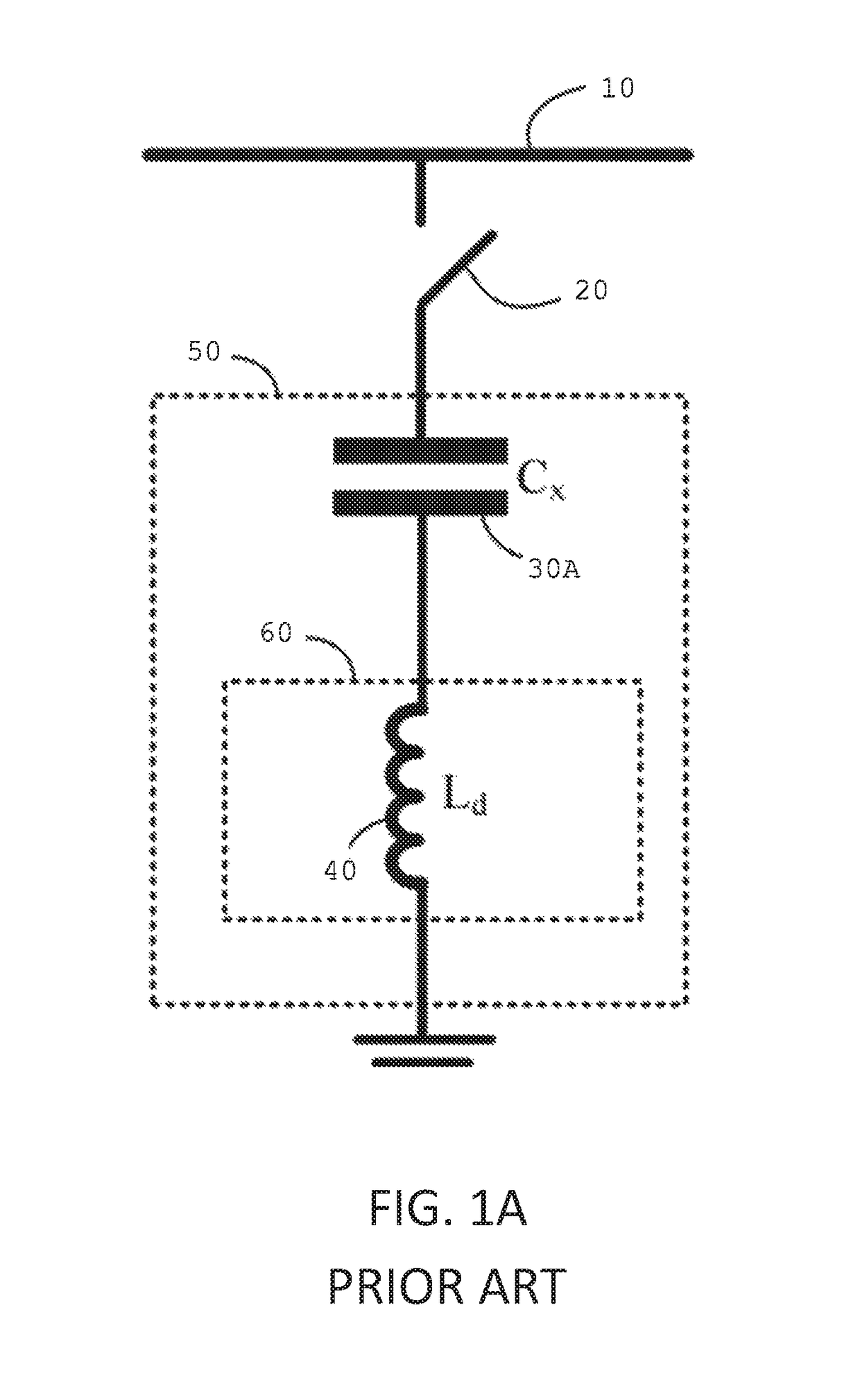

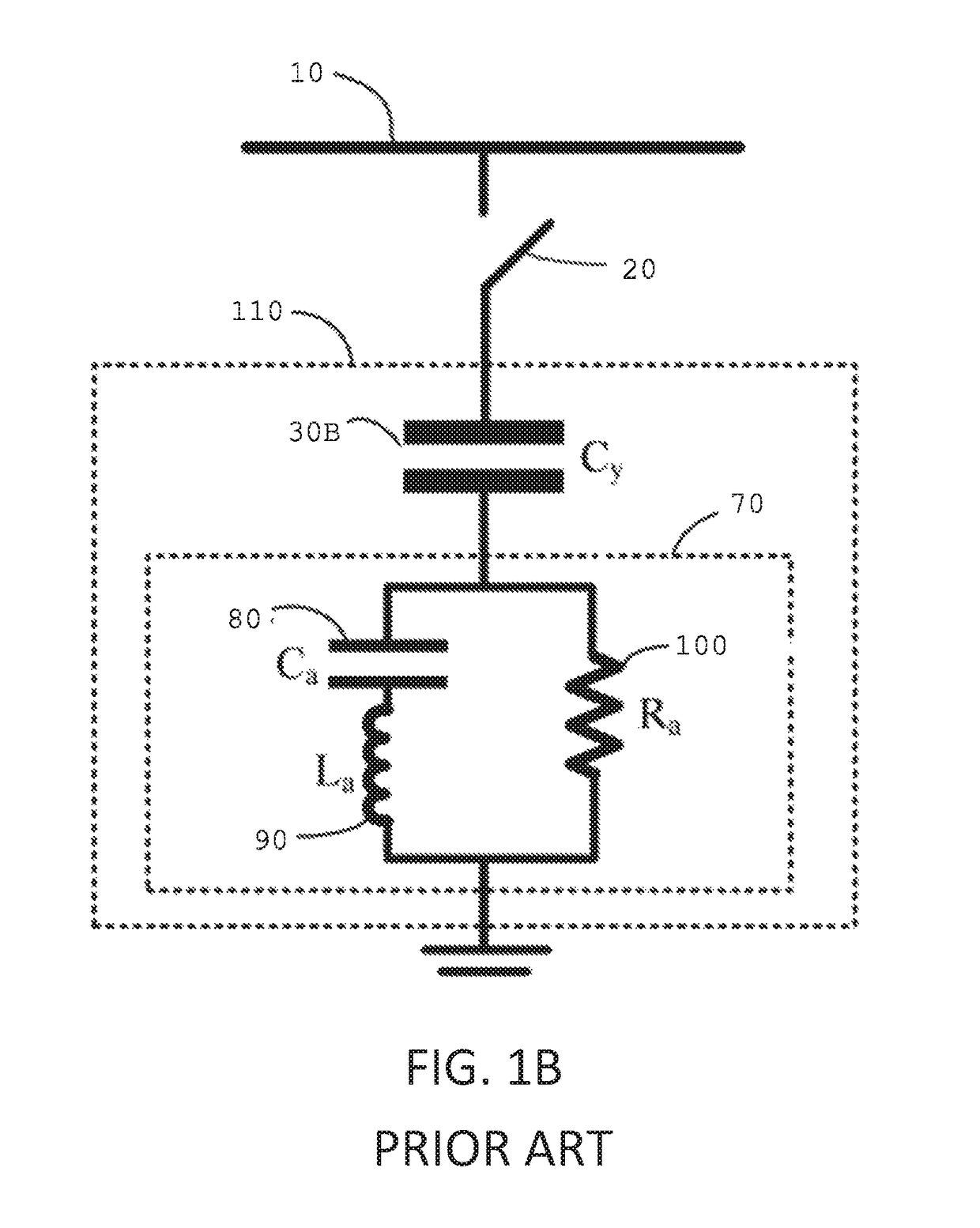

System using a subcircuit shared between capacitors for providing reactive power

ActiveUS9941697B1Adequate detuningAdequate dampingReactive power adjustment/elimination/compensationReactive power compensationCouplingElectric power system

Systems and devices that provide a shared detuning, damping, or filtering element to one or more capacitors. A number of circuit branches are coupled in parallel to each other between a first coupling point and a second coupling point. A subcircuit is coupled between the second coupling point and a third coupling point. Each branch includes at least one capacitor that provides reactive power to power systems while the subcircuit is configured to provide detuning, damping, or filtering to the multiple branches.

Owner:XU WILSUN

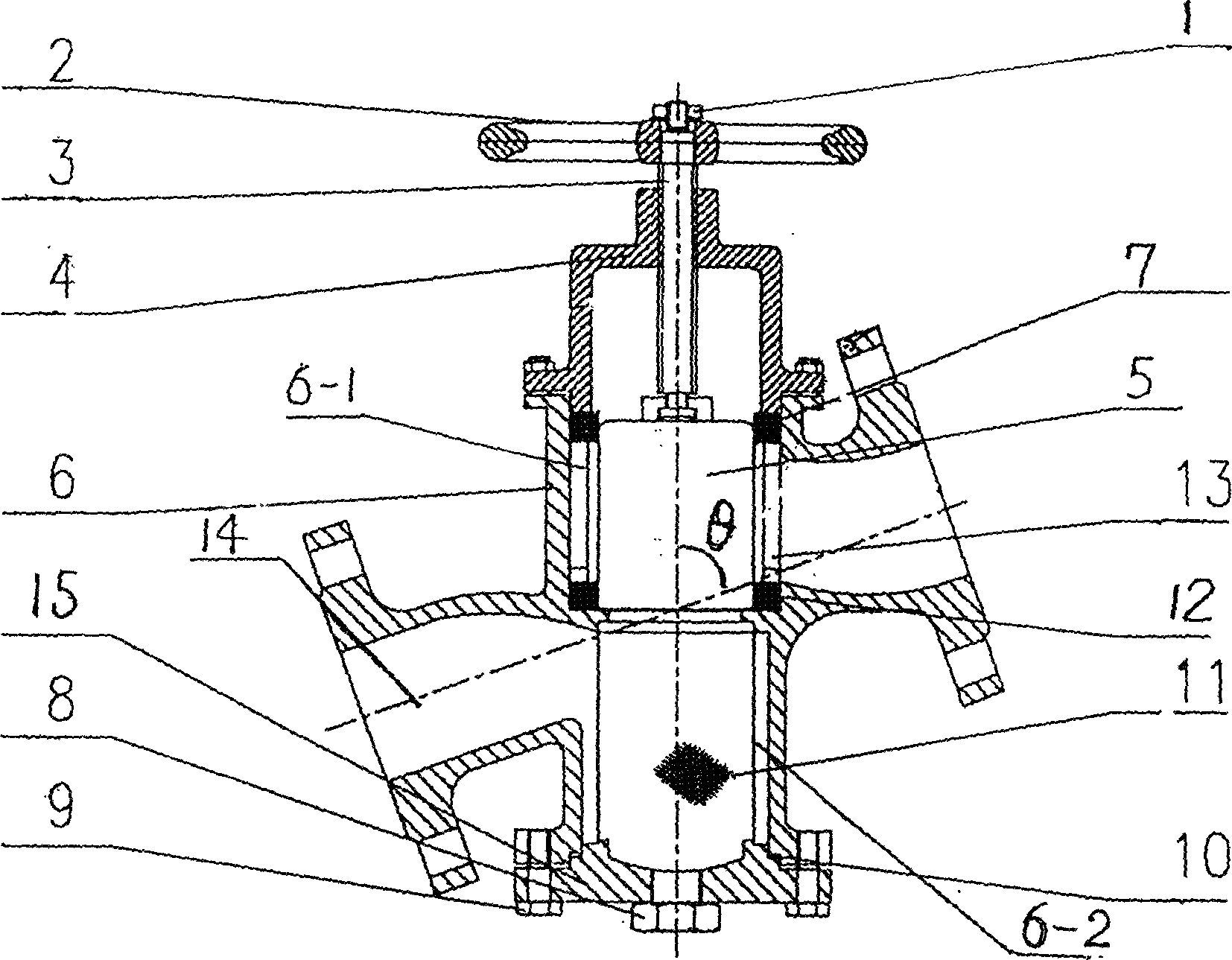

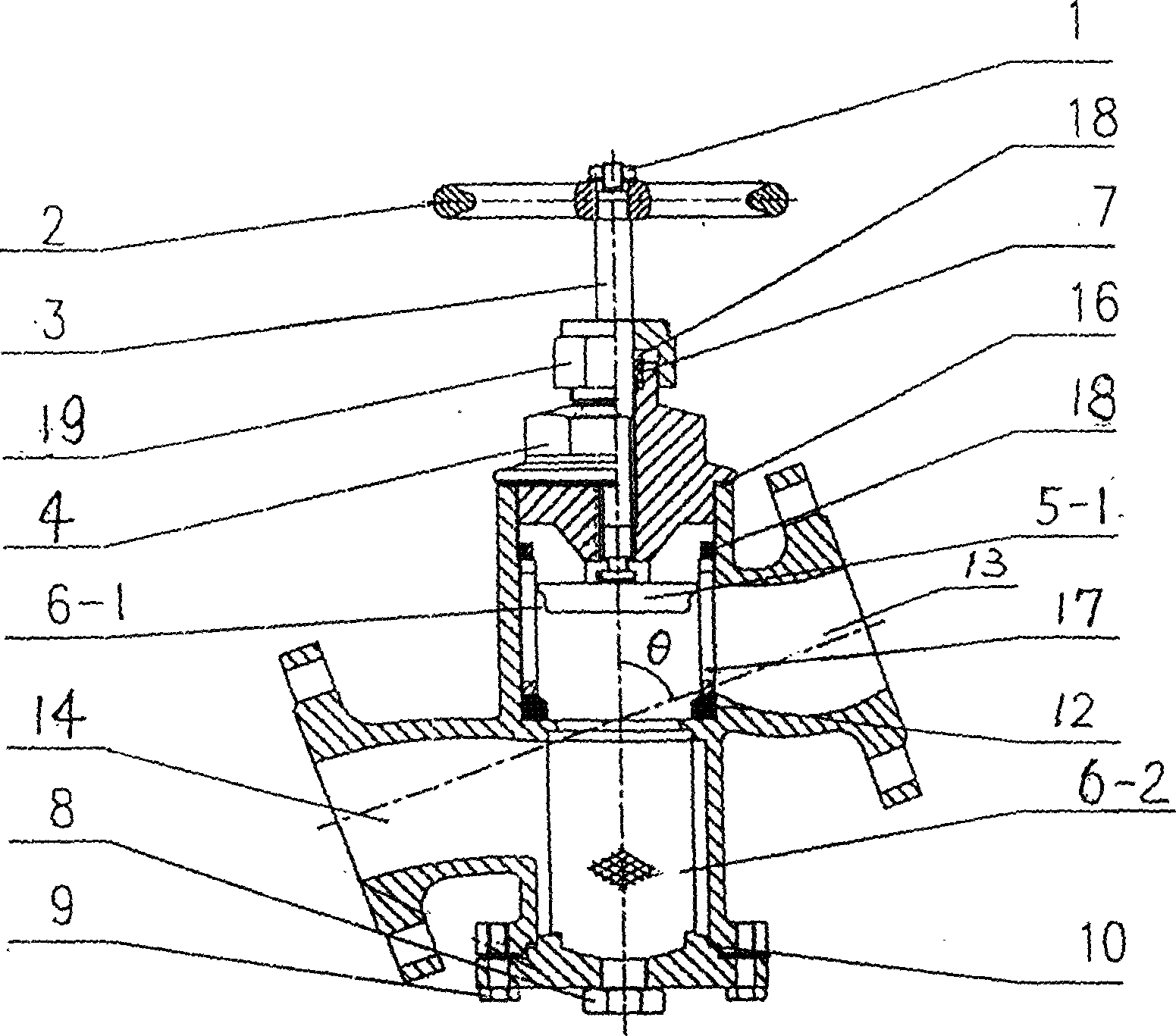

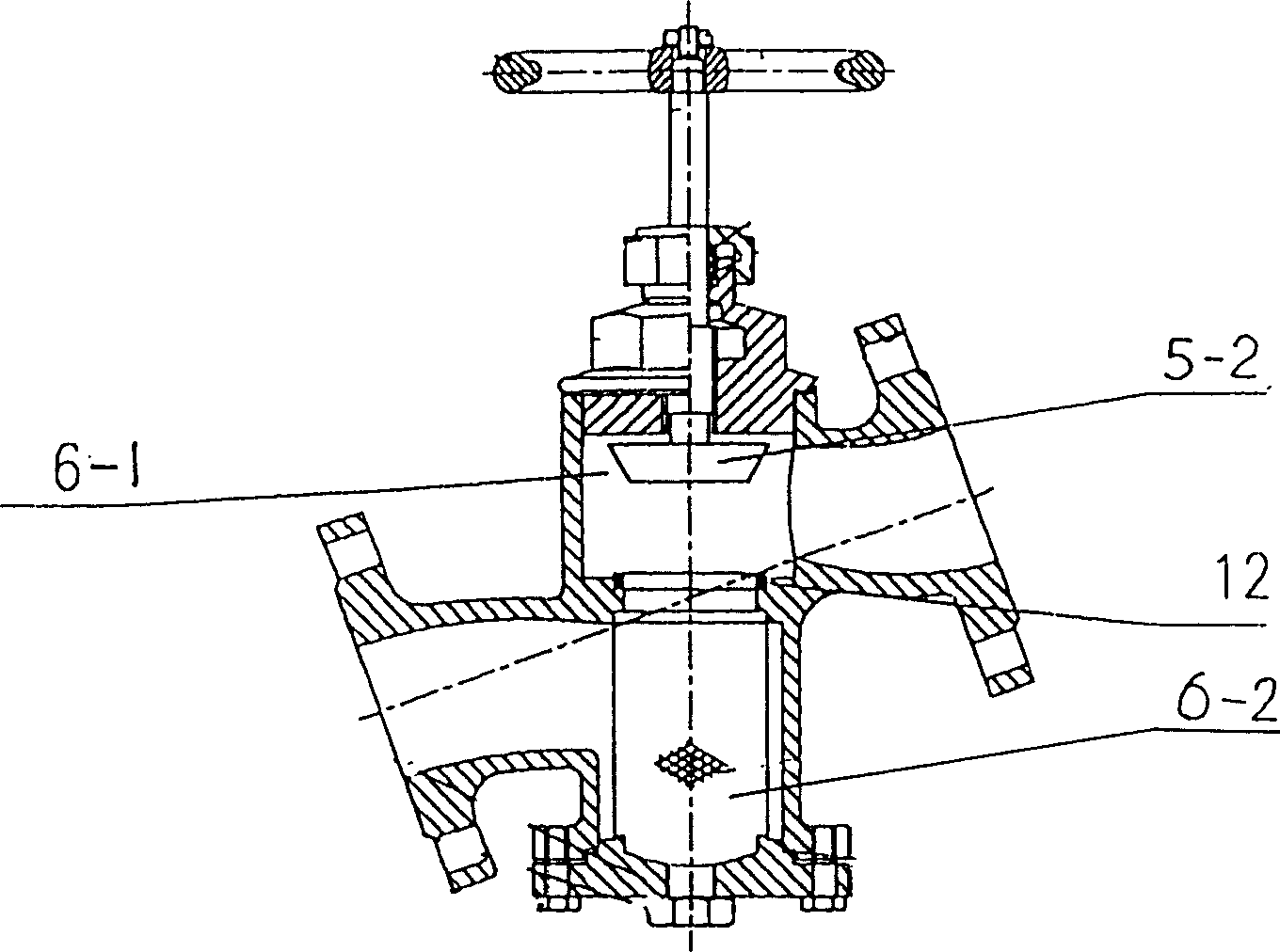

Cut-off filtering composite valve

InactiveCN1534227AReduce manufacturing costExtended service lifeFiltration separationLift valveMechanical engineeringPlunger

Owner:方吉全

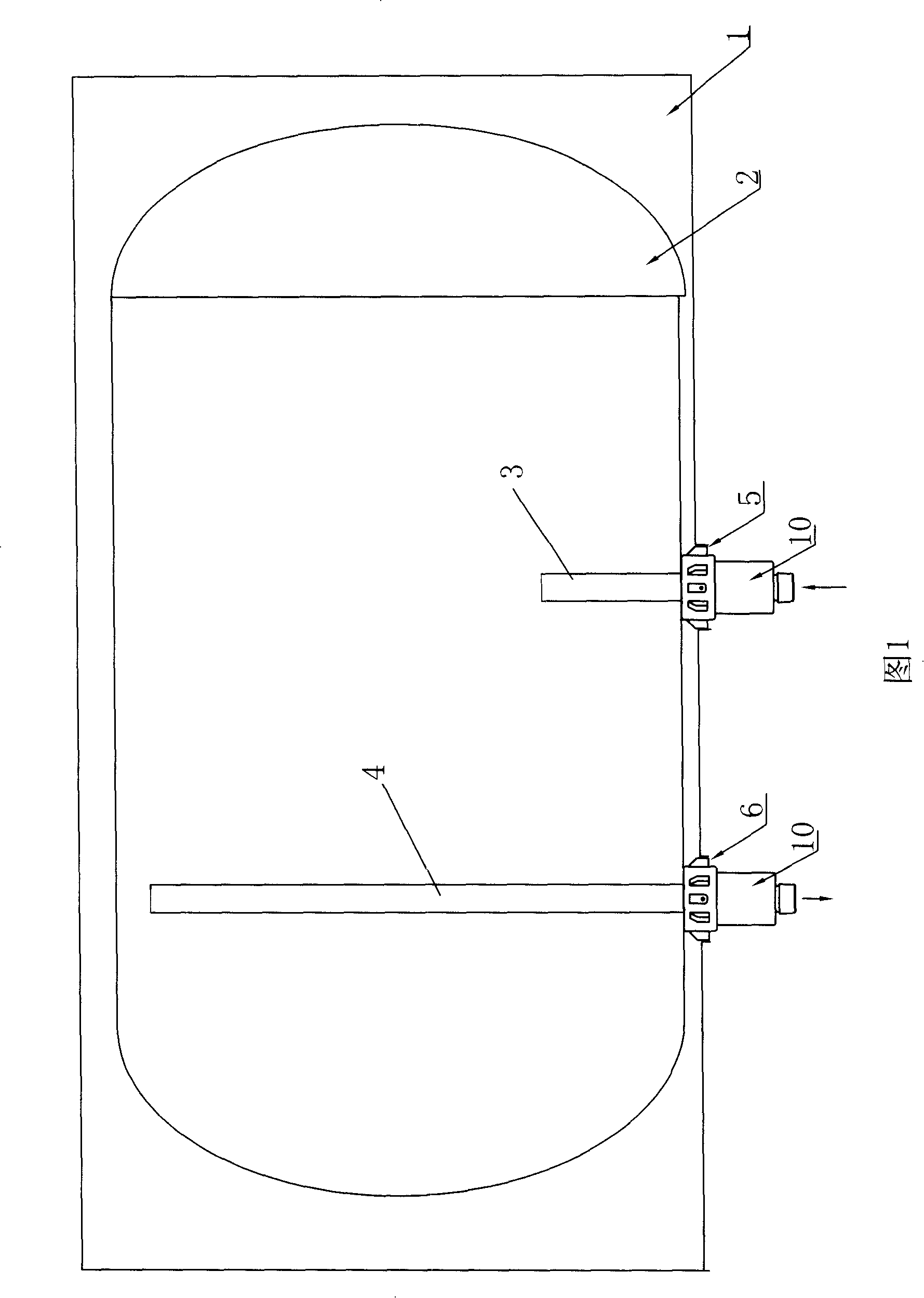

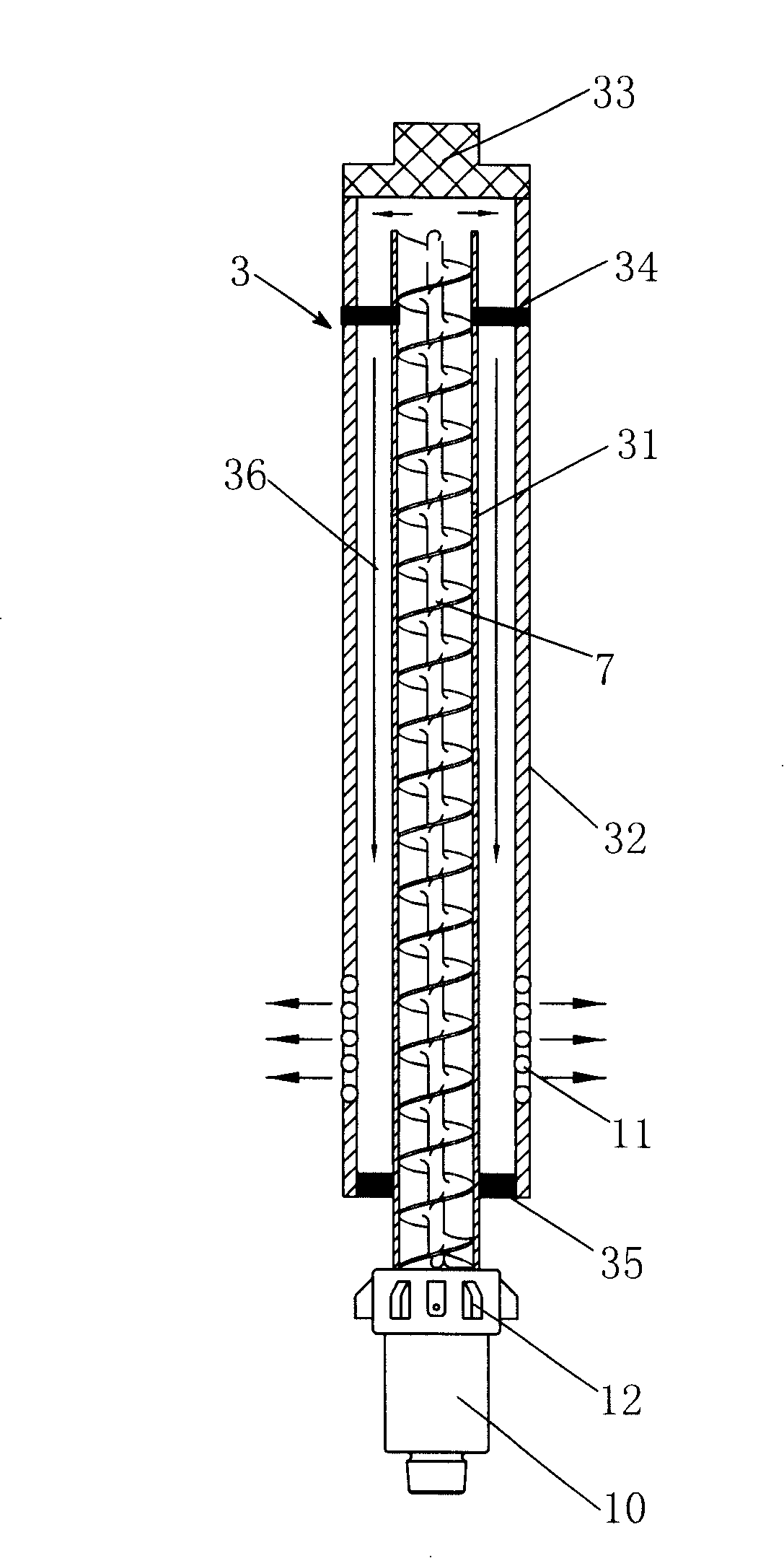

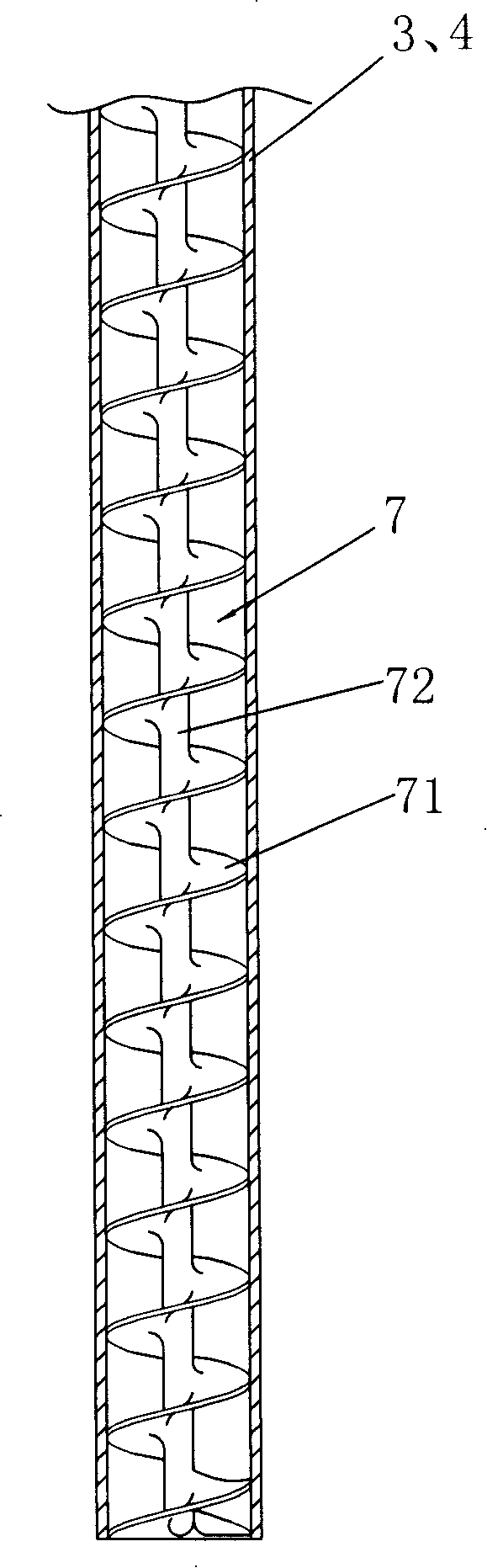

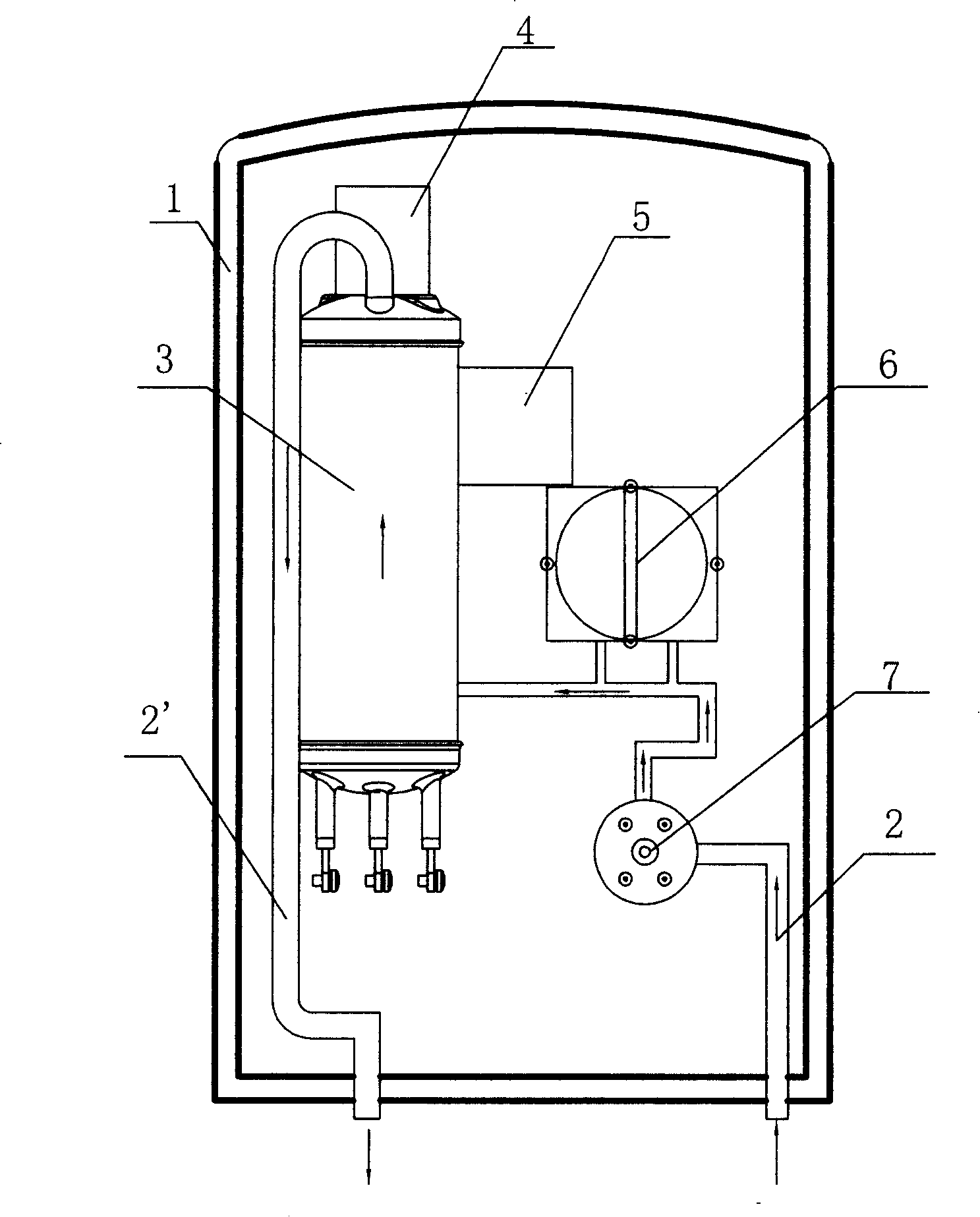

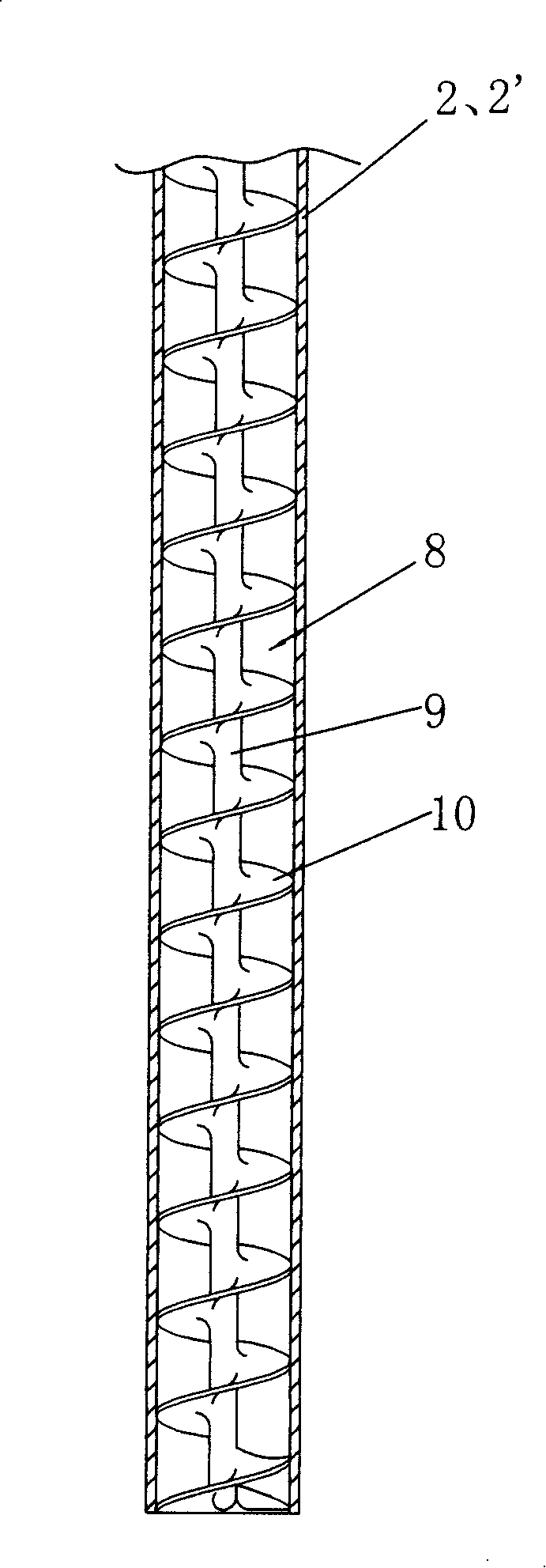

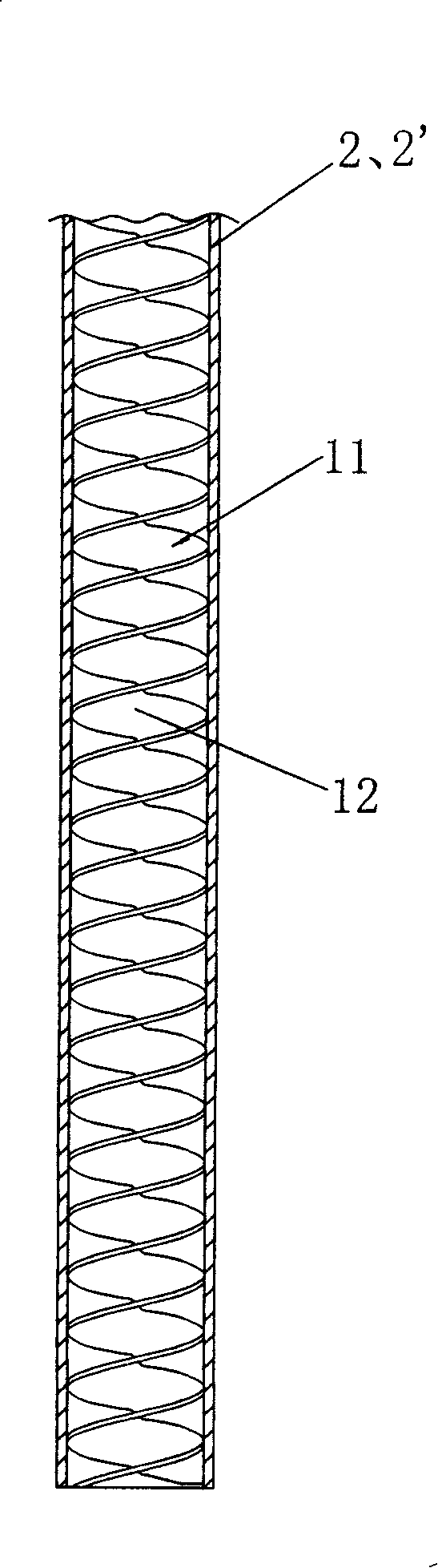

Water-storing type electricity-proof wall water heater

The invention discloses a water-storage water heater with electricity-protection wall technique, which comprises a shell, an inner frame, an insulating inlet water pipe and an insulating outlet water pipe. The shell is provided thereon with a water inlet and a water outlet. The insulating inlet / outlet water pipes are provided inside with an insulating mechanism which allows the length of inlet / outlet water paths inside the pipes to be larger than the actual length of the insulating inlet / outlet water pipes, a screw-like spiral bar in a spiral conveyor is arranged inside each of the insulating inlet water pipe and the insulating outlet water pipe, so as to form a spiral through water path inside the pipe, or a twisted bar twisted from a plastic sheet is used to replace the screw-like spiral bar. The insulation mechanism tallies with the inner holes of the pipes in shape, the water paths inside the pips twist and circulate along the twisted plane of the insulation mechanism and is fixed inside the insulating inlet / outlet water pipes via screws, and the insulating inlet / outlet water pipes, the inner frame and the shell are fixed each other via improved screws. The invention has the advantages of no need of being installed by a user, good hidden effect, no increase in occupied space, and good electricity-protection effect; and solves the problems of inconvenient use and potential electric shock caused by the improper installation when the user installs the water heater by himself.

Owner:HAIER GRP CORP +1

Making storage system having modifiable conductor and memory

InactiveUS8356758B1Lower-cost equipmentLow costRecord carriers used with machinesElectricityTransceiver

An electronic storage system includes a substrate with a state region, a transceiver with memory and a controller, and a code circuit disposed over the substrate separate from the transceiver and electrically connected thereto. The code circuit includes a conductor whose electrical or mechanical state can be externally altered. At intervals, the transceiver electrically excites the code circuit and detects the electrical state of an input pad connected to the code circuit. The electrical state corresponds to the excitation and to the electrical or mechanical state of the conductor. The controller stores the detected state or a representation thereof in the memory. In response to a downlink signal, the transceiver transmits an uplink signal representing the stored detected electrical state(s) of the input pad, or the stored representations thereof.

Owner:EASTMAN KODAK CO

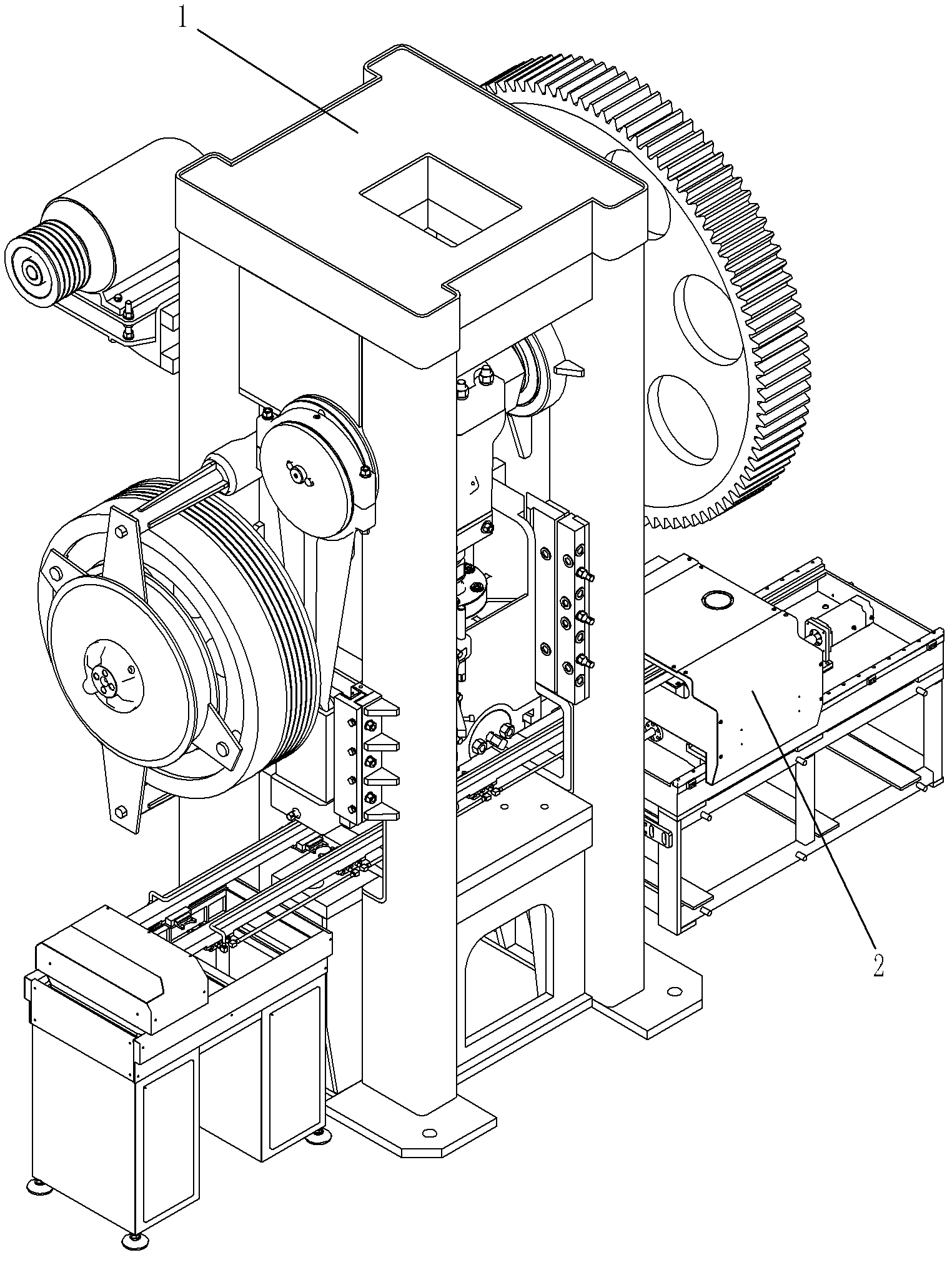

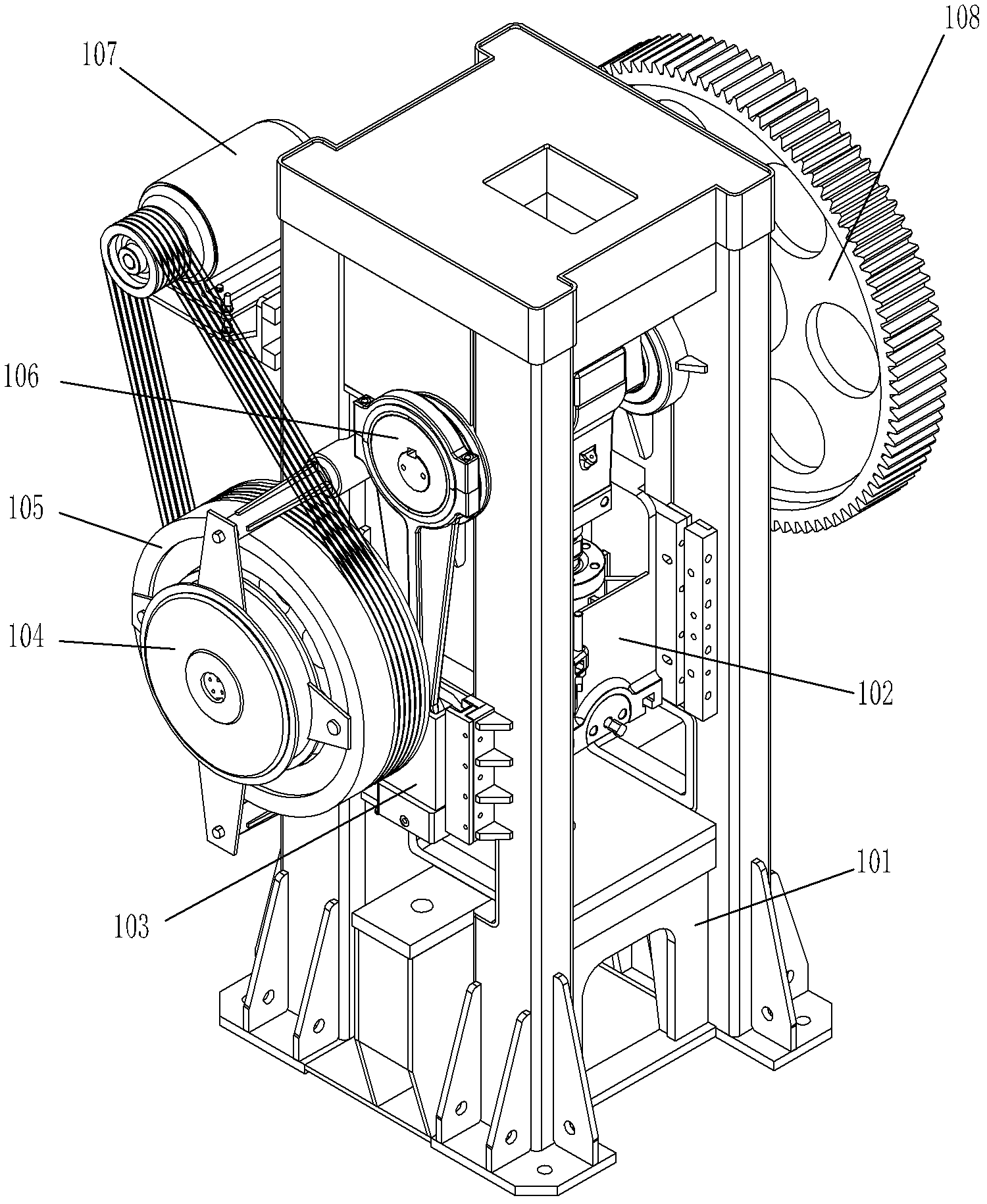

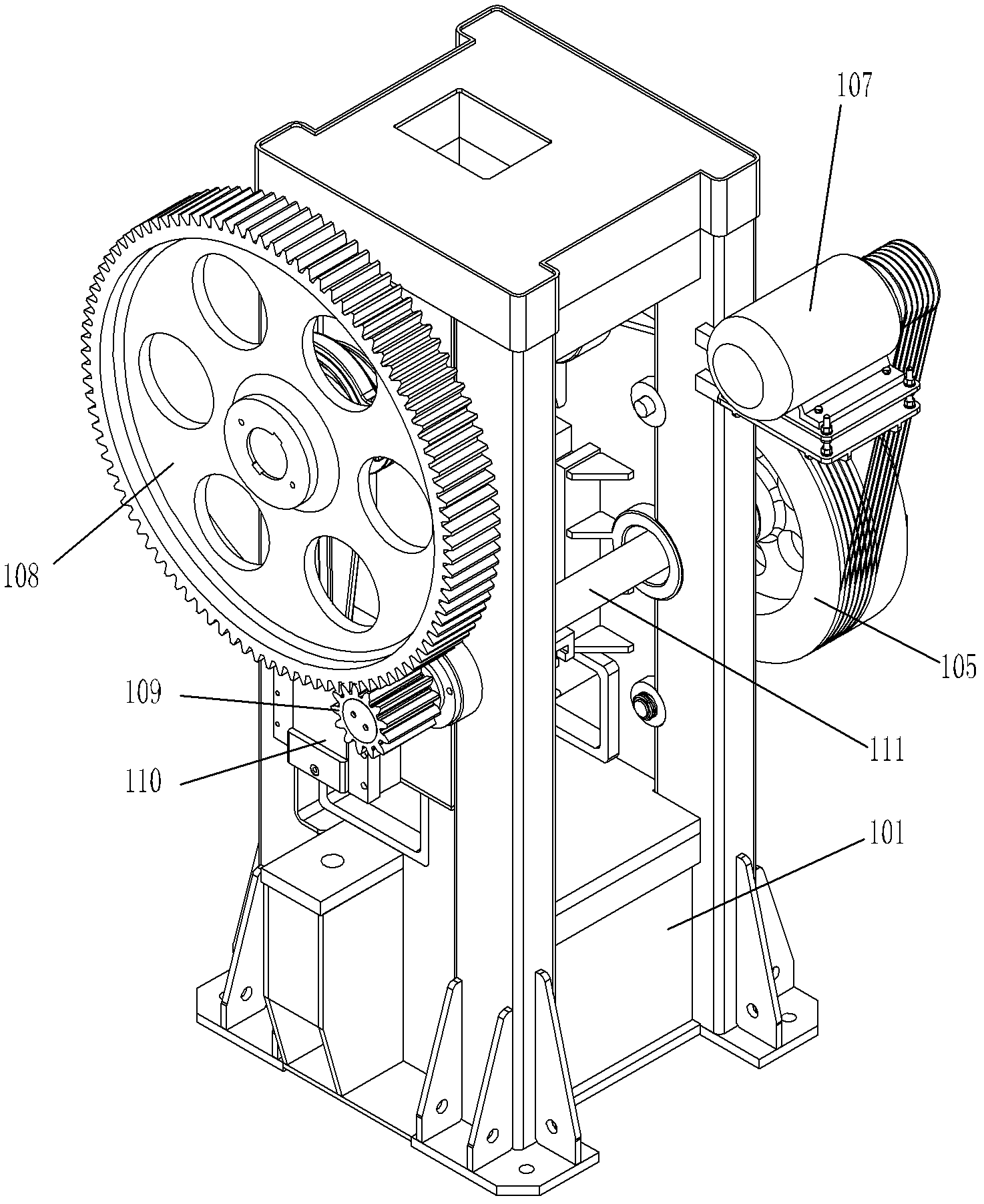

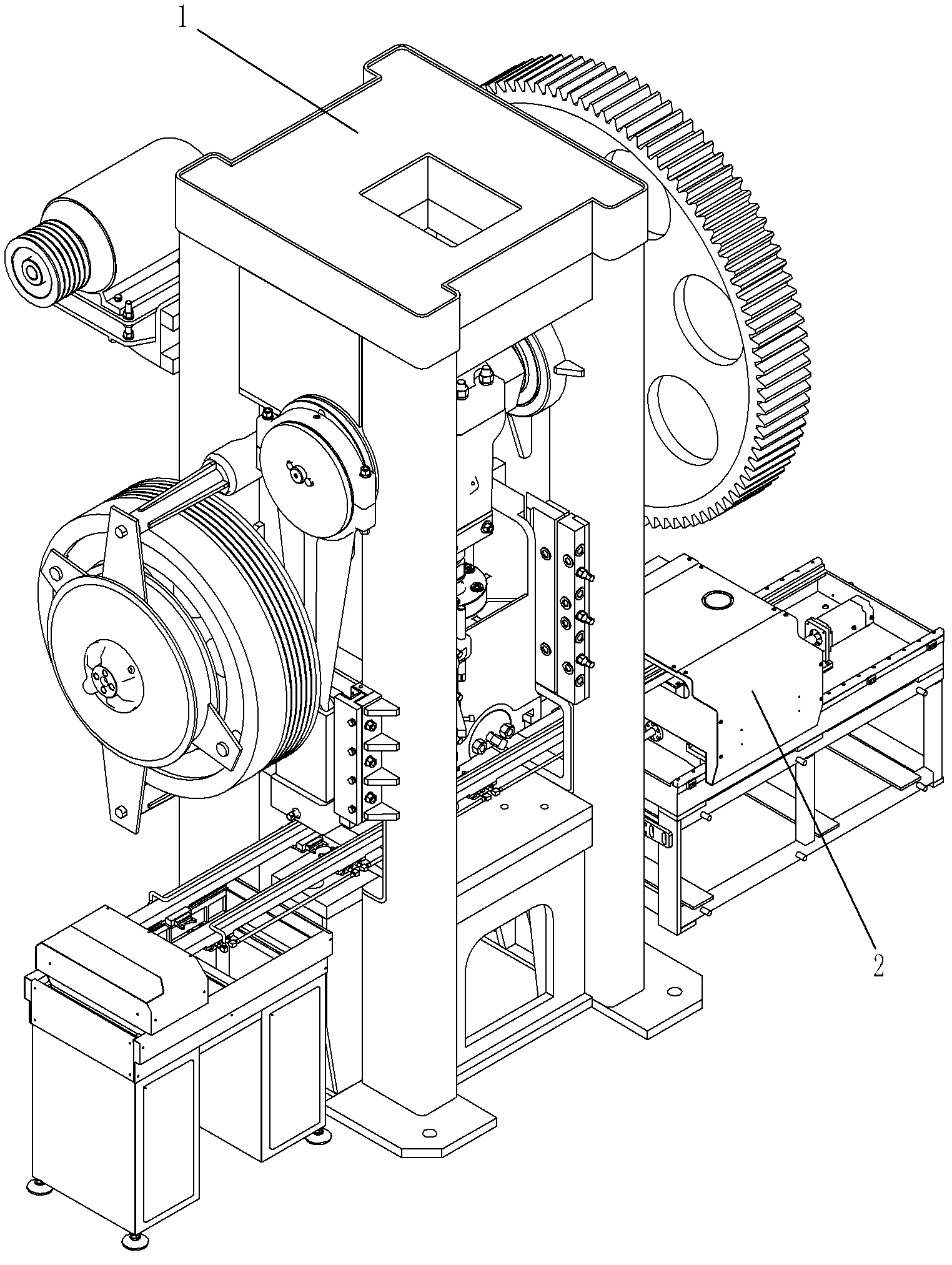

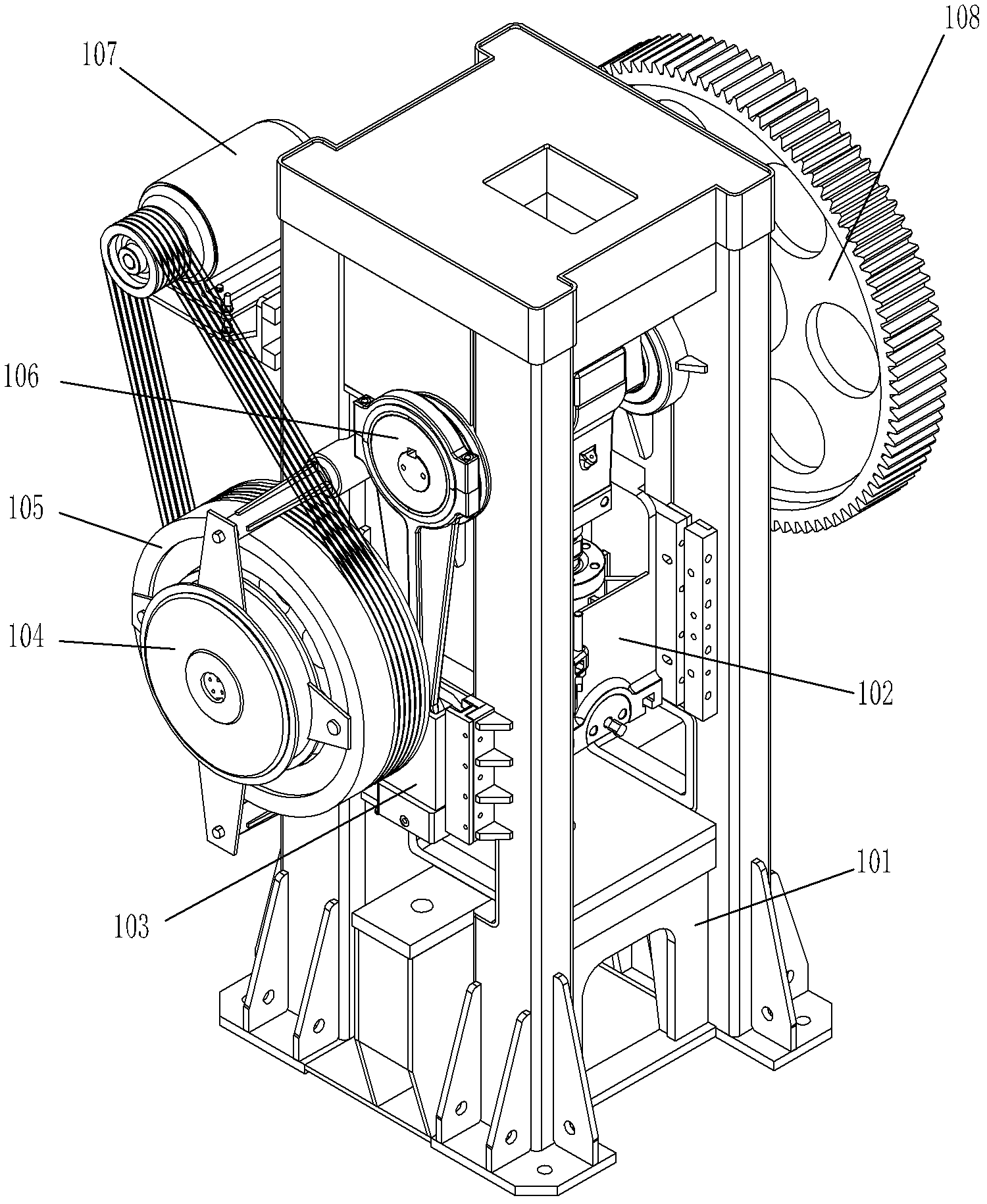

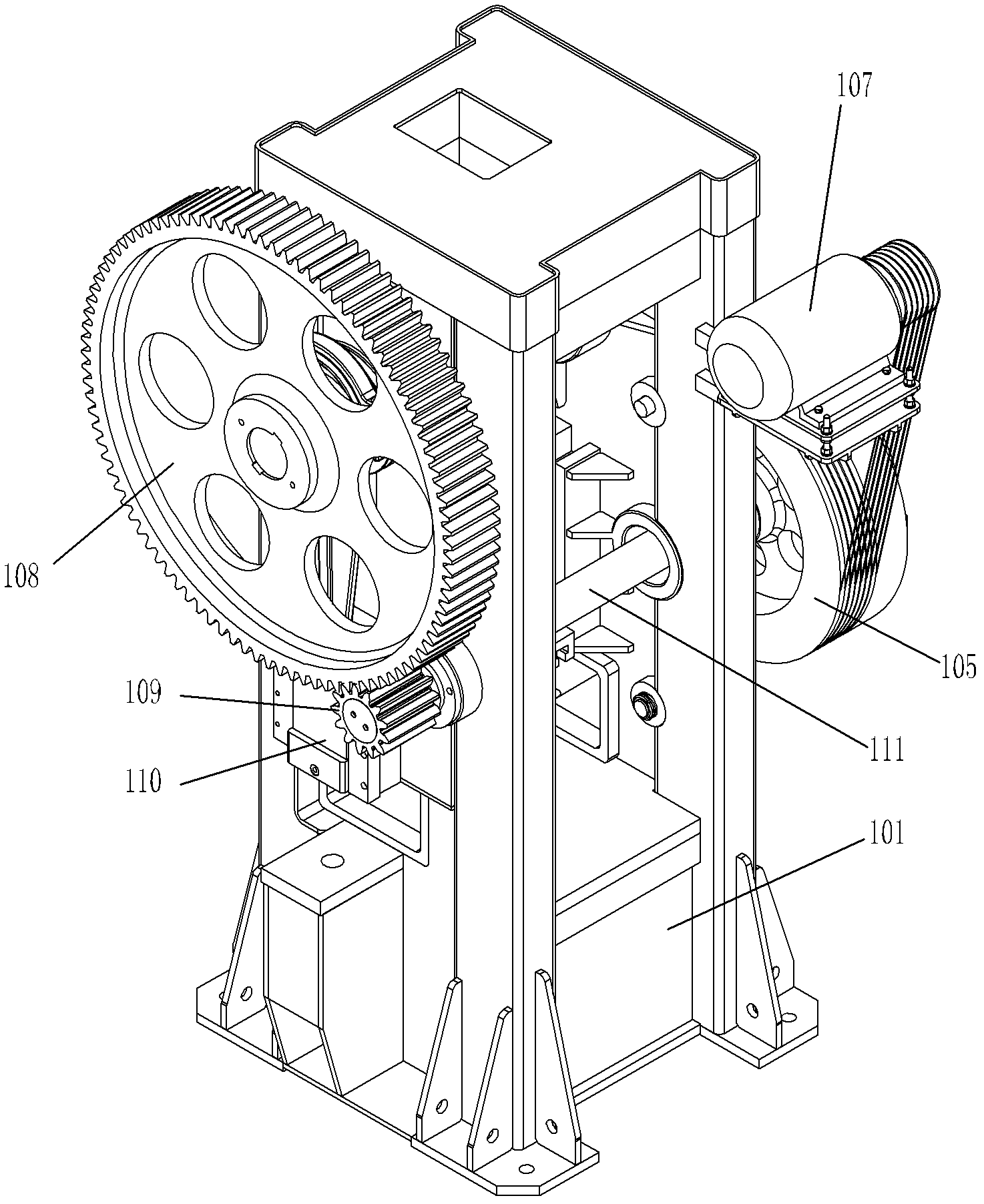

Hot forging production line

ActiveCN102601283AReduce equipment cost and use spaceIncrease productivityForging press detailsForging press drivesClutchMachine press

The invention discloses a hot forging production line, comprising a press and a feeding manipulator. A rack of the press is set with a motor, a flywheel, a clutch brake, a transmission shaft, a crankshaft, a slide block A, a slide block B and a slide block C. The transmission shaft and the crankshaft are rotatably set on the rack respectively. On end of the transmission shaft is set with the flywheel and the clutch brake. The flywheel and the motor are in transmission connection. The other end of the transmission shaft is in transmission connection with the crankshaft. The slide block A is vertically and glidingly set between two side wall plates of the rack and in transmission connection with the crankshaft through a connecting rod A and an eccentric wheel A. The slide block B is vertically and glidingly set outside the left wall plate of the rack and in transmission connection with the crankshaft through a connecting rod B and an eccentric wheel B. The slide block C is vertically and glidingly set outside the right wall plate of the rack and in transmission connection with the crankshaft through a connecting rod C and eccentric wheel C. The rack is set with a corresponding work table. The technical scheme is used for realizing multi-process multi-station processing of hot forging technology and capable of lowering the device cost and use space, and improving productivity.

Owner:ANHUI SAFE ELECTRONICS

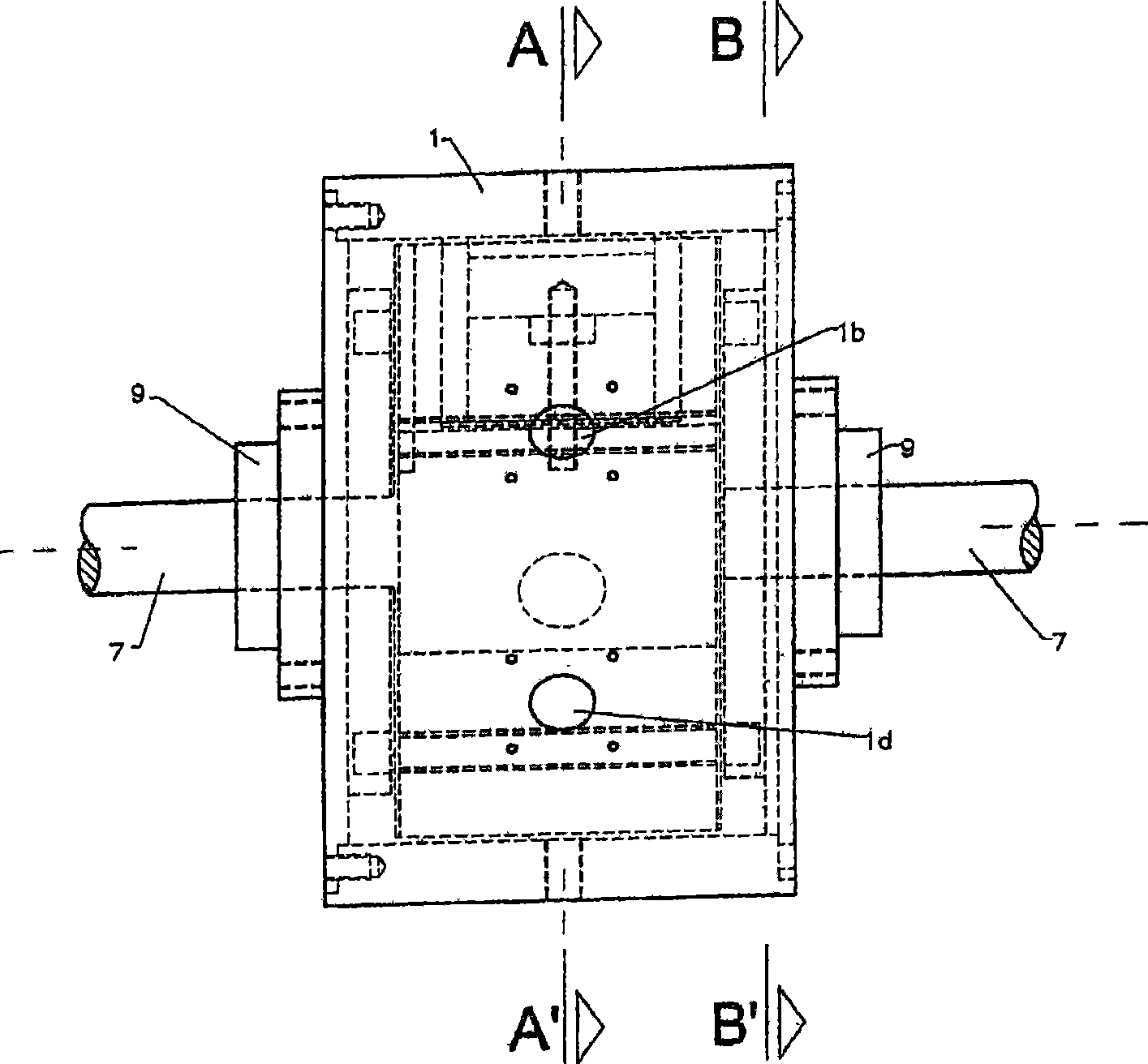

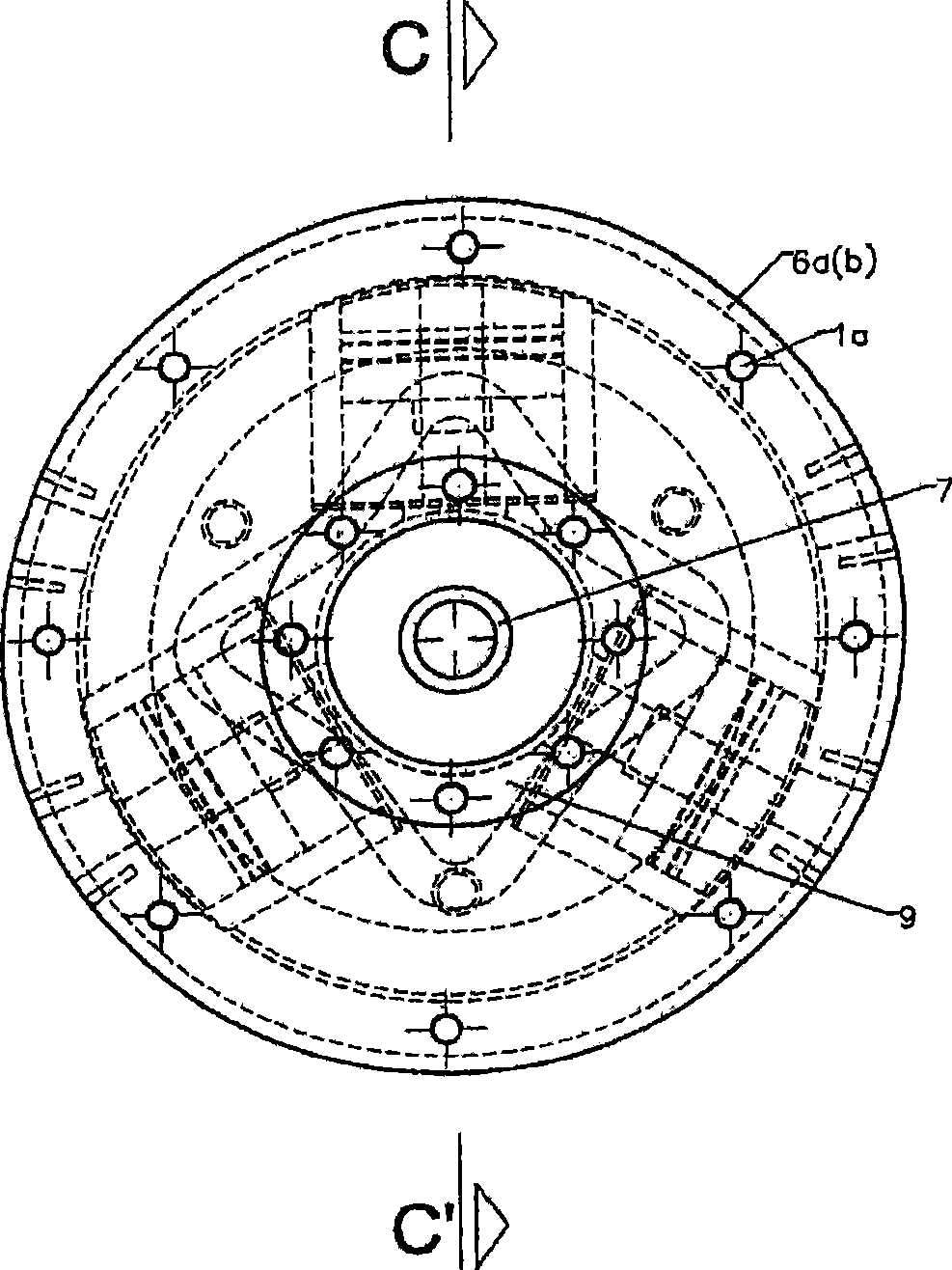

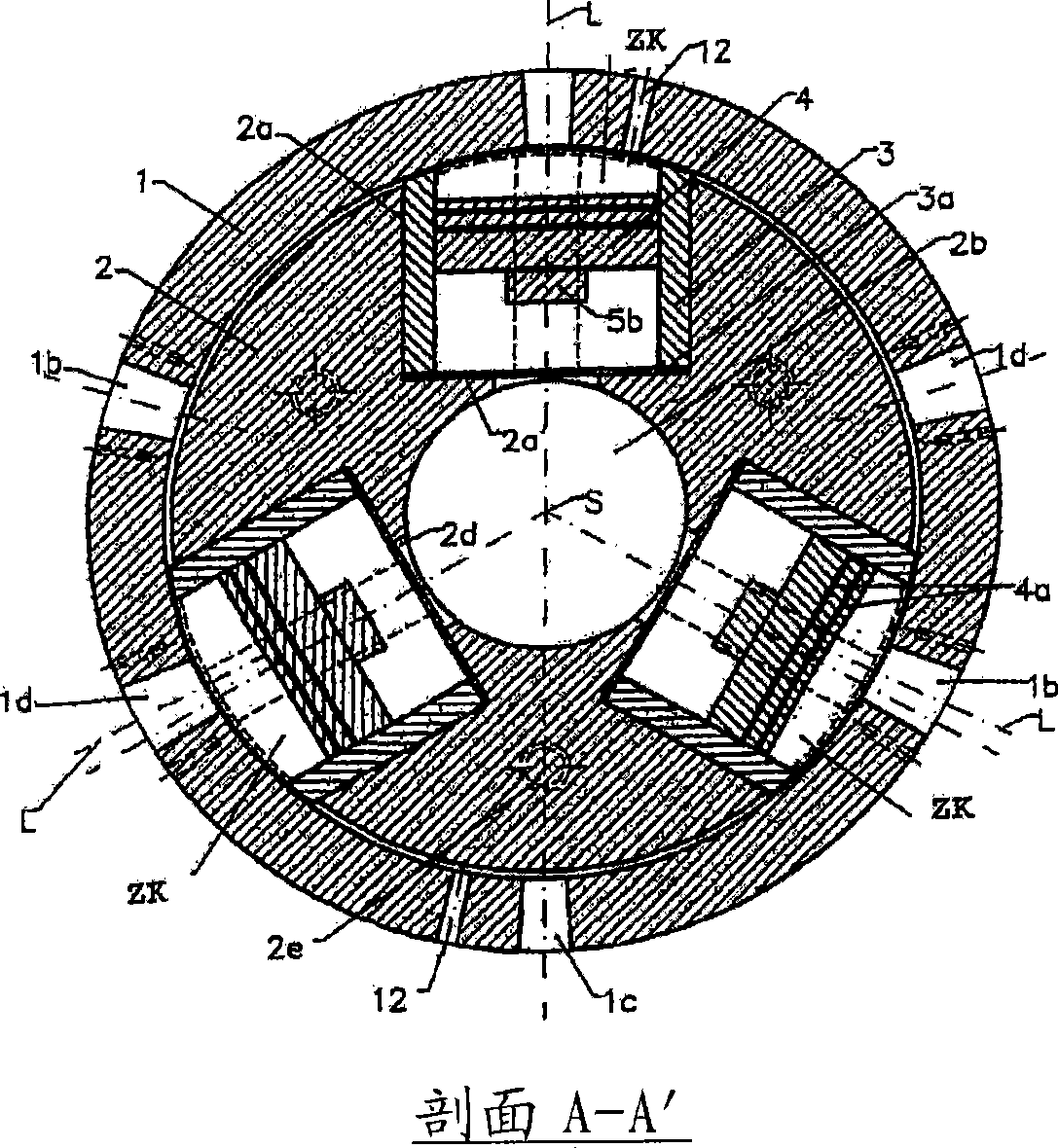

Engine with rotary piston

InactiveCN101371006ASmall structureSave materialInternal combustion piston enginesEngines with rotating cylindersEngineeringMechanical engineering

Disclosed is a rotary piston engine comprising a rotor which is rotatably mounted in a housing and in which several pistons can be moved in a radial direction between an outer and an inner dead center. Each piston is provided with a piston rod which sits on a transversal shaft that is fastened to a sliding piece at each end, said sliding piece being movable within radial grooves in the rotor, on both sides of the piston. The external side of the sliding pieces which faces away from the piston is fitted with a pin that is accommodated in a star-shaped continuous guiding groove which is fixed to the housing. The guiding groove extends around an axis of rotation of the rotor and causes the pistons to move in a radial direction between the inner and outer dead centers.

Owner:DEZMOTEC

Forging production line

ActiveCN102601285ALow costReduce the space requiredForging/hammering/pressing machinesForging press drivesProduction lineEngineering

The invention discloses a forging production line comprising a press machine and a feeding mechanical arm. The press machine comprises a sliding block A, a sliding block B and a Sliding block C, wherein the sliding block A is vertically and slidably arranged between the two side wall boards of a rack and connected with a crank shaft in a transmission way; the sliding block B is vertically and slidably arranged outside the left side wall board of the rack and connected with the crank shaft in a transmission way; the sliding block C is vertically and slidably arranged outside the left side wall board of the rack and connected with the crank shaft in a transmission way; and the rack is provided with corresponding work tabletops. The feeding mechanical arm comprises two clamping arms which are paired to use and straddle on a left rack and a right rack, wherein the two clamping arms are driven by a driving device C to move oppositely for gathering or separating from each other; and the two clamping arms can move left and right and four pairs of clamping claws for clamping blanks are oppositely arranged on the two clamping arms. In the technical scheme, a single multiple-station press machine is adopted and used for implementing multiple-procedure and multiple-station processing in the hot forging technology, the equipment cost and the occupied space are reduced, and the production efficiency is enhanced.

Owner:CHANGCHUN JIANBANG AUTOMOBILE PROD

Instant-heating type electricity-proof wall water heater

The invention discloses an instant-heating anti-electrical wall water heater, which comprises an outer bottom casing, a water inlet and outlet insulating tube which is installed on the outer bottom casing, a heating cap, a control circuit, and a thermoregulator, a water-flow regulating valve and a pressure switch which are arranged on the water inlet insulating tube. The invention is characterized in that the thermoregulator comprises an auto-reset thermoregulator which can keep outlet water in constant temperature and is controlled by water temperature, and a manual reset thermoregulator which is manually controlled to monitor the water heater. An insulating mechanism which leads the length of the inlet and outlet watercourse in the tube longer than the actual length of the water inlet and outlet insulating tube is arranged in the water inlet and outlet insulating tube, a spiral rod which takes screw bolt shape in a screw conveyer is arranged in the water inlet and outlet insulating tube, which leads the watercourse to form a spiral connecting watercourse in the tube, or a rotative surface twist strip which is twisted and coiled by a twist plate of a plastic flake is arranged in the water inlet and outlet insulating tube. The invention has simple structure, good hidden effect, simple and convenient employment, which cannot increase manufacture cost and service space, and inconvenience and electroshock hidden danger which is caused by improper installation can be eliminated when the water heater is installed by the user.

Owner:HAIER GRP CORP +1

Low-floor vehicle, bogie and axle end structure of bogie

ActiveCN109733433AReduce complexityReduce manufacturing costLinear/angular speed measurementBogiesBogieEngineering

The invention discloses a low-floor vehicle, a bogie and an axle end structure of the bogie. The axle end structure comprises a speed measuring gear and a friction disk, wherein the speed measuring gear with a middle through hole is used for being fixedly connected to the end surface of a wheel; the outer end surface of the speed measuring gear is provided with a plurality of speed measuring teethuniformly distributed in the circumferential direction; the friction disk is fixedly connected to the speed measuring gear, and specifically configured on the outer end surface of the speed measuringgear and on the radial outer circumference of the speed measuring teeth; an axle end front cap is mounted on the outer sides of the speed measuring gear and the friction disk in a covering manner; abody central part of the axle end front cap is used for being fixedly connected to an axle end of a vehicle axle through the middle through hole of the speed measuring gear; and a speed sensor interface and a brush interface which are separately arranged corresponding to the speed measuring teeth and the friction disk are formed on the axle end front cap. The axle end structure of the bogie is optimized, and the space of the axle end is fully utilized to integrate the functions of grounding and speed measuring into the axle end of the bogie; and the axle end structure of the bogie is simple and reliable in structure, and further reduces the difficulty of wiring while reducing the design complexity of the bogie.

Owner:CRRC QINGDAO SIFANG CO LTD

Motor vehicle power train

InactiveCN101980882AGet rid of fixed connectionSmall torqueGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingDrive wheelAutomatic transmission

The invention relates to a motor vehicle power train, especially for heavy-duty commercial vehicles; comprising a main drive engine, especially an internal combustion engine, comprising an output shaft for driving the drive wheels of the motor vehicle; an electric motor, comprising a rotor and a stator, also for driving the drive wheels of the motor vehicle; an automatic transmission, comprising a plurality of selectively settable drive connections for the implementation of gears, and a transmission input shaft and a transmission output shaft in order to selectively set a plurality of gear ratios between the transmission input shaft and the transmission output shaft, with the rotor of the electric motor being disposed in a drive connection between the output shaft of the main drive engine and the transmission input shaft, and can be disengaged from the output shaft by means of a clutch; at least one ancillary unit which can be driven by the main drive engine. The invention is characterized in that the rotor of the electric motor comprises an exterior drive having a gearing or friction surface which has a driving connection to the at least one ancillary unit in order to drive the same by means of the rotor.

Owner:VOITH PATENT GMBH

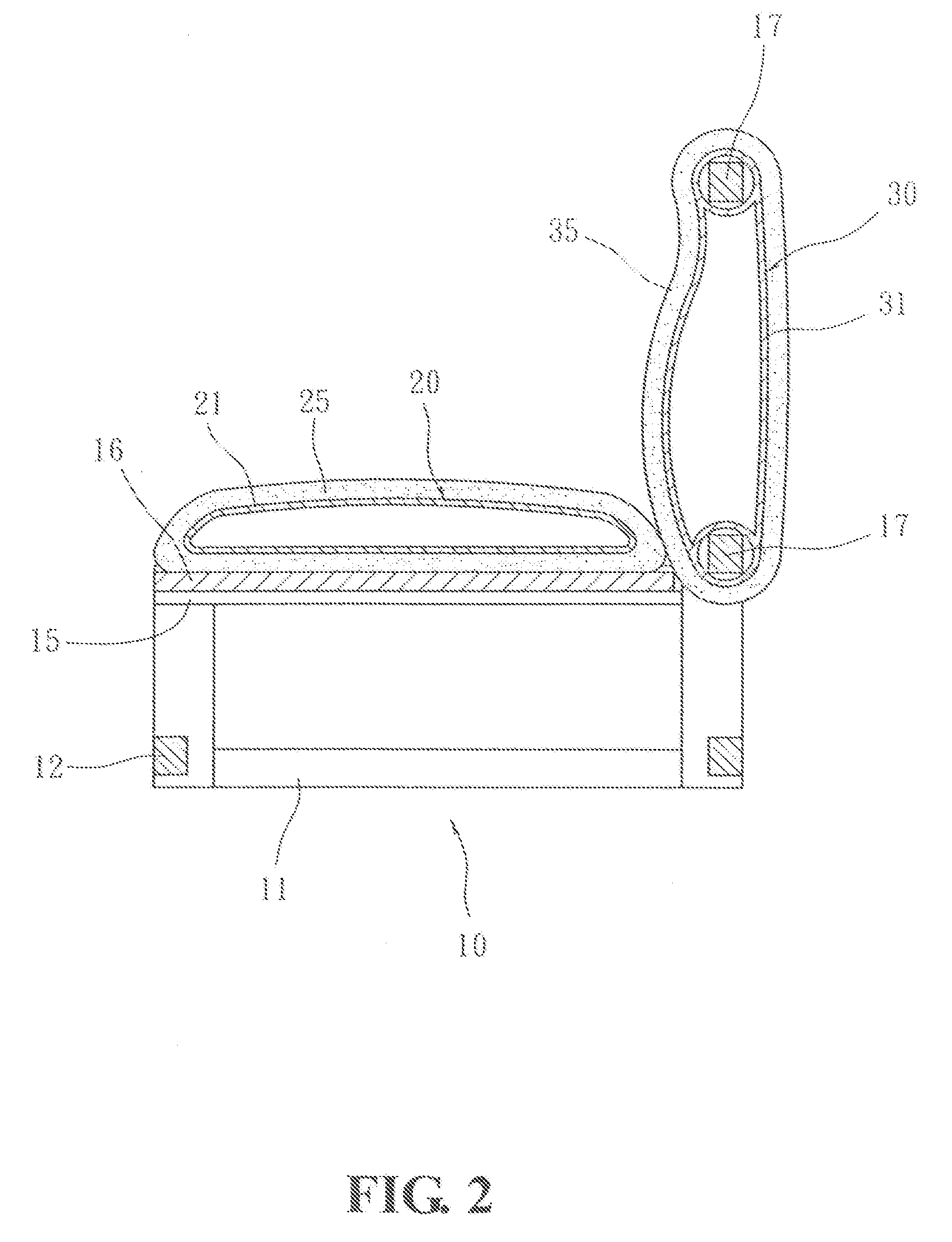

Built-up inflatable sofa

InactiveUS20080012410A1Reduce inconvenienceReduce the space requiredSofasCouchesEngineeringAirbag deployment

A sofa of the present invention mainly contains a built-up seat frame which can be easily assembled and disassembled, an inflatable seat cushion positioned horizontally on the seat frame, and an inflatable backrest positioned vertically at a side of the seat cushion. The seat cushion and the backrest are basically air bags with air faucets. A user can pump air into or release air from the air bags for an appropriate degree of softness.

Owner:CHANG MIN RONG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com