Frequency conversion control method

A frequency conversion control and frequency reduction technology, applied in the field of frequency conversion control, can solve the problems of increasing the cost of the unit, increasing the heat balance of the energy storage water tank, and the impact of water temperature, so as to achieve the effects of reducing cost and space, efficient and safe operation, and reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

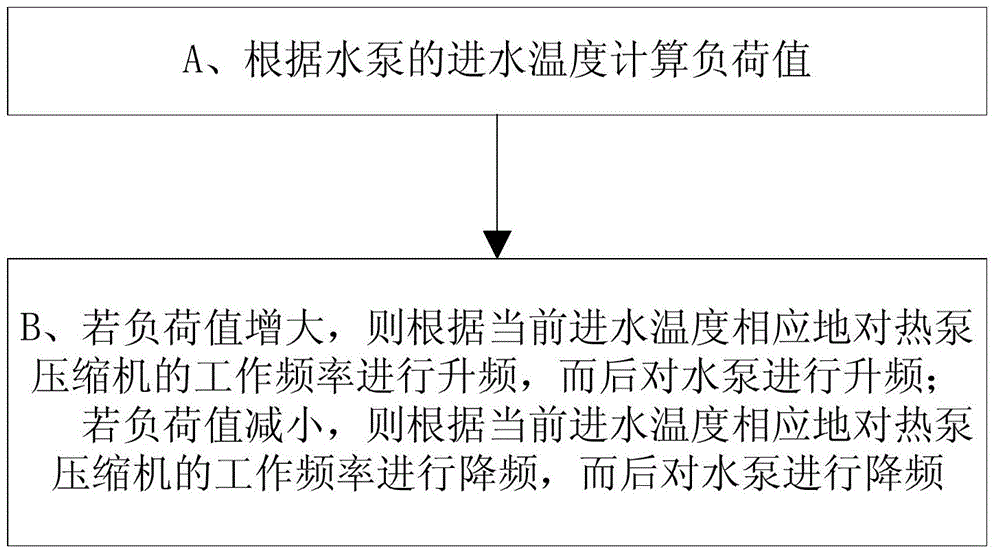

[0029] refer to figure 1 , a frequency conversion control method, comprising the following steps:

[0030] A. Calculate the load value according to the water inlet temperature of the pump;

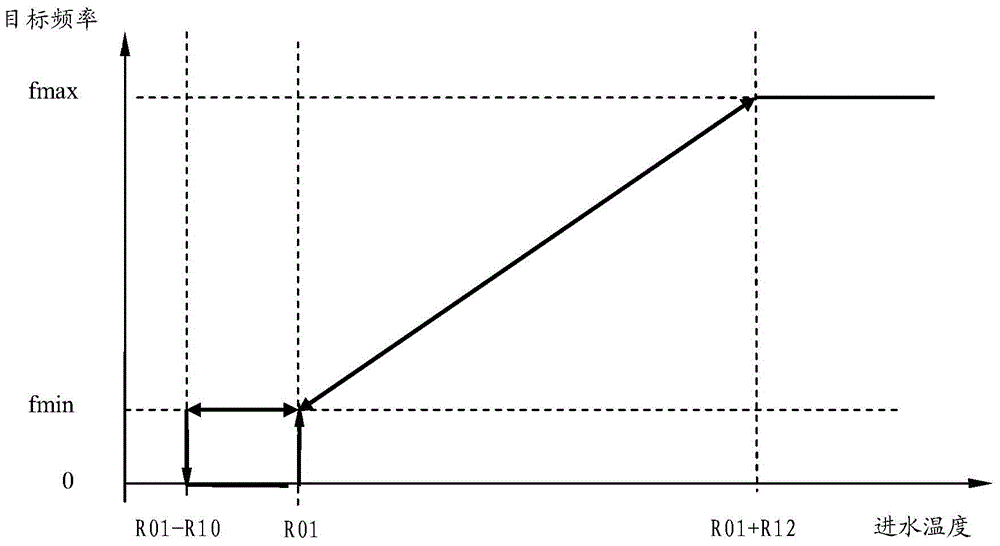

[0031] B. If the load value increases, the operating frequency of the compressor will be increased according to the current inlet water temperature to meet the demand for temperature compensation with greater output capacity, and then the frequency of the water pump will be increased to increase the water flow to meet the temperature compensation requirements. The need for temperature compensation;

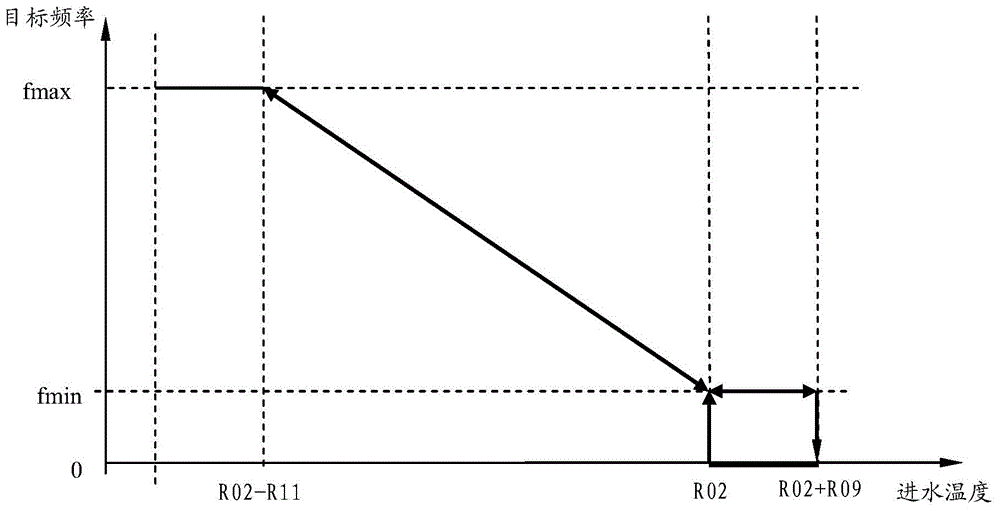

[0032] If the load value decreases, the operating frequency of the compressor will be reduced according to the current inlet water temperature to meet the temperature compensation requirements with a smaller output capacity, and then the water pump will be reduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com