Cut-off filtering composite valve

A combined valve and filter cavity technology, which is applied in the direction of filtration separation, valve lift, valve device, etc., can solve the problems of short service life of valves, blockage of pipeline valves, and single function, so as to prolong service life, reduce manufacturing costs, and improve The effect of overhaul efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

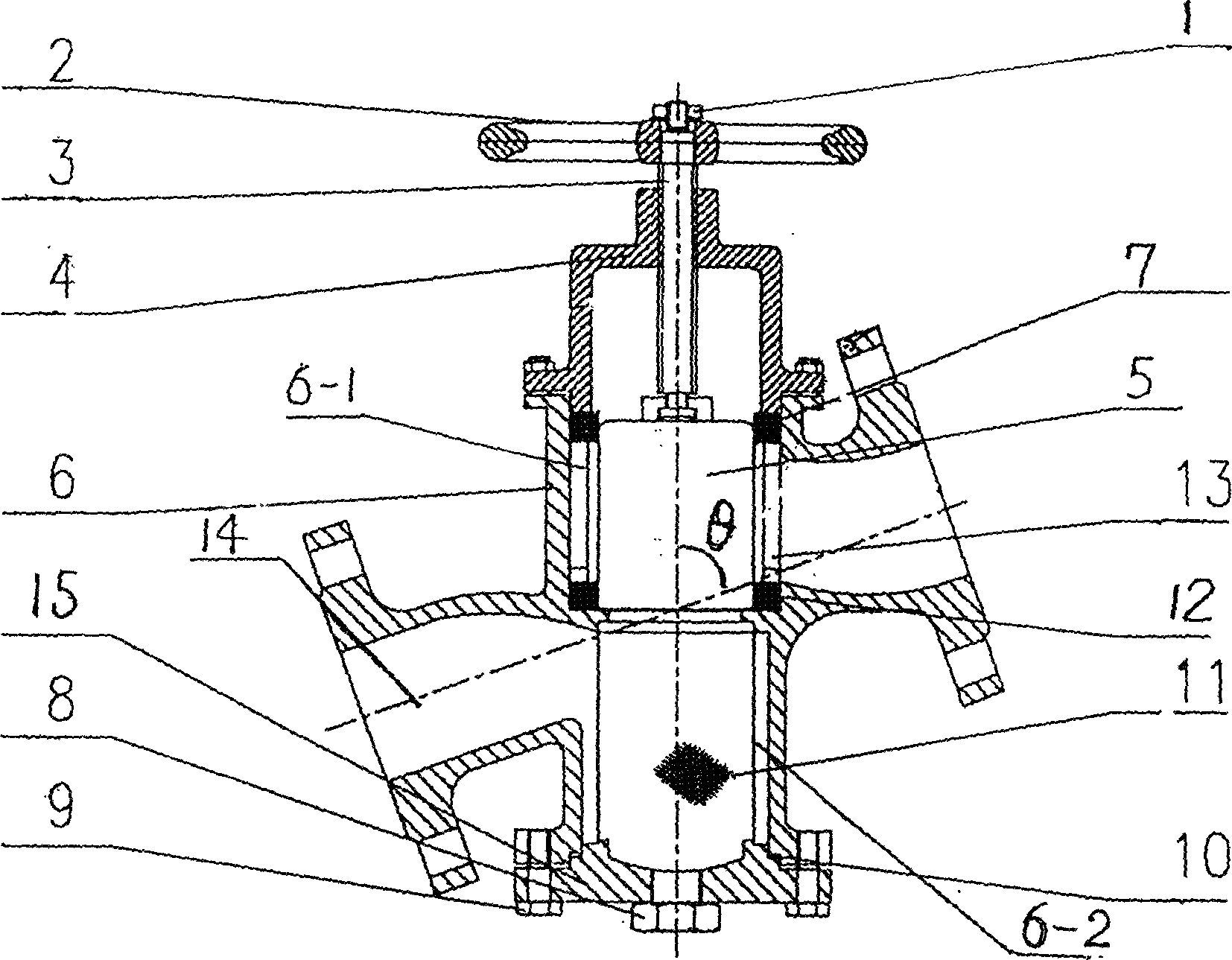

[0012] Such as figure 1 The plunger-type cut-off filter combination valve shown has a plunger valve part composed of a valve body 6, a valve cover 4, a valve stem 3 and a plunger 5 with the same structure as the known technology, and is characterized in that it will The valve body is set in two parts, the upper cut-off cavity 6-1 and the lower filter cavity 6-2, the hand wheel 2 is fastened to the upper end of the valve stem 3 through the valve stem nut 1, and the valve cover 4 is sealed on the upper port of the valve body 6, and its The valve stem 3 passes through the valve cover 4 and its lower end is connected with the cylindrical plunger 5 in the valve body. The upper sealing ring 7 and the lower sealing ring 12 in the cut-off cavity are respectively placed at the upper and lower ports of the valve body inlet, and the valve body inlet 13 It communicates with the cut-off cavity, and the outlet 14 of the valve body communicates with the lower filter cavity of the valve body ...

Embodiment 2

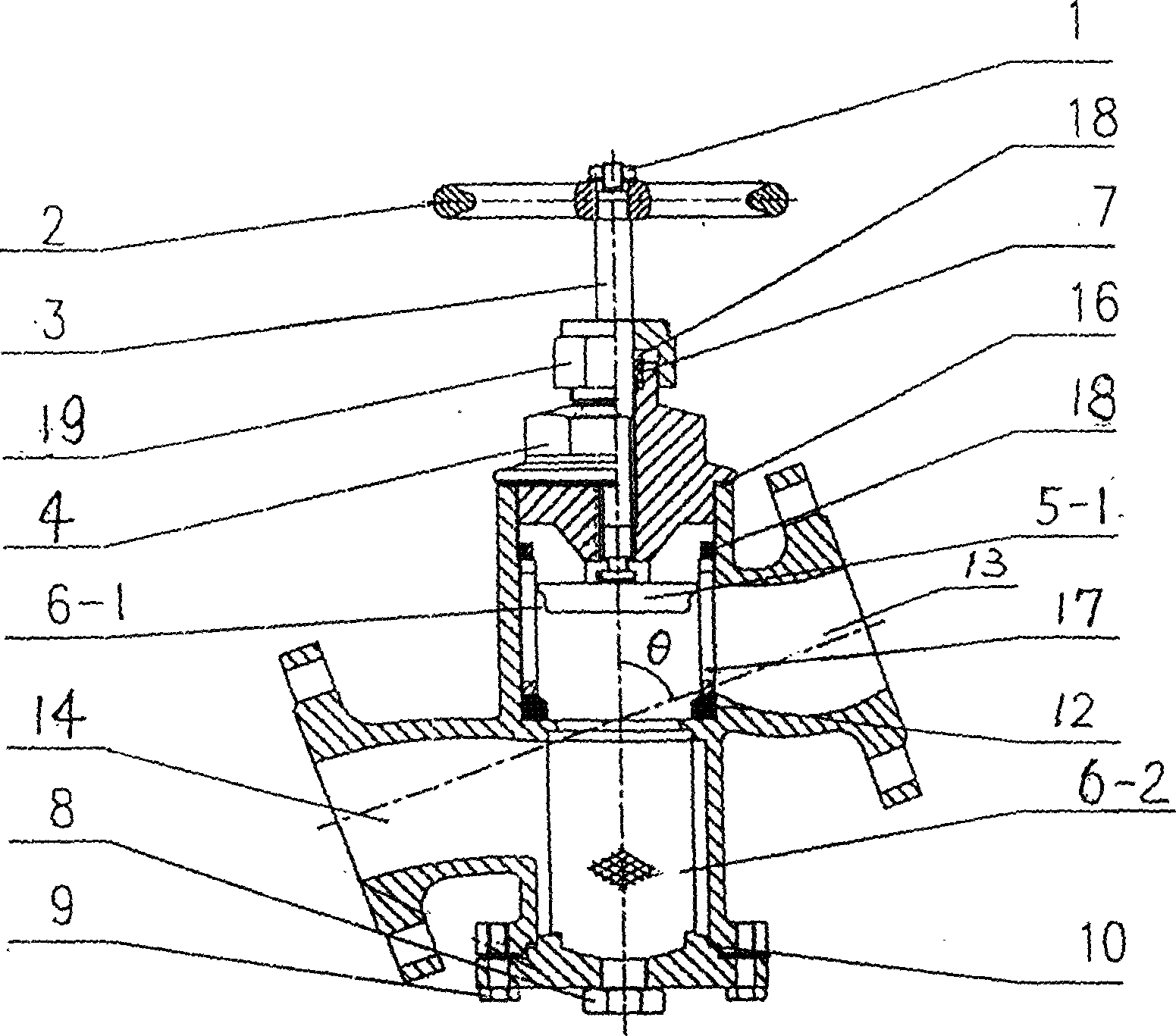

[0014] Such as figure 2 Another novel plunger-type cut-off filter combination valve shown is an improvement on the basis of known plunger-type cut-off valves. It sets the valve body of the plunger valve into two parts, the upper cut-off chamber 6-1 and the lower filter chamber 6-2, the inlet 13 of the valve body communicates with the cut-off chamber, and the outlet 14 of the valve body is connected with the cylindrical filter. According to the structure of the valve body and the best flow direction of the connecting pipeline, the axes of the cut-off cavity and filter cavity of the valve body and the connecting axis of the inlet and outlet pipelines of the valve body form a positive angle of θ<90° . The difference from the plunger valve in Embodiment 1 is that the plunger 5-1 used in the cut-off chamber 6-1 vertically connected to the filter chamber 6-2 and the lower sealing elastic ring 12 installed on the sealing platform of the valve body have at least two The composite s...

Embodiment 3

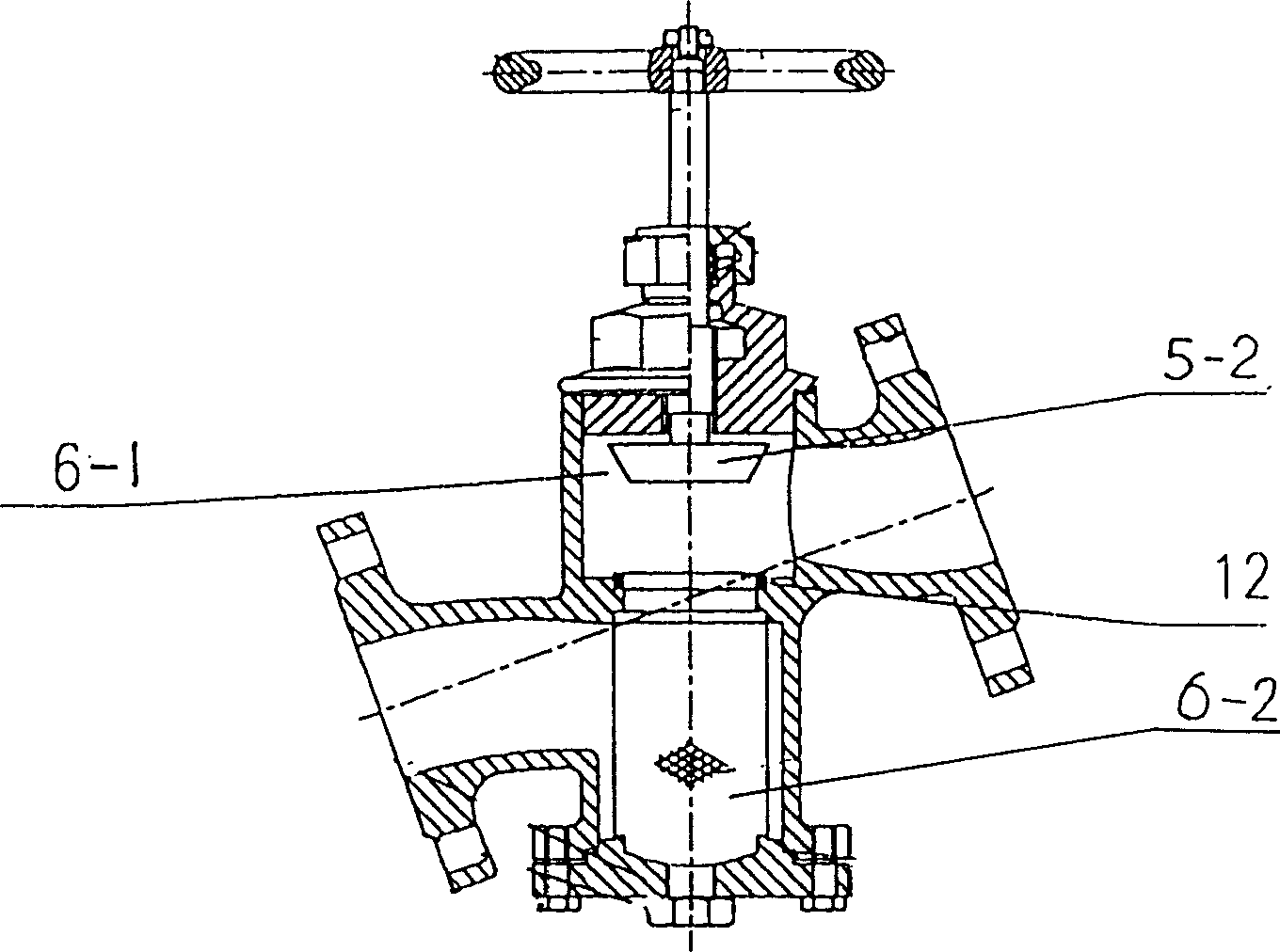

[0016] Such as image 3 What is shown is a disc-type cut-off filter combined valve. On the basis of the improved parts of Embodiments 1 and 2, the different parts of the plunger valve are the ones used in the plunger chamber 6-1 vertically connected to the filter chamber 6-2. The cut-off disc plunger 5-2 and the cut-off gasket 12 are standard structures of known technologies. The inlet and outlet of the valve body are connected with the pipeline by flanges.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com