Low-floor vehicle, bogie and axle end structure of bogie

A bogie shaft and shaft end technology, which is applied in the field of rail transit, can solve the problems of increasing the complexity of the bogie, increasing vehicle wiring, and many functional requirements, and achieves the effects of simple and reliable structure, reduced complexity, and reduced manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

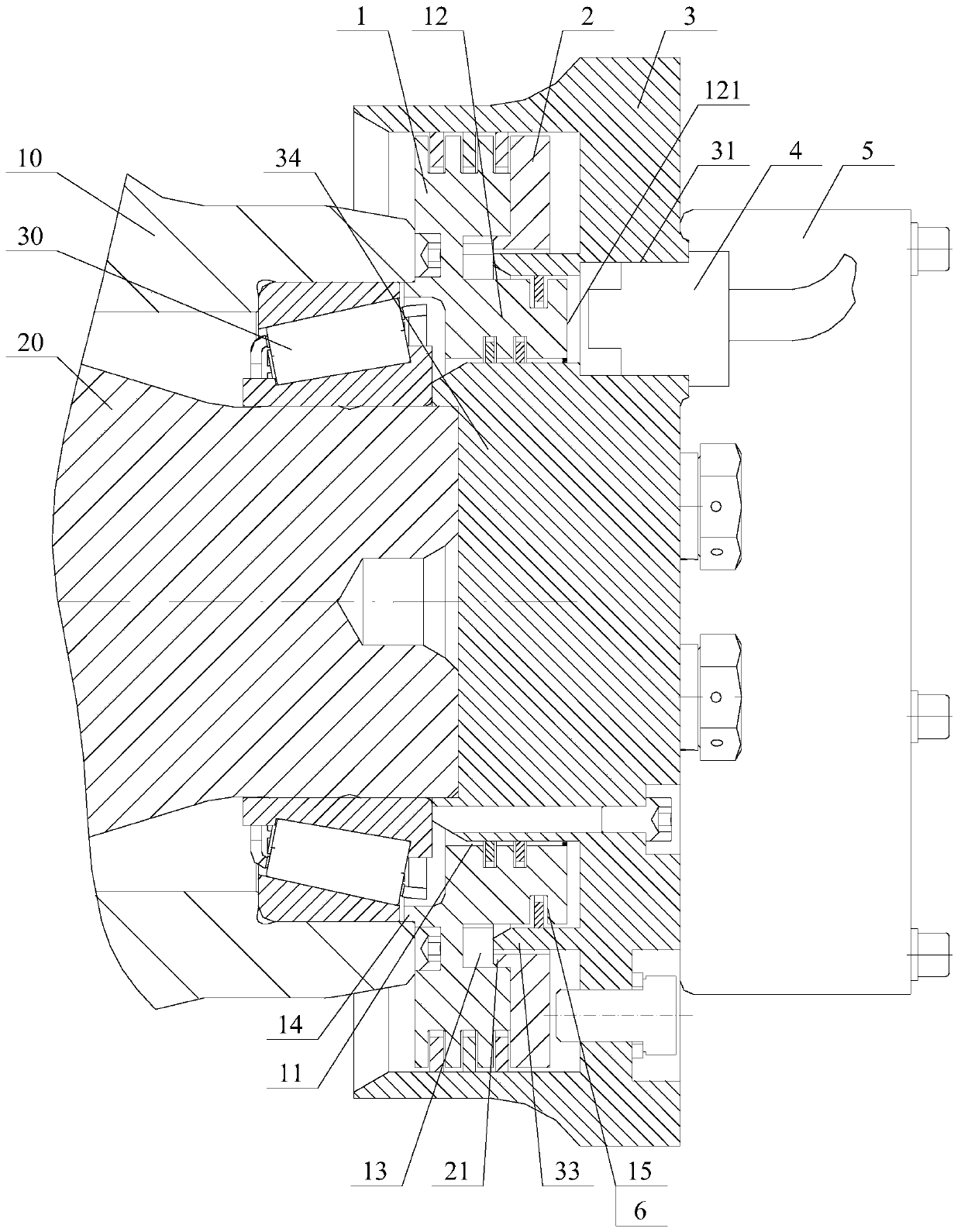

[0025] Without loss of generality, this embodiment uses figure 1 The axle end form of the bogie shown in is used as the basis for description, and the innovative improvement scheme of the axle end structure proposed in this application is explained in detail. It should be understood that the outline shapes and size ratios of the axles of the bogie and the wheels shown in the figure do not constitute a technical solution for protection claimed in the present application and constitute a substantive limitation.

[0026] See figure 1 , which is a schematic diagram of the overall structure of the axle end structure of the bogie according to this embodiment.

[0027] It should be clear that the assembly relationship between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com