Light emitting diode radiating module and applied display apparatus

A technology of light-emitting diodes and heat dissipation modules, applied in lighting devices, cooling/heating devices of lighting devices, indirect heat exchangers, etc., can solve problems such as poor heat dissipation mechanism, dry heat pipes, and unusable heat pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the heat dissipation module and the heat pipe thereof according to the present invention will be described below with reference to related drawings.

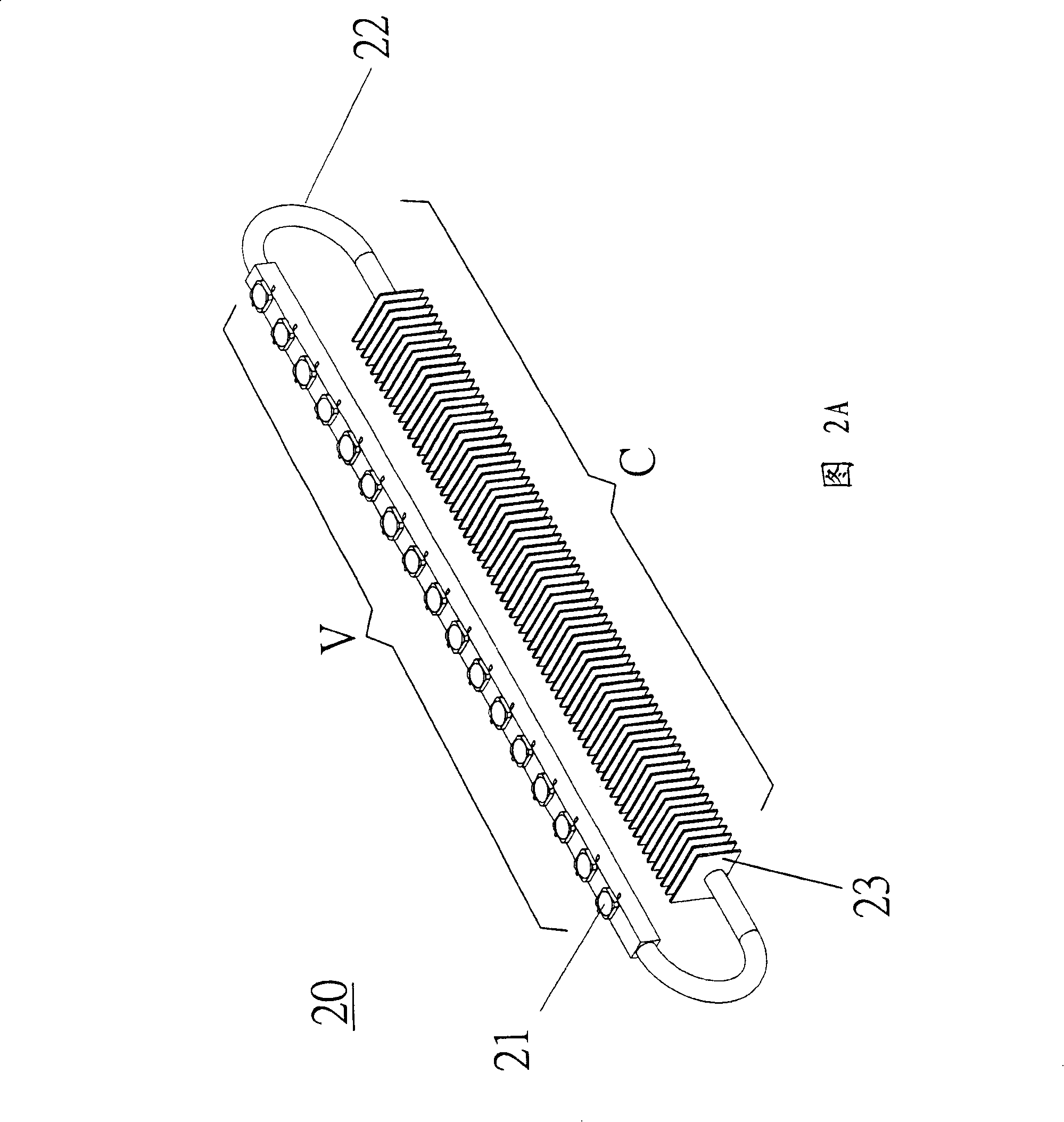

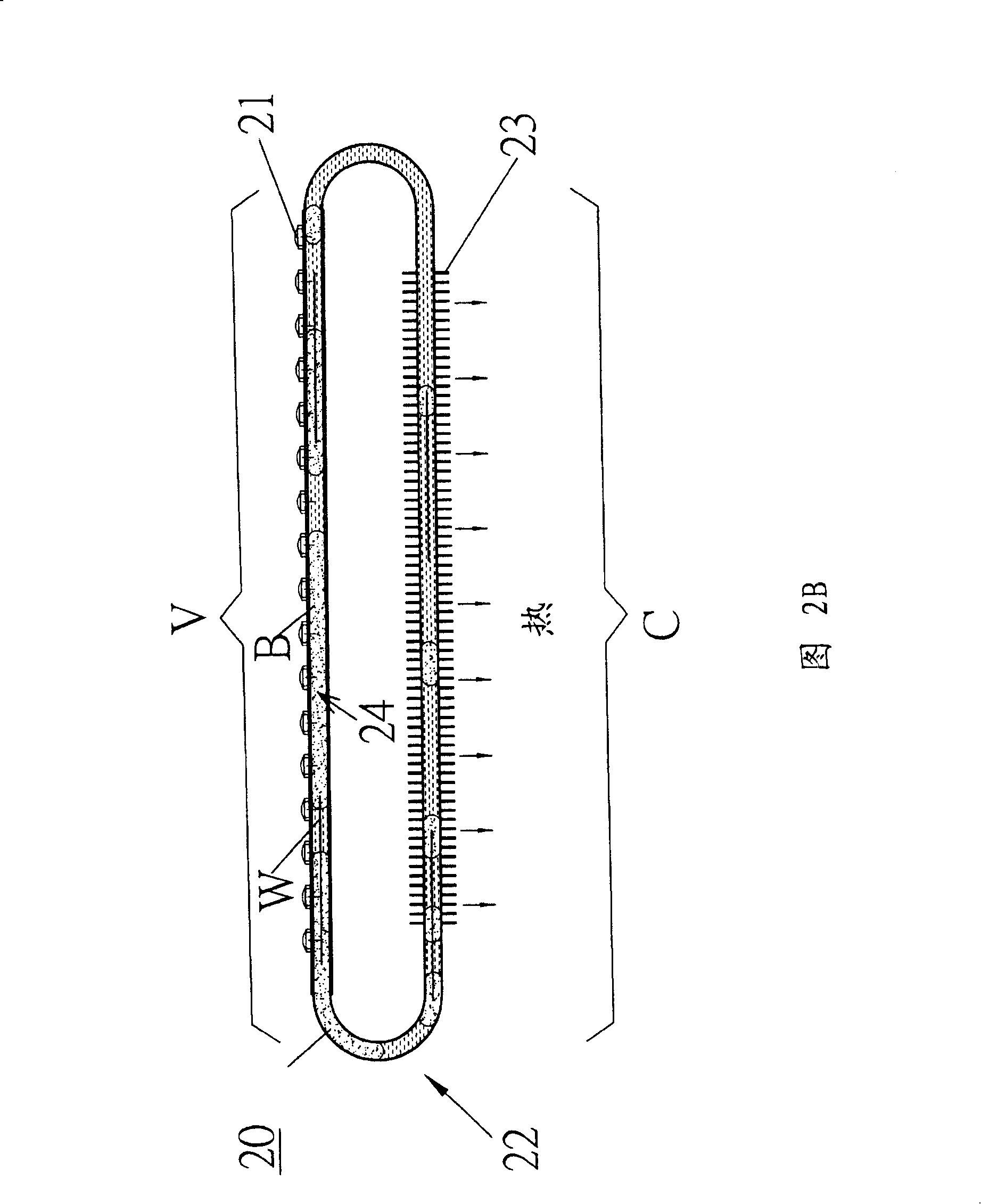

[0029] Please refer to FIG. 2A and FIG. 2B at the same time. FIG. 2A is a schematic diagram of an LED cooling module according to a preferred embodiment of the present invention, and FIG. 2B is a schematic side sectional view of FIG. 2A . As shown in FIG. 2A , the LED cooling module 20 according to a preferred embodiment of the present invention includes a plurality of LEDs 21 , a pulsed heat pipe 22 and a plurality of cooling fins 23 . A plurality of light emitting diodes 21 are individually arranged on the pulse heat pipe 22 , and a plurality of cooling fins 23 are also connected to the pulse heat pipe 22 . The material of the impulse heat pipe 22 includes a material with high thermal conductivity, such as aluminum, copper, titanium, molybdenum, silver, stainless steel, carbon steel or other alloys.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com