A hot filling valve

A technology of hot filling and valve seat, which is applied in packaging, bottle filling, liquid bottling, etc. It can solve the problems of difficult valve body cleaning, large fluctuations in liquid level accuracy, and affecting the taste of materials, so as to avoid repeated heating and sterilization, The cam drive is accurate and stable, avoiding the effect of unstable production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below through specific examples.

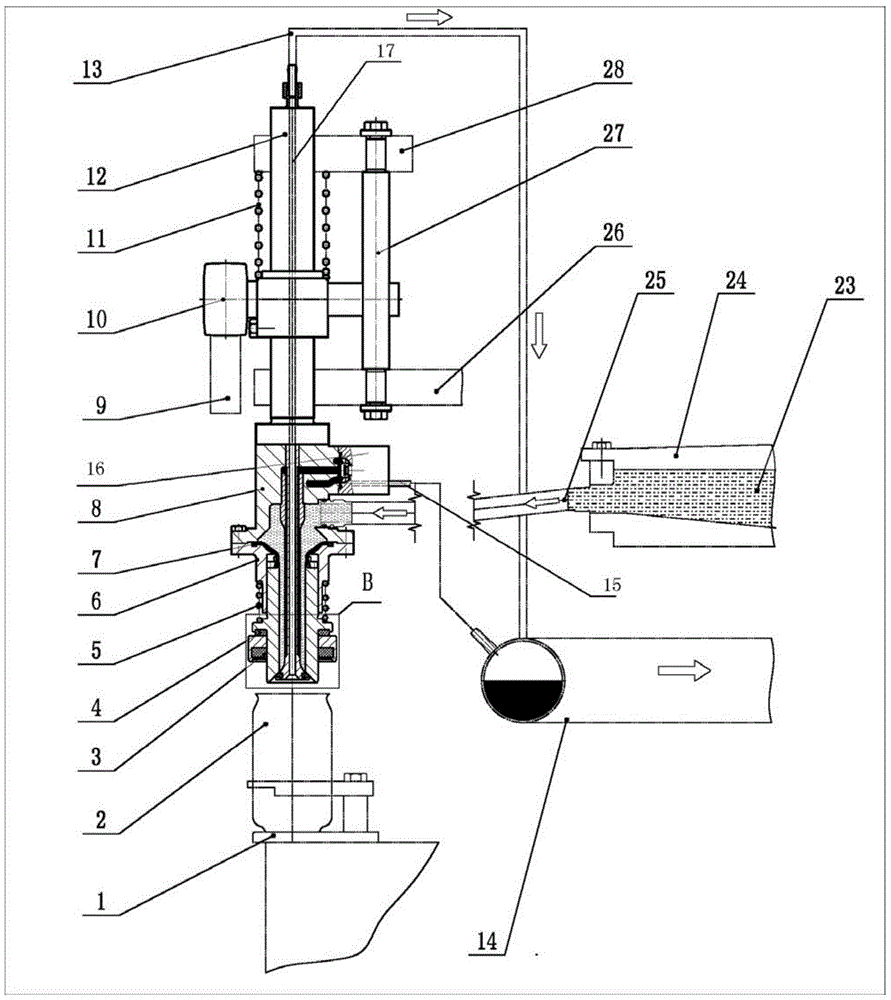

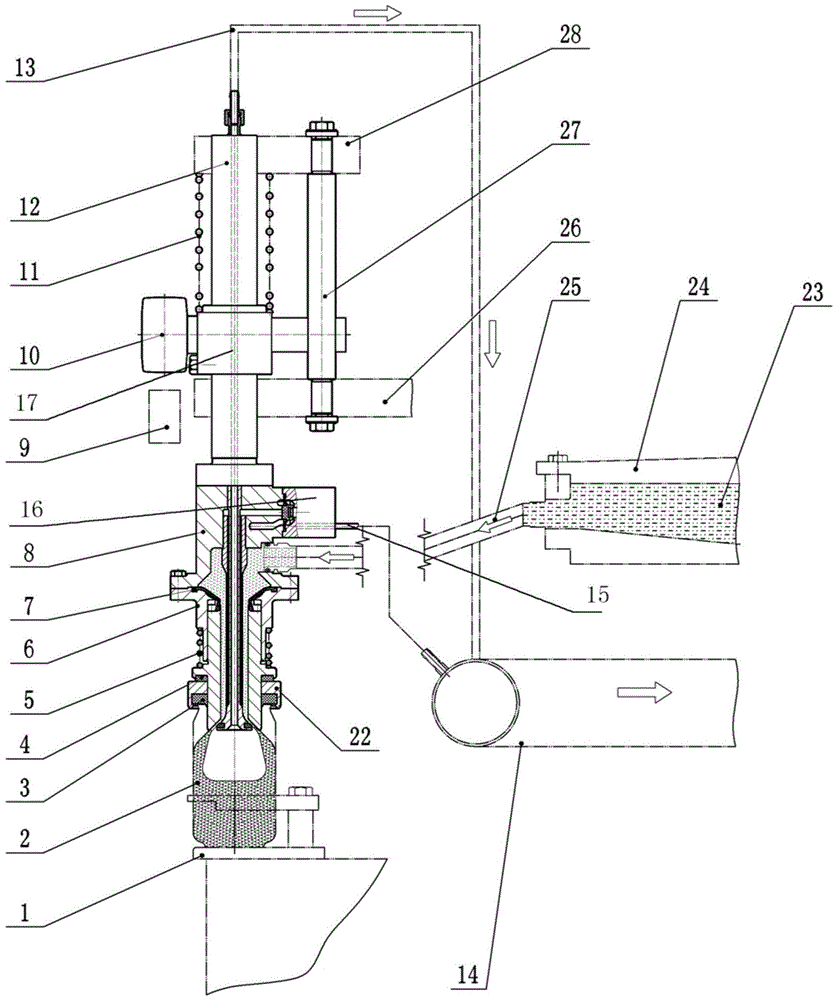

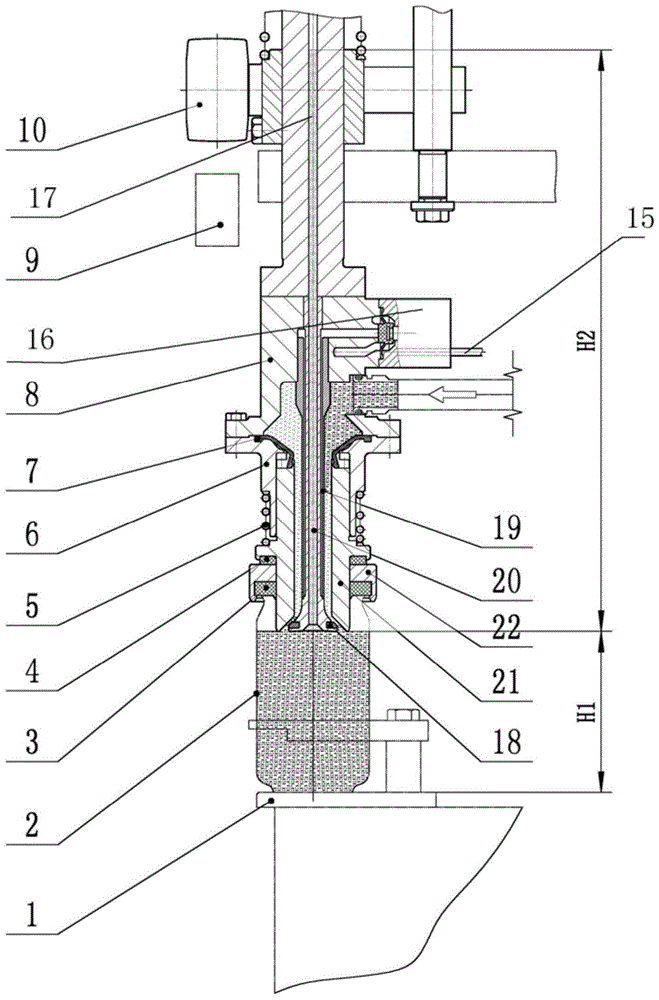

[0021] Such as figure 1 , 2 , 3, 4, and 5, a hot filling valve includes a valve seat, a valve core 20, an outer sliding sleeve 21 and a sealing seat 22, and the valve seat can be vertically lifted and installed on a supporting rotating disk 26. The valve seat is connected with the valve seat lifting drive mechanism, and the valve seat includes an upper valve seat 8 and a lower valve seat 6, and the upper valve seat 8 is provided with a valve core fixing hole for fixing the valve core 20, for fixing the valve core The casing fixing hole and the upper valve cavity of the casing 19, the lower valve seat 6 is provided with a lower valve cavity and a sliding sleeve installation hole, the upper valve seat 8 and the lower valve seat 6 are fixedly connected by bolts, and the filling The liquid inlet and the return port are arranged on the upper valve seat 8, and the valve core 20 is v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com