A method for controlling the feeding and discharging of raw materials on a freeze-drying machine

A control method and freeze dryer technology, applied in the field of freeze dryers, can solve problems such as being unfavorable for sterilization, low freeze drying efficiency, low heat transfer efficiency, etc., so as to reduce the risk of cross contamination, improve the level of automation, and improve freeze drying. The effect of drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

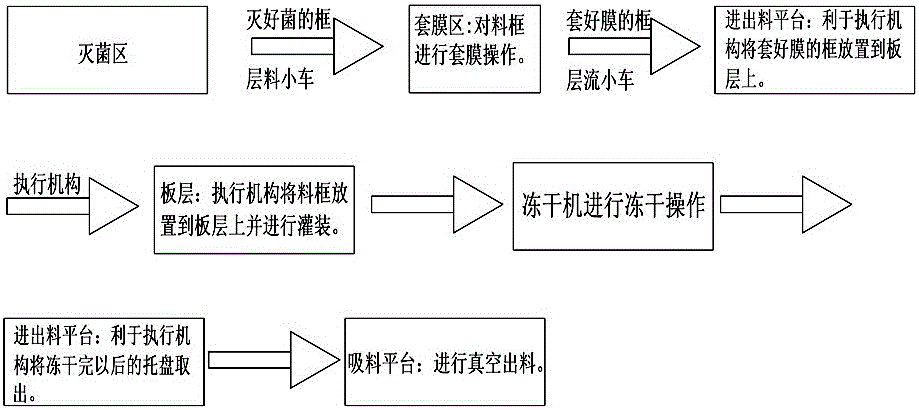

[0036] Such as figure 1 Shown, the control method of raw material medicine feeding and discharging on a kind of lyophilizer of the present invention, its flow process is:

[0037] (1) Sterilize the material frame 15 in the sterilization area;

[0038] (2) Transfer the sterilized material frame 15 to the mantle area by a laminar flow trolley to form a mantle to form a material tray;

[0039] (3) Use the lifting method to send the material tray to the plate layer of the freeze dryer, and fill the medicine bottles on the material tray;

[0040] (4) Carry out the above steps in a cycle until all the layers of the freeze dryer are filled with material trays, and then perform the freeze-drying operation;

[0041] (5) Send the tray out of the freeze-drying box by lifting.

[0042] (6) Carry out vacuum suction on the tray by means of vacu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com