Environment-friendly release agent for autoclaved aerated concrete block and preparation method of environment-friendly release agent

A concrete block, autoclaved and aerated technology, which is applied in the direction of manufacturing tools, petroleum industry, ceramic molding machines, etc., can solve the problems of high preparation cost, large adhesion, long film-forming time of demoulding materials, etc., reaching critical Effects of low surface tension, reduced bonding force, good chemical inertness and hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

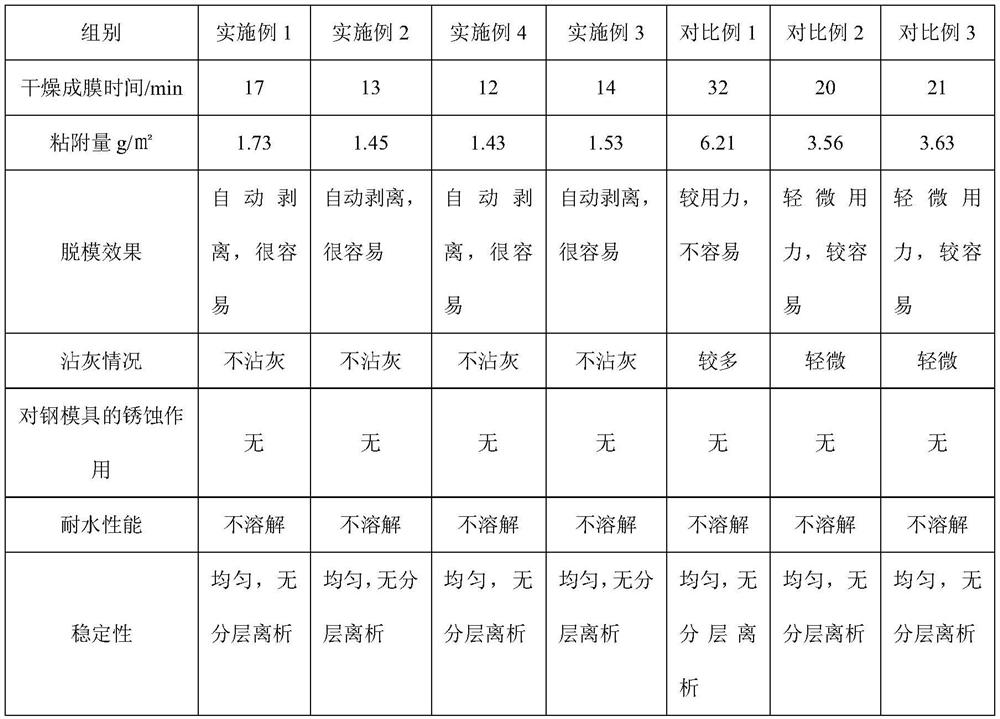

Examples

Embodiment 1

[0030] An environment-friendly release agent for autoclaved aerated concrete blocks, comprising the following raw materials:

[0031] Rapeseed oil 10kg, POSS-phosphorylated rapeseed oil polymer 3.5kg, polyethylene glycol 3kg, nanometer calcium carbonate 0.1kg, ammonium polycarboxylate 0.4kg, compound emulsifier 2kg, dodecyl alcohol ester 0.1kg, emulsification 0.1kg of silicone oil, 0.05kg of xanthan gum, and 10kg of water; among them, the compound emulsifier includes 0.3kg of Span60, 0.7kg of Tween80, 0.7kg of Op-10, and 0.3kg of SDBS.

[0032] An environment-friendly release agent for autoclaved aerated concrete blocks, comprising the following steps:

[0033] Disperse POSS-phosphorylated rapeseed oil polymer in rapeseed oil containing polyethylene glycol to obtain a dispersion; dissolve the composite emulsifier, emulsified silicone oil, and xanthan gum in hot water at 70°C to obtain emulsified water; Add nano-calcium carbonate, ammonium polycarboxylate, and emulsified water...

Embodiment 2

[0039] An environment-friendly release agent for autoclaved aerated concrete blocks, comprising the following raw materials:

[0040] Tea seed oil 15kg, POSS-phosphorylated tea seed oil polymer 2kg, polyethylene glycol 3kg, nano calcium carbonate 0.2kg, ammonium polycarboxylate 0.3kg, compound emulsifier 2kg, dodecyl alcohol ester 0.2kg, emulsified silicone oil 0.2kg, xanthan gum 0.1kg, water 30kg; Among them, the compound emulsifier includes Span60 0.5kg, Tween80 1kg, Op-10 1kg, SDBS 0.5kg.

[0041] An environment-friendly release agent for autoclaved aerated concrete blocks, comprising the following steps:

[0042] Disperse POSS-phosphorylated tea seed oil polymer into tea seed oil containing polyethylene glycol to obtain a dispersion; dissolve compound emulsifier, emulsified silicone oil, and xanthan gum in hot water at 80°C to obtain emulsified water; Add nano-calcium carbonate, ammonium polycarboxylate, and emulsified water into the dispersion, first add 0.1kg of dodecyl...

Embodiment 3

[0048] An environment-friendly release agent for autoclaved aerated concrete blocks, comprising the following raw materials:

[0049] Tea seed oil 20kg, POSS-phosphorylated tea seed oil polymer 4kg, polyethylene glycol 1kg, nano calcium carbonate 0.1kg, ammonium polycarboxylate 0.3kg, compound emulsifier 3kg, dodecyl alcohol ester 0.3kg, emulsified silicone oil 0.2kg, xanthan gum 0.13kg, water 40kg; Among them, the compound emulsifier includes Span60 0.5kg, Tween80 1kg, Op-10 1kg, SDBS 0.5kg.

[0050] An environment-friendly release agent for autoclaved aerated concrete blocks, comprising the following steps:

[0051] Disperse POSS-phosphorylated tea seed oil polymer into tea seed oil containing polyethylene glycol to obtain a dispersion; dissolve compound emulsifier, emulsified silicone oil, and xanthan gum in hot water at 85°C to obtain emulsified water; Add nano-calcium carbonate, ammonium polycarboxylate, and emulsified water into the dispersion, first add 0.15kg of dodec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com