Concrete mold releasing agent

A concrete release agent and gravimetric technology, applied in the field of concrete release agents, can solve the problems of polluting steel bars and concrete quality, inconvenient release, etc. grey effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

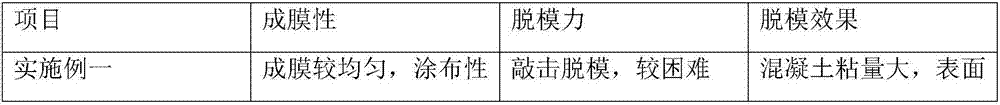

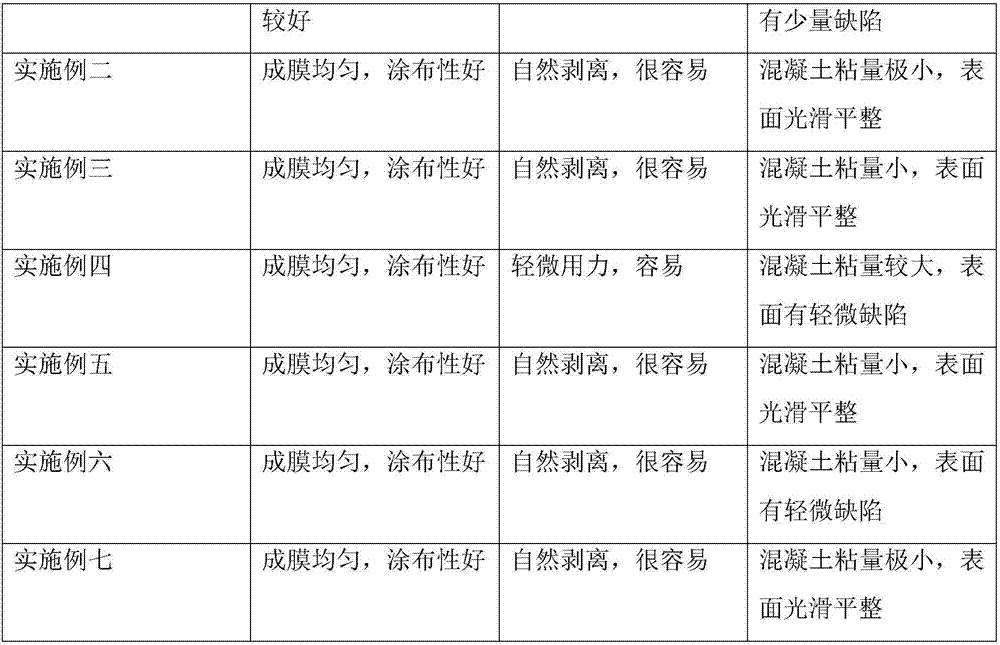

Examples

Embodiment 1

[0013] A concrete release agent, by weight, comprises the following components:

[0014] 5 parts of alkenyl-terminated polyoxyethylene ether, 8 parts of acrylic acid, 0.33 parts of ammonium persulfate, 0.13 parts of mercaptopropionic acid, 0.25 parts of hydrogen peroxide, 0.03 parts of hydroxylated vegetable oil, 0.05 parts of sodium grape carbonate, 0.02 parts of silicone, polyethylene glycol 2 parts of alcohol, 3 parts of polyvinyl alcohol, 5 parts of deionized water, 4 parts of polyacrylamide, 0.5 part of hydrochloric acid, 1 part of sodium lauryl sulfate, and 0.5 part of urea.

[0015] The molecular weight of the terminal alkenyl polyoxyethylene ether is 2000.

Embodiment 2

[0017] A concrete release agent, by weight, comprises the following components:

[0018] 11 parts of alkenyl polyoxyethylene ether, 17 parts of acrylic acid, 0.74 parts of ammonium persulfate, 0.27 parts of mercaptopropionic acid, 0.45 parts of hydrogen peroxide, 0.06 parts of hydroxylated vegetable oil, 0.08 parts of sodium grape carbonate, 0.03 parts of silicone, polyethylene glycol 9 parts of alcohol, 6 parts of polyvinyl alcohol, 8 parts of deionized water, 6 parts of polyacrylamide, 1.7 parts of hydrochloric acid, 5 parts of sodium lauryl sulfate, and 1.5 parts of urea.

[0019] The molecular weight of the terminal alkenyl polyoxyethylene ether is 2500.

Embodiment 3

[0021] A concrete release agent, by weight, comprises the following components:

[0022] 8 parts of alkenyl polyoxyethylene ether, 12 parts of acrylic acid, 0.54 parts of ammonium persulfate, 0.20 parts of mercaptopropionic acid, 0.35 parts of hydrogen peroxide, 0.045 parts of hydroxylated vegetable oil, 0.065 parts of sodium grape carbonate, 0.025 parts of silicone, polyethylene glycol 5.5 parts of alcohol, 4.5 parts of polyvinyl alcohol, 6.5 parts of deionized water, 5 parts of polyacrylamide, 1.1 parts of hydrochloric acid, 3 parts of sodium lauryl sulfate, and 1 part of urea.

[0023] The molecular weight of the terminal alkenyl polyoxyethylene ether is 2250.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com