Oil-proof coating of down jacket and production method of oil-proof coating

A technology of oil-repellent coating and down jacket, which is applied in the field of clothing, can solve the problems of poor oil repellency and affecting the wearing time of down jackets, achieve good heat insulation effect, increase oil resistance, and prolong the wearing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

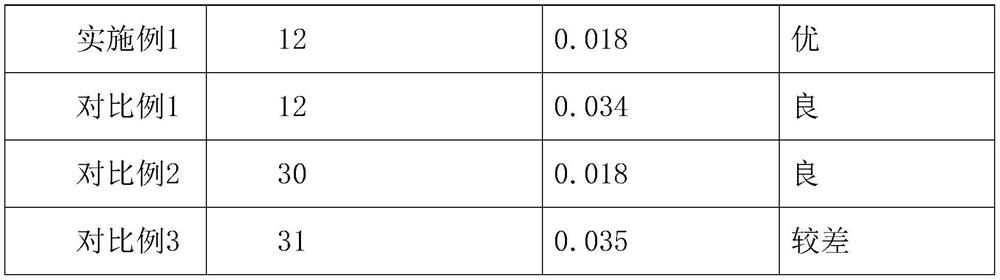

Embodiment 1

[0020] An oil-proof coating for down jackets, the raw materials for the preparation of the oil-proof coating include by weight: 8 parts of auxiliary (the auxiliary refers to fluoride, and refers to sulfur tetrafluoride), 5 parts of polytetrafluoroethylene, and 5 parts of carbon dioxide. 10 parts of silicon aerogel powder, 8 parts of polyurethane solution, 2 parts of foaming agent (an stearic acid), 3 parts of resin (composed of fluorocarbon resin and acrylic resin), 30 parts of polyether polyol (polytetrahydrofuran diol) ), 5 parts of isocyanate, 2 parts of catalyst (stannous octoate), 10 parts of polyethylene adipate, 6 parts of polypropylene glycol, 15 parts of filler (composed of titanium dioxide and polytetrafluoroethylene) and 15 parts of curing agent ( hexamethylene diisocyanate and benzoyl peroxide).

[0021] A production method of oil-repellent coating for down jacket, comprising the following steps:

[0022] The first step: vacuum dehydration of polyether polyol (pol...

Embodiment 2

[0028] An oil-proof coating for down jackets, the raw materials for the preparation of the oil-proof coating include by weight: 10 parts of auxiliary (the auxiliary refers to fluoride, and refers to sulfur tetrafluoride), 8 parts of polytetrafluoroethylene, and 8 parts of carbon dioxide. 11 parts of silicon aerogel powder, 9 parts of polyurethane solution, 4 parts of foaming agent (an stearic acid), 6 parts of resin (composed of fluorocarbon resin and acrylic resin), 35 parts of polyether polyol (polytetrahydrofuran diol) ), 8 parts of isocyanate, 3 parts of catalyst (stannous octoate), 12 parts of polyethylene adipate, 7 parts of polypropylene glycol, 16 parts of filler (composed of titanium dioxide and polytetrafluoroethylene) and 18 parts of curing agent Methylene diisocyanate and benzoyl peroxide).

[0029] A production method of oil-repellent coating for down jacket, comprising the following steps:

[0030] The first step: vacuum dehydration of the polyether polyol (poly...

Embodiment 3

[0036] An oil-repellent coating for down jackets, the raw materials for preparing the oil-repellent coating include, in parts by weight: 12 parts of auxiliary (the auxiliary refers to fluoride, and refers to sulfur tetrafluoride), 10 parts of polytetrafluoroethylene, and 10 parts of carbon dioxide. 12 parts of silicon aerogel powder, 10 parts of polyurethane solution, 5 parts of foaming agent (an stearic acid), 8 parts of resin (composed of fluorocarbon resin and acrylic resin), 40 parts of polyether polyol (polytetrahydrofuran diol) ), 10 parts of isocyanate, 4 parts of catalyst (stannous octoate), 15 parts of polyethylene adipate, 10 parts of polypropylene glycol, 18 parts of filler (composed of titanium dioxide and polytetrafluoroethylene) and 20 parts of curing agent ( hexamethylene diisocyanate and benzoyl peroxide).

[0037]A production method for oil-repellent coating of down jacket, comprising the following steps:

[0038] The first step: vacuum dehydration of the pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com