Patents

Literature

36results about How to "Improve oil stain resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oil-water emulsion separation membrane of metal organic framework compound/polyacrylonitrile

InactiveCN107983180AImprove oil stain resistanceEasy to separateSemi-permeable membranesMembranesYarnMetal-organic framework

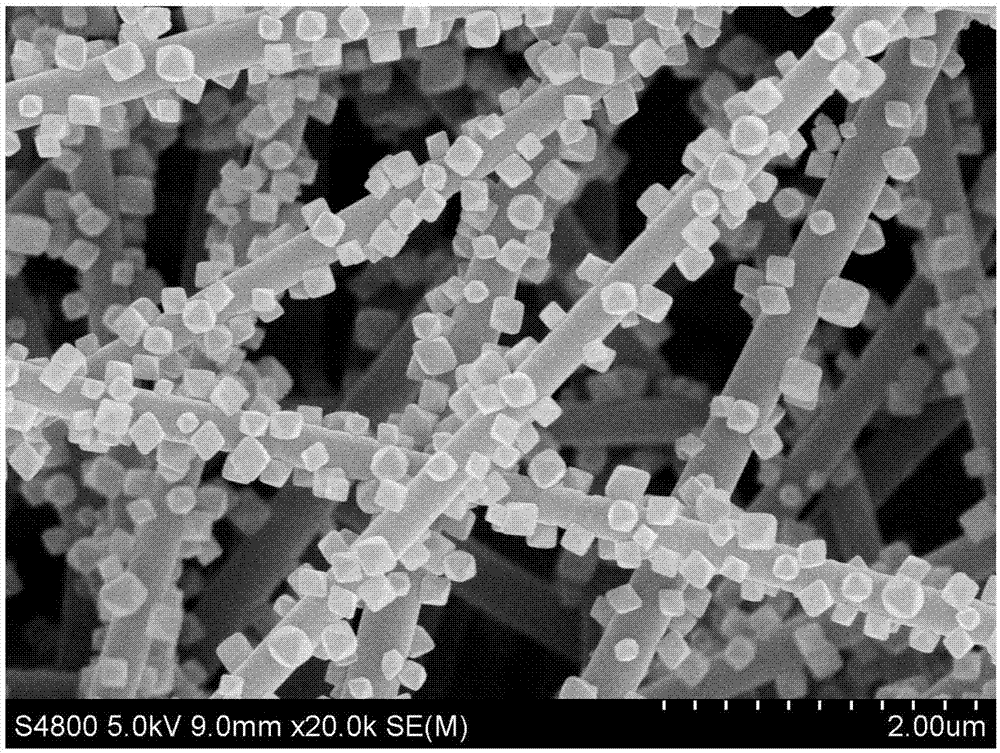

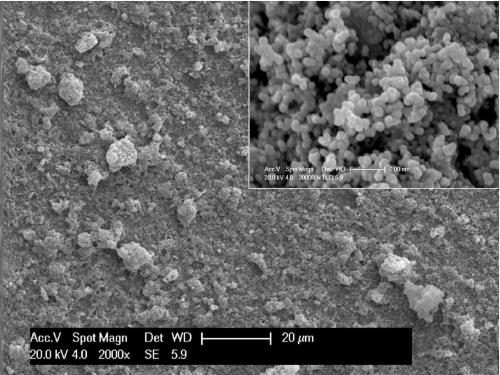

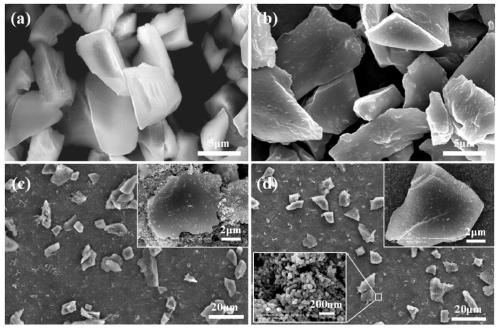

The invention relates to an oil-water emulsion separation membrane of a metal organic framework compound / polyacrylonitrile. According to the oil-water emulsion separation membrane, polyacrylonitrile is used as a raw material and is prepared into a fiber membrane with the yarn diameter of about 300 nanometers and extremely high porosity by utilizing an electrostatic spinning technology; then the fiber membrane is subjected to a hydrolytic action so that functional groups including hydroxyl, carboxyl and the like are formed on surfaces of fibers; furthermore, the fiber membrane and amino on hydrophilic UIO-66-NH2 can form hydrogen bonding and electrostatic adsorption; finally, a porous fiber membrane with a hydrophilic multi-grade structure is prepared. The porous fiber membrane can be usedfor carrying out efficient separation on oil-water emulsion and has extremely low oil adhesion and relatively high oil stain resistance; furthermore, a preparation method of the oil-water emulsion separation membrane is simple and feasible, is safe and environmentally friendly and has very good application value.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

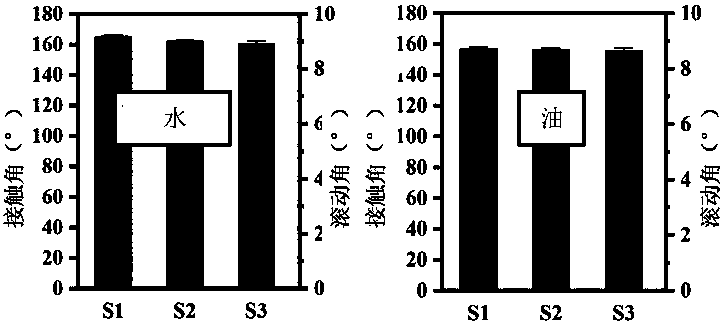

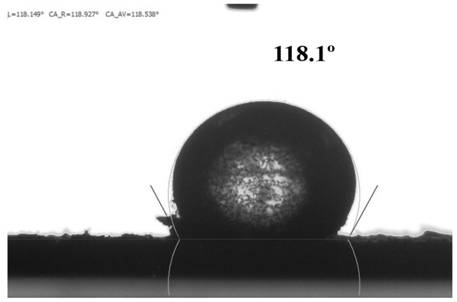

Effective water-collecting self-cleaning super-amphiphobic coating and preparation method thereof

ActiveCN110041741AEnhanced condensation characteristicsImprove dew drop nucleation efficiencyAntifouling/underwater paintsPaints with biocidesMicro nanoCoated surface

The invention relates to an effective water-collecting self-cleaning super-amphiphobic coating and a preparation method thereof and belongs to the field of preparation of ultra-infiltration functionalcoating materials. A multilevel micro-nano coarse structure coating layer with a combination of nanometer porous structure and hydrophilic microparticle structure is formed on the surface of the coating. The preparation method comprises the following steps: firstly, adding a chained aqueous silica sol after alkalization into a volatile organic solution, and then performing hydrophobic modification on the surface, thereby acquiring a super-amphiphobic finishing coat; coating micron particles with a hydrophilic polymer, hybridizing the micron particles with the super-amphiphobic finishing coat,coating on a bottom surface and drying, thereby acquiring a super-amphiphobic hybridized coating surface. The coating has an excellent condensation reinforcing dew formation effect, an excellent water drop self-repelling bouncing desorption effect and an efficient water mist collecting effect, has a super-hydrophobic and super-oleophobic super-amphiphobic characteristic, shows excellent self-cleaning and anti-oil properties, is widely applied to the fields of self-cleaning, water mist collection, desalination, condensation heat exchange, and the like, is simple in equipment and process, is easy for operation and is suitable for large-scale preparation and production.

Owner:SOUTHEAST UNIV

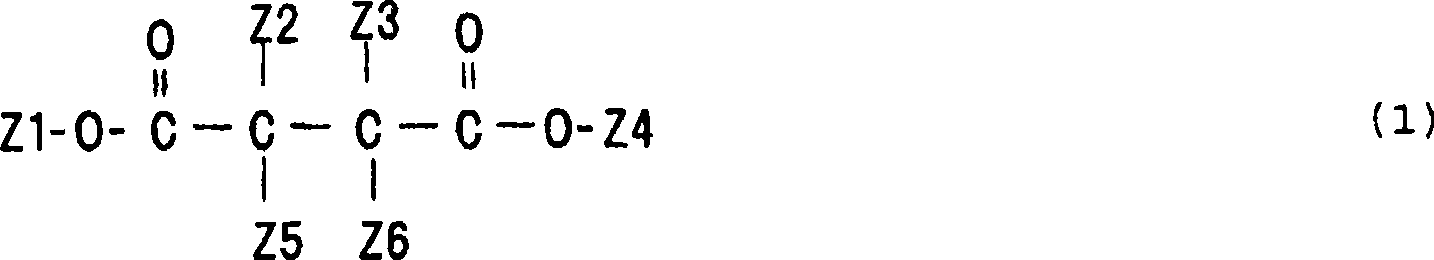

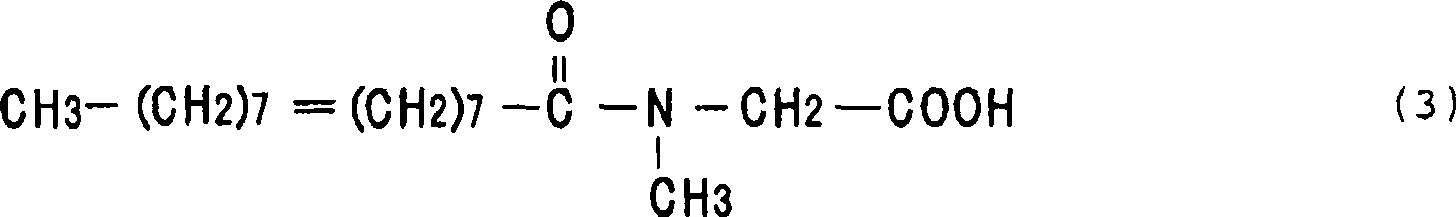

Lubricating oil composition

The present invention provides a lubricating oil composition comprising at least one type of base oil selected from mineral oils and synthetic oils, and a succinate ester and a sarcosinic acid as rust prevention agents. The succinate ester content is preferably set at 0.01 to 0.1 wt. %, and the sarcosinic acid content is preferably set at 0.001 to 0.01 wt. %. Further, they are preferably set such that the resulting weight ratio of the succinate ester content and sarcosinic acid content is 1 : 0.01 to 0.7. The lubricating oil composition according to the present invention shows excellent rust prevention properties and a satisfactorily long oxidation lifetime. Further it allows to attain a high level of anti- sludge performance and extreme pressure performance and lubrication performance, even when it is used for example in turbine bearings in combined cycle generators having multiplier gears operated under severe high temperature and high pressure conditions.

Owner:SHELL INT RES MAATSCHAPPIJ BV

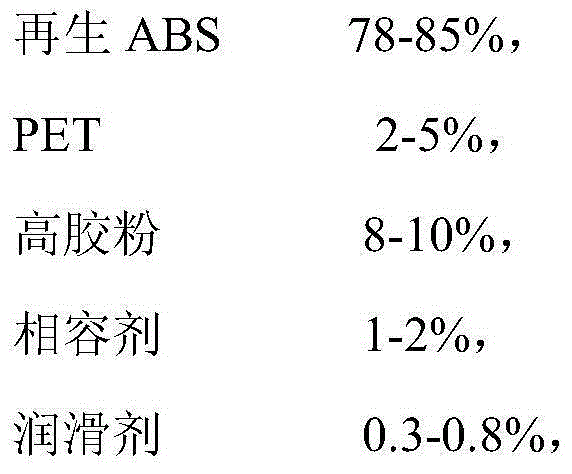

High-impact greasy-dirt-resistant modified regenerated ABS material and preparation method thereof

InactiveCN105199303AImprove impact resistanceImprove oil stain resistancePolymer scienceRubber toughening

The invention discloses a high-impact greasy-dirt-resistant modified regenerated ABS material and a preparation method thereof. The modified regenerated ABS material is prepared from, by weight, 78%-85% of regenerated ABS, 2%-5% of PET, 8%-10% of ABS, 1%-2% of compatilizer, 0.3%-0.8% of lubricating agent, 0.4%-0.8% of antioxygen and 2%-5% of filler. The PET resin, nano BaSO4 and ABS of the specific content are added, the impact resistance and greasy dirt resistance of the ABS material are improved, the use requirement of the ABS material as a high-impact greasy-dirt-resistant storage battery shell is met, impact strength is improved due to rubber toughening of the ABS, and the PET resin and nano BaSO4 achieve the functions of improving the surface polarity of the ABS material and reducing surface microdefects of the ABS material.

Owner:GUANGDONG TIANBAO NEW MATERIALS CO LTD

Preparation method of oil-stain-resistant polypropylene plastic

The invention discloses a preparation method of oil-stain-resistant polypropylene plastic. Organic silicon resin with low surface energy is subjected to graft modification and then is subjected to melt blending with polypropylene resin to prepare anoil-stain-resistant polypropylene-based composite material for kitchens. The polypropylene-based composite material has relatively low surface tension, and can achieve the purpose of oil stain resistance when being used for preparing kitchen utensils; meanwhile, the surface of the product becomes more glossy, the wear resistance is also improved, and the service life of the product is prolonged; and the composite material is easy to clean, environmentally friendly, and practical.

Owner:摩特卡(杭州)进出口贸易有限公司

Ultrathin tempered film and preparation process thereof

InactiveCN110922052AImprove tempered strengthHigh hardnessFlexible article cleaningCoatingsNumerical controlCutting glass

The invention discloses an ultrathin tempered film and a preparation process thereof. The preparation process comprises the following processes: S1, cutting: cutting a glass substrate into required shapes and sizes by adopting a cutting machine; S2, CNC fine carving: carving a hole site corresponding to the type of an electronic product in the cut glass substrate by a numerical control machine tool; S3, primary ultrasonic cleaning: putting the glass substrate into an ultrasonic cleaning machine, and cleaning; S4, tempering and strengthening: tempering and strengthening the glass substrate through a physical method and a chemical method; S5, AF electric / spray plating: carrying out electric / spray plating of anti-fingerprint oil on the surface of the glass substrate; S6, secondary ultrasoniccleaning: putting the glass substrate into an ultrasonic cleaning machine, and carrying out secondary cleaning; and S7, protective film coating: laminating protective films on two surfaces of the glass substrate, packaging and warehousing. The prepared ultrathin tempered film is light and thinner, has good toughness and shock resistance, and can be safely used for a long time.

Owner:东莞市国基光电有限公司

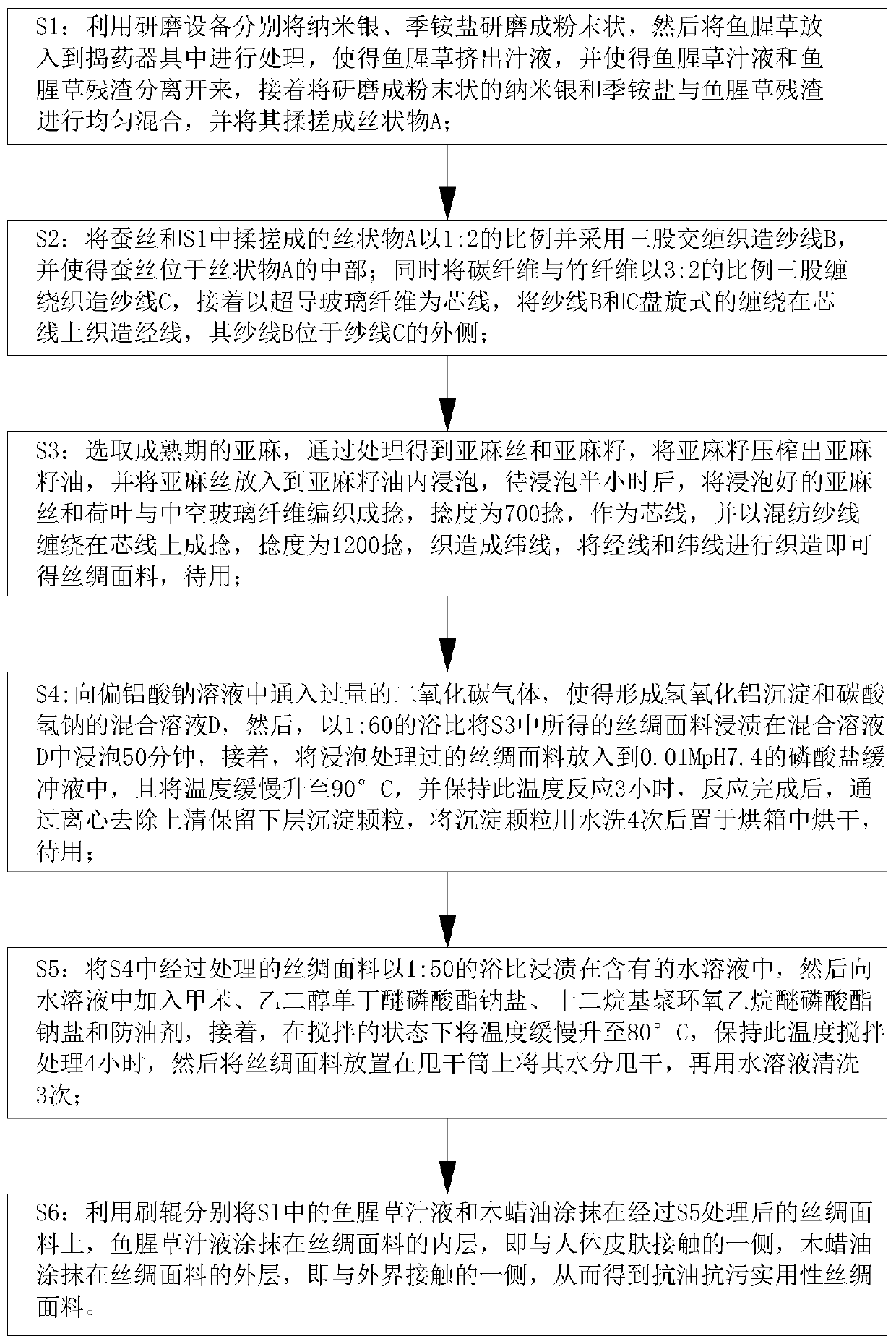

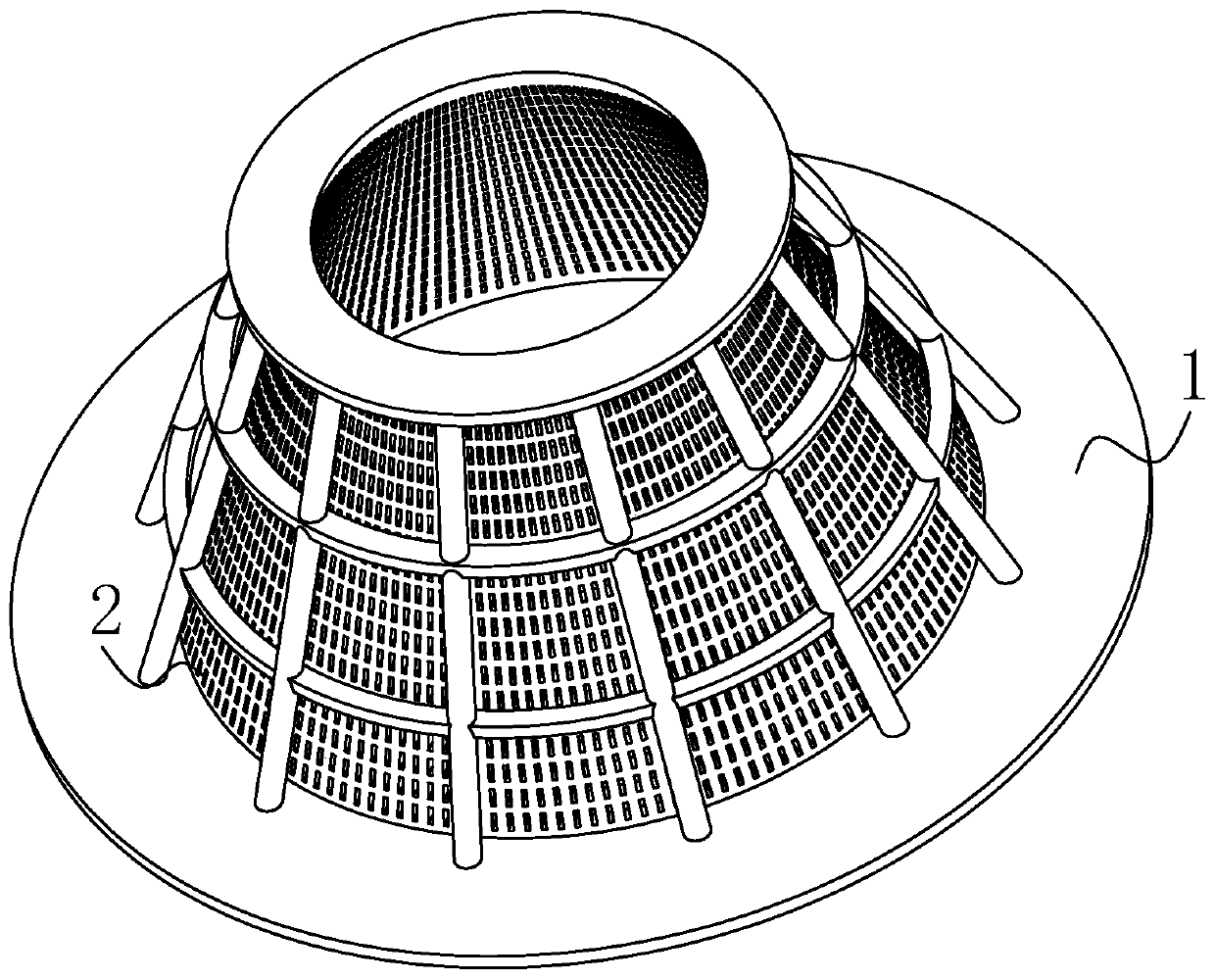

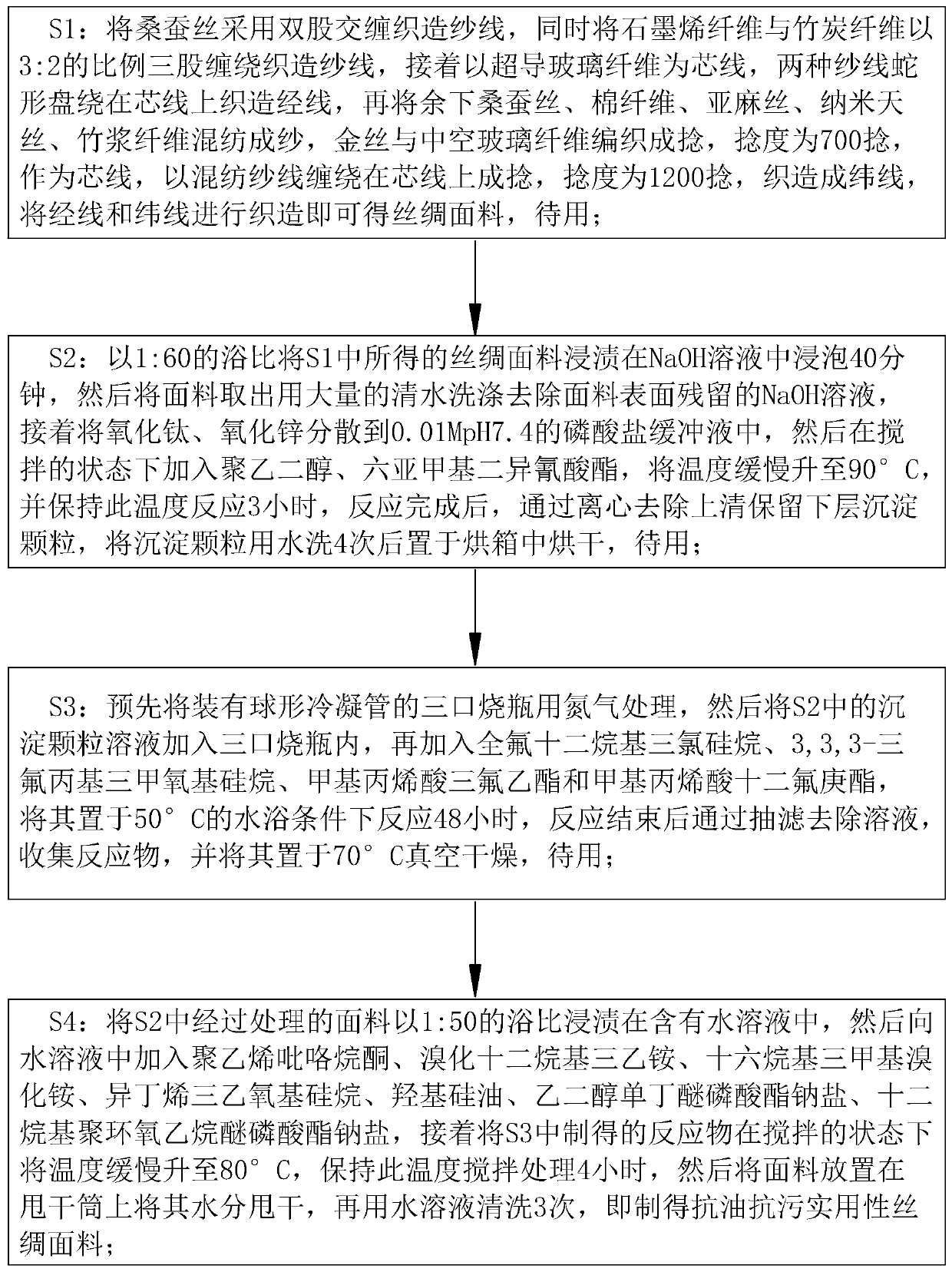

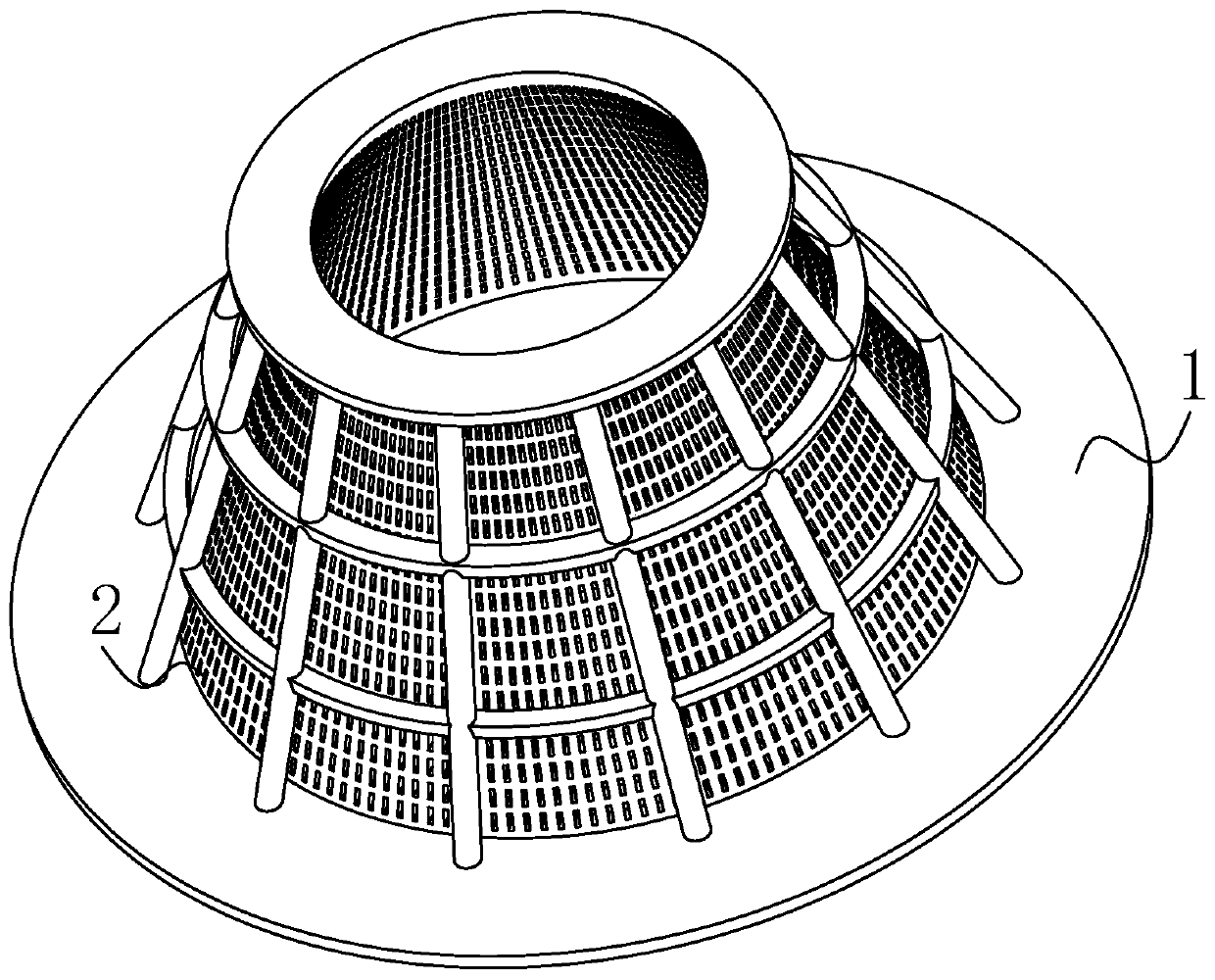

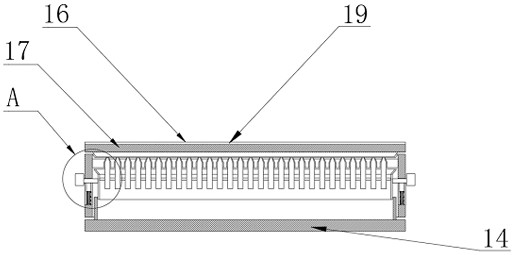

Oil-proof stain-proof practical silk fabric

PendingCN111206319AEffective dispersionAvoid accumulationStain/soil resistant fibresYarnFiberPolymer science

The invention belongs to the technical field of silk textile manufacturing, and particularly relates to an oil-proof stain-proof practical silk fabric. The oil-proof stain-proof practical silk fabriccomprises the following components required for production in parts by weight: 30 parts of silk, 60 parts of houttuyniae herba, 30 parts of nano-silver, 30 parts of quaternary ammonium salt, 60 partsof folium nelumbinis, 10 parts of oil-proof agent, 50 parts of flax, 10 parts of wax oil, 30 parts of bamboo fibers, 10 parts of carbon fibers, 30 parts of sodium metaaluminate solution, 30 parts of carbon dioxide gas, 10 parts of phosphate buffer solution, 12 parts of superconducting glass fibers, 12 parts of hollow glass fibers, 14 parts of methylbenzene, 4 parts of ethylene glycol monobutyl ether phosphate sodium salt and 6 parts of dodecyl polyoxyrthylene ether phosphate sodium salt. The silk fabric disclosed by the invention is not liable to stain with oil stain in an oil stain environment; even though under the strong sunshine condition and under the condition of contact with the external environment for long time, the fabric also cannot have phenomena of aging, color fading and stain accumulation; and meanwhile, the silk fabric eliminates discomfort generated for a human body by static electricity.

Owner:浙江宝石蝶围巾有限公司

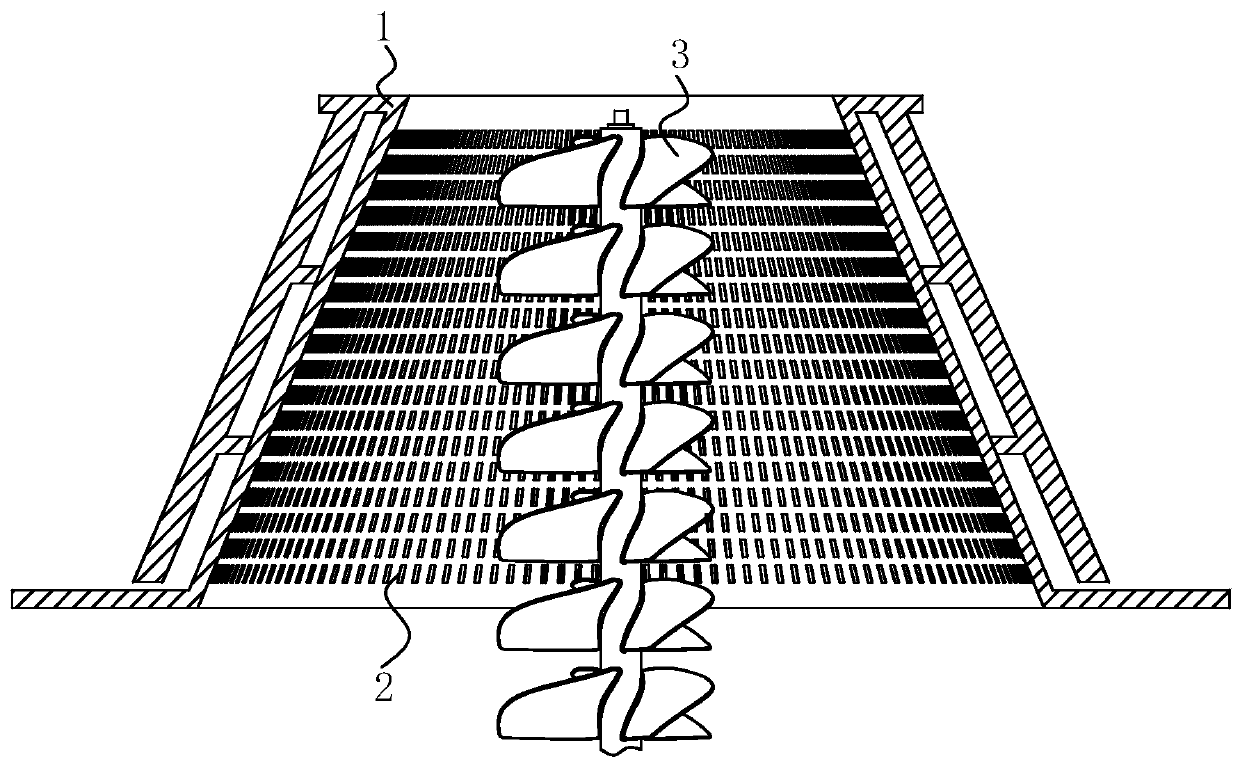

Preparation method of oily sewage treatment dynamic membrane based on metal net-ceramic composite base membrane

PendingCN114870646AImprove hydrophilicityImprove oil stain resistanceSemi-permeable membranesMembranesCeramic compositeSewage treatment

The invention discloses a preparation method of an oily sewage treatment dynamic membrane based on a metal net-ceramic composite base membrane. According to the preparation method, a porous metal net is adopted as a dynamic membrane substrate, a hydrophilic material ceramic layer is uniformly coated on the surface of the metal net through a magnetron sputtering technology, and a hydrophilic metal net-ceramic composite base membrane dynamic membrane is formed. According to the dynamic membrane prepared by the preparation method, on the premise of ensuring high water flux of the dynamic membrane, the oil pollution resistance of the dynamic membrane is improved, the acid-base and other strong cleaning periods of the dynamic membrane are prolonged, and the equipment operation and maintenance cost and the medicament consumption are reduced.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

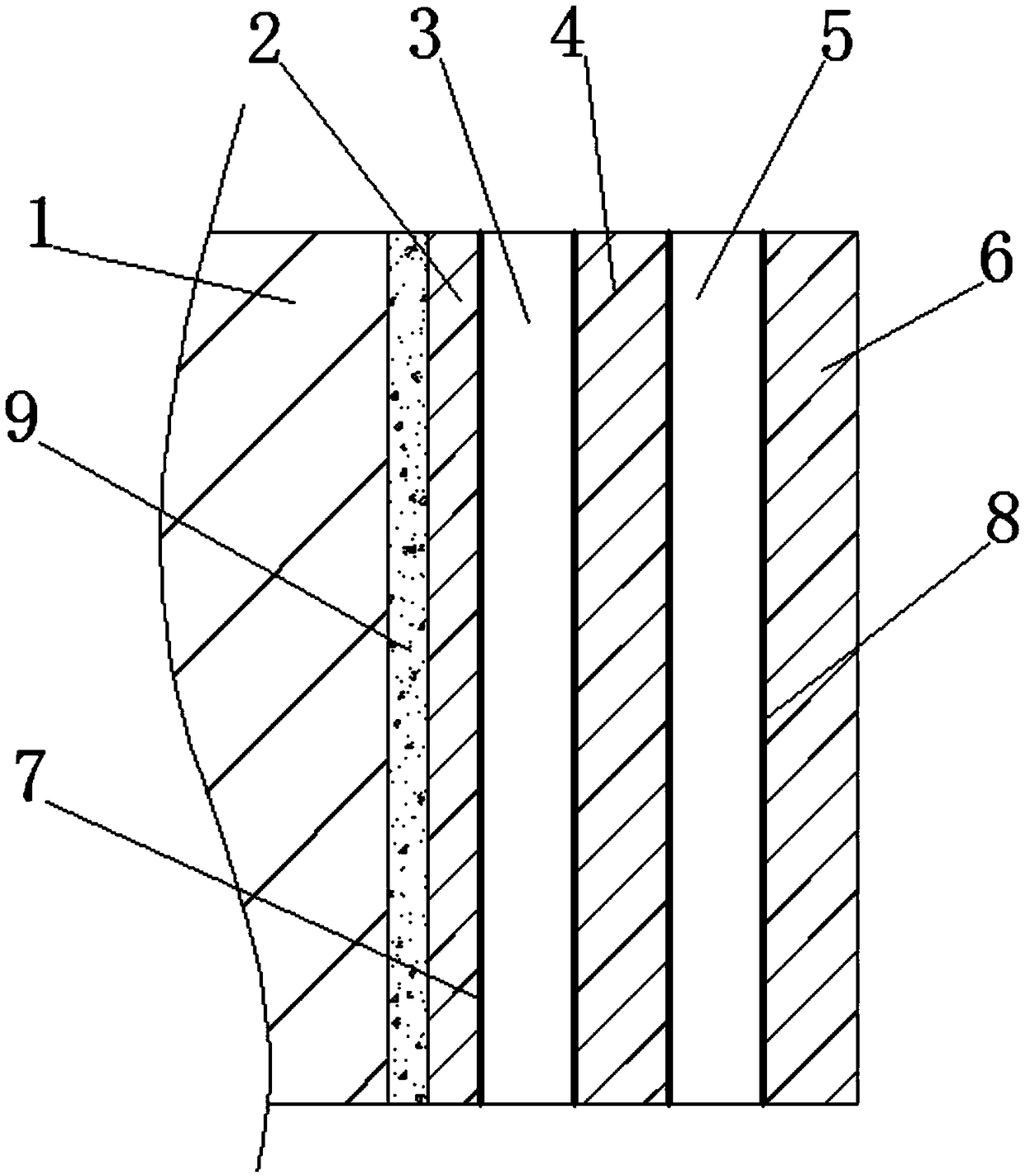

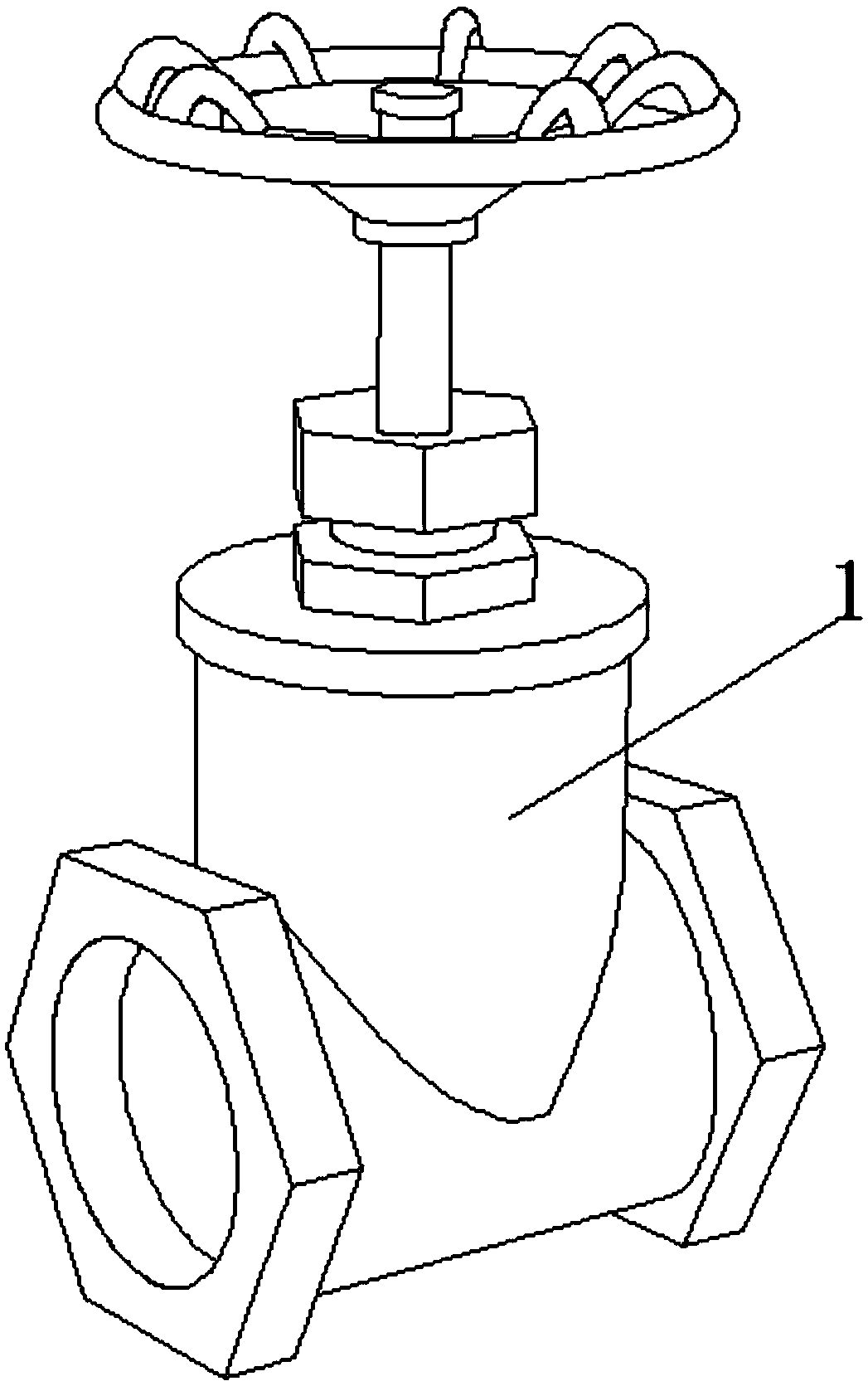

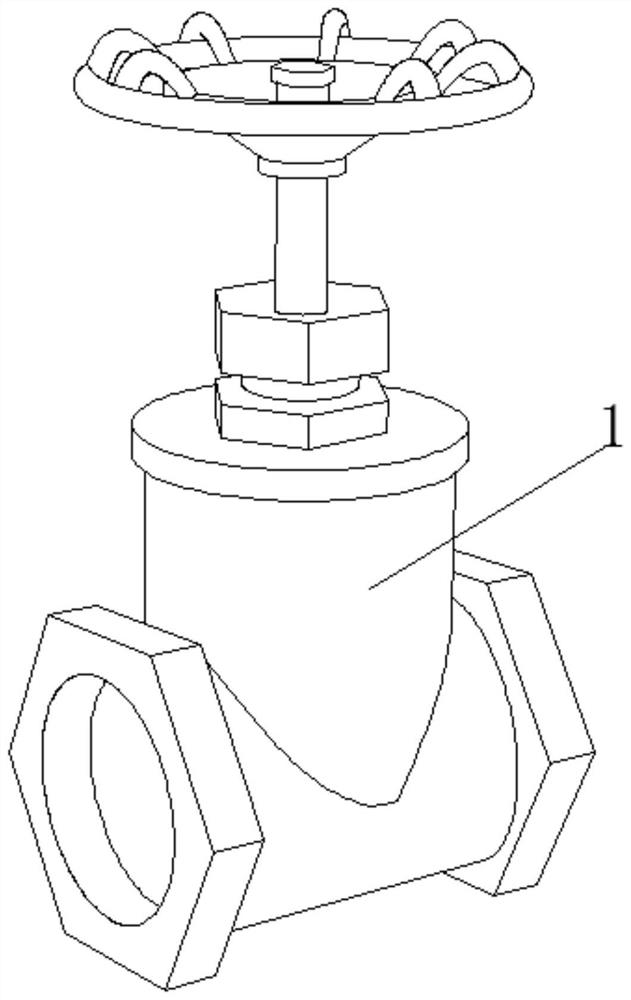

Anticorrosion coating for manual threaded valve

InactiveCN109294305AImprove waterproof performanceImprove oil stain resistanceAntifouling/underwater paintsPaints with biocidesEngineeringHeavy duty

The invention discloses an anticorrosion coating for a manual threaded valve and belongs to the field of corrosion prevention of valves. The anticorrosion coating for the manual threaded valve comprises the threaded valve, the outer end of the threaded valve is coated with an anticorrosion coating, the anticorrosion coating comprises a primer coating, a heavy-duty anticorrosion layer, a lotus leafself-cleaning coating, an inner self-cleaning coating and an outer waterproof self-cleaning layer which are applied to the surface of the threaded valve sequentially from left to right, the anticorrosion coating is not prone to peeling and falling by improving the waterproof performance and oil stain resistance of the anticorrosion coating, so that the corrosion resistance of the valve is significantly improved; and the anticorrosion coating has self-healing capacity when beginning to crack or have holes by use of a self-healing material, the effective acting time of the anticorrosion coatingis greatly prolonged, and the service life of the threaded valve in the anticorrosion coating is prolonged.

Owner:ZHEJIANG JIANENG VALVE CO LTD

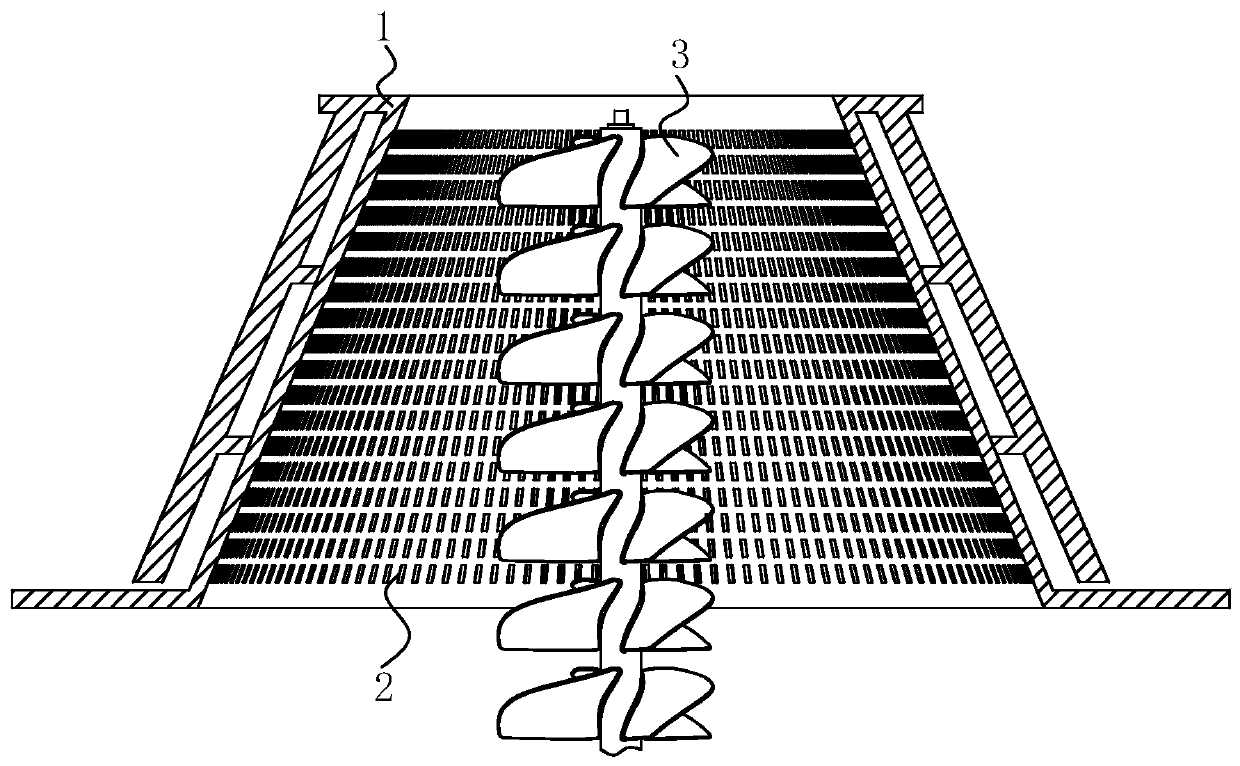

Oil-resistant anti-fouling practical silk fabric

InactiveCN110938927AEffective dispersionAvoid accumulationStain/soil resistant fibresYarnPolymer sciencePolyethylene glycol

The invention belongs to the technical field of silk textile manufacturing, and particularly relates to an oil-resistant anti-fouling practical silk fabric. The oil-resistant anti-fouling practical silk fabric comprises the following components in parts by weight: 50 parts of mulberry silk, 30 parts of cotton fibers, 10 parts of graphene fibers, 9 parts of superconducting glass fibers, 12 parts ofhollow glass fibers, 2 parts of bamboo charcoal fibers, 0.6 parts of golden silk, 3 parts of linen silk, 11 parts of nano tencel, 2 parts of bamboo pulp fibers, 30 parts of an NaOH solution, 40 partsof titanium oxide, 30 parts of zinc oxide, 10 parts of a phosphate buffer solution, 8 parts of polyethylene glycol and 5 parts of hexamethylene diisocyanate. The silk fabric is mainly used for solving the problems that in the prior art, the fabric is prone to being contaminated by oil stains and must be cleaned in time to keep the clean state as the silk fabric is in an oil stain environment, thefabric has the phenomena of aging, color fading and stain accumulation after the fabric is under the conditions of strong sunlight and contact with the external environment for a long term, and the silk fabric causes discomfort to the human body due to static electricity.

Owner:浙江宝石蝶围巾有限公司

A stain-resistant dining table board

Owner:湖州久凯智能家居有限公司

Oil-stain-resistant and anti-slip gloves and preparation method thereof

PendingCN114431564AClosely connectedImprove stabilityGlovesTextiles and paperOrganosiliconCarboxylic group

The invention discloses an anti-oil anti-slip glove and a preparation method thereof, and relates to the technical field of gloves. The oil-stain-resistant and anti-slip glove sequentially comprises a cotton fabric layer, an organic silicon layer and an amphiphobic layer from inside to outside, adding the phase change microcapsules into the carboxyl organic silicon emulsion, coating the cotton fabric layer, and curing to obtain a glove base body; carboxyl on the carboxyl organic silicon emulsion reacts with amino on the cotton fabric, so that the organic silicon layer is tightly connected with the fabric layer; coating a modified polyphenylene sulfide coating on the organic silicon layer, and forming an amphiphobic coating on the surface of the coating by using femtosecond laser; the oil-stain-resistant anti-slip glove prepared by the invention has good heat storage and temperature regulation functions, has amphiphobic property, and is good in toughness and stripping resistance.

Owner:王君

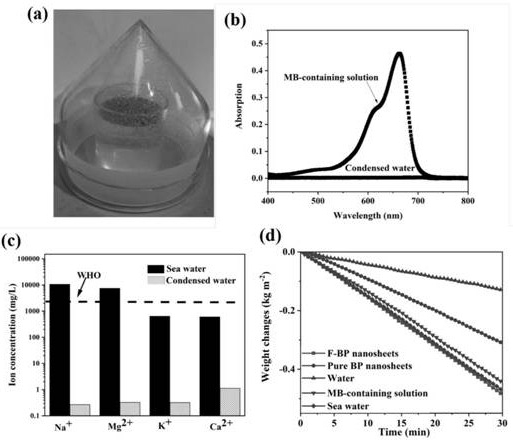

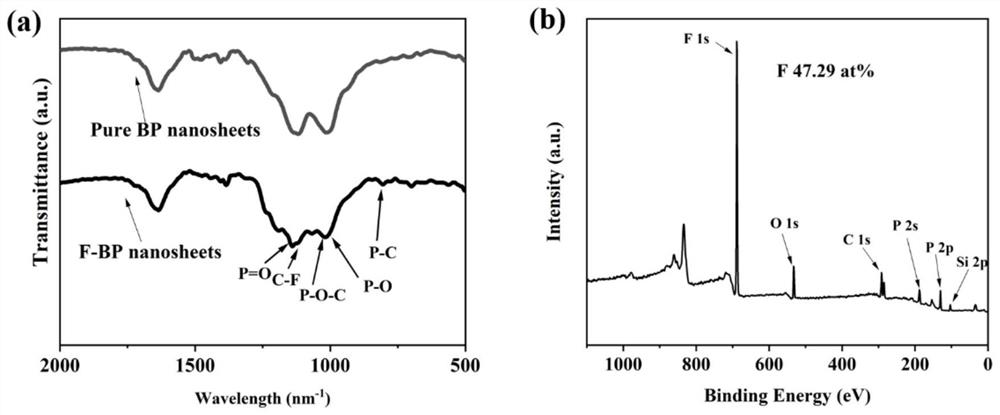

A self-floating portable black phosphorous-based light-to-heat vapor conversion material and its preparation method

ActiveCN111498932BEasy to prepareEasy to operateGeneral water supply conservationSeawater treatmentPhysical chemistryPhotothermal conversion

Owner:UNIV OF SCI & TECH OF CHINA

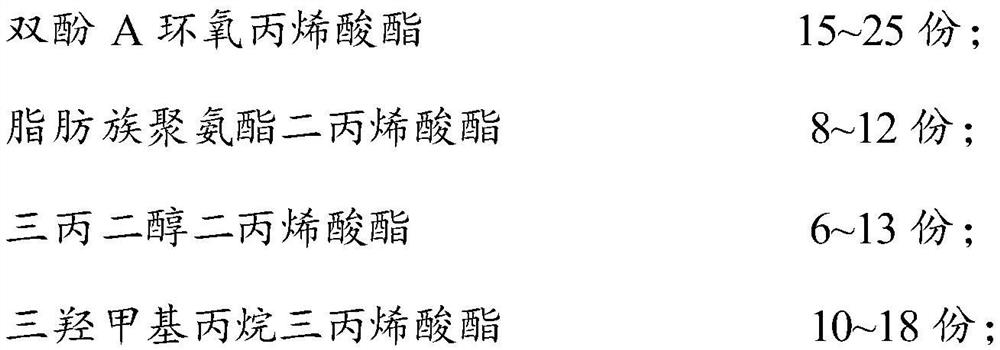

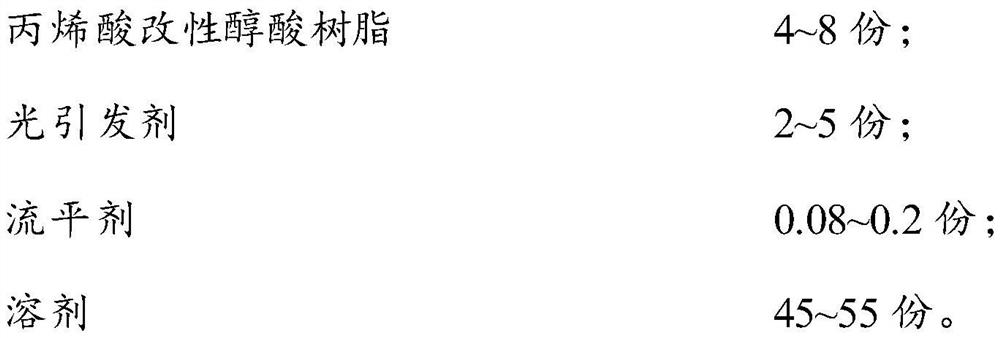

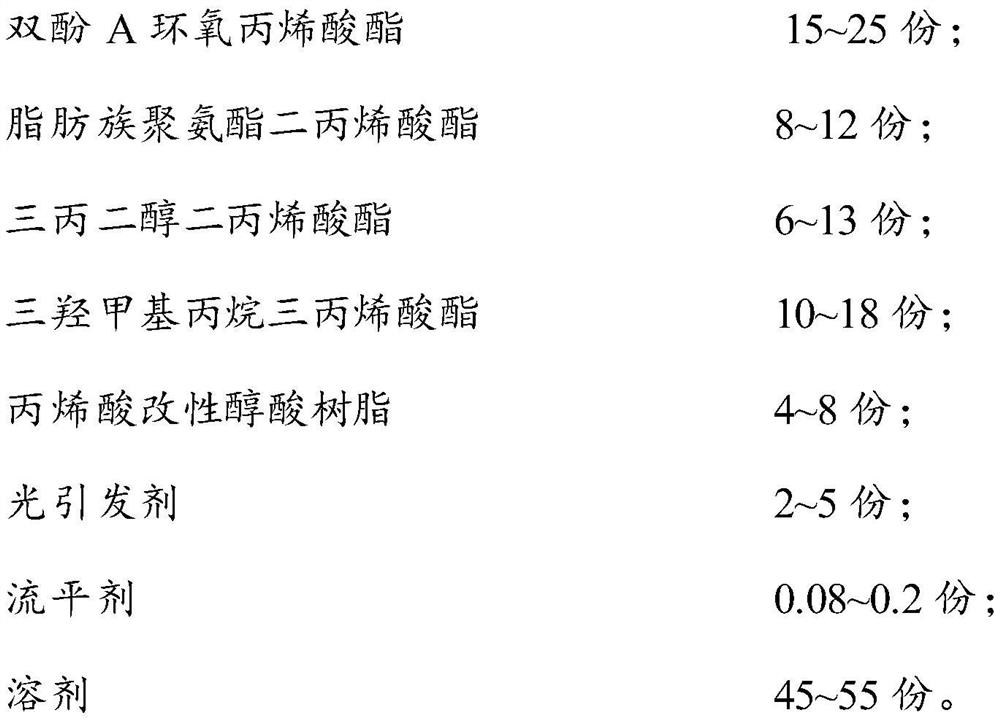

A kind of UV curing vacuum coating wrinkle primer and preparation method thereof

ActiveCN110591512BLow costImprove adhesionAntifouling/underwater paintsPaints with biocidesTripropylene glycolPolymer science

The application discloses a UV-curable vacuum coating wrinkle primer and a preparation method thereof, which comprises the following components in parts by weight: 15-25 parts of bisphenol A epoxy acrylate; 8-12 parts of aliphatic polyurethane diacrylate 6-13 parts of tripropylene glycol diacrylate; 10-18 parts of trimethylolpropane triacrylate; 4-8 parts of acrylic modified alkyd resin; 2-5 parts of photoinitiator; 0.08-0.2 parts of leveling agent parts; solvent 45 to 55 parts. Through the reasonable matching of various components, the cured coating can take into account the advantages of ordinary UV paint such as energy saving, environmental protection, high efficiency, and economy, and has low curing energy and good wrinkle decoration effect.

Owner:HUNAN SOKAN NEW MATERIAL

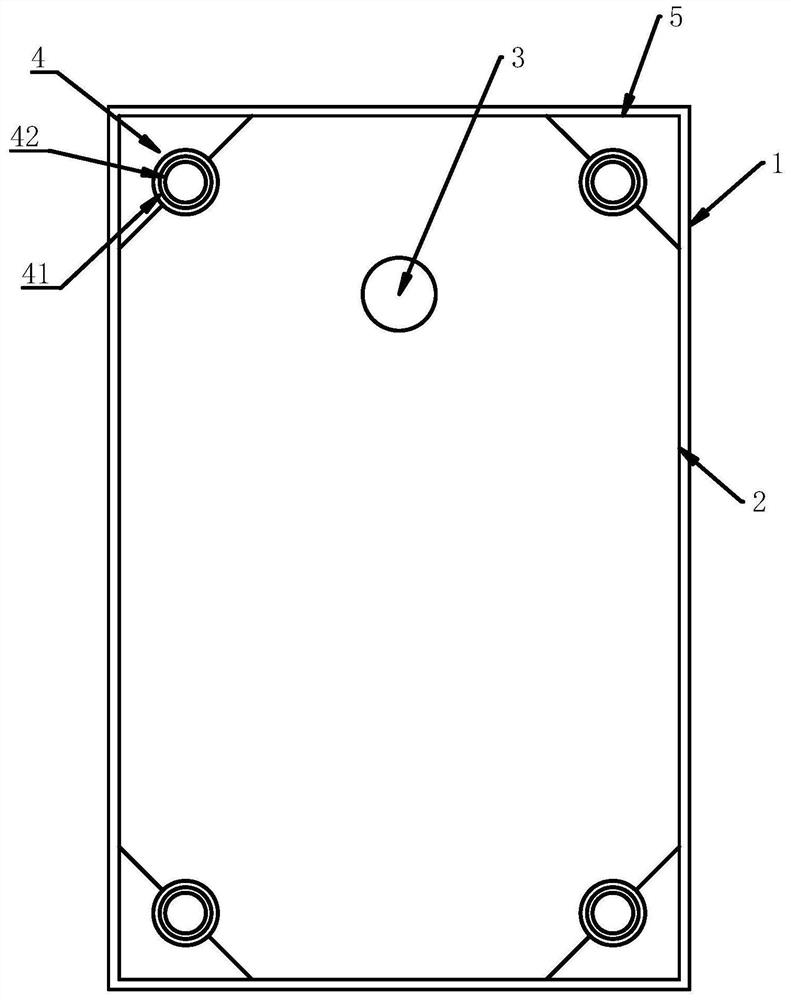

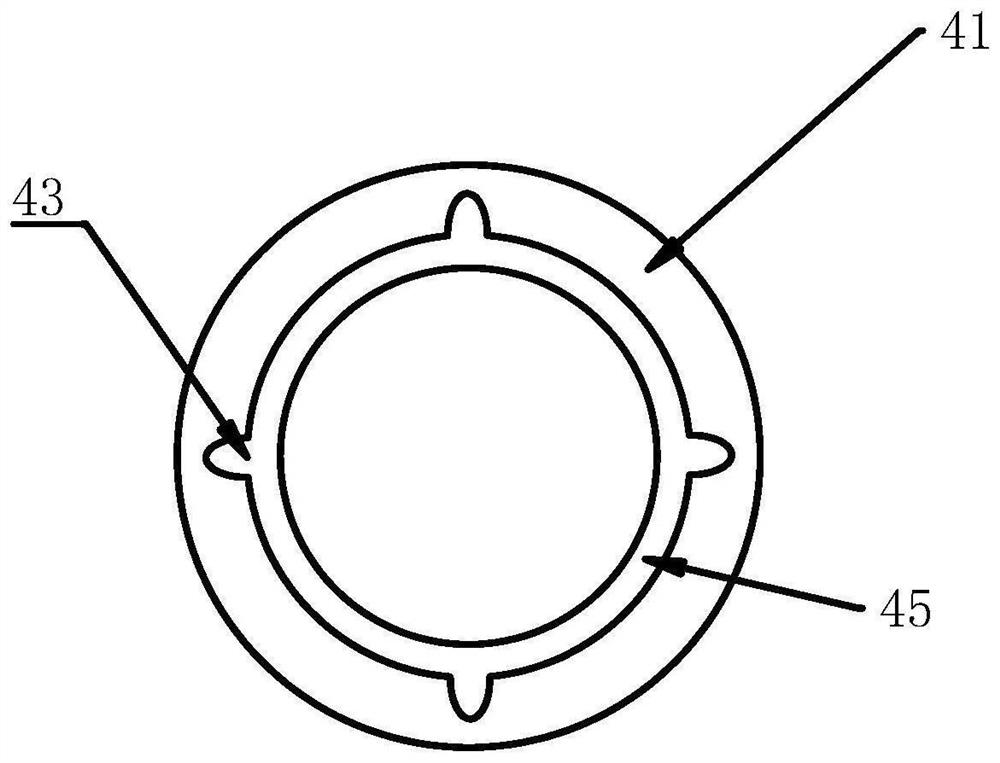

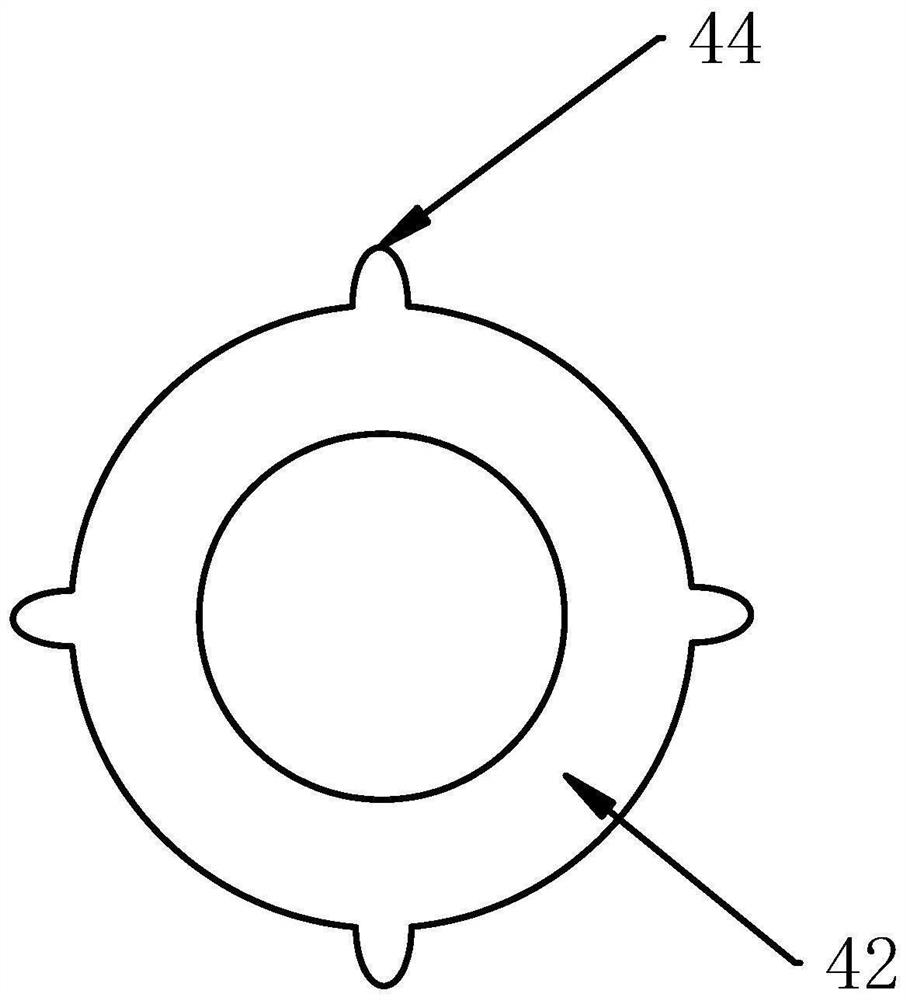

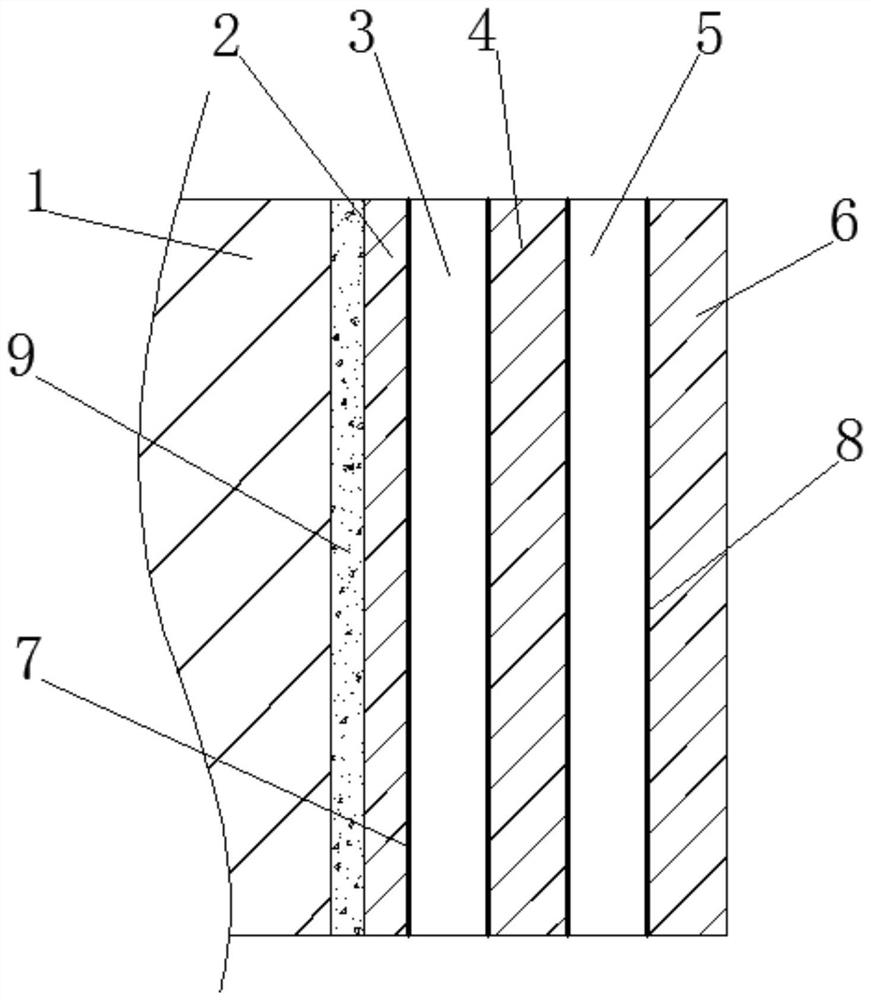

Lining improved type environment-friendly logistics packaging box and manufacturing method and unfolding structure thereof

PendingCN113148368AReduce leak rateGuaranteed tightnessWrapper twisting/gatheringRigid containersLogistics managementMoisture resistance

The invention relates to the field of logistics packaging boxes, and specifically relates to a lining improved type environment-friendly logistics packaging box comprising a box body. A lining bag is arranged in the box body in an attached mode, openings are correspondingly formed in the lining bag and the box body, and the four corners of the lining bag are connected with the four corners in the box body in a sealed mode to form four sealing parts. An unfolding structure of the environment-friendly logistics packaging box comprises a box face, a first top cover and a first connecting cover are arranged at the bottom of the box face, a second top cover, a third top cover and a second connecting cover are arranged at the top of the box face, and auxiliary pasting faces are arranged on the first connecting cover and the second connecting cover correspondingly. According to the lining improved type environment-friendly logistics packaging box, a manufacturing method of the lining improved type environment-friendly logistics packaging box and the unfolding structure of the lining improved type environment-friendly logistics packaging box, the leakage rate is decreased through the design of the lining bag, the sealing performance is guaranteed, residues are reduced, the stability during transportation is high, and the box body has the high load bearing capacity, the high anti-falling capacity, the high water resistance, the high moisture resistance, the high oil stain resistance and the like.

Owner:兰林

An anti-corrosion wrapping coating for threaded manual valves

InactiveCN109294305BImprove waterproof performanceImprove oil stain resistanceAntifouling/underwater paintsPaints with biocidesStructural engineeringCorrosion resistant

The invention discloses an anti-corrosion wrapping coating for a threaded manual valve, which belongs to the field of valve anti-corrosion. An anti-corrosion wrapping coating for a threaded manual valve includes a threaded valve. Layers include primer coating, heavy anti-corrosion layer, lotus leaf self-cleaning coating, inner self-cleaning coating, outer waterproof self-cleaning layer, primer coating, heavy anti-corrosion layer, lotus leaf self-cleaning coating, inner self-cleaning coating, outer waterproofing The self-cleaning layer is applied on the surface of threaded valves from left to right in turn, which can improve the waterproofness and oil resistance of the anti-corrosion coating, making the anti-corrosion coating not easy to peel off, and making the corrosion resistance of the valve reach remarkable At the same time, through the use of self-healing materials, the anti-corrosion coating has the ability of self-healing when cracks or holes are first formed, which greatly prolongs the effective time of the anti-corrosion coating and makes the internal threaded valve extended service life.

Owner:ZHEJIANG JIANENG VALVE CO LTD

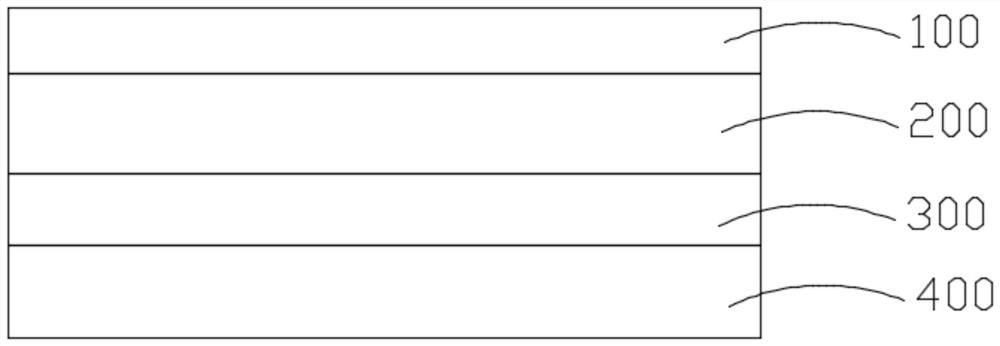

Anti-oil stain tablecloth

PendingCN112322209AEasy and effective cleaningImprove oil stain resistanceAntifouling/underwater paintsPaints with biocidesPolyesterPolymer science

The embodiment of the invention relates to the technical field of film processing, and particularly discloses an anti-oil stain tablecloth which comprises an anti-stain coating, a transparent film layer, a pressure-sensitive adhesive layer and a PET release film layer, the surface of the transparent film layer is coated with the anti-stain coating, and the anti-stain coating comprises polyurethaneand nano titanium dioxide doped with zinc, fluorine, nitrogen and boron. According to the transparent film layer provided by the invention, polyester polyol, diisocyanate, urethane acrylate, nano silicon dioxide and cellulose acetate butyrate are adopted, and a curing agent, a catalyst, an antioxidant, a chain extender and a stabilizer are used as auxiliary materials, so that the oil stain resistance of the tablecloth can be effectively improved, and oil stains attached to the surface of the tablecloth can be effectively and conveniently cleaned.

Owner:FOSHAN WEIMING PLASTICS

PVA/ABS corrosion-resistant, high-toughness permanent antistatic composite material and preparation method thereof

The invention provides a PVA / ABS (polyvinyl acetate / acrylonitrile-butadiene-styrene) corrosion-resistant, high-tenacity and permanent antistatic composite material and a preparation method thereof. The composite material comprises 10-30 parts of PVA with different polymerization degrees, 50-80 parts of emulsion polymerization ABS, 5-10 parts of compatilizers, 5-8 parts of nano-talcum powder, 5-10 parts of plasticizers, 0.3-0.5 part of antioxidant, 0.5-1 part of lubricants and 0.1-0.5 part of dispersing agents. The corrosion-resistant, high-tenacity and permanent antistatic composite material prepared by the method has high corrosion resistance, excellent resistance to solvents, greasy dirt and other chemicals, high tenacity and permanent antistatic capacity. The shortcomings of poor antistatic effect, short antistatic time, low mechanical strength and the like of common plastics are successfully overcome, and development of safety and corrosion resistance of household appliance industry in use is promoted. Higher requirements of contemporary people for comfort level and safety of household appliances are met.

Owner:ORINKO NEW MATERIAL CO LTD

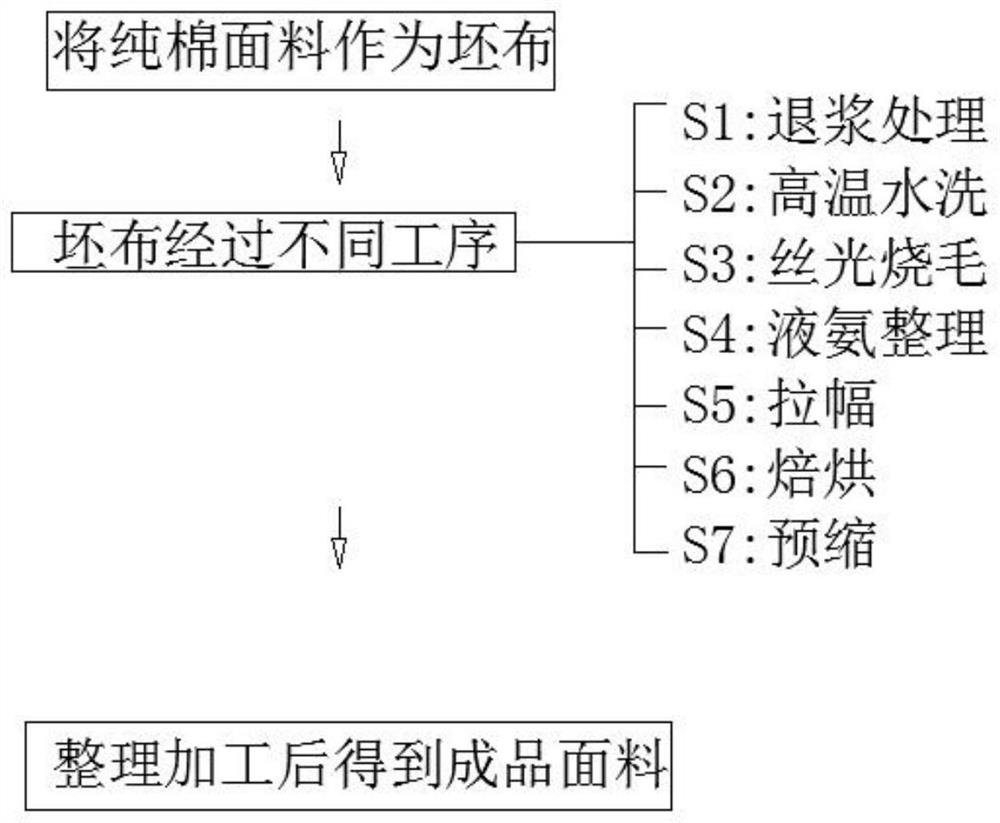

Processing method of anti-oil shirt fabric

PendingCN114657769AReasonable designEasy to operateStain/soil resistant fibresSingeingProcess engineeringComposite material

The invention discloses a processing method of an anti-oil shirt fabric, a pure cotton fabric is used as a gray fabric, the gray fabric is subjected to different procedures and finishing processing to obtain a finished fabric, and the specific flow of the different procedures comprises S1, desizing treatment, S2, high-temperature water washing, S3, mercerizing singeing, S4, liquid ammonia finishing, S5, tentering, S6, baking and S7, preshrinking. According to the processing method of the anti-oil shirt fabric, disclosed by the invention, after liquid ammonia, soil release finishing is carried out, so that compared with direct soil release finishing after mercerizing, the improvement of the soil release performance of the fabric is more facilitated, and the oil resistance of the fabric is further effectively improved; the easy-to-clean performance and the washing resistance of the fabric can be improved, so that the service life of the fabric is effectively prolonged.

Owner:GUANGDONG QUNHAO CLOTHING

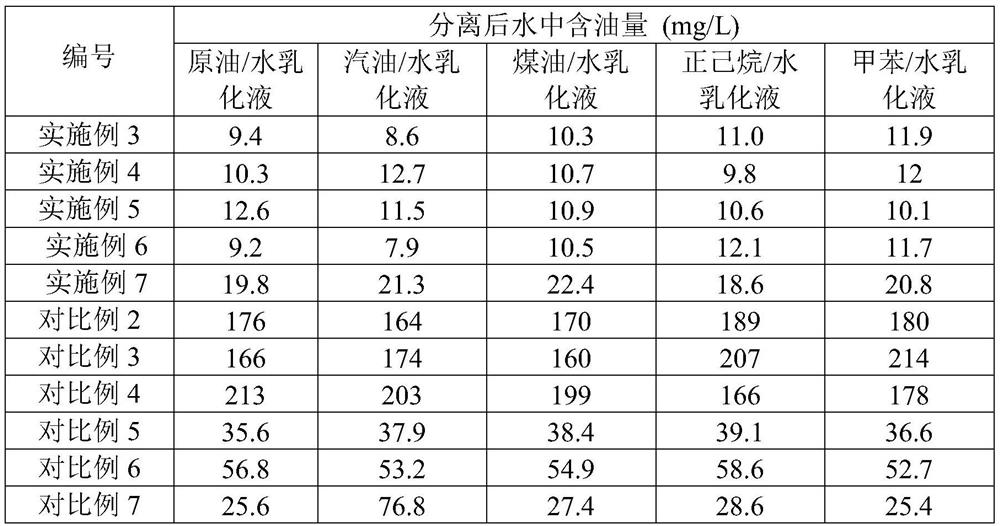

Method for preparing high-performance oil-water separation membrane

ActiveCN112755803AHydrophilicImprove mechanical strength and mechanical propertiesSemi-permeable membranesMembranesMetal-organic frameworkSewage treatment

The invention provides a method for preparing a high-performance oil-water separation membrane, which comprises the following steps of: S1, preparing a mixed solution containing a polymeric monomer, an initiator, a membrane material and an organic solvent, and carrying out polymerization reaction; S2, adding a metal organic framework material into the reaction solution obtained in the step S1 to obtain a membrane casting solution; and S3, coating the surface of a base membrane with the membrane casting solution, and carrying out membrane forming treatment to obtain the high-performance oil-water separation membrane. The prepared oil-water separation membrane is high in hydrophilicity, mechanical property and mechanical strength, high in water flux and high in oil-water separation capacity, and the technical scheme is easy for industrial production and has a wide application prospect in the field of oily sewage treatment.

Owner:CHINA PETROLEUM & CHEM CORP +1

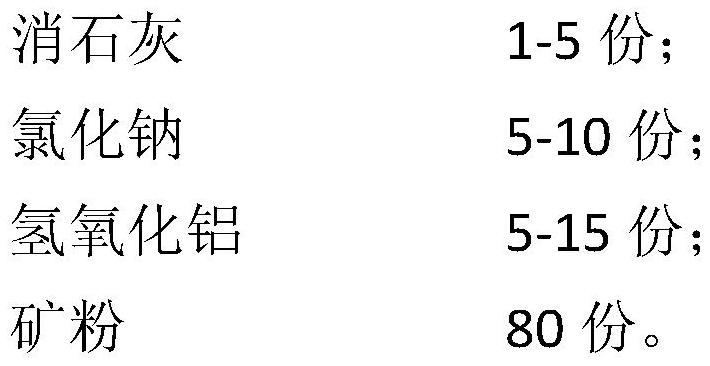

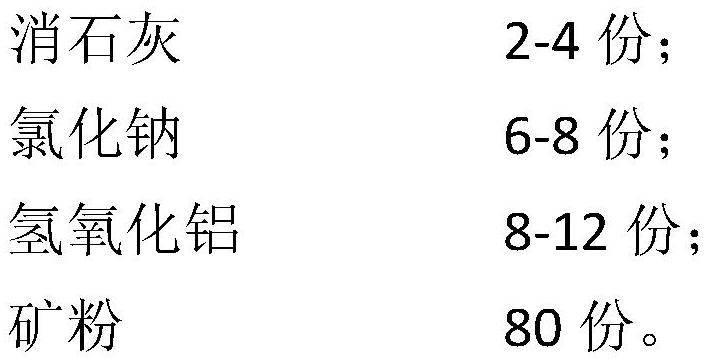

Multifunctional ultra-thin surface layer material for road and its application

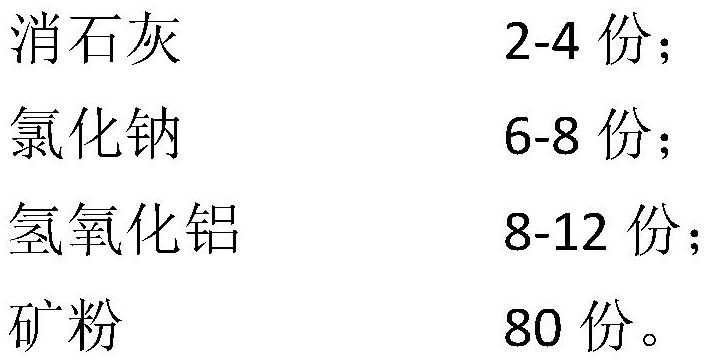

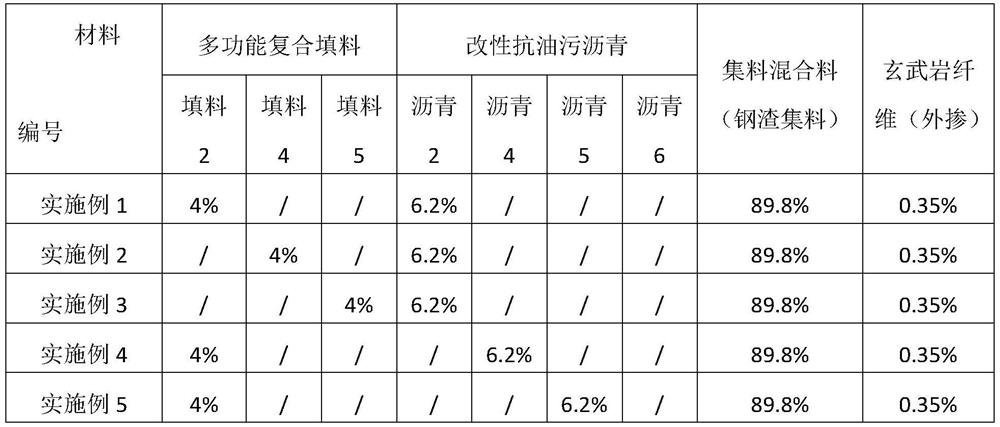

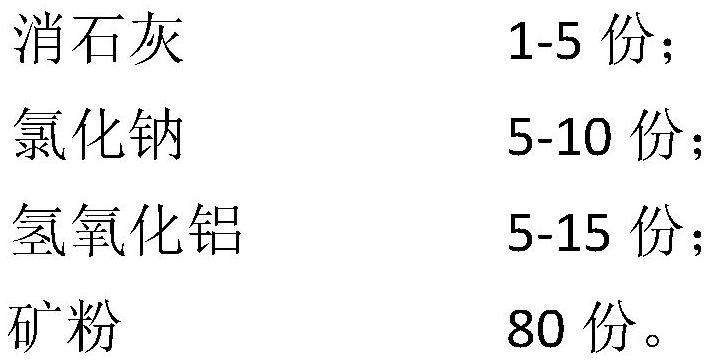

ActiveCN112694286BImprove adhesionIncreased durabilityIn situ pavingsPaving detailsRoad engineeringAluminium hydroxide

The invention discloses a multifunctional ultra-thin surface layer material for roads and an application thereof, belonging to the field of road engineering. The surface layer material includes multifunctional composite filler, modified oil-resistant asphalt and mixture, and the multifunctional composite filler is composed of slaked lime, sodium chloride, aluminum hydroxide and mineral powder; the modified oil-resistant asphalt is composed of long Composition of alkyl silicone oil, glycerin and SBS modified asphalt. Compared with the prior art, the road ultra-thin surface layer paved with the multifunctional ultra-thin surface layer material for roads of the present invention has the properties of ultra-thin, anti-skid, noise reduction, ice-melting, flame-retardant, oil-resistant, anti-rutting, etc. Features, it can be used for both new road construction and old road maintenance, and has good promotion and application value.

Owner:SHANDONG HI SPEED COMPANY +2

Multifunctional ultrathin surface layer material for roads and application thereof

ActiveCN112694286AImprove adhesionIncreased durabilityIn situ pavingsPaving detailsRoad engineeringAluminium hydroxide

The invention discloses a multifunctional ultrathin surface layer material for roads and application thereof, and belongs to the field of road engineering. The surface layer material comprises multifunctional composite filler, modified oil-stain-resistant asphalt and a mixture, and the multifunctional composite filler is composed of slaked lime, sodium chloride, aluminum hydroxide and mineral powder; the modified oil-stain-resistant asphalt is composed of long-chain alkyl silicone oil, glycerin and SBS modified asphalt. Compared with the prior art, the road ultra-thin surface layer paved by the multifunctional ultra-thin surface layer material for the roads has the characteristics of ultra-thinness, skid resistance, noise reduction, ice melting, flame retardance, oil stain resistance, rut resistance and the like, can be used for new pavement construction and old road maintenance, and has very good popularization and application values.

Owner:SHANDONG HI SPEED COMPANY +2

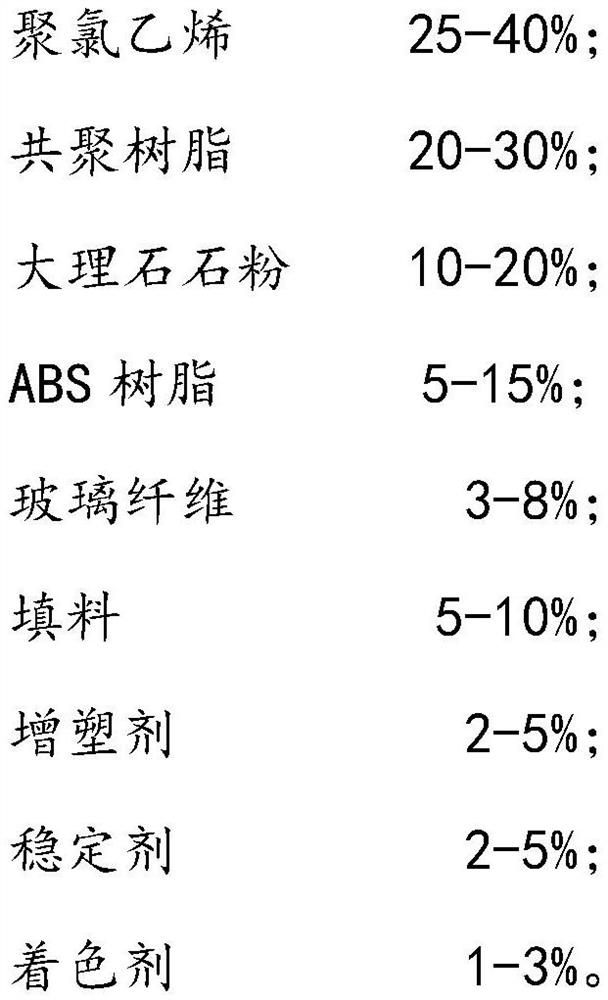

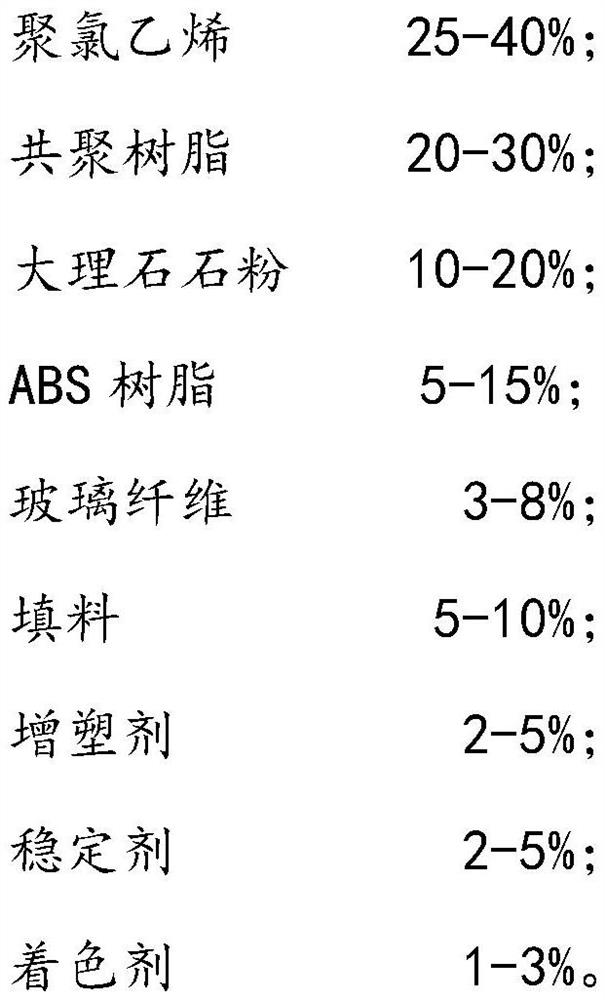

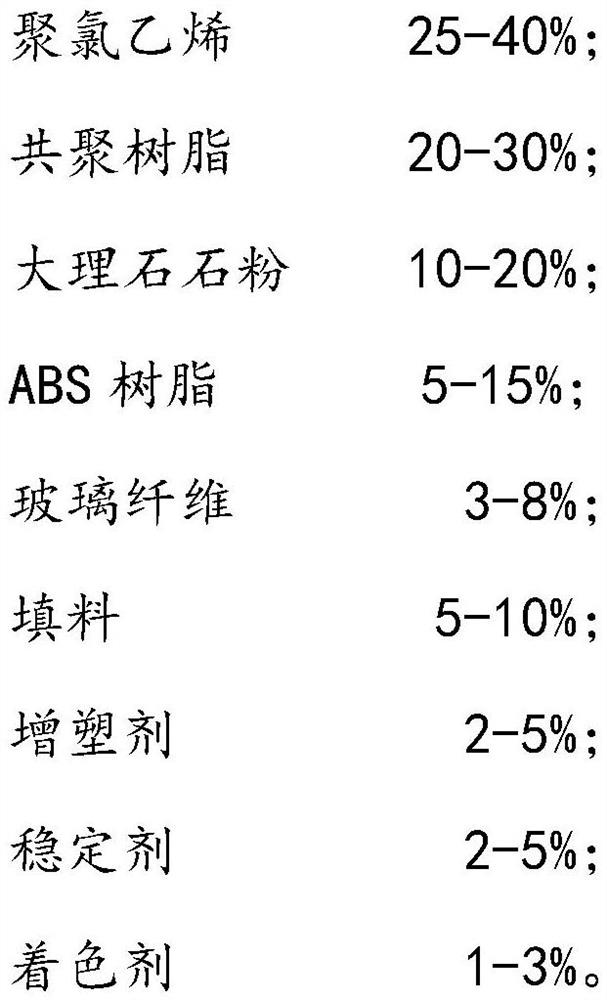

Preparation method of oil-stain-resistant stone-plastic floor

InactiveCN112812466AImprove oil stain resistanceImprove wear resistanceFlooringGlass fiberPolymer science

The invention provides a preparation method of an anti-oil-stain stone-plastic floor, belonging to the technical field of preparation of stone-plastic floors. According to the preparation method of the anti-oil-stain stone-plastic floor, the anti-oil-stain stone-plastic floor comprises the following specific raw materials: 25-40% of polyvinyl chloride, 20-30% of copolymer resin, 10-20% of marble powder, 5-15% of ABS resin, 3-8% of glass fibers 5-10% of a filler, 2-5% of a plasticizer, 2-5% of a stabilizer, and 1-3% of a coloring agent. Specifically, the anti-oil-stain stone-plastic floor comprises the following raw materials: 35% of the polyvinyl chloride, 20% of the copolymer resin, 15% of the marble powder, 10% of the ABS resin, 5% of the glass fibers, 5% of the filler, 5% of the plasticizer, 3% of the stabilizer, and 2% of the coloring agent. By adopting the polyvinyl chloride, the copolymer resin and the marble powder as main materials and adding a proper amount of the ABS modified resin and the glass fibers, the structural firmness of the stone-plastic floor can be greatly improved, and meanwhile, the wear resistance and oil stain resistance of the stone-plastic floor are also greatly improved, so the overall working efficiency of the stone-plastic floor is greatly improved, and the stone-plastic floor is worthy of being vigorously popularized.

Owner:欧迪嘉建材江苏有限公司

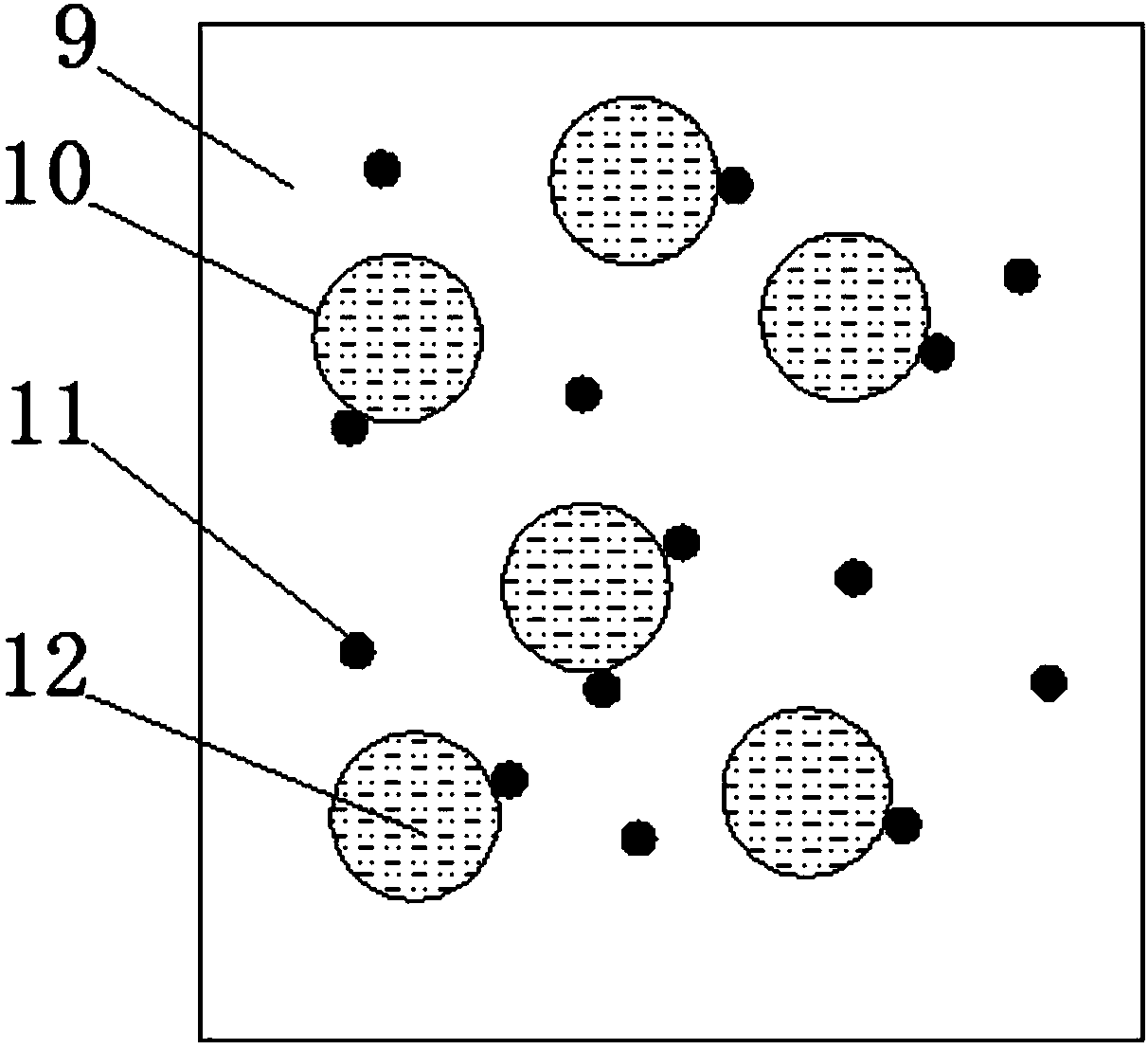

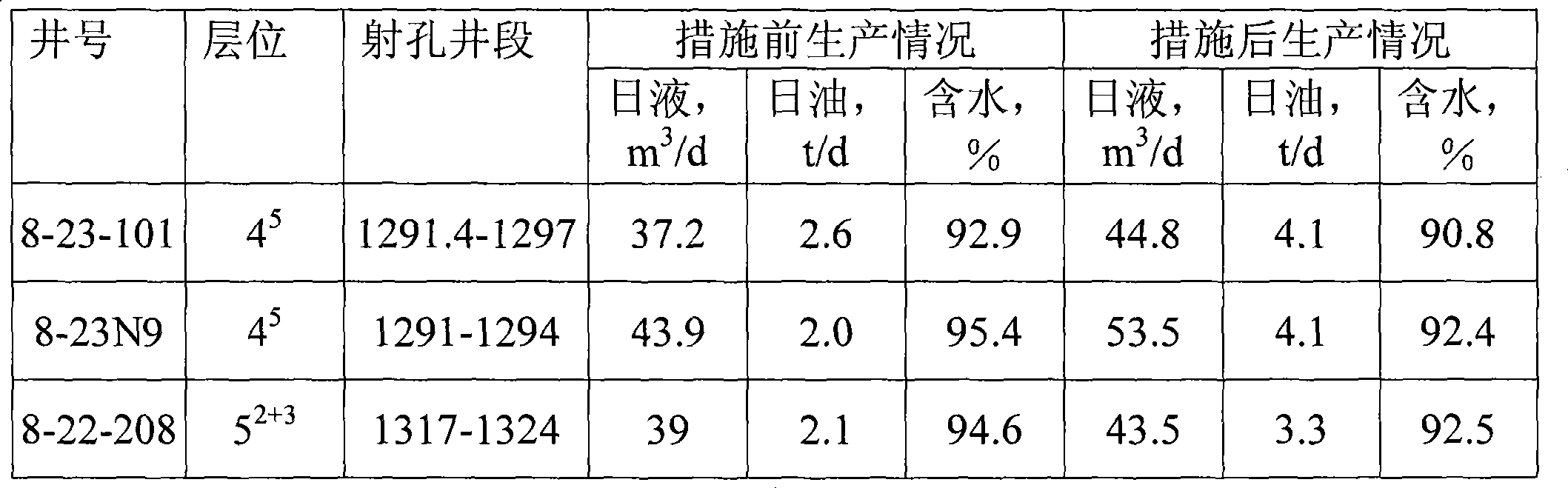

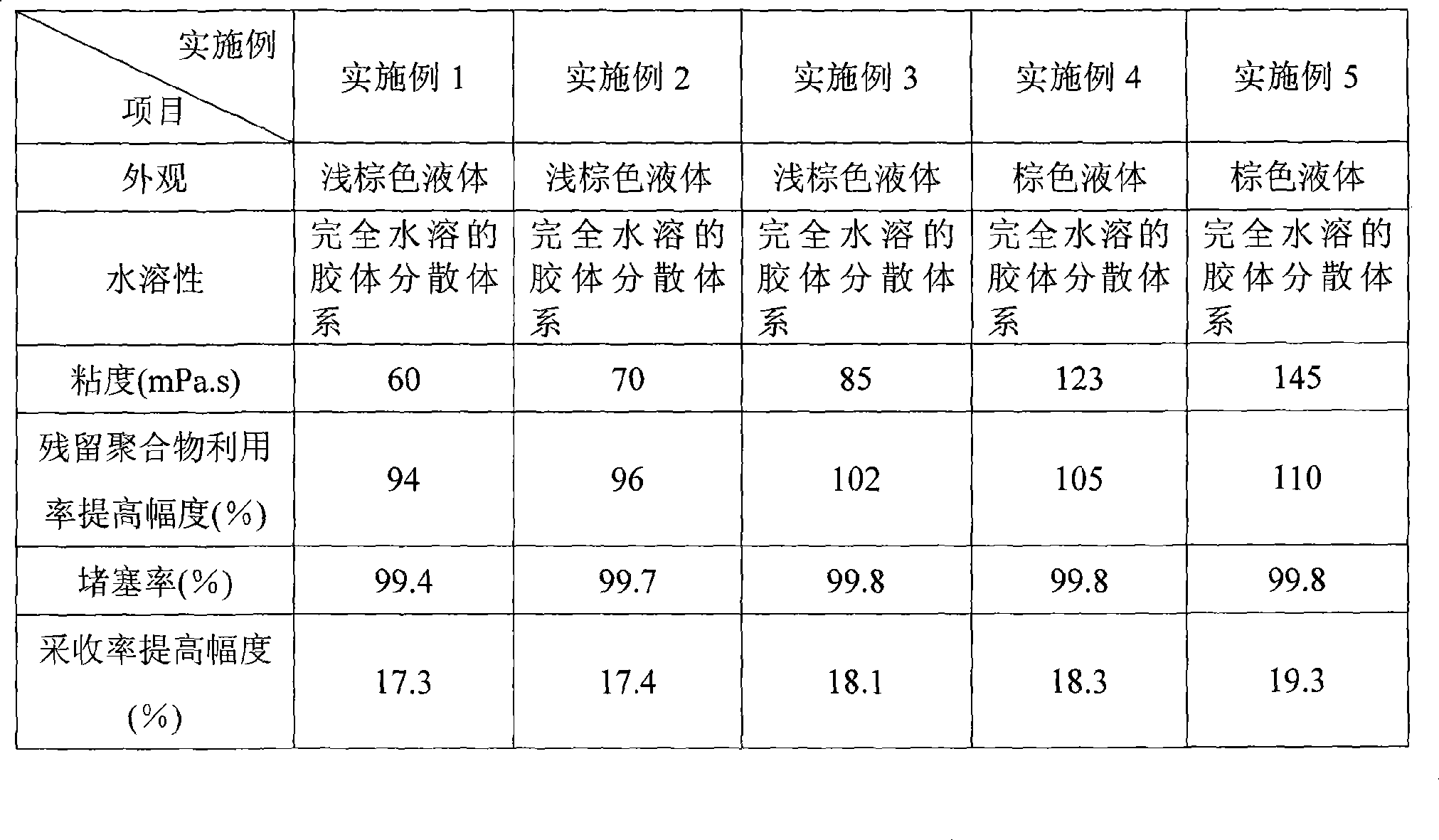

Multifunctional composite treating agent for polymer flooding and successive water flooding oil reservoir

InactiveCN101362939ARealize deep profile controlAchieve fixationDrilling compositionPolymer scienceWater flooding

The invention relates to a polymer flooding subsequent water-drive oil reservoir multifunctional composite disposing agent which solve the technical problems that the re-utilization ratio and water injection recovery ratio of the existing polymer are low, the site construction cost is high and the residual polymer flocculating constituent and profile modifying agent have no interaction; the polymer flooding subsequent water-drive oil reservoir multifunctional composite disposing agent is prepared by the method as follows: benzene derivative and formaldehyde, with suitable quantity, which are substituted by hydroxyl groups are poured into a three-neck flask and heated into liquid; alkali catalyst is added into the flask; the temperature of the flask is kept and the flask is mixed; subsequently, the formaldehyde is poured into the three-neck flask; the temperature of the flask raises and the flask is mixed continuously; then, the alkali catalyst is added, the temperature is increased, and the mixing is carried out subsequently; residual parts of the formaldehyde is added into the flask, the temperature raises and kept constant and the mixing is carried out subsequently; after the reaction is finished, transparent red brown liquid can be gained and solid filling material and water are added into the red brown liquid so as to be mixed as colloid dispersoid system. The polymer flooding subsequent water-drive oil reservoir multifunctional composite disposing agent can be widely applied to the exploitation of crude oil in the oilfield.

Owner:蒋官澄

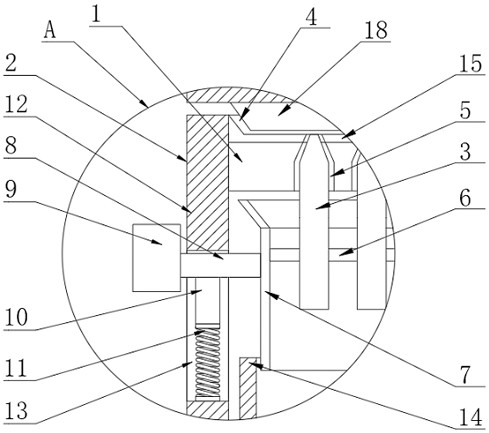

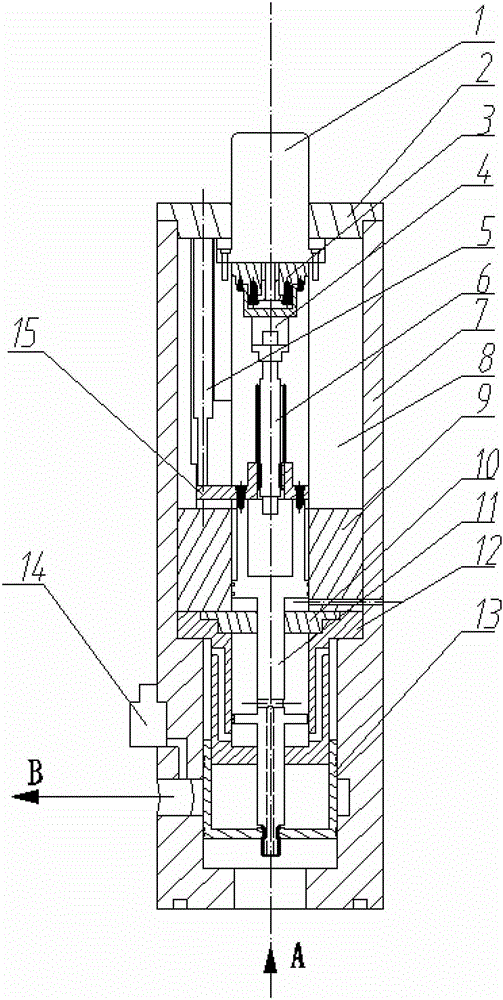

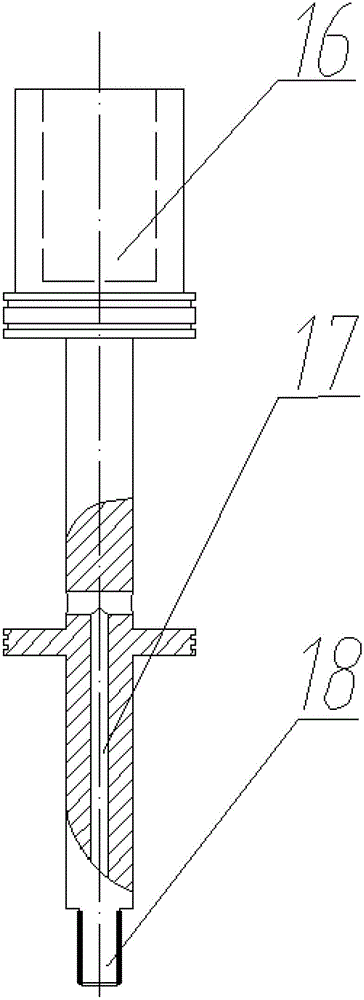

Balanced high-pressure large-current AC (Alternating Current) servo direct-driven cartridge valve

The invention discloses a balanced high-pressure large-current AC (Alternating Current) servo direct-driven cartridge valve, comprising an AC servo motor, wherein the AC servo motor and a harmonic reducer are connected to a valve sleeve, the output shaft of the AC servo motor is connected with the input shaft of the harmonic reducer, the output shaft of the harmonic reducer is connected with a leading screw by a coupler, the leading screw is provided with a sliding block, the sliding block is connected with a linear displacement sensor, the sliding block is connected with a valve rod, the end of the valve rod is provided with an external thread, a valve core is provided with an internal thread, the valve rod drives the opening and closing of the valve core by internal thread connection, a small end cover is connectedly fixed on a valve seat, and is fixedly connected with a valve core sleeve, a valve sleeve is inserted in the valve seat and fixed in the valve seat by a top end cover, the top end cover is fixed with the valve seat, and the valve seat is installed in a hydraulic system by a plug-in manner, so that the influence of the oil-liquid pressure on the valve is reduced, and the instant hydraulic power of the valve is small. According to the invention, as a closed-loop control servo direct-driven manner is adopted, the valve has the advantages of simple structure, rapid response, accurate control and high linearity.

Owner:XI AN JIAOTONG UNIV

HF nano-film and preparation method thereof

InactiveCN109306244AWear-resistantEasy to cleanAntifouling/underwater paintsPaints with biocidesCross-linkEpoxy

The invention relates to an HF nano-film and further discloses a preparation method thereof. The HF nano-film is prepared from the following components in parts by weight: 50-70 parts of a perfluorosilane polymer, 33-46 parts of water, 5-8 parts of polycarbonate, 6-8 parts of methyl acrylate, 2-5 parts of epoxy-modified organic silicone resin, 1-3 parts of propylene carbonate, 2-5 parts of hydroxyethyl cellulose, 10-12 parts of a film-forming assistant, 2-3 parts of a cross-linking agent and 1-3 parts of a plasticizer. Each Si bond of glass is connected with a plurality of active fluorine bonds, on the basis that fluorine has multiple excellent characteristics of water and oil repellence, low friction, abrasion and corrosion resistance and the like, finally a 15-nanometer-thick ultrathin nano-coating with the functions of being ultrathin, easy to clean, resistant to abrasion, high in smoothness and the like is formed on a mobile phone screen; and operation is easy, the application range is wide, the quick effect is achieved, and the HF nano-film is non-combustible, safe and non-toxic.

Owner:深圳市派旗纳米技术有限公司

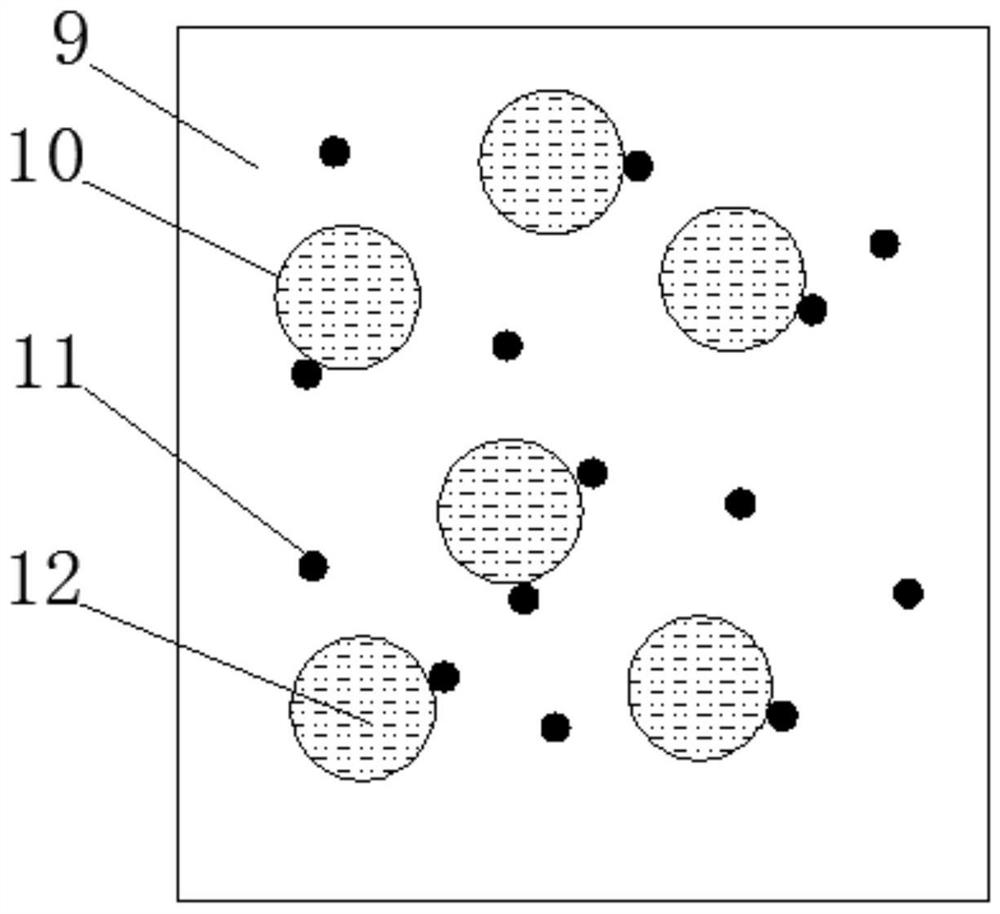

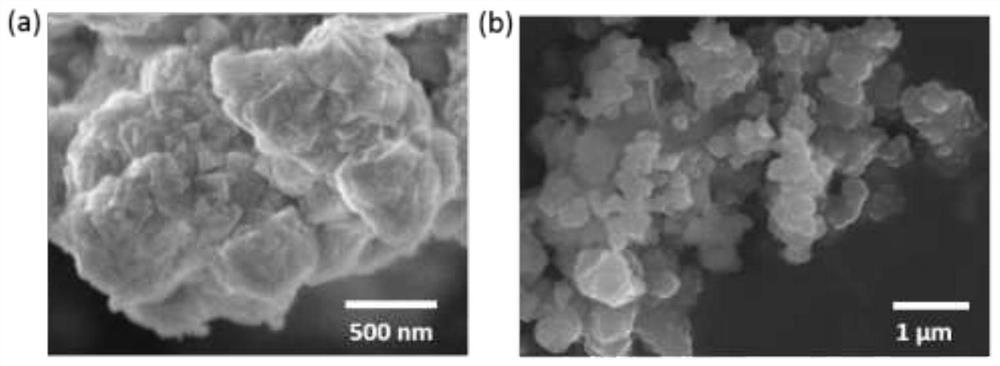

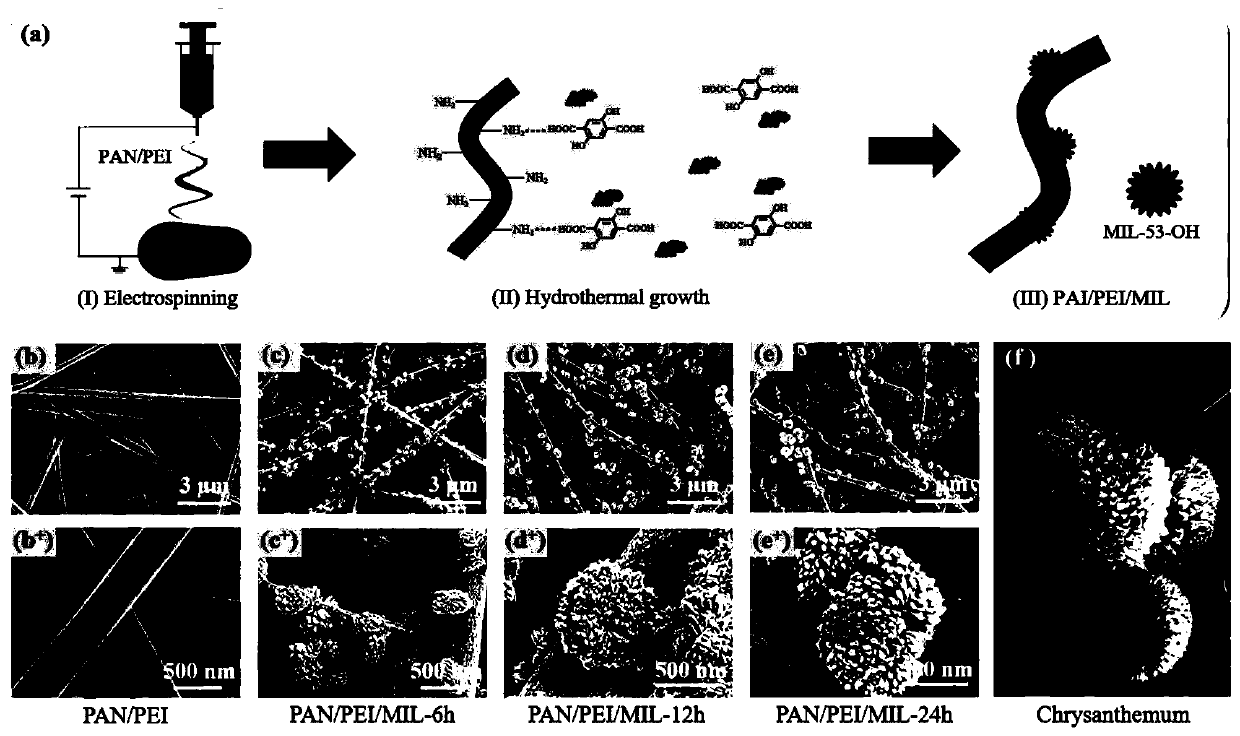

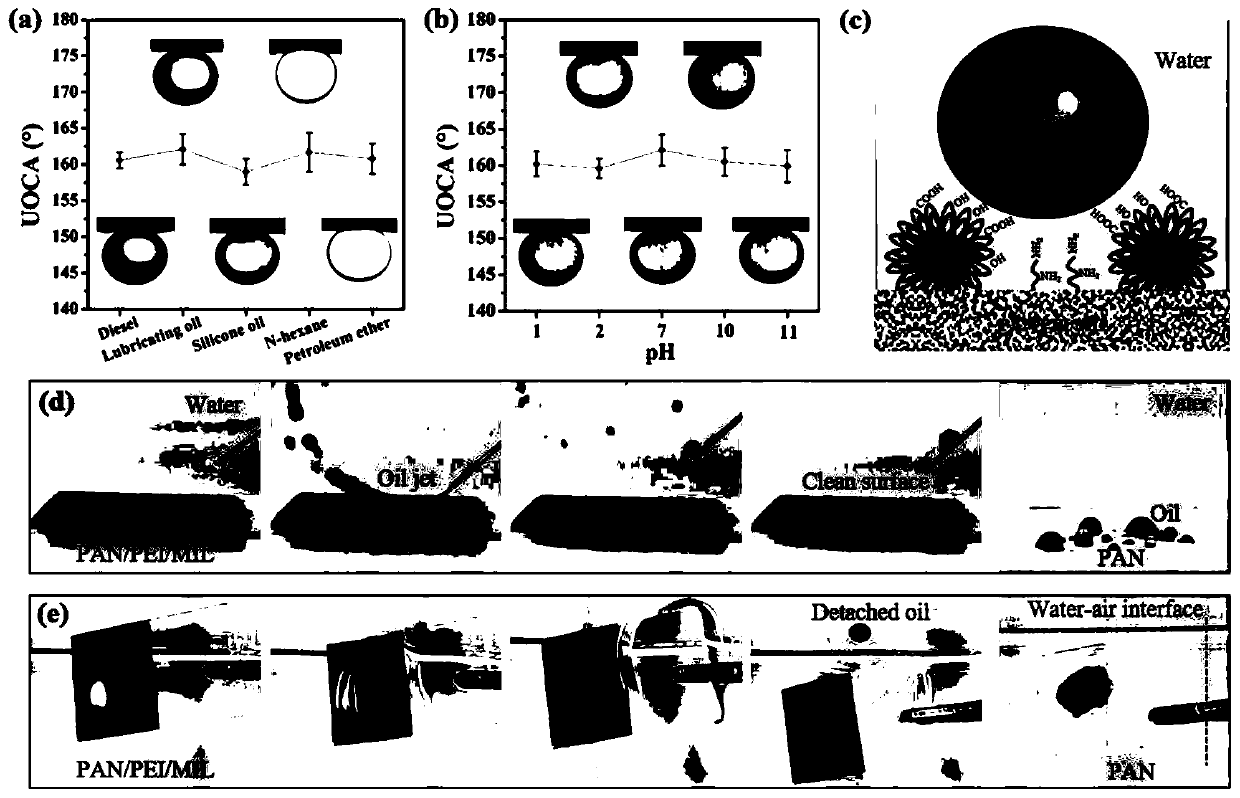

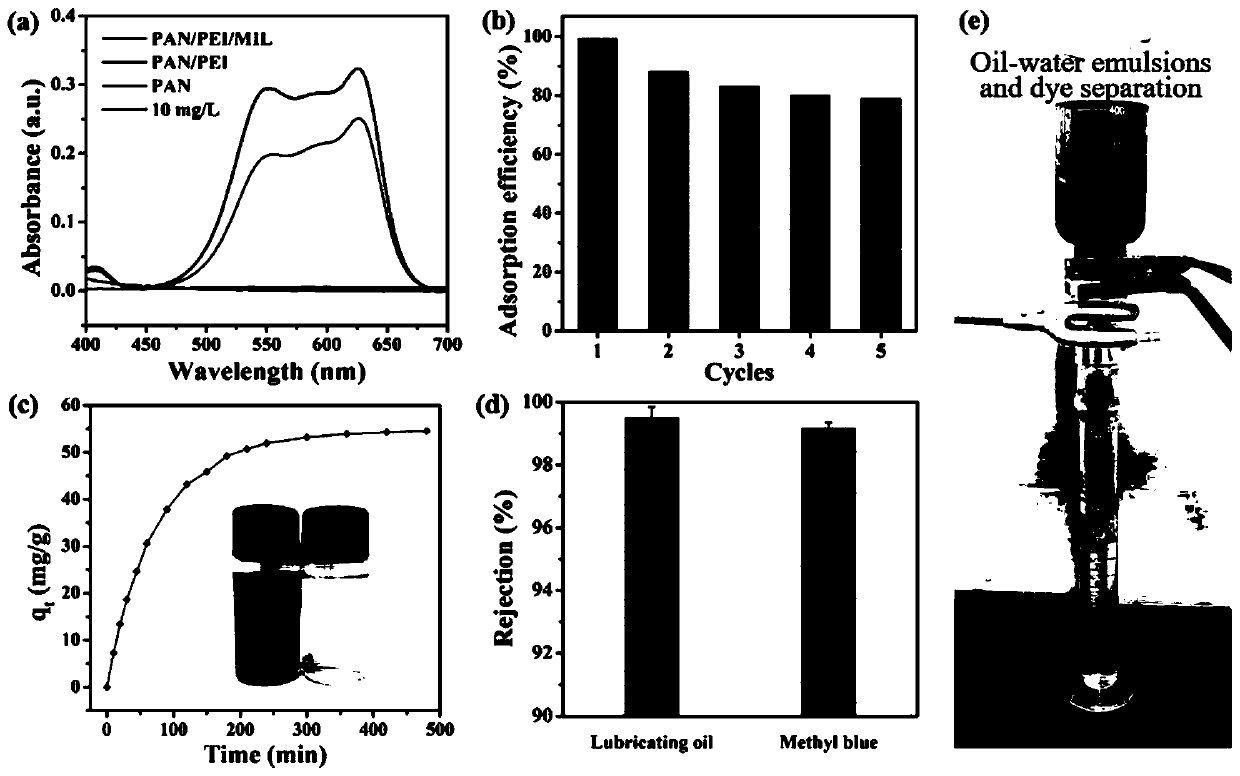

Oily sewage separation membrane with flower-like structure, and preparation method thereof

InactiveCN110960889AImprove oil stain resistanceEasy to separateNon-miscible liquid separationSpinningCarboxyl radical

The invention relates to an oily sewage separation membrane with a flower-like structure, and a preparation method thereof. According to the preparation method, a fiber membrane with a filament diameter of about 500 nm and extremely high porosity is prepared by using polyacrylonitrile and polyethyleneimine as raw materials through an electrostatic spinning technology; an MIL-53-OH metal organic framework compound with a flower-like structure grows on the surface of the fiber membrane through a hydrothermal synthesis method; by using the adsorption effect of the amino on the polyethyleneimine chain and the hydroxyl and the carboxyl on the MIL-53-OH to water, and the synergistic effect of the MIL-53-OH nanoflower-like structure, the efficient separation of oil-water emulsion and an organic dye is achieved, wherein the separation flux (4260 L / m<2>.h) achieves ten times the separation flux of the traditional commercial separation membrane, and the separated water can achieve the national sewage discharge standard; and the fiber membrane has excellent acid resistance and excellent alkali resistance, and has good application prospect in actual industrial production.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

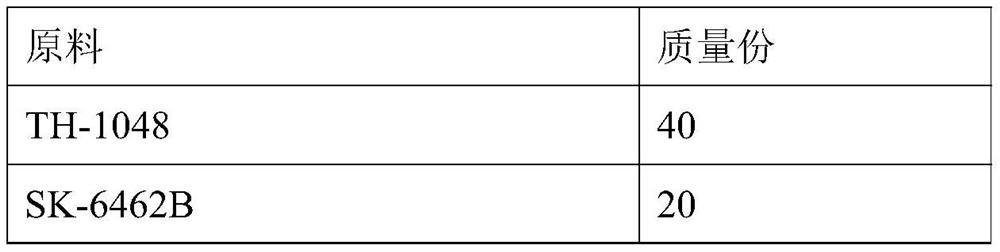

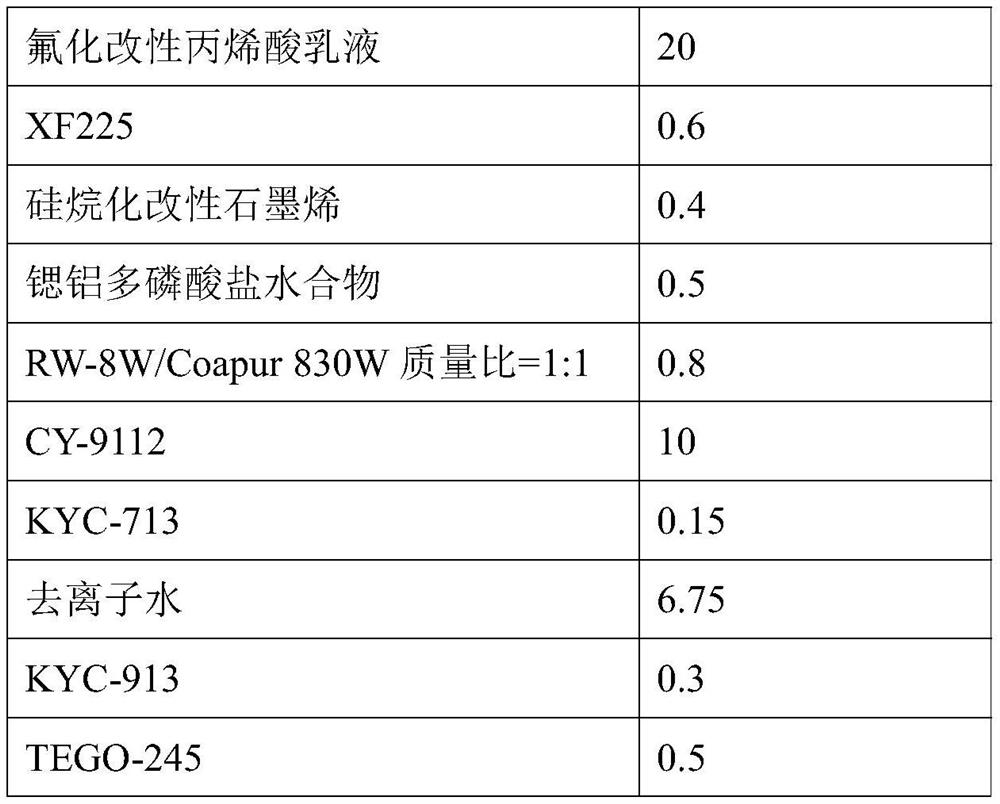

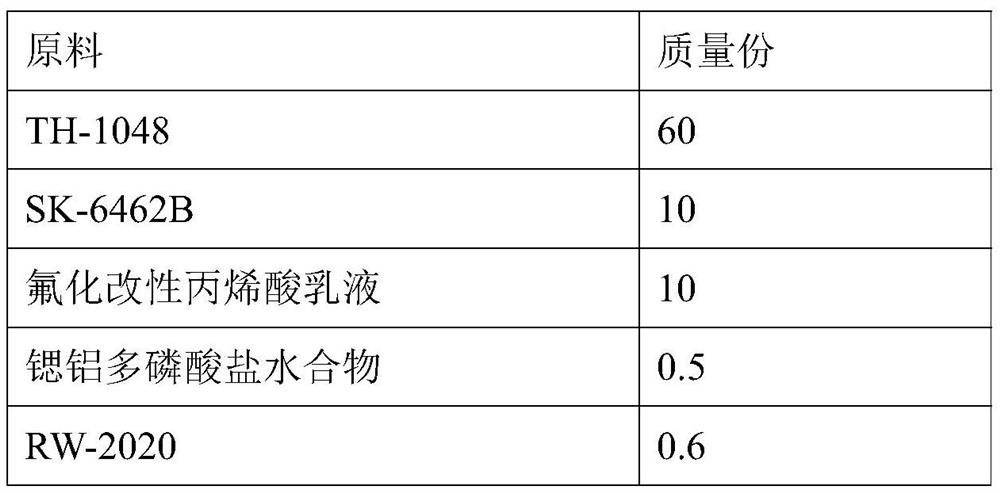

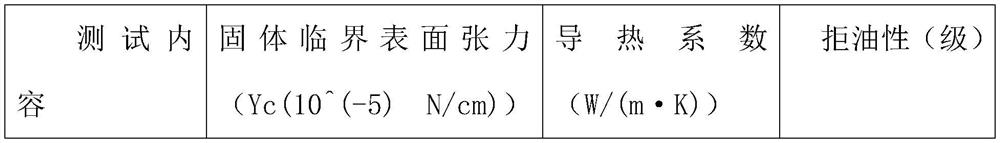

A kind of water-based graphene coating for aluminum buckle plate and preparation method thereof

ActiveCN110804378BImprove applicabilityGood oil resistanceAntifouling/underwater paintsPaints with biocidesGraphene coatingGraphite

The invention discloses a water-based graphene coating for aluminum gussets and a preparation method thereof. This water-based graphene coating comprises the following components by mass: 40-60 parts of water-based polycarbonate resin, 20-40 parts of water dispersion emulsion, 0.1-1 part of functionalized graphene, 5-11 parts of filler, 0 parts of pigment ~1.5 parts, wetting agent 0.1~3 parts, rust inhibitor 0.3~2 parts, defoamer 0.1~1 part, thickener 0.2~1 part, dispersant 0.1~0.5 parts, water 3~10 parts. Also disclose the preparation method of this waterborne graphene coating simultaneously. The water-based graphene coating provided by the invention has the advantages of no VOC emission, strong applicability, good oil pollution resistance, excellent water resistance, environmental protection and pollution-free, long anti-corrosion timeliness, etc., and can meet the use requirements of aluminum gusset plate surface coating.

Owner:广州盛门新材料科技有限公司

Oil-proof coating of down jacket and production method of oil-proof coating

PendingCN114717852AGood heat insulationIncrease oil resistanceTextiles and paperBulk chemical productionCyanate esterPolytetrafluoroethylene

The invention discloses a down jacket oil-proof coating and a production method thereof, and the oil-proof coating is prepared from the following raw materials: an auxiliary agent, polytetrafluoroethylene, silicon dioxide aerogel powder, a polyurethane solution, a foaming agent, resin, polyether polyol, isocyanate, a catalyst, polyethylene glycol adipate, polypropylene glycol, a filling agent and a curing agent, foaming slurry prepared from a foaming agent is coated on the coating, so that the coating has heat insulation and heat preservation functions, the oil-proof coating has a better heat insulation effect, the interior of the down jacket cannot be transferred to the coating, the temperature of the coating is lower, and the surface tension of oil stain liquid falling onto the coating cannot be reduced; the oil stain liquid is prevented from immersing into the coated fabric, so that the oil stain resistance of the down jacket is improved through the oil-proof coating, and the wearing time of the down jacket is prolonged.

Owner:GAOFAN (ZHEJIANG) INFORMATION TECH CO LTD

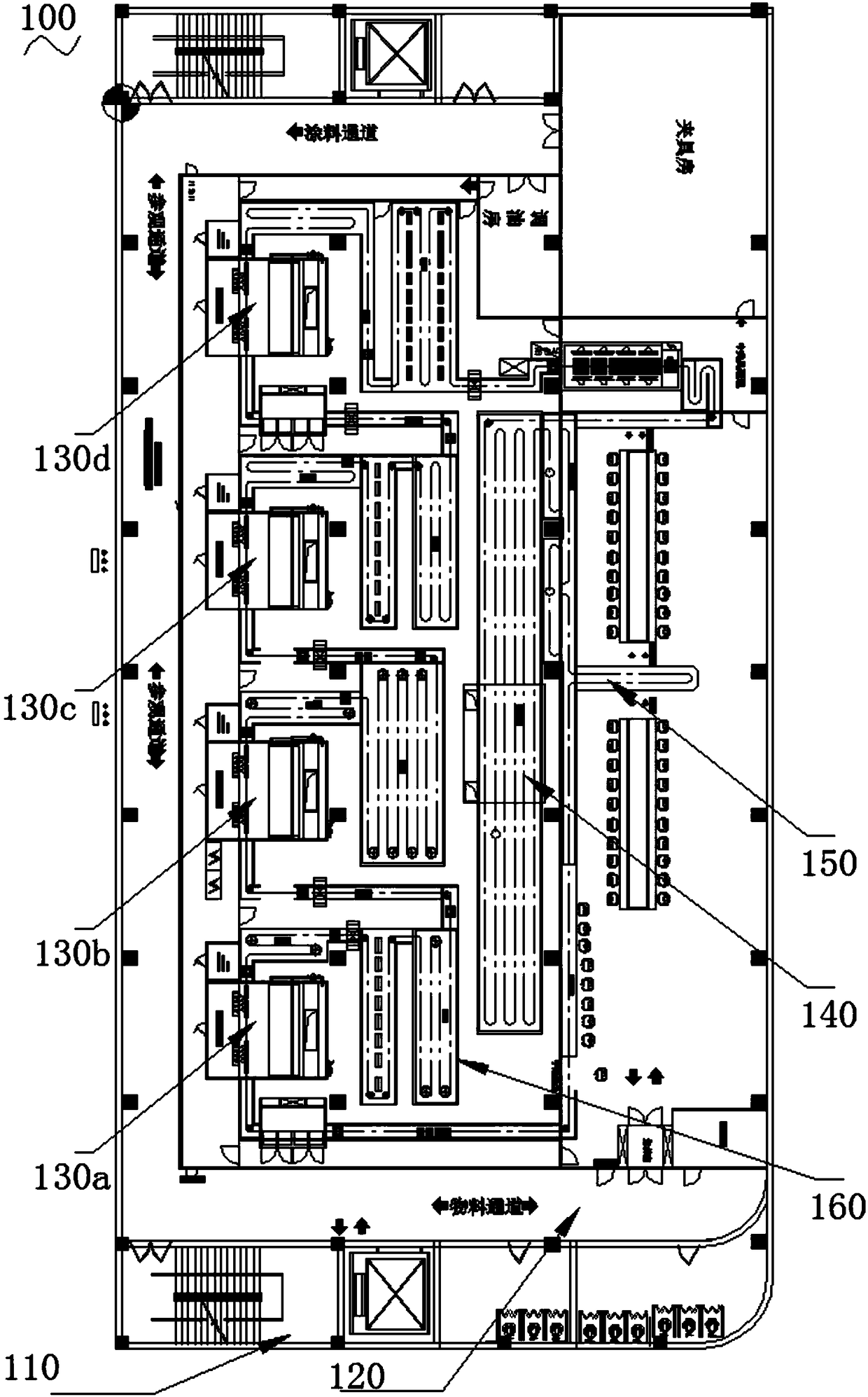

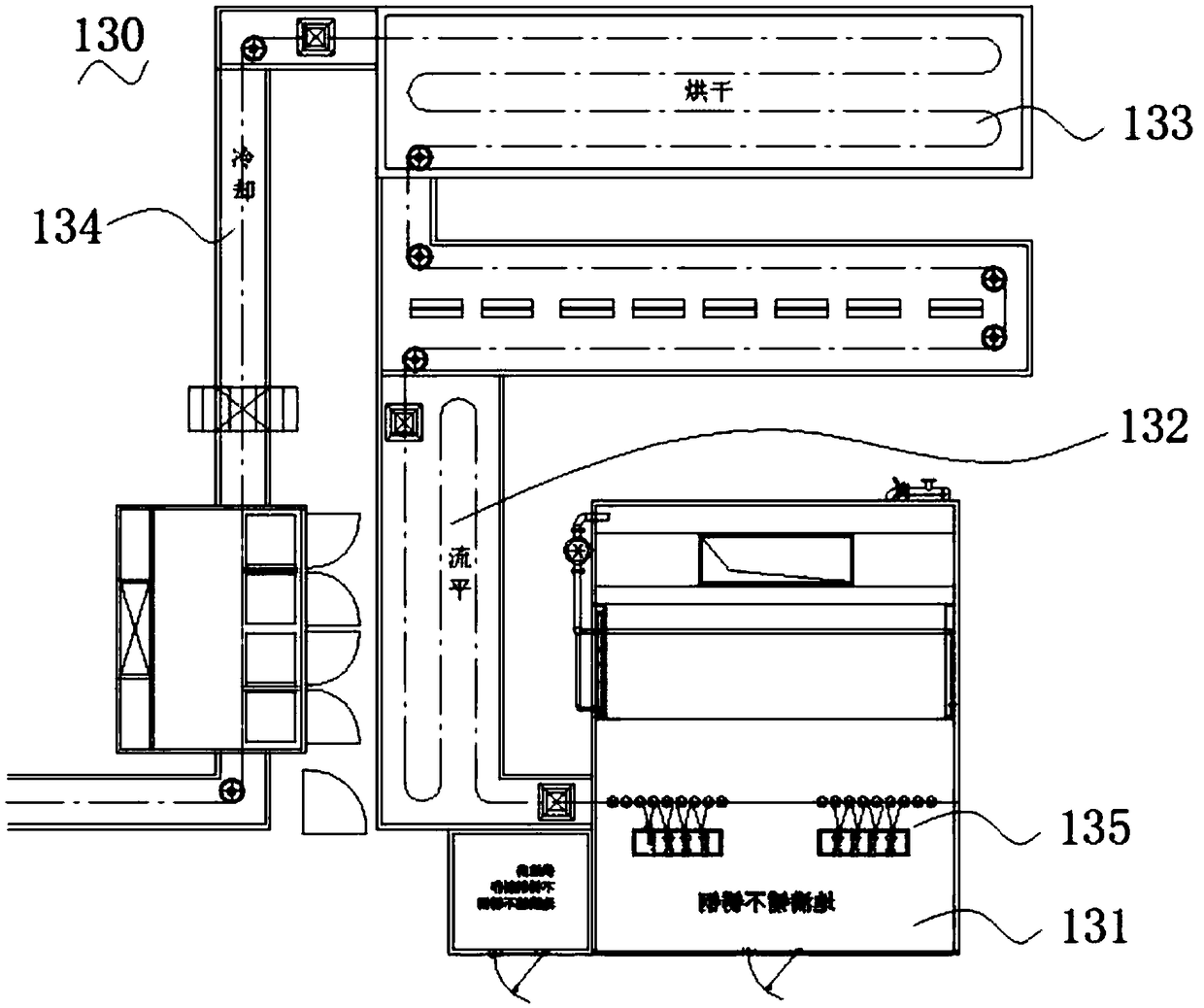

Paint spraying production line for glass plate and paint spraying process

PendingCN108298829AImprove performanceOil stain resistance, drop resistance and impact resistanceCoatingsPre treatmentPower station

The invention relates to the field of spraying equipment and particularly relates to a paint spraying production line for a glass plate and a paint spraying process. The paint spraying production linecomprises a spraying chamber, a preprocessing station arranged in the spraying chamber and used for preprocessing the glass, a plurality of paint spraying stations connected on the preprocessing station and used for spraying a paint on the surface of one side or the surfaces of two sides of the glass, a post-processing station connected with the paint spraying stations, and a conveyer belt connected between the stations and used for transporting the glass, and further comprises a clamp arranged on the conveyer belt and used for bearing the glass, and a power station driving the conveyer beltto move; the preprocessing station is vertical to a connecting line of the paint spraying stations, and the connecting line of the paint spraying stations is parallel with the post-processing station.The paint spraying production line improves the performance of the glass plate, the use rate of the space is high, the degree of automation is high, the paint spraying efficiency and the quality arehigh, and the functions are diversified.

Owner:东莞市新力光表面处理科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com