An anti-corrosion wrapping coating for threaded manual valves

A manual valve and coating technology, applied in the direction of anti-corrosion coatings, coatings, anti-fouling/underwater coatings, etc., can solve the problems of holes, poor anti-corrosion ability, peeling and falling off of anti-corrosion coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

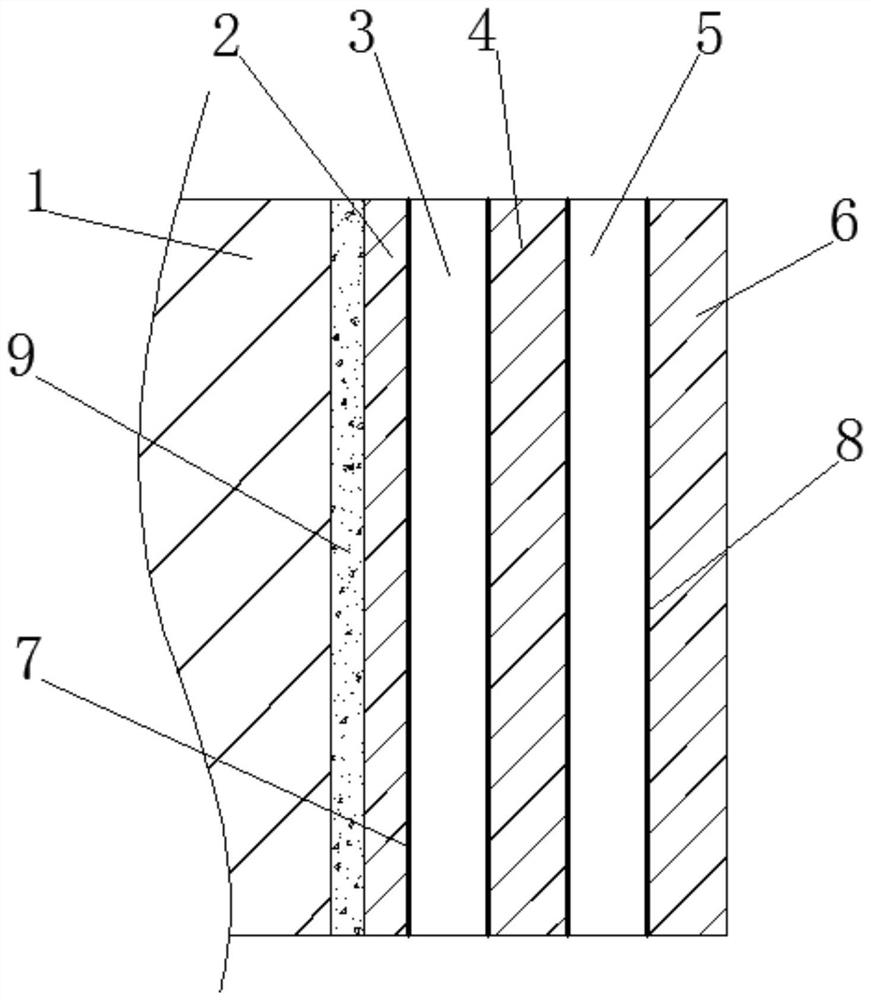

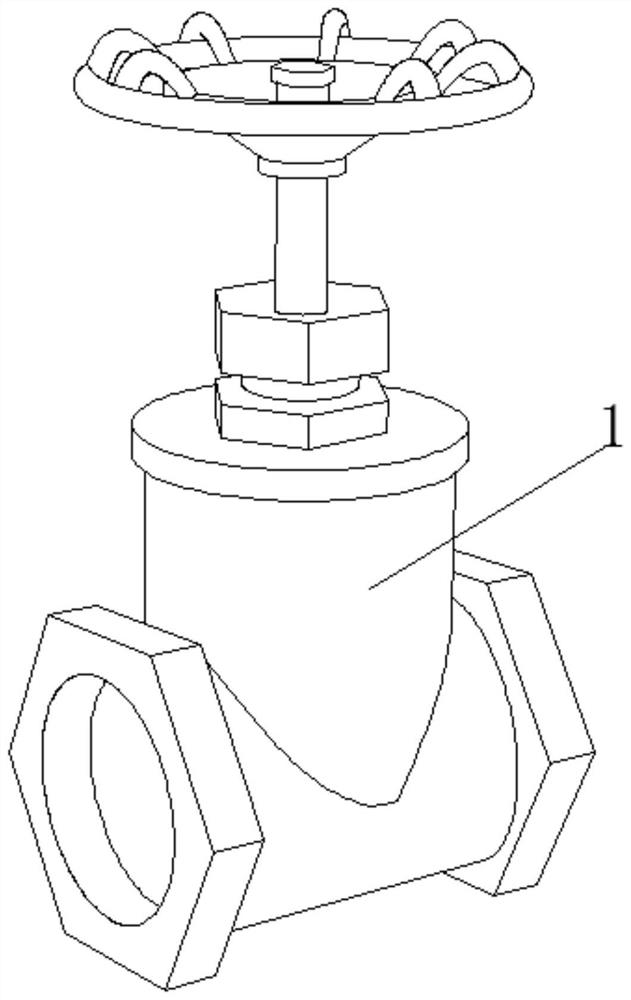

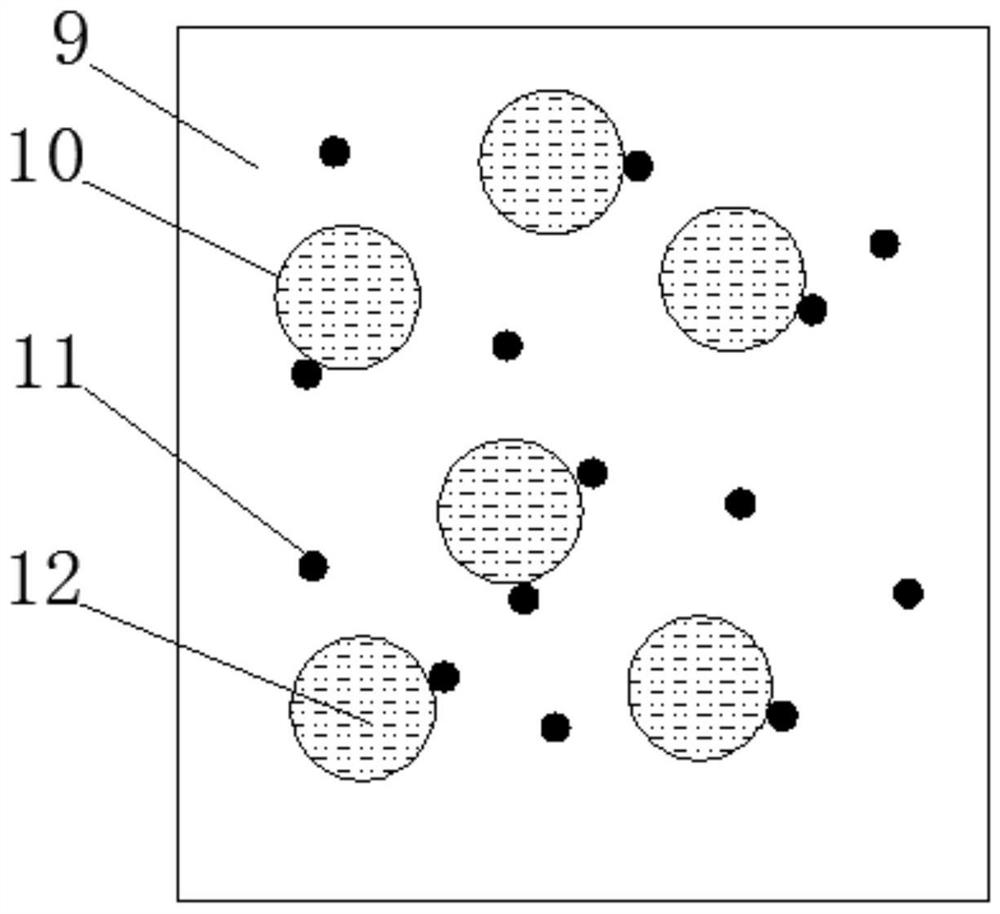

[0041] see Figure 1-2 , an anti-corrosion wrapping coating for a threaded manual valve, comprising a threaded valve 1, the outer end of the threaded valve 1 is coated with an anti-corrosion coating, and the anti-corrosion coating includes a primer coating 2, a heavy anti-corrosion layer 3, and a lotus leaf self-cleaning coating 4. Inner self-cleaning coating 5, outer waterproof self-cleaning layer 6, primer coating 2, heavy anti-corrosion layer 3, lotus leaf self-cleaning coating 4, inner self-cleaning coating 5, outer waterproof self-cleaning layer 6 from left to right Apply to the surface of threaded valve 1 in turn. The primer coating 2 is made of silicone resin coating, which is an elemental organic coating. Silicone coatings have excellent electrical insulation performance, high temperature resistance and corrosion resistance. The heavy-duty anti-corrosion layer 3. Composite ceramic high-temperature anti-corrosion coating is used. The coating can resist acid and alkali c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com