Oily sewage separation membrane with flower-like structure, and preparation method thereof

A flower-like structure, oily water technology, applied in the separation method, immiscible liquid separation, liquid separation, etc., can solve the problems of high porosity of specific surface area and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

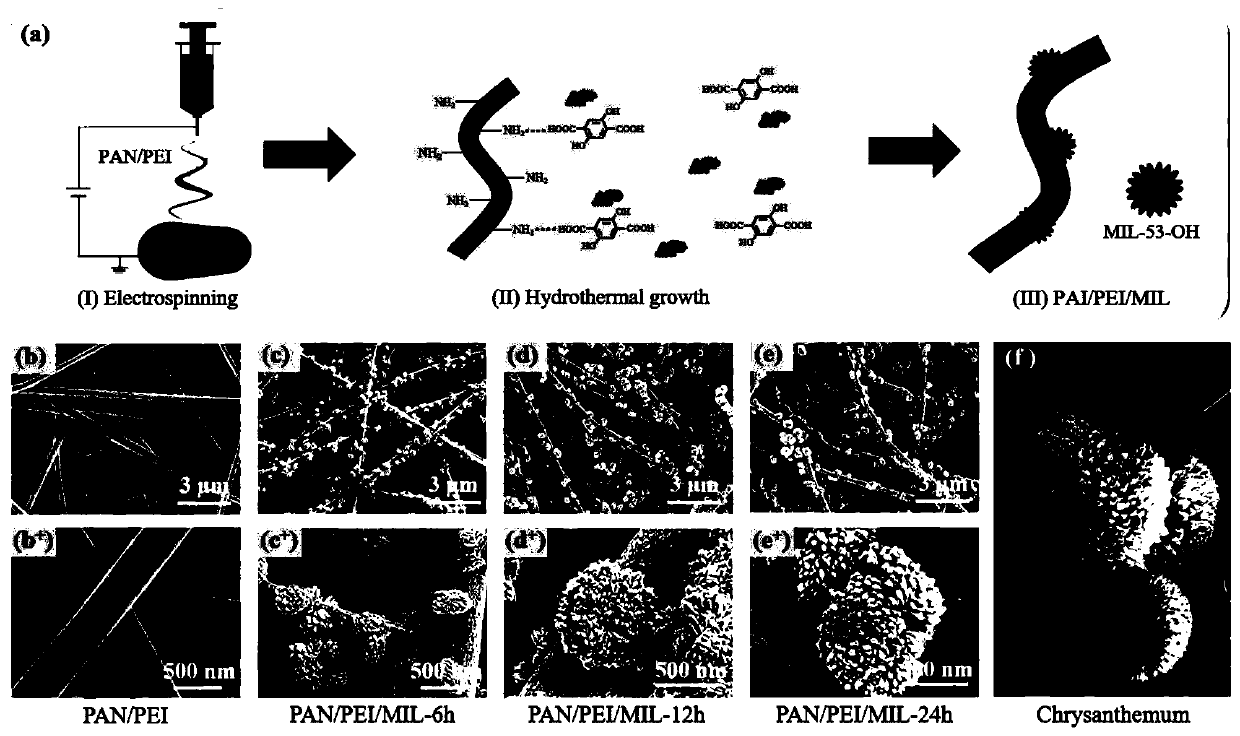

[0017] Example 1, 0.526 g of polyacrylonitrile and 0.263 g of polyethyleneimine were weighed and added to 5 ml of dimethylformamide solution, and magnetically stirred at room temperature for 12 hours to obtain a polyacrylonitrile / polyethyleneimine precursor solution. Draw the polyacrylonitrile / polyethyleneimine precursor solution with a 5 ml syringe, and install a No. 21 needle; put the syringe into the syringe pump of the electrospinning equipment; adjust the advance speed of the syringe pump to 1 ml per hour; Set the translation distance to 10 cm; adjust the distance from the needle to the receiver to 12 cm; cover the roller receiver with a layer of tinfoil, and adjust the receiver rotation speed to 60 rpm; connect the positive high voltage of the high voltage power supply to the syringe Needle, adjust the voltage to 12 kV; connect the negative high voltage of the high-voltage power supply to the roller receiver, adjust the voltage to -2 kV; start the syringe pump system, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com