Paint spraying production line for glass plate and paint spraying process

A glass plate and production line technology, applied in coating and other directions, can solve the problems of unstable touch screen operation, corroded electronic components, unclear touch screen, etc., and achieves the effect of good spraying quality, high spraying quality and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

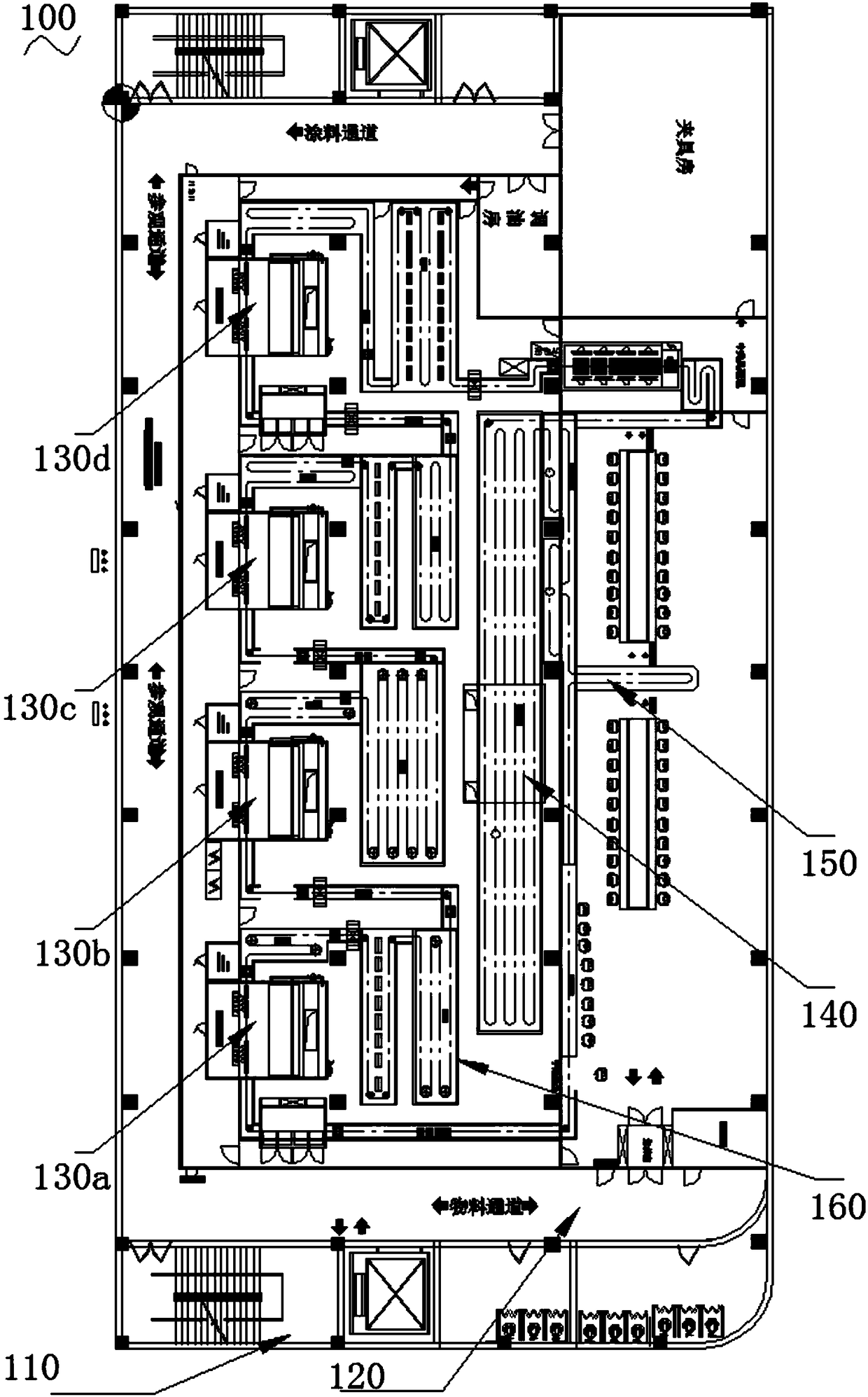

[0039] There are four painting stations 130. The first painting station 130a sprays the first layer of anti-blue paint, the second painting station 130b sprays the second layer of anti-blue paint, and the third painting station 130c sprays the third layer of anti-blue paint. , The fourth spray painting station 130d sprays anti-blue paint, through four sprays, the glass plate has a better anti-blue effect.

Embodiment 2

[0041] There are four painting stations 130, the first painting station 130a sprays the first layer of oil-resistant paint, the second painting station 130b sprays the second layer of oil-resistant paint, and the third painting station 130c sprays the third layer of oil-resistant paint , The fourth spraying station 130d sprays oil-resistant paint, and through four sprays, the glass plate has a better anti-oil effect.

Embodiment 3

[0043] There are four painting stations 130. The first painting station 130a sprays the first layer of enhanced paint, the second painting station 130b sprays the second layer of enhanced paint, and the third painting station 130c sprays the third layer of enhanced paint. The spray paint station 130d sprays the fourth layer of enhanced paint. Through four sprays, the mechanical strength of the glass plate is greatly enhanced, and the impact resistance of the glass plate is improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com