High-impact greasy-dirt-resistant modified regenerated ABS material and preparation method thereof

An ABS material and oil-resistant technology, which is applied in the field of high-impact, oil-resistant modified and recycled ABS materials and its preparation, can solve the problem of damage to the positive pile head and chuck, which affects the service life of the battery, and the recycled ABS is vulnerable to oil pollution. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

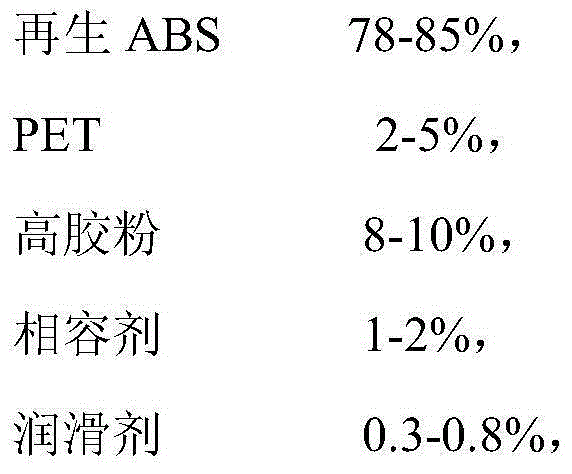

[0025] A high-impact, oil-resistant modified recycled ABS material comprising the following components by weight ratio:

[0026]

[0027] The preparation method of the above-mentioned high-impact, oil-resistant modified regenerated ABS material comprises the following steps:

[0028] (1) Dry the PET at 110-120°C for 4 hours;

[0029] (2) Dry the regenerated ABS at 80°C for 8 hours;

[0030] (3) PET processed through step (1), regenerated ABS processed through step (2), high rubber powder, SEBS-MAH, calcium stearate, nano BaSO 4 , the antioxidant is added to the high-speed mixer according to the weight ratio and mixed, and stirred at room temperature for 10-15 minutes;

[0031] (4) Put the above-mentioned mixture into a twin-screw extruder, and melt, knead, extrude, cool, dry, and pelletize at a temperature of 80-220°C and a screw speed of 350-450 rpm. , Packaging to get the product.

Embodiment 2

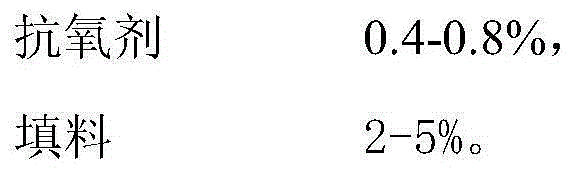

[0033] A high-impact, oil-resistant modified recycled ABS material comprising the following components by weight ratio:

[0034]

[0035] The preparation method of the above-mentioned high-impact, oil-resistant modified regenerated ABS material is the same as in Example 1.

Embodiment 3

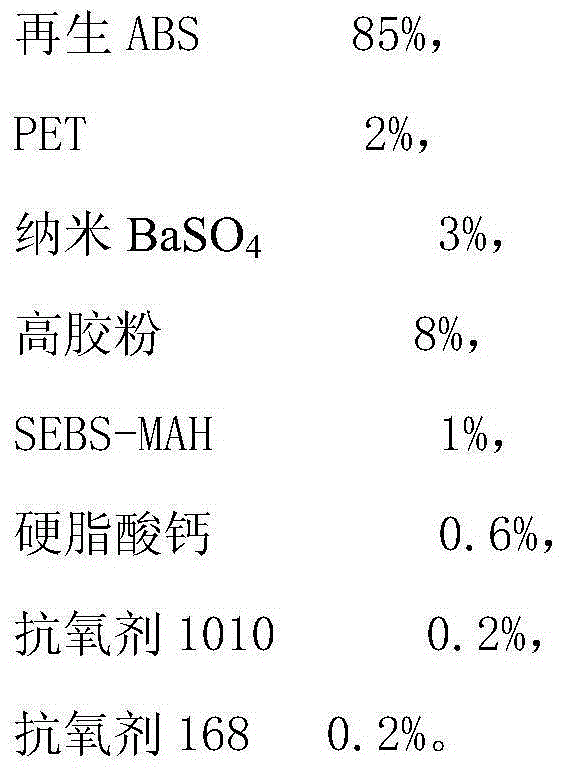

[0037] A high-impact, oil-resistant modified recycled ABS material comprising the following components by weight ratio:

[0038]

[0039] The preparation method of the above-mentioned high-impact, oil-resistant modified regenerated ABS material is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com