Method for preparing high-performance oil-water separation membrane

An oil-water separation membrane, high-performance technology, applied in separation methods, liquid separation, semi-permeable membrane separation, etc., can solve the problems of unsatisfactory oil-water separation effect, poor anti-pollution ability, fast flux attenuation, etc., and achieve anti-oil pollution Improved capacity, strong oil-water separation capacity, and high water flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

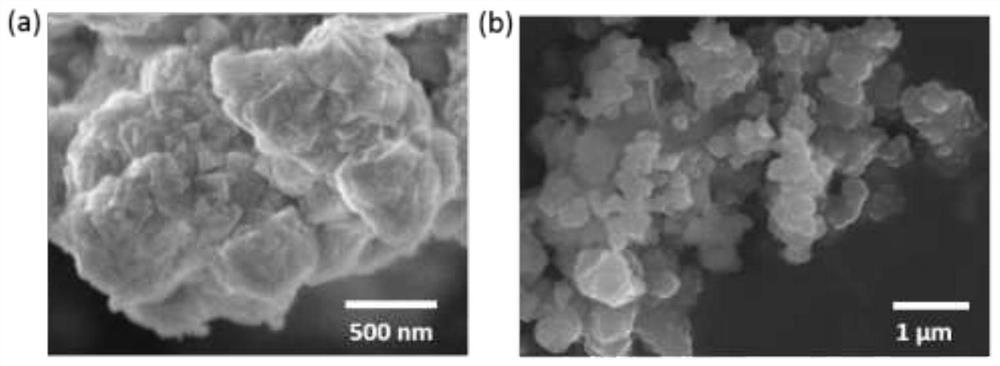

Image

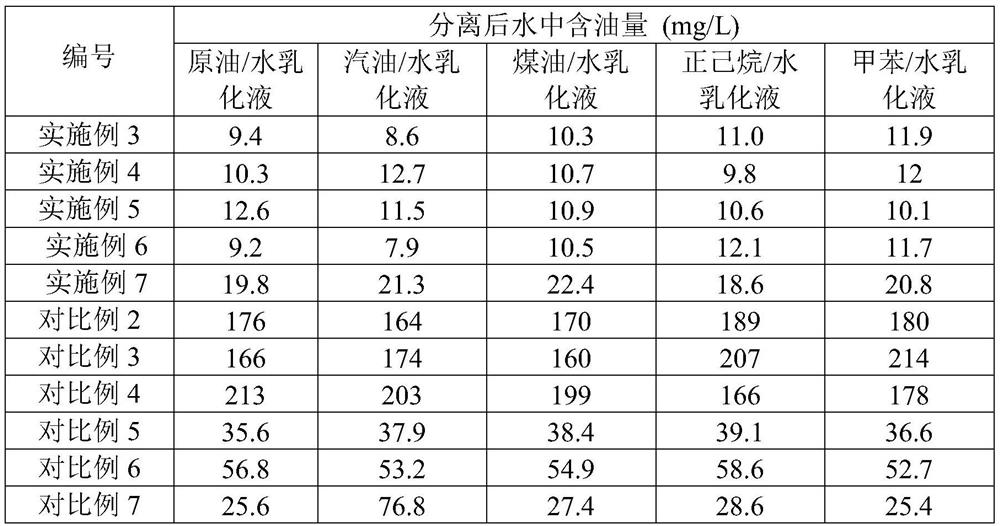

Examples

Embodiment 1

[0054] Preparation of metal-organic framework materials:

[0055] (1) Take 3.00g of zirconium tetrachloride powder, 3.12g of nitroterephthalic acid powder, and 0.20g of deionized water, put them into a single-necked flask filled with 360g of N,N dimethylformamide after mixing, and ultrasonically treat for 12min , to fully dissolve it.

[0056] (2) Transfer the solution in the flask to a polytetrafluoroethylene-lined stainless steel reactor, place the temperature in a convection heating furnace to 110° C., and react for 36 hours; after the reaction is completed, wait for the reactor to cool down and collect the reaction product. The reaction product was transferred to a centrifuge tube, and centrifuged at 14000 rpm for 18 min to separate solid particles. Under the condition of normal temperature, the solid particles obtained by the reaction were washed with ethanol solution for 8 hours, and then the solid particles after washing were obtained by centrifugation using the above ...

Embodiment 2

[0059] Preparation of metal-organic framework materials:

[0060] (1) Get 30g zirconium tetrachloride powder, 31.2g nitroterephthalic acid powder, 1.5g deionized water, drop into after mixing and fill 30Kg N, in the single-necked flask of N dimethylformamide, ultrasonic treatment 35min, Let it fully dissolve.

[0061] (2) Transfer the solution in the flask to a polytetrafluoroethylene-lined stainless steel reaction kettle, place the temperature in a convection heating furnace to 110° C., and react for 45 hours; after the reaction is completed, wait for the reaction kettle to cool down, and collect the reaction product. The reaction product was transferred to a centrifuge tube, and centrifuged at 14800 rpm for 32 minutes to separate solid particles. Under the condition of normal temperature, the solid particles obtained by the reaction were washed with ethanol solution for 38 hours, and then the solid particles after washing were obtained by centrifugation using the above sepa...

Embodiment 3

[0064] (1) Dissolve 9 parts by mass of dried polyethersulfone and 3 parts by mass of polymerized monomer 2-methacryloyloxyethylphosphorylcholine (MPC) in 58 parts by mass of N,N-dimethyl 0.06 parts by mass of azobisisobutyronitrile was added to the mixed solution of formamide and 29.4 parts by mass of ethanol, and reacted at 60° C. for 24 hours under the protection of helium gas.

[0065] (2) After the reaction, 1.0 parts by mass of the metal-organic framework material prepared in Example 2 was added, stirred and dissolved at 40° C., vacuumized and degassed to form a casting solution.

[0066] (3) Fix the pretreated base film on the film scraping machine, and make the film according to the following parameters, the base film speed: 1.2m / s, the thickness between the scraper and the base film is 250 μm, cast the film After the liquid is scraped onto the surface of the base membrane, the base membrane containing the casting solution is immersed in water, and after washing with wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com