PVA/ABS corrosion-resistant, high-toughness permanent antistatic composite material and preparation method thereof

A composite material and corrosion-resistant technology, applied in the field of polymers, can solve the problems of poor stability of antistatic agent modified ABS, restrict the development of antistatic ABS, and it is difficult to achieve permanent antistatic, so as to improve the plasticizing effect and improve the permanent Antistatic effect, excellent antistatic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A kind of polyvinyl alcohol (PVA) / acrylonitrile-butadiene-styrene copolymer resin (ABS resin) corrosion-resistant, high-toughness permanent antistatic composite material in the present embodiment is to be made up of following raw material by weight:

[0037]

[0038]

[0039] Concrete preparation method comprises the following steps:

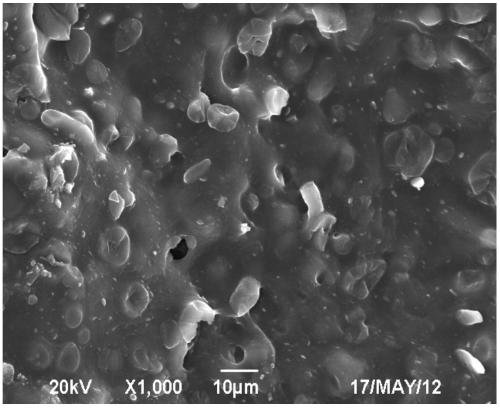

[0040] (1) Add polyvinyl alcohol 1788, 0588, ABS-DG-417, nano talc powder, KT-2, JH-005, TSA-2F, 1076, 168 into the high-speed mixer in proportion to 80 degrees high-speed mixing 3- After 5 minutes, turn on the high-speed mixer to release air and cool to room temperature.

[0041] (2) Add glycerin, diethylene glycol, and liquid wax to (1) and stir at a high speed of 70 degrees for 2 minutes, then open the high-speed mixer to deflate, then add nano-montmorillonite and stir at a high speed of 70-80 degrees for 5 minutes, The exhaust was cooled to room temperature.

[0042] (3) Extrude and granulate the mixture obtained in (2) in a t...

Embodiment 2

[0044] A kind of polyvinyl alcohol (PVA) / acrylonitrile-butadiene-styrene copolymer resin (ABS resin) corrosion-resistant, high-toughness permanent antistatic composite material in the present embodiment is to be made up of following raw material by weight:

[0045]

[0046]

[0047] Concrete preparation method comprises the following steps:

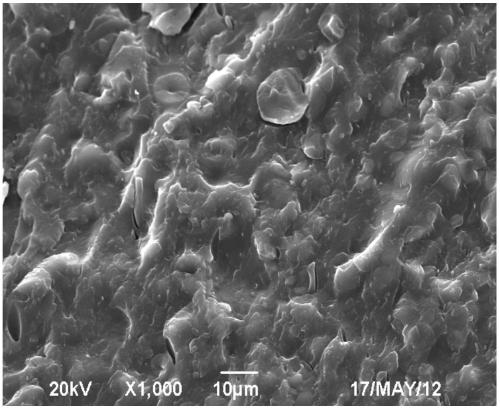

[0048] (1) Add polyvinyl alcohol 1788, 0588, ABS121H, nano talcum powder, KT-2, JH-005, EBS, 1076, 168 into the high-speed mixer in proportion to 80 degrees high-speed mixing for 3-5 minutes, turn on the high-speed mixing Vent the machine to cool to room temperature.

[0049] (2) Add glycerin, diethylene glycol, and liquid wax. Add simethicone oil to (1) and stir at 70°C for 2 minutes at high speed, then turn on the high-speed mixer to deflate, then add nano-montmorillonite and stir at 70-80°C for 5 minutes, exhaust and cool to room temperature.

[0050] (3) Extrude and granulate the mixture obtained in (2) in a twin-screw extruder,...

Embodiment 3

[0052] A kind of polyvinyl alcohol (PVA) / acrylonitrile-butadiene-styrene copolymer resin (ABS resin) corrosion-resistant, high-toughness permanent antistatic composite material in the present embodiment is to be made up of following raw material by weight:

[0053]

[0054]

[0055] Concrete preparation method comprises the following steps:

[0056] (1) Add polyvinyl alcohol 1788, 0588, 1988, ABS121H, nano talcum powder, KT-2, JH-005, EBS, 1076, 168 into the high-speed mixer according to the proportion and mix at 80 degrees for 3-5 minutes at high speed, open The high-speed mixer was vented and cooled to room temperature.

[0057] (2) Add glycerin, diethylene glycol, polyethylene glycol, liquid wax, and simethicone to (1) and stir at a high speed of 70 degrees for 2 minutes, then turn on the high-speed mixer to deflate, and then add nano-montmorillonite Stir at a high speed of 70-80 degrees for 5 minutes, exhaust and cool to room temperature.

[0058] (3) Extrude and g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com