Processing method of anti-oil shirt fabric

A processing method and anti-oil stain technology, applied in the field of textile fabrics, can solve the problems of reducing the stain resistance of gray cloth fiber surface, inconvenient gray cloth easy decontamination finishing process, and inconvenient removal of pollutants, so as to improve oil stain resistance and wash resistance Performance, design and reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

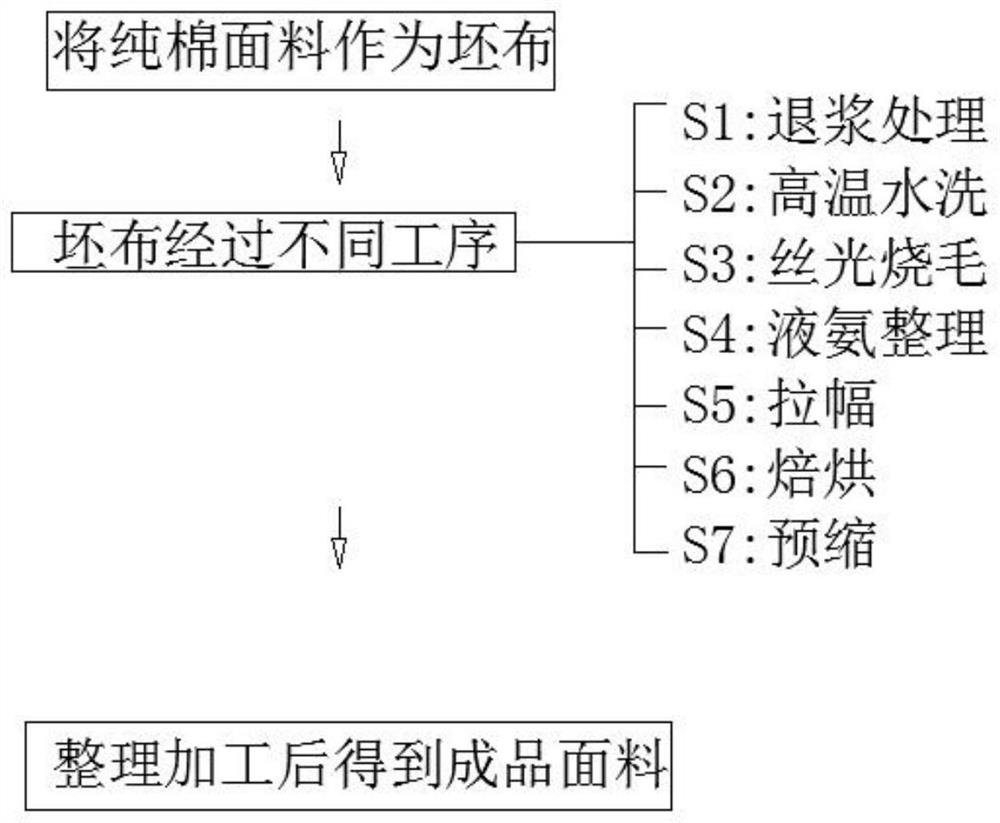

[0040] The pure cotton fabric is used as the grey fabric, and the grey fabric is processed through different processes to obtain the finished fabric;

[0041]It should be noted here that, because the hydrophilic segment in the fluorine-containing easy-to-clean finishing agent cooperates with the hydrophilic group on the pure cotton fabric, it is sufficient to minimize the interfacial energy of the fabric in the aqueous solution, so pure cotton The dirt on the fabric is easily separated from the fabric, so pure cotton fabric is selected as the grey fabric of the shirt fabric, which is convenient for users to clean the shirt.

[0042] The specific processes of different processes include:

[0043] S1: Desizing treatment: Desizing the grey fabric through a desizing process to obtain a grey fabric 1. The desizing process is enzyme desizing, alkali desizing, oxidizing desizing and acid desizing.

[0044] S2: high temperature washing: after desizing, grey fabric 1 must be washed wi...

Embodiment 3

[0055] The pure cotton fabric is used as the grey fabric, and the grey fabric is processed through different processes to obtain the finished fabric;

[0056] It should be noted here that, because the hydrophilic segment in the fluorine-containing easy-to-clean finishing agent cooperates with the hydrophilic group on the pure cotton fabric, it is sufficient to minimize the interfacial energy of the fabric in the aqueous solution, so pure cotton The dirt on the fabric is easily separated from the fabric, so pure cotton fabric is selected as the grey fabric of the shirt fabric, which is convenient for users to clean the shirt.

[0057] The specific processes of different processes include:

[0058] S1: Desizing treatment: Desizing the grey fabric through a desizing process to obtain a grey fabric 1. The desizing process is enzyme desizing, alkali desizing, oxidizing desizing and acid desizing.

[0059] S2: High-temperature washing: After desizing, the first grey fabric must be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com