Anti-oil stain tablecloth

An anti-oil stain and tablecloth technology, applied in the direction of biocide-containing paint, anti-fouling/underwater paint, film/flake adhesive, etc. The effect of cleaning and improving oil resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

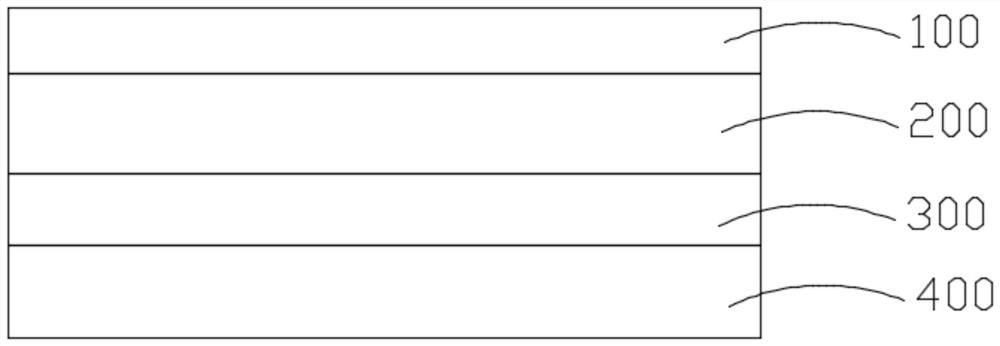

[0020] Such as Figure 1-2 As shown, in a preferred embodiment provided by the present invention, an oil stain-resistant tablecloth includes an anti-stain coating 100, a transparent film layer 200, a pressure-sensitive adhesive layer 300 and a PET release film layer 400, wherein the anti-oil Dirty coating 100 is coated on the surface of transparent film layer, and described antifouling coating 100 comprises polyurethane and the nano-titanium dioxide that is doped with zinc, fluorine, nitrogen, boron; Described transparent film layer 200 comprises following composition by weight Raw materials: 60 parts of polyester polyol, 25 parts of diisocyanate, 10 parts of polyurethane acrylate, 10 parts of nano silicon dioxide, 5 parts of cellulose acetate butyrate, 2 parts of curing agent, 1 part of catalyst, 1 part of antioxidant, 1 part of chain extender and 1 part of stabilizer.

[0021] Further, in the preferred embodiment provided by the present invention, the transparent film layer...

Embodiment 2

[0025] Such as Figure 1-2 As shown, in a preferred embodiment provided by the present invention, an oil stain-resistant tablecloth includes an anti-stain coating 100, a transparent film layer 200, a pressure-sensitive adhesive layer 300 and a PET release film layer 400, wherein the anti-oil The dirty coating 100 is coated on the surface of the transparent film layer, and the anti-fouling coating 100 includes polyurethane and nano-titanium dioxide doped with zinc, fluorine, nitrogen and boron;

[0026] Further, in the preferred embodiment provided by the present invention, the transparent film layer 200 includes the following raw materials in parts by weight: 65 parts of polyester polyol, 28 parts of diisocyanate, 13 parts of polyurethane acrylate, nano-dioxide 13 parts of silicon, 7 parts of cellulose acetate butyrate, 3 parts of curing agent, 2 parts of catalyst, 2 parts of antioxidant, 2 parts of chain extender and 2 parts of stabilizer.

[0027] Further, in the preferred ...

Embodiment 3

[0034] Such as Figure 1-2 As shown, in a preferred embodiment provided by the present invention, an oil stain-resistant tablecloth includes an anti-stain coating 100, a transparent film layer 200, a pressure-sensitive adhesive layer 300 and a PET release film layer 400, wherein the anti-oil The dirty coating 100 is coated on the surface of the transparent film layer, and the anti-fouling coating 100 includes polyurethane and nano-titanium dioxide doped with zinc, fluorine, nitrogen and boron;

[0035] Further, in the preferred embodiment provided by the present invention, the transparent film layer 200 includes the following raw materials in parts by weight: 70 parts of polyester polyol, 30 parts of diisocyanate, 15 parts of polyurethane acrylate, nanometer dioxide 15 parts of silicon, 8 parts of cellulose acetate butyrate, 4 parts of curing agent, 3 parts of catalyst, 3 parts of antioxidant, 3 parts of chain extender and 3 parts of stabilizer.

[0036] Further, in the prefe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com