Ash removal device capable of relieving high-temperature corrosion

A soot cleaning device and high-temperature corrosion technology, which is applied to the removal of solid residue, treatment of combustion products, combustion methods, etc., can solve the problems of high-temperature corrosion at the superheater, cannot be lowered, and the effect is not obvious, so as to reduce ash accumulation and corrosion, avoiding heating surfaces, prolonging the effect of running time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

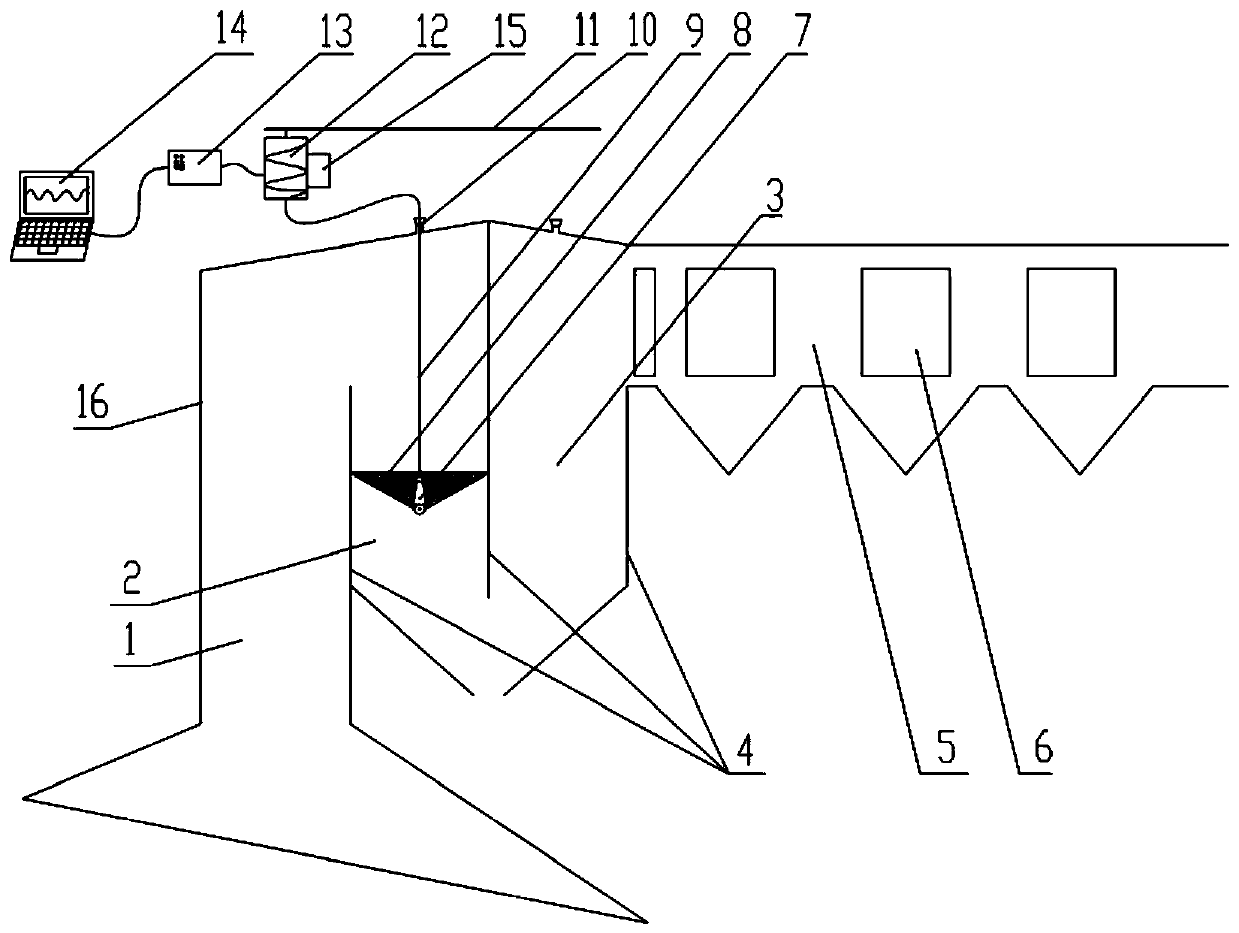

[0015] according to figure 1 As shown, the present invention has a horizontal flue 5, a horizontal flue superheater 6, a rotary nozzle 7, a water supply hose 9, a guide pipe 10, a navigation suspension 11, a hose driving device 12, an electric control box 13, and a PLC remote control On the basis of the system 14, the booster pump 15 and the furnace 16, it is characterized in that: the first flue 1, the second flue 2, and the third flue 3 are installed vertically in series in the furnace 16. the flue, the horizontal flue 5 communicates with the third flue 3 tail port, the horizontal flue superheater 6 is installed in the horizontal flue 5, and the tops of the second flue 2 and the third flue 3 are respectively provided with The guide pipe 10 is provided with a navigation suspension 11 above the furnace 16, and a hose driving device 12 and a booster pump 15 are installed on the mobile platform of the navigation suspension 11. One end of the water supply hose 9 on the hose drivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com