Multifunctional composite treating agent for polymer flooding and successive water flooding oil reservoir

A composite treatment and water flooding technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of high on-site construction costs, low reuse rate and water injection recovery rate, residual polymer flocs and adjustment There are no problems such as the interaction of splitting agents, and the effects of convenient on-site construction, improved recovery rate and reduced labor intensity of workers are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

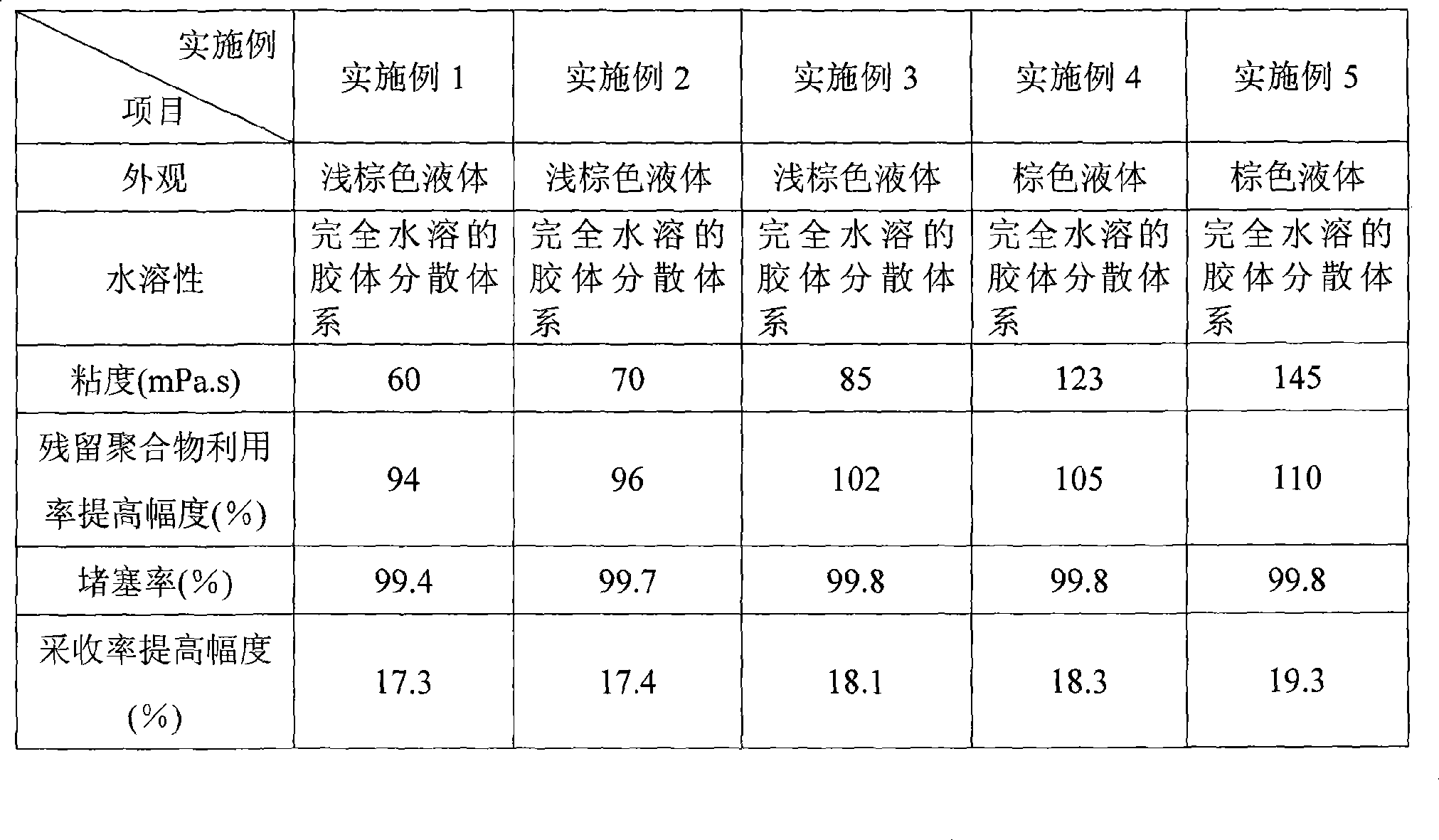

Embodiment 1

[0021] Weigh an appropriate amount of phenol according to phenol: formaldehyde = 1: 1.5 (molar ratio), pour it into a three-necked flask, heat it to 45 ° C, and make it melt into a liquid; weigh the catalyst hydrogen according to the ratio of 2.5% of the total mass of phenol and formaldehyde Add sodium oxide into the three-necked flask that has melted phenol, the solution is pink, and a few particles appear; keep the temperature of the three-necked flask at 45°C, stir for 20 minutes, pour 70% of the weighed formaldehyde into the three-necked flask, the solution is brown Red, raise the temperature of the three-necked flask to 50°C, continue to stir and react for 60 minutes, and the color will gradually become darker; weigh the catalyst sodium hydroxide according to the ratio of 1% of the total mass of phenol and formaldehyde, add it to the three-necked flask, and raise the temperature of the three-necked flask to 60°C, keep stirring at a constant temperature for 20 minutes; fina...

Embodiment 2

[0023] Weigh an appropriate amount of phenol according to phenol: formaldehyde = 1: 2 (molar ratio), pour it into a three-necked flask, heat it to 48 ° C, and make it melt into a liquid; weigh the catalyst hydrogen according to the ratio of 3% of the total mass of phenol and formaldehyde pure substances Add sodium oxide into the three-necked flask that has melted phenol, the solution is pink, and a few particles appear; keep the temperature of the three-necked flask at 48°C, stir for 23 minutes, pour 75% of the weighed formaldehyde into the three-necked flask, the solution is brown Red, raise the temperature of the three-necked flask to 55°C, continue to stir the reaction for 65min, the color will gradually become darker; weigh the catalyst sodium hydroxide according to the ratio of 1% of the total mass of phenol and formaldehyde, add it to the three-necked flask, raise the temperature of the three-necked flask to 65°C, keep stirring at a constant temperature for 25 minutes; fi...

Embodiment 3

[0025] Weigh an appropriate amount of phenol according to phenol: formaldehyde = 1: 3.5 (molar ratio), pour it into a three-necked flask, heat it to 50 ° C, and make it melt into a liquid; weigh the catalyst hydrogen according to the ratio of 3.5% of the total mass of pure phenol and formaldehyde Add sodium oxide into the three-necked flask that has melted phenol, the solution is pink, and a few particles appear; keep the temperature of the three-necked flask at 50°C, stir for 25 minutes, pour 80% of the weighed formaldehyde into the three-necked flask, the solution is brown Red, raise the temperature of the three-necked flask to 60°C, continue to stir and react for 70min, and the color will gradually become darker; weigh the catalyst sodium hydroxide according to the ratio of 0.5% of the total mass of phenol and formaldehyde, add it to the three-necked flask, and raise the temperature of the three-necked flask to 70°C, keep stirring at a constant temperature for 30 minutes; fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com