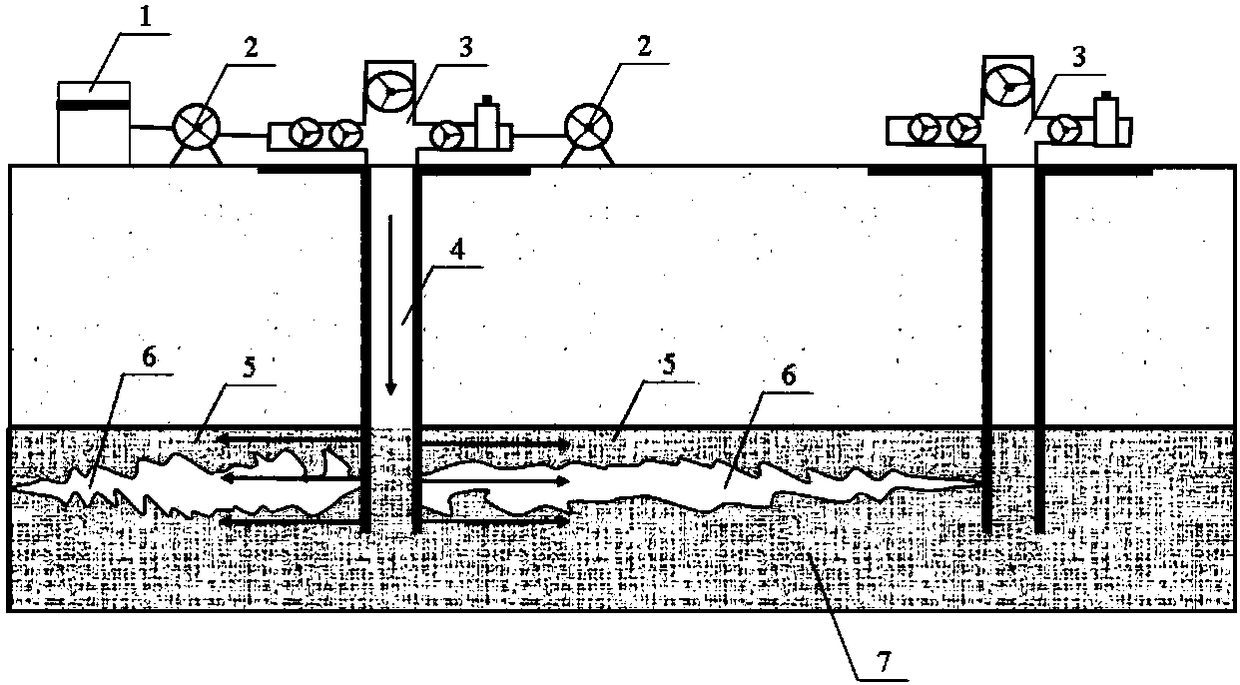

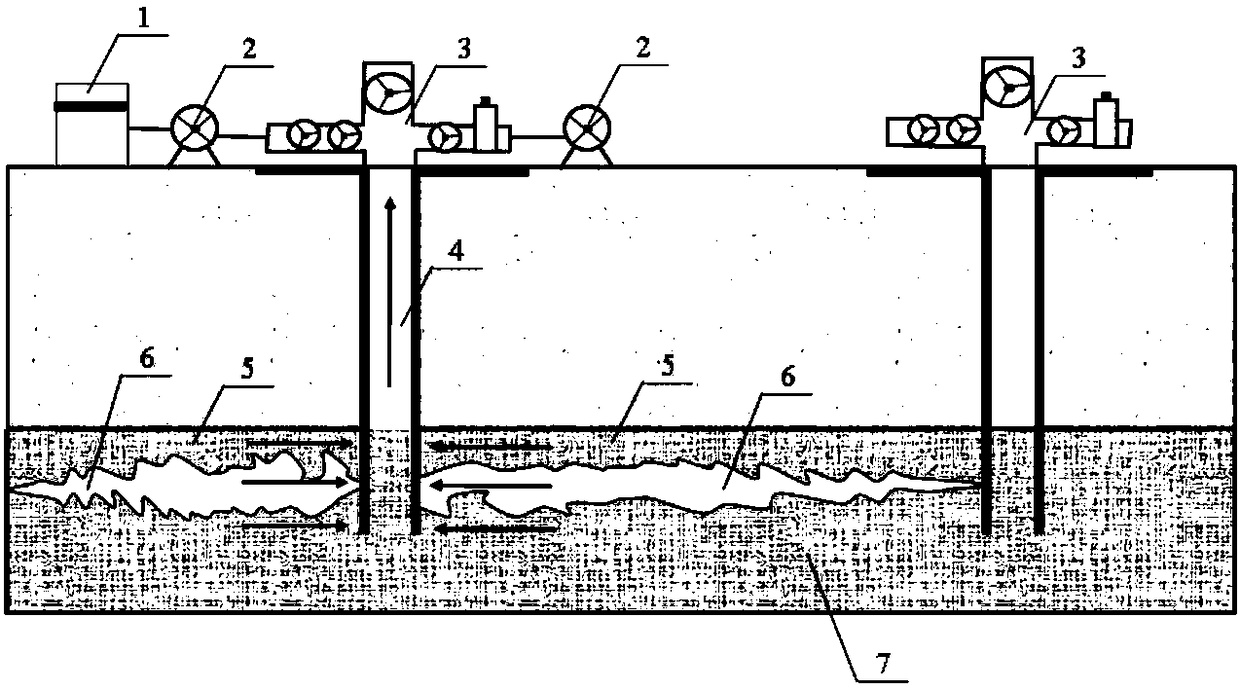

Method and system for improving recovery yield of water channeling layer

A recovery factor and water channeling technology, applied in chemical instruments and methods, production fluids, earthwork drilling, etc., can solve problems such as effective plugging of unfavorable water channeling layers, inability to exert plugging control and flooding, and insufficient effect. To achieve the effect of small flow resistance, large flow resistance and lower fluidity ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Put the tight oil core in the core holder, inject saturated water first, and then inject saturated oil to obtain a simulated water channeling reservoir; the temperature of the simulated water channeling reservoir is 85°C, and the experimental pressure is 60MPa.

[0034] At a temperature of 60°C and an absolute pressure of 10 MPa, the supercritical CO 2 , polyoxyethylene lauryl polyoxypropylene ether (C 12 E. 9 P 3 ) and co-solvent pentanol in a mass ratio of 100:1:3 were mixed evenly to obtain supercritical CO 2 Mix fluids.

[0035] Inject the above-mentioned supercritical CO into the above-mentioned simulated water channeling reservoir 2 Mixed fluid, supercritical CO 2The injection volume of the mixed fluid is 0.3PV, the well is shut down, and the well is soaked for 24h at a temperature of 85°C and an absolute pressure of 60MPa, and then the well is opened for production.

[0036] After testing, the recovery rate of the simulated water channeling reservoir is 29....

Embodiment 2

[0038] Put the tight oil core in the core holder, inject saturated water first, and then inject saturated oil to obtain a simulated water channeling reservoir; the temperature of the simulated water channeling reservoir is 90°C, and the experimental pressure is 50MPa.

[0039] At a temperature of 60°C and an absolute pressure of 10 MPa, the supercritical CO 2 , two (2-ethylhexyl) sodium sulfosuccinate and co-solvent ethanol are mixed uniformly in a mass ratio of 100:1.5:4 to prepare supercritical CO 2 Mix fluids.

[0040] Inject the above-mentioned supercritical CO into the above-mentioned simulated water channeling reservoir 2 Mixed fluid, supercritical CO 2 The injection volume of the mixed fluid is 0.25PV, the well is shut down, and the well is soaked for 24 hours under the conditions of a temperature of 90°C and an absolute pressure of 50MPa, and then the well is opened for production.

[0041] After testing, the recovery rate of the simulated water channeling reservoir...

Embodiment 3

[0043] Put the tight oil core in the core holder, inject saturated water first, and then inject saturated oil to obtain a simulated water channeling reservoir; the temperature of the simulated water channeling reservoir is 80°C, and the experimental pressure is 60MPa.

[0044] At a temperature of 60°C and an absolute pressure of 10 MPa, the supercritical CO 2 , polyoxyethylene lauryl polyoxypropylene ether (C 12 E. 9 P 3 ) and co-solvent amyl alcohol are mixed evenly in a mass ratio of 100:0.8:2.5 to prepare supercritical CO 2 Mix fluids.

[0045] Inject the above-mentioned supercritical CO into the above-mentioned simulated water channeling reservoir 2 Mixed fluid, supercritical CO 2 The injection volume of the mixed fluid is 0.2PV, the well is shut down, and the well is soaked for 24h under the conditions of a temperature of 80°C and an absolute pressure of 60MPa, and then the well is opened for production.

[0046] After testing, the recovery rate of the simulated wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com