A heavy oil recovery method using electric heating to enhance water flooding efficiency

A mining method and electric heating technology, which are applied in the fields of production fluids, earthwork drilling, wellbore/well components, etc., can solve the problems of low fingering sweep coefficient, low initial output, slow production effect, etc., and achieve simple installation and operation. , the effect of reducing the fluidity ratio and improving the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

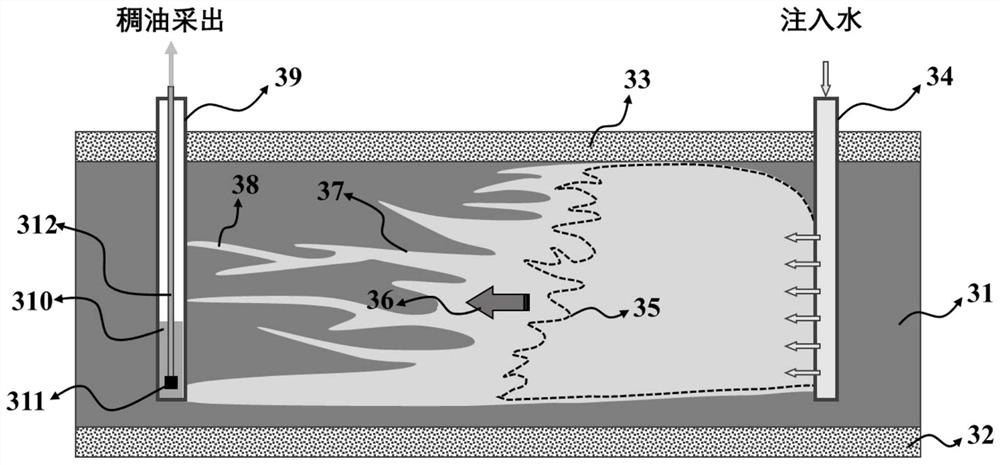

[0037] Embodiment 1: as Figure 5 As shown, the present invention is applied in heavy oil production, and it is carried out as follows: put the electric heating device 51 into the oil casing annular space of the vertical production well 39 according to the installation process of the electric heating device mentioned above, and pass the electric heating device power line 52 It is connected with power supply equipment; the heat 53 generated by the electric heating device spreads around the vertical production well 39, so that the formation temperature within 3 meters nearby rises to above 100°C. According to the unsteady-state heat transfer process of the fixed-point heat source, the time t required to raise the temperature from the position L of the heat source to the temperature T can be calculated as follows:

[0038]

[0039] in is the pre-measured average thermal diffusivity of oil layers to characterize the thermal diffusivity of oil layers with different porosity an...

Embodiment 2

[0044] Embodiment 2: The present invention can also be applied to heavy oil recovery in the combination of vertical injection well-horizontal production well group, as shown in Figure 7. The process of this embodiment is similar to that of embodiment 1, and the technical effect obtained is the same as that obtained in embodiment 1. It can also increase the initial water flooding heavy oil production and reduce the viscous fingering phenomenon in the later stage of displacement.

[0045] To sum up, the heavy oil recovery method of electric heating enhanced water drive efficiency in the present invention combines the mechanisms and advantages of thermal recovery and cold fluid displacement. By applying electric heating in a specific range near the production well, the effective period of the water flooding heavy oil production process is shortened and the production efficiency is improved; the thermal diffusion of electric heating makes the displacement front near the production ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com