Initiation system of electron transfer activated regenerated catalyst and gelation time control method

A regeneration catalyst and electron transfer technology, which is applied in chemical instruments and methods, chemical recovery, drilling compositions, etc., can solve problems such as slow initiation, difficult control of gelation time, uncontrollable gelation time, etc., to reduce freedom Base concentration, polymerization reaction controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

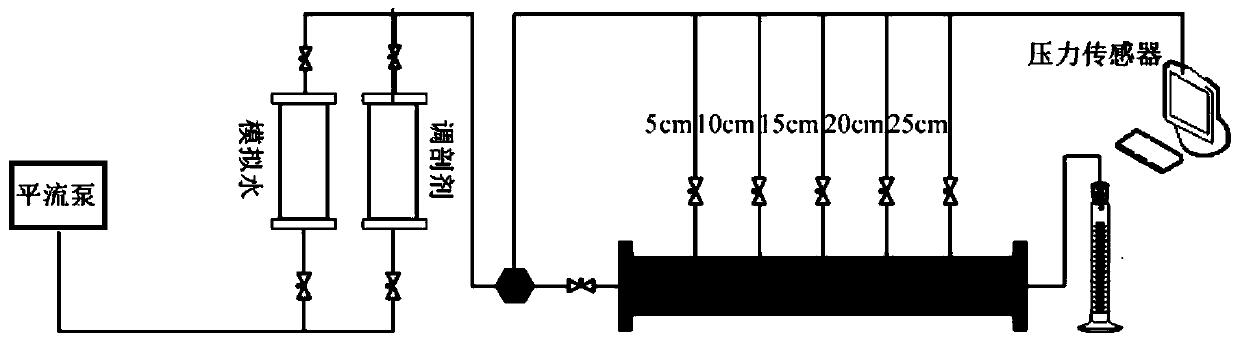

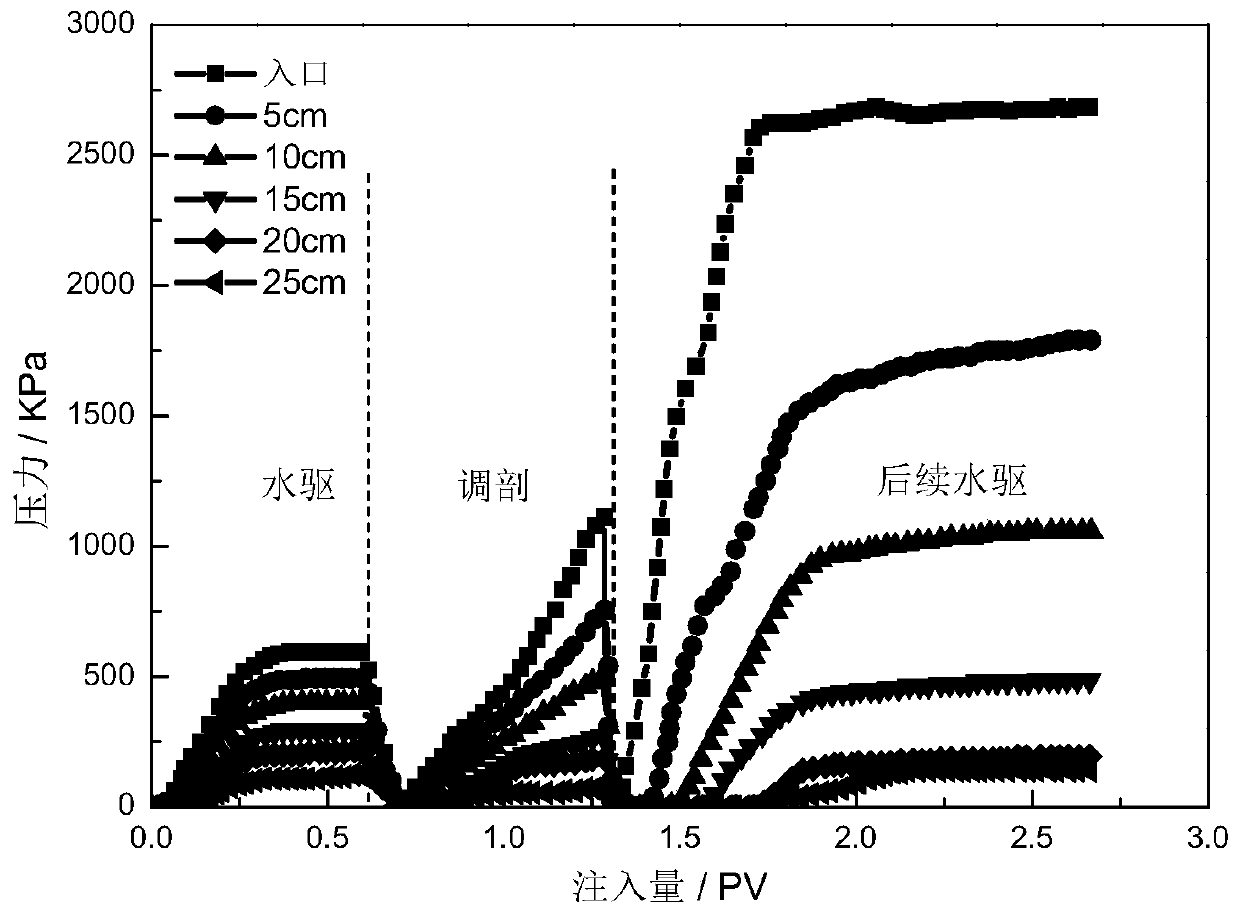

Method used

Image

Examples

Embodiment 1

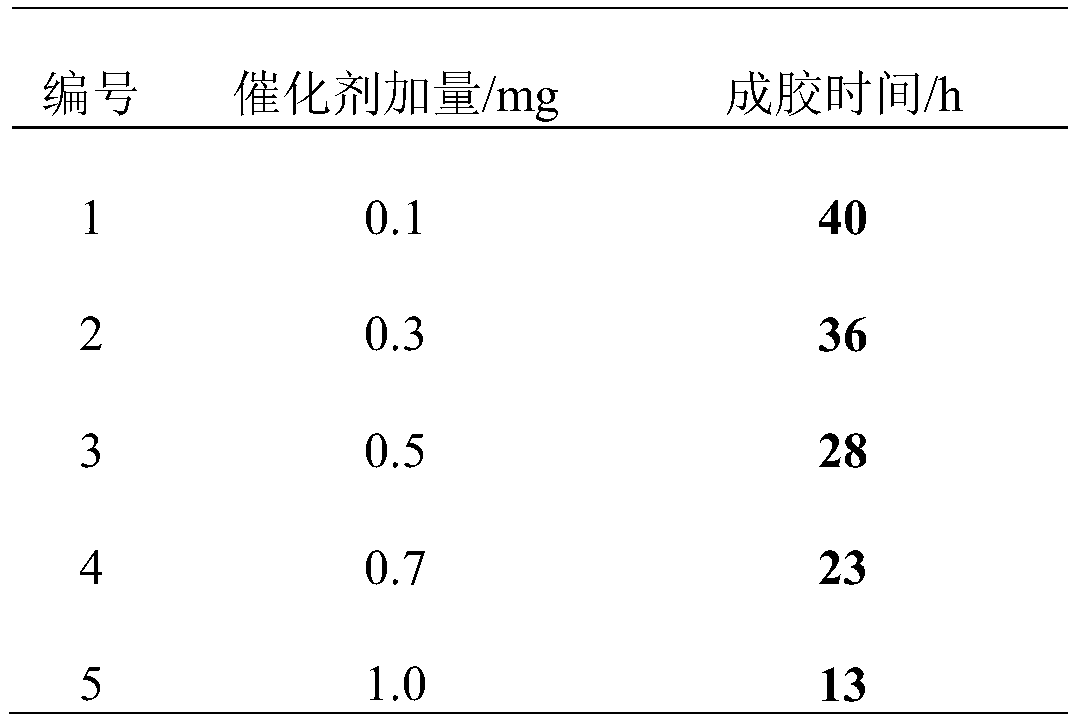

[0027] Evaluation of Gelling Time in Polymerization System at 60℃

[0028] Put 5g of acrylamide monomer and 0.05g of cross-linking agent in a 250mL beaker, dissolve them in 95mL of distilled water, add the ARGET initiation system, stir until completely dissolved, and then put them in a constant temperature water bath at 60°C for reaction Several hours until gel formation occurs. Among them, the initiator is sodium chloroacetate, the dosage is 0.02g; the ligand is vitamin C, the dosage is 0.009g; the catalyst is ferric chloride, the dosage is 0.1mg~1mg, and the gelling time is between 13h~40h. The corresponding time is shown in Table 1:

[0029] Table 1 Gelling time at 60℃ with different catalyst additions

[0030]

Embodiment 2

[0032] Evaluation of Gelling Time in Polymerization System at 70℃

[0033] Put 5g of acrylamide monomer and 0.05g of cross-linking agent in a 250mL beaker, and dissolve them in 95mL of distilled water, add ARGET trigger system, stir until completely dissolved, then put it in a 70°C constant temperature water bath for reaction Several hours until gel formation occurs. Among them, the initiator is sodium chloroacetate, the dosage is 0.02g; the ligand is vitamin C, the dosage is 0.009g; the catalyst is ferric chloride, the dosage is 0.1mg~0.5mg, and the gelling time is between 12~30h. The specific corresponding time is shown in Table 2:

[0034] Table 2 Gelling time at 70°C with different catalyst additions

[0035]

Embodiment 3

[0037] Evaluation of Gelling Time in Polymerization System at 80℃

[0038] Put 5g of acrylamide monomer and 0.05g of cross-linking agent in a 250mL beaker, and dissolve them in 95mL of distilled water, add ARGET trigger system, stir until completely dissolved, then put it in a 70°C constant temperature water bath for reaction Several hours until gel formation occurs. The initiator is sodium chloroacetate, the dosage is 0.02g; the ligand is vitamin C, the dosage is 0.009g; the catalyst is ferric chloride, the dosage is 0.5mg~1mg, and the gelling time is between 12~55h. The specific corresponding time is shown in Table 3:

[0039] Table 3 Gelling time at 80°C with different catalyst additions

[0040]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com