Oil-water emulsion separation membrane of metal organic framework compound/polyacrylonitrile

A metal organic framework, polyacrylonitrile technology, applied in the field of oil-water emulsion separation membrane, oil-water separation materials, can solve the problems of high porosity, low density and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

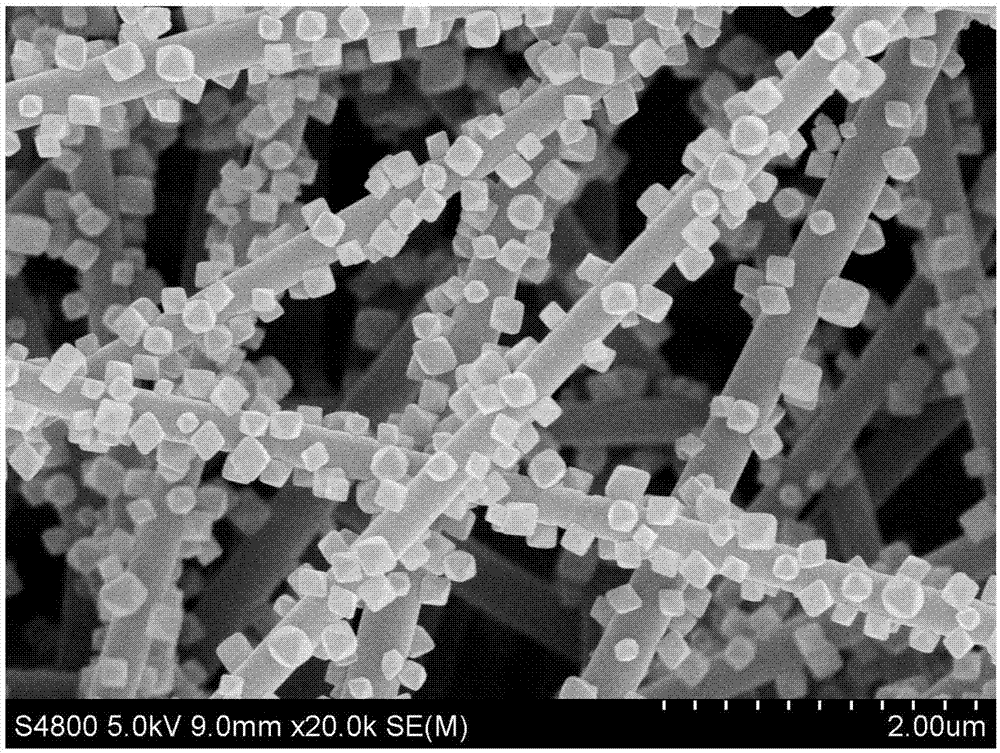

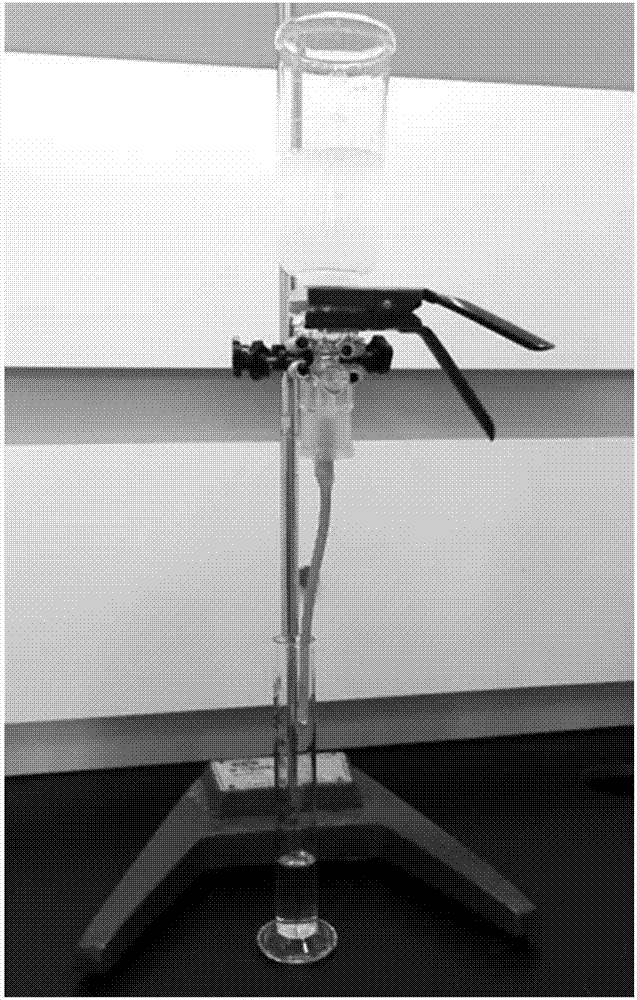

[0019] Example 1, 0.70134 grams of zirconium tetrachloride and 0.5361 grams of 2-aminoterephthalic acid were dissolved in 300 milliliters of dimethylformamide for 10 minutes of ultrasonication and stirred for 1 hour; 17.7355 grams of glacial acetic acid was added, ultrasonicated for 30 minutes, stirred for 1 hour hours; transferred to a reaction kettle, hydrothermal reaction at 120°C for 24 hours; centrifuged three times with dimethylformamide and absolute ethanol respectively, and dried in a drying oven at 60°C for 12 hours. Add 0.52639 grams of polyacrylonitrile to 5 ml of dimethylformamide solution, stir magnetically at room temperature for 12 hours to obtain a uniform precursor solution; inhale the precursor solution into a 5 ml syringe, install a 21-gauge needle, and put the syringe into an electrostatic In the syringe pump of the spinning equipment, adjust the advancing speed of the syringe pump to 1 ml per hour, set the translation distance to 12 cm, and adjust the dista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com