Preparation method of oil-stain-resistant stone-plastic floor

A stone-plastic floor, anti-oil technology, applied in construction, building structure, floor and other directions, can solve the problems of poor anti-oil performance, time-consuming and laborious cleaning, easy to be contaminated with oil, etc., to improve work efficiency and improve wear resistance. and oil stain resistance, and the effect of improving the firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

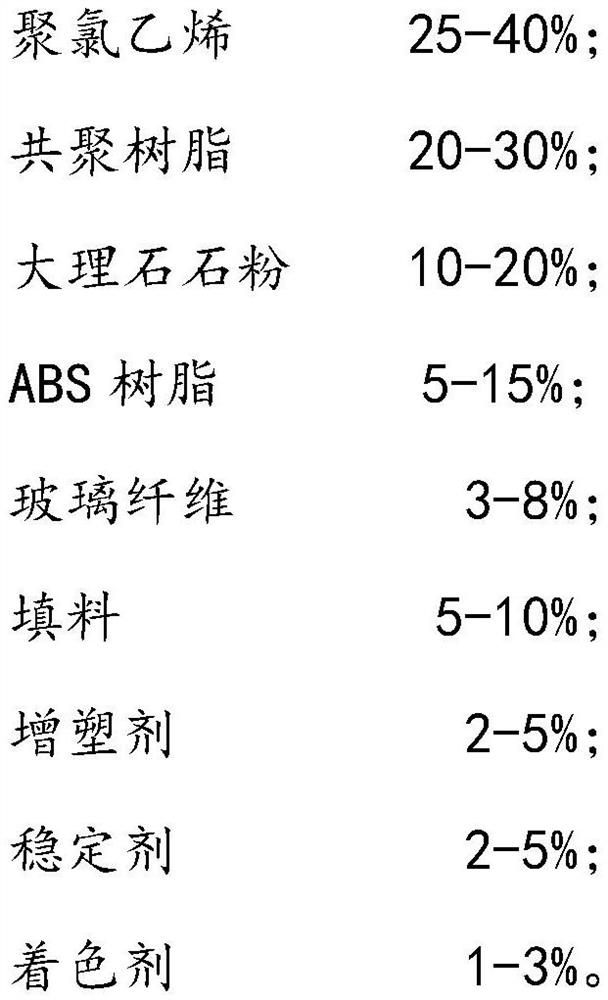

[0030] An embodiment of the present invention provides an oil-resistant stone-plastic floor, which includes the following specific raw materials:

[0031]

[0032] The raw materials are proportioned according to the following proportions: 35% polyvinyl chloride, 20% copolymer resin, 15% marble stone powder, 10% ABS resin, 5% glass fiber, 5% filler, 5% plasticizer, 3% stabilizer and Colorant 2%.

[0033] A preparation method for an oil-resistant stone-plastic floor, comprising the following specific steps:

[0034] S1. Pour 35% polyvinyl chloride, 20% copolymer resin, 15% marble stone powder and 10% ABS resin into the raw material tank, and use a vacuum pump to remove 35% polyvinyl chloride, 20% copolymer resin, 15 % marble stone powder and 10% ABS resin are all pumped into the mixer;

[0035] S2. After the mixing machine has mixed 35% polyvinyl chloride, 20% copolymer resin, 15% marble stone powder and 10% ABS resin, all the mixed raw materials are introduced into the hea...

Embodiment 2

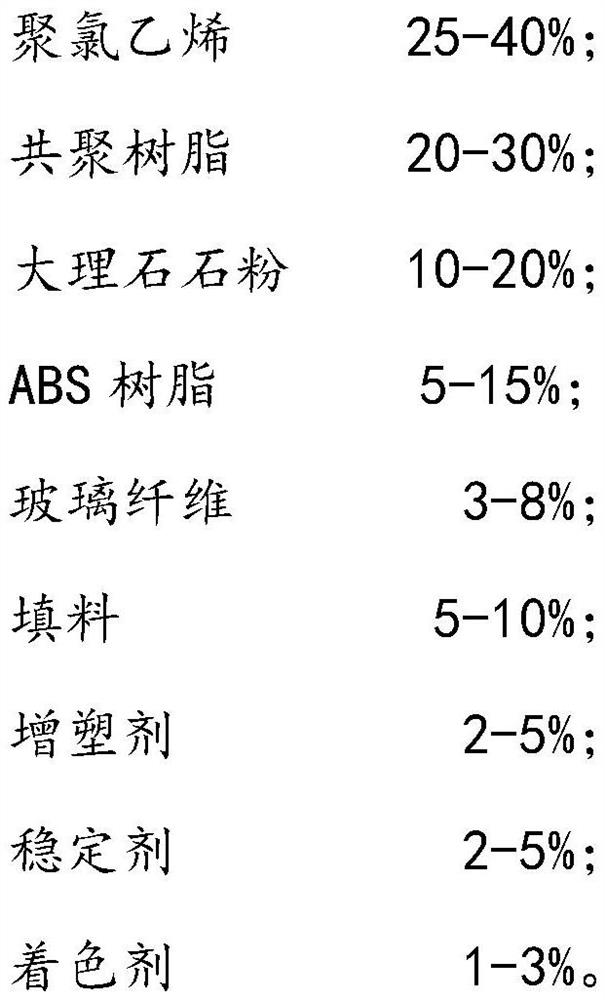

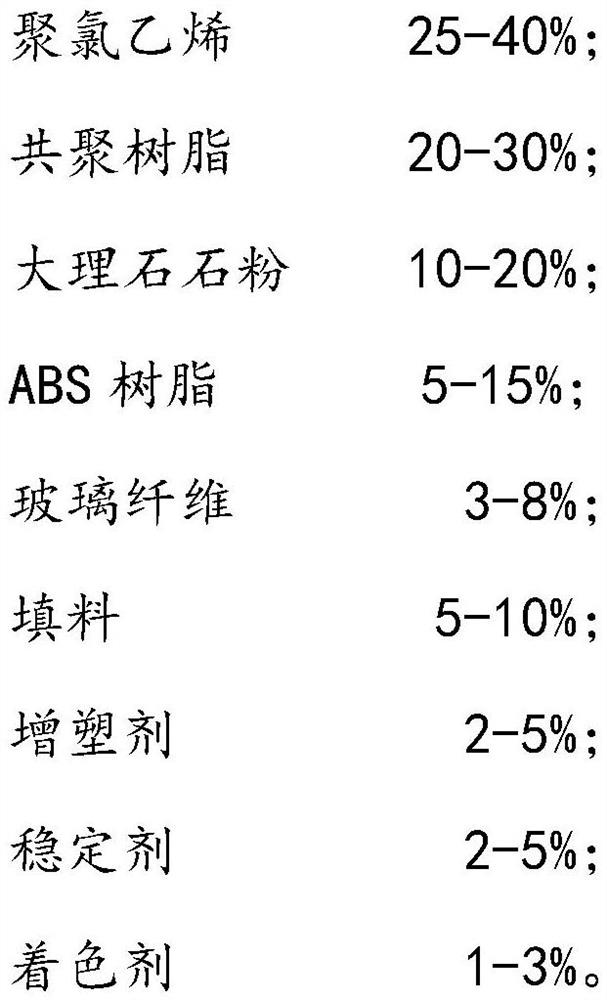

[0048]In this example, on the basis of Example 1, by changing some raw materials and processing technology, the stone-plastic floor produced can also be made to have better wear resistance and oil stain resistance. The specific raw material formula and preparation scheme are as follows:

[0049] Including the following specific raw materials: 25-40% polyvinyl chloride; 20-30% copolymer resin; 10-20% marble stone powder; 5-15% ABS resin; 5-10% filler; 2-5% plasticizer; stabilizer 2-5%; colorant 1-3%; fiberglass mesh and wear-resistant panels.

[0050] The raw materials are mixed according to the following proportions: 40% of polyvinyl chloride, 20% of copolymer resin, 20% of marble stone powder, 5% of ABS resin, 5% of filler, 5% of plasticizer, 4% of stabilizer and 1% of colorant.

[0051] A preparation method for an oil-resistant stone-plastic floor, comprising the following specific steps:

[0052] S1. Pour 40% polyvinyl chloride, 20% copolymer resin, 20% marble stone powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com