Multifunctional ultra-thin surface layer material for road and its application

A multi-functional surface layer technology, applied to roads, roads, pavement details, etc., can solve the problems of difficult manufacturing process control, single-improved asphalt surface layer, and high construction cost, so as to facilitate road drainage and improve oil pollution resistance , outstanding flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

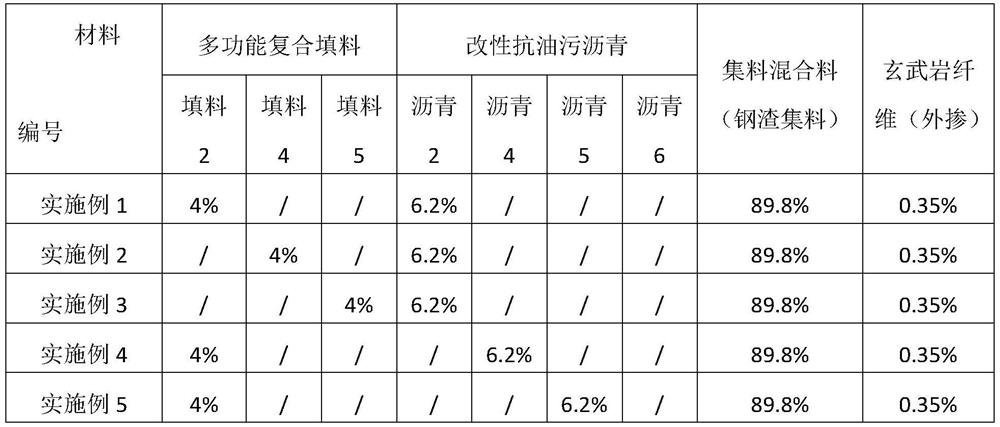

[0039] The present invention will be further described below in conjunction with specific examples, but not as a limitation to the present invention.

[0040] 【Example】

[0041] 1. Preparation of multifunctional composite filler

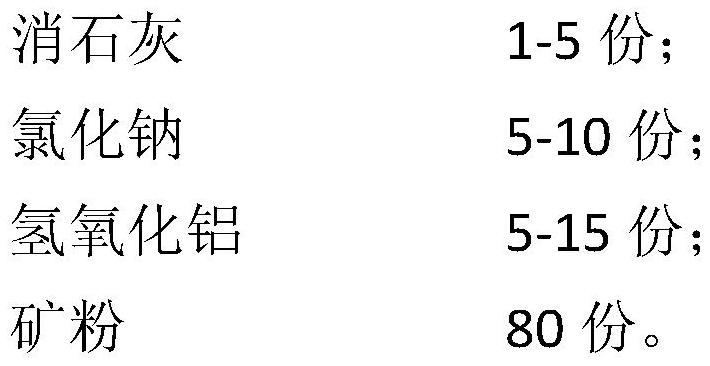

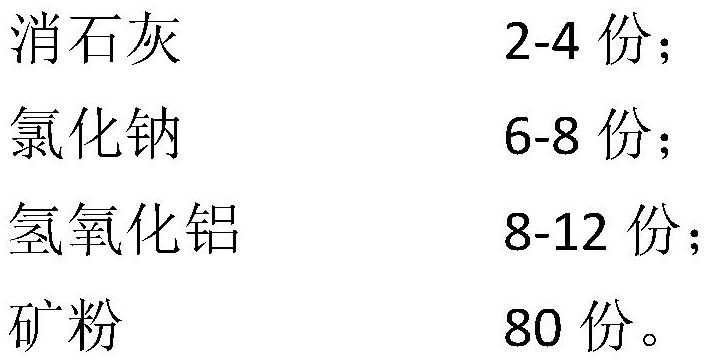

[0042] Table 1: Raw materials of multifunctional composite filler

[0043] filler 1 filler 2 filler 3 filler 4 filler 5 Slaked lime, Kg 2 3 4 3 3 Sodium chloride, Kg 6 7 8 0 7 Aluminum hydroxide, Kg 8 10 12 10 0 Mineral powder, Kg 80 80 80 87 90

[0044] After mixing the slaked lime, sodium chloride, aluminum hydroxide and mineral powder in the formulated quantity, they are ground to below 80 mesh to obtain a multifunctional composite filler, which is ready for use.

[0045] 2. Preparation of modified oil pollution resistant asphalt

[0046] Table 2: Raw materials of modified oil pollution resistant asphalt

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com