A kind of UV curing vacuum coating wrinkle primer and preparation method thereof

A technology of vacuum coating and ultraviolet light, applied in the field of coatings, can solve the problems of low production efficiency and unenvironmental protection of heat-cured wrinkle coatings, achieve good wrinkle decoration effect, improve adhesion and good flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] This embodiment also provides the preparation method of the above UV-cured vacuum coating wrinkle primer, including:

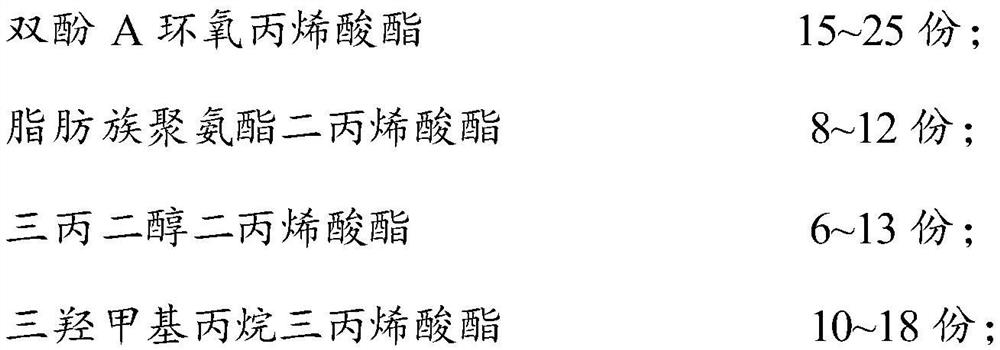

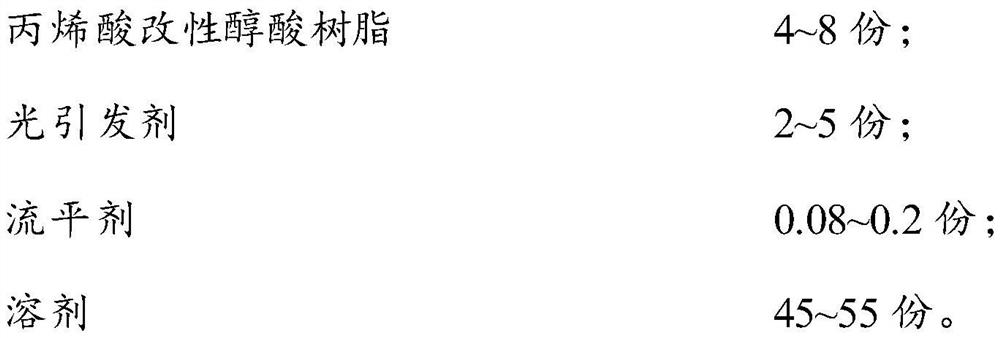

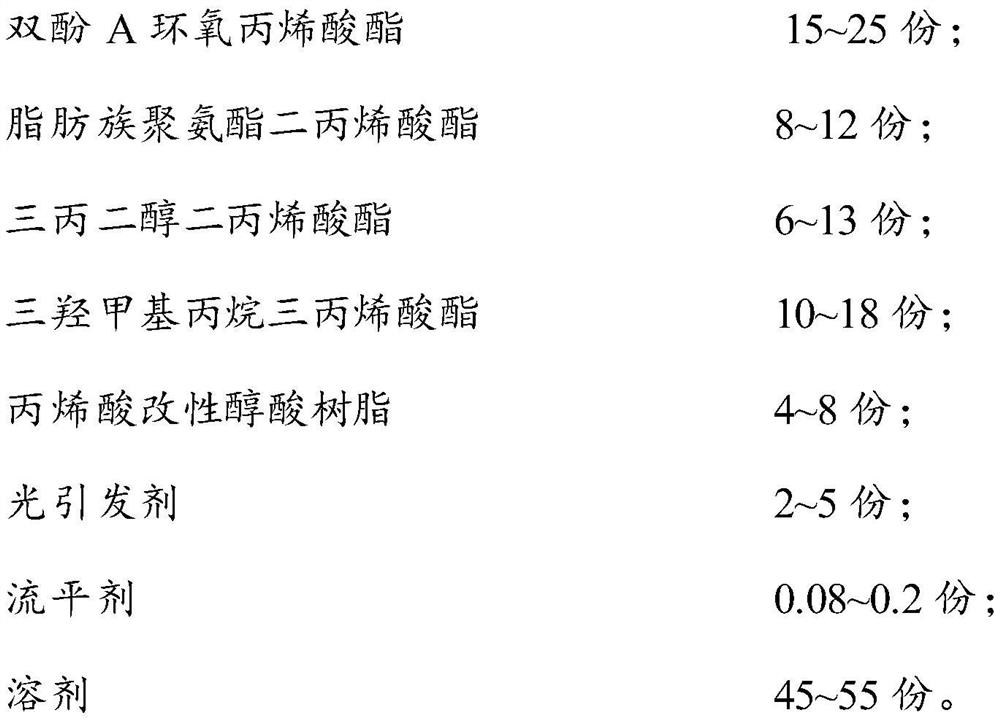

[0028] Add bisphenol A epoxy acrylate, aliphatic polyurethane diacrylate, tripropylene glycol diacrylate, and trimethylolpropane triacrylate into the stirring tank in sequence according to the proportion and stir to dissolve, then add acrylic modified alkyd resin, light The initiator is evenly dispersed, and finally add leveling agent and solvent and stir evenly before filtering.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com