Green dispersion dye composition and application thereof in wool dyeing

A technology of disperse dyes and compositions, applied in the field of wool dyeing, can solve the problems of low price of disperse dyes, high price of reactive dyes, difficult to popularize and use, and achieve excellent solubilization and dyeing effect, bright color and large market application prospect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

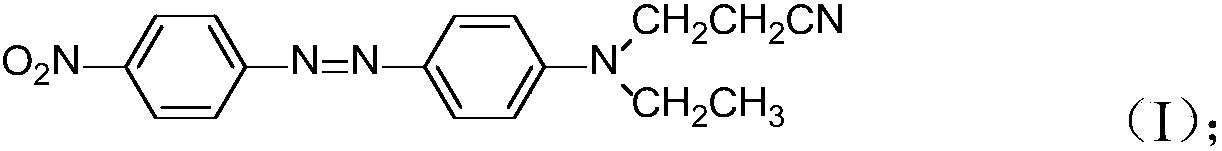

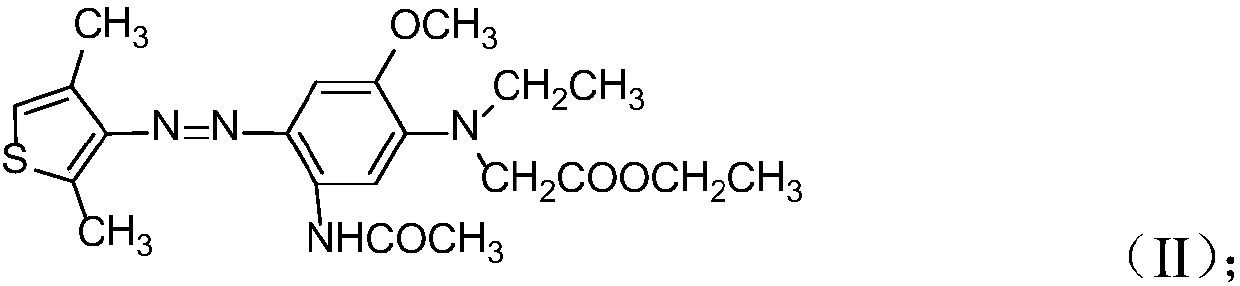

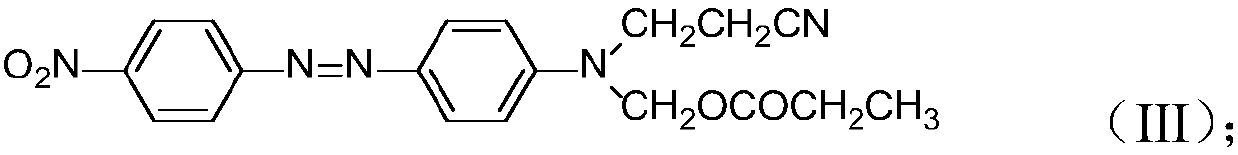

[0057] 36g of component A shown in formula (I), 20g of component B shown in formula (II), 22g of component C shown in formula (III), and 16g of the group shown in formula (IV) Part D, 4g of component E represented by formula (IV) and 180g of additives are blended with water, ground and dispersed with a sand mill, and then spray-dried to obtain a finished dye.

[0058] In terms of mass percentage, in this example, the auxiliary agent is composed of the following components: Pingpingjia O-15 54%, triethylene glycol monobutyl ether 6%, octadecyl betaine 6%, cetyl bromide Base pyridine 4%, polyamide polyamine epichlorohydrin 7%, chitosan 4%, poloxamer 7%, penetrant POWEZOL SUP 12%;

[0059] Among them, the average molecular weight of polyamide polyamine epichlorohydrin is 10000D, the deacetylation degree of chitosan is 80%, and the average molecular weight is 4000D.

Embodiment 2

[0061] 30g of component A shown in formula (I), 29g of component B shown in formula (II), 19g of component C shown in formula (III), and 17g of the group shown in formula (IV) Part D, 5g of component E represented by formula (IV) and 120g of additives are blended with water, ground and dispersed with a sand mill, and then spray-dried to obtain a finished dye.

[0062] In terms of mass percentage, in this example, the auxiliary agent is composed of the following components: Pingpingjia O-20 52%, triethylene glycol monobutyl ether 8%, octadecyl betaine 7%, cetyl bromide Base pyridine 3%, polyamide polyamine epichlorohydrin 8%, chitosan 3%, poloxamer 9%, penetrant POWEZOL SUP 10%;

[0063] Among them, the average molecular weight of polyamide polyamine epichlorohydrin is 12000D, the degree of deacetylation of chitosan is 85%, and the average molecular weight is 5000D.

Embodiment 3

[0065] 50g of component A shown in formula (I), 20g of component B shown in formula (II), 15g of component C shown in formula (III), and 12g of the group shown in formula (IV) Part D, 3g of component E represented by formula (IV) and 240g of additives are blended with water, ground and dispersed with a sand mill, and then spray-dried to obtain a finished dye.

[0066] In terms of mass percentage, in this example, the auxiliary agent is composed of the following components: Pingpingjia O-30 60%, triethylene glycol monobutyl ether 5%, octadecyl betaine 3%, cetyl bromide Base pyridine 4%, polyamide polyamine epichlorohydrin 6%, chitosan 4%, poloxamer 4%, penetrant POWEZOL SUP 14%;

[0067] Among them, the average molecular weight of polyamide polyamine epichlorohydrin is 8000D, the degree of deacetylation of chitosan is 70%, and the average molecular weight is 3000D.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com