Mask outer packaging bag capable of invalidating regularly and production method thereof

A timing failure and outer packaging bag technology, applied in the field of packaging bags, can solve problems such as environmental pollution, mask packaging bag corrosion, mask pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] This example is a method of preparing an antibacterial hydrophobic resin comprising the steps of:

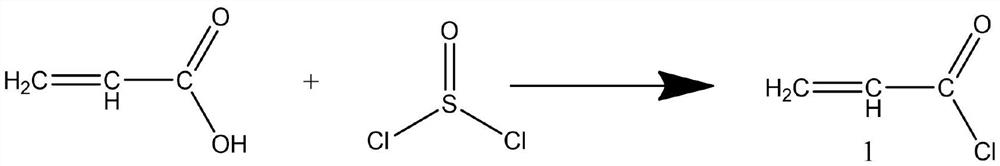

[0060] Step 1: 0.03 mol of dichlorosulfoxide, 0.01 g of the polymerization agent is added to the three flask mounted to a thermometer, a condensate return tube, a constant voltage drip funnel, and a stirrer, stirring at a temperature of 10 ° C, stirring The rate of 0.1 mol acrylic acid was added dropwise over the conditions of 200R / min, and the drip rate was 1 drop / s, and the reaction was refluxed after the dropping temperature of 40 ° C, and the reaction product was cooled after the reaction was completed. At room temperature, the fraction of 30 ° C was collected under pressure of 18.7 kPa, and an intermediate 1 was collected under conditions of 18.7 kPa.

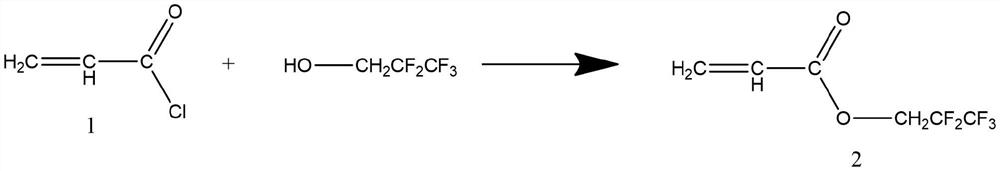

[0061] Step 2: 0.01 g of the polymerization agent to benzene and 0.1 mol1H, 1H-pentafluoropropanol were added to the three flasks mounted with a thermometer, a constant pressure drip funnel, and a stirrer, at a temper...

Embodiment 2

[0068] This example is a method of preparing an antibacterial hydrophobic resin comprising the steps of:

[0069] Step 1: 0.06 mol of dichlorosulfoxide, 0.03 g of the polymer polymer added to the three flask mounted with a thermometer, condensate return tube, constant voltage drip funnel, and stirrer, stirring at a temperature of 20 ° C, stirring The mixture was added dropwise on the side of the rate of 300r / min, and the drip rate was 1 drop / s, and the reaction was refluxed under the temperature of 50 ° C, and the reaction product was cooled after the reaction was completed. After room temperature, the fraction of 32 ° C was collected under pressure of 18.7 kPa, resulting in an intermediate 1;

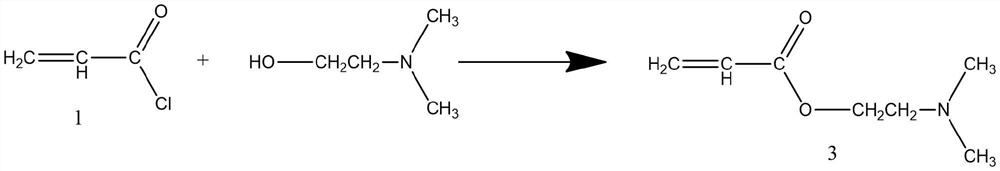

[0070] Step 2: Add 0.03 g of the polymer polymer to the three flask mounted with a thermometer, a constant voltage drip funnel, and a stirrer, and a stirring rate at a temperature of 85 ° C, stirring at a temperature of 85 ° C, stirring rate A 0.1 mol intermediate 1 was added dropwise ...

Embodiment 3

[0077] This embodiment is a method of producing a mask outer packaging bag for a certain time, including the following steps:

[0078] S31: In accordance with the weight, 50 parts of the antibacterial hydrophobic resin from Example 1, 20 copies of butyl acetate, 10 titanium powder, 5 silicon powder, and spare;

[0079] S32: The antibacterial hydrophobic resin, butyl acetate is added to the mixer, and mixed for 30 min under conditions having a stirring rate of 500 r / min to give a mixture;

[0080] S33: Add titanium white powder to the mixture, silicon fine powder continues to stir mixture for 1 h to obtain antibacterial hydrophobic coating;

[0081] S34: 0.1 parts of PBAT20, 60 parts of polylactic acid and 1,4-bis-tert-butyl peroxy isopropylbenzene, and spare;

[0082] S35: Place PBAT, polylactic acid in a vacuum drying tank, dried under temperature of 80 ° C, then dried PBAT, polylactic acid, and crosslinking agent 1,4-bis-t-butyl peroxide Benzene is added to the screw extruder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com